RS485 Communication Output

Cautions during Use

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. Use the product, after 3 sec of supplying power.

3. Before use, set the mode and function according to the specification. Especially, be cautious that the product

does not operate when OUT ADJ. is set to 0%. Since changing the mode/parameter during operation may

result in malfunction, set the mode and function after disconnecting load output.

4. Re-supply the power to the unit after the unit is discharged completely.

Failure to follow this instruction may result in malfunction.

5. To ensure the reliability of the product, install the product on the panel or metal surface vertically to the ground.

6. Install the unit in the well ventilated place.

7. While supplying power to the load or right after turning off the power of the load, do not touch the body and

heat sink. Failure to follow this instruction may result in a burn due to the high temperature.

8. Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the power.

9. Do not wire to terminals which are not used.

10. Since inter element can be damaged when using with coil load, inductive load, etc., the inrush current must

be under the rated load current.

11. Do not use near the equipment which generates strong magnetic force or high frequency noise.

12. This unit may be used in the following environments.

①Indoors (in the environment condition rated in 'Specifications') ②Altitude max. 2,000m

③Pollution degree 2 ④Installation category III

※

Applicable for models with RS485 communication output through option output (SPR3-

T

).

Please refer to ' Ordering Information'.

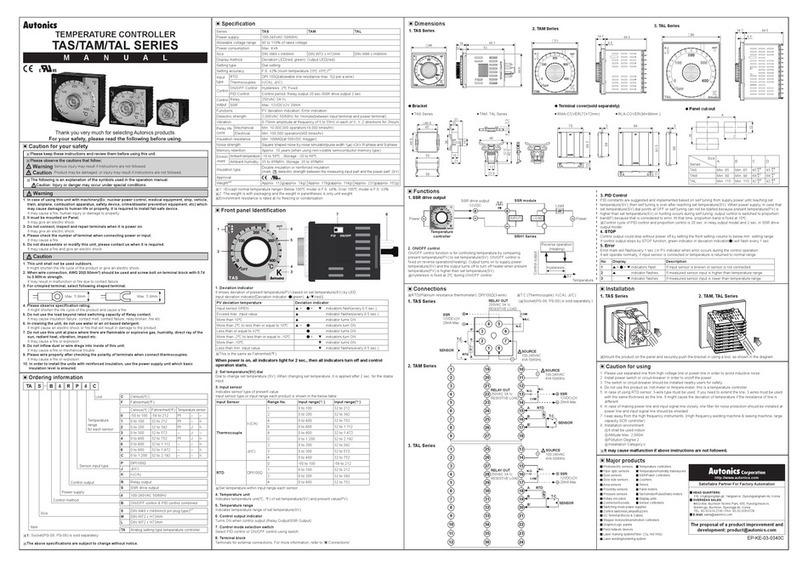

1. Communication Specifications

Comm. protocol Modbus RTU Comm. speed

2400, 4800, 9600, 19200,

38400 bps

Connection method RS485

Application standard

Compliance with EIA RS485 Comm. response time

5 to 99ms (default: 20ms)

Max. connections 31 units (address: 1 to 99) Start bit 1-bit (xed)

Synchronization method

Asynchronous Data bit 8-bit (xed)

Comm. method Two-wire half duplex Parity bit None, Even, Odd

Comm. distance Max. 800m Stop bit 1-bit, 2-bit

2. Application of system organization

※

It is recommended to use Autonics communication converter; SCM-WF48 (Wi-Fi to RS485·USB wireless

communication converter, sold separately), SCM-US48I (USB to RS485 converter, sold separately),

SCM-38I (RS232C to RS485 converter, sold separately). Please use twisted pair wire, which is suitable

for RS485 communication, for SCM-WF48, SCM-US48I and SCM-38I.

Terminating

resistance

(100 to 120Ω)

B(-)

A(+)

ON OFF

A(+)

RS485

DEVICE

#1

RS485

DEVICE

#2

RS485

DEVICE

#30

RS485

DEVICE

#31

A(+) A(+)B(-) B(-) B(-)

Computer

RS485

Comm.

converter

RS232C/

USB/Wi-Fi

Major Products

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO₂, Nd: YAG)

Laser Welding/Cutting System

http://www.autonics.com

HEADQUARTERS:

