GA 5752 5678 GB 07 3

Table of contents

Table of contents

1 Introduction ..............................................................................................................................................5

1.1 Foreword ....................................................................................................................................................5

1.2 How to use these operating instructions .................................................................................................... 5

1.2.1 Abbreviations ............................................................................................................................... 5

1.2.2 Symbols ....................................................................................................................................... 5

1.2.2.1 Cross-references ....................................................................................................... 5

1.2.2.2 Actions and responses .............................................................................................. 5

1.2.3 Definitions .................................................................................................................................... 6

1.2.3.1 Design of safety notes ............................................................................................... 6

1.2.3.2 Design of other notes ................................................................................................ 6

1.2.4 Symbols used .............................................................................................................................. 6

1.3 Disposal......................................................................................................................................................7

1.3.1 ATMOS products.......................................................................................................................... 7

1.3.2 Packaging .................................................................................................................................... 8

1.4 Overview ....................................................................................................................................................8

1.5 Basic requirements.....................................................................................................................................8

1.5.1 Use in accordance with the intended purpose ............................................................................. 8

1.5.2 Applicable standards.................................................................................................................... 9

1.5.3 Intended purpose ......................................................................................................................... 9

1.5.3.1 Possible applications ............................................................................................... 10

1.5.4 Version LS FLOW flowmeter installation version ....................................................................... 10

1.5.5 Interface description................................................................................................................... 10

1.5.5.1 Flowmeter outlet ...................................................................................................... 10

1.5.5.2 Connection tube ...................................................................................................... 11

1.5.5.3 Tube adapter for Air and O2 .................................................................................... 11

2 Safety notes............................................................................................................................................12

2.1 General safety notes ................................................................................................................................ 12

2.2 Product safety notes.................................................................................................................................12

3 Initial operation.......................................................................................................................................14

3.1 Equipment inspection...............................................................................................................................14

3.2 Mounting accessories...............................................................................................................................14

3.2.1 General ...................................................................................................................................... 14

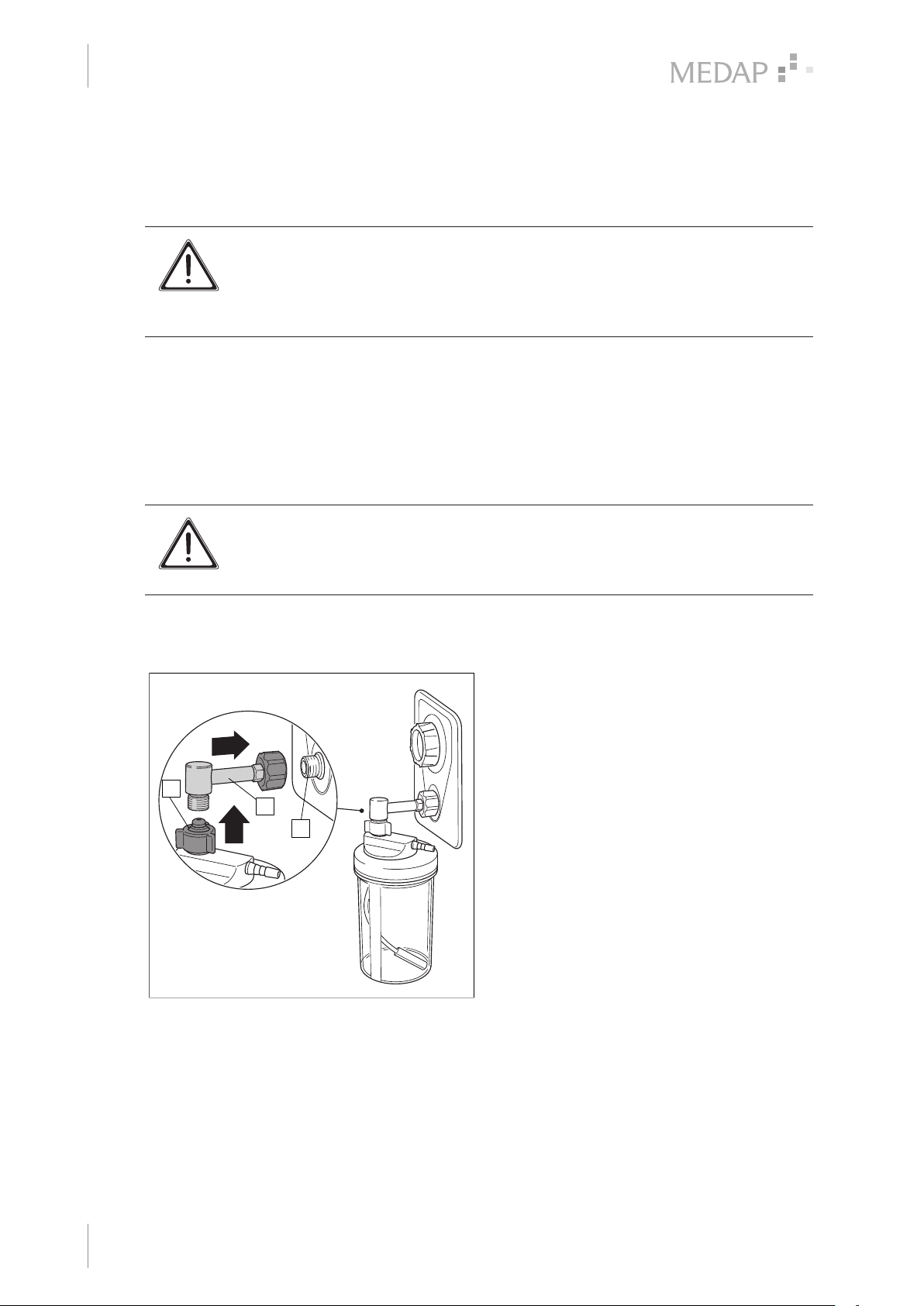

3.2.2 Connection of bubble humidifier (REF 5752 5315).................................................................... 14

3.2.3 Connection of disposable humidifiers from other manufacturers............................................... 14

4 Operation ................................................................................................................................................15

4.1 Function check .........................................................................................................................................15

4.2 Setting the flow for treatment ................................................................................................................... 15