18, Bansong-ro 513beon-gil, Haeundae-gu, Busan,

South Korea, 48002

TEL: 82-51-519-3232

DRW180136AC

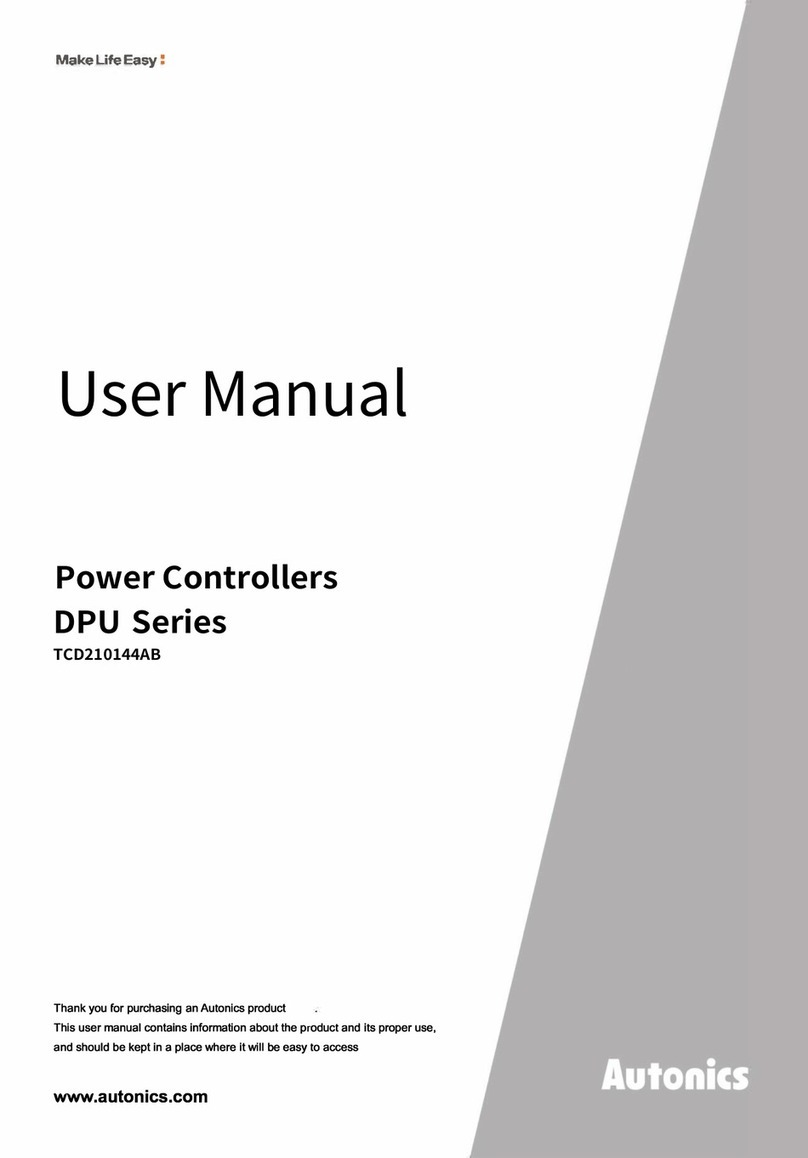

Derating Curve

User Manual for Communication

For the detail information and instructions, please refer to user manual for communication, and be sure

to follow cautions written in the technical descriptions (catalog, homepage).

Visit our homepage (www.autonics.com) to download manuals.

Comprehensive Device Management Program [DAQMaster]

DAQMaster is a comprehensive device management software for setting parameters and monitoring

processes. DAQMaster can be downloaded from our website at www.autonics.com.

Item Minimum specications

System IBM PC compatible computer with Pentium Ⅲor above

Operations Windows 98/NT/XP/Vista/7/8/10

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS232C serial port (9-pin), USB port

Rated load current 25A

25

15

20

10

5

0

010 20 30 40 70

Ambient temperature [℃]

50 6055

50

30

40

20

10

0

010

20 30

40 70

Ambient temperature [℃]

Rated load current 50A

25 50 6055

100

60

80

40

20

0

010 20 70

Ambient temperature [℃]

Rated load current 100A

50 605530 4035

35

21

28

14

7

0

010 20

30 40

70

Ambient temperature [℃]

Rated load current 35A

35 50 6055

150

90

120

60

30

0

0

Ambient temperature [℃]

Rated load current 150A

10

20 30

40 70

25 50 6055

70

42

56

28

14

0

010 20

30 40

70

Ambient temperature [℃]

Rated load current 70A

35 50 6055

Load current [A]

Load current [A]

Load current [A]

Load current [A]

Load current [A]

Load current [A]

B(-)

A(+)

Monitoring group Parameter 1 group[PR1] Parameter 2 group[PR2]

4 sec2 sec

3 sec 3 sec

RUN mode

※If there is no key input for 30 sec while setting SV or the parameters, the new settings are ignored,

and the unit will return to RUN mode with previous settings.

※Hold the key for 3 sec while in setting mode to return to RUN mode.

Parameter Group

Setting range: 0 to 100 sec

※

When control method [C-M]is ONF, settings can not be

changed.

3 sec

2 sec

SOFT START

S-T 000

※1

SOFT UP

U-T 000

D-T 000

SOFT DOWN

Output low-limit value

L-L 000

Output high-limit value

H-L 100

※2

PR1

Setting range

: 0% ≤ Output low-limit value[L-L] ≤ Output high-limit value[H-L] ≤ 100%

Parameter 1 group

RUN mode

Actual input signal [%]

Functions

Output limit (OUT ADJ)

SOFT UP/DOWN [U-T/D-T]

Input slope correction [SPN]

Input correction [INB]

RUN/STOP switching

RUN/STOP status of the power controller can be switched with the external

RUN/STOP contact.

In the RUN mode, the operation indicator on the front turns on. ON/OFF

RESET

In the event of system anomalies and alarms, RESET input restarts the

power controller.(Parameters are not initialized.)

Or, hold the

, keys

for 2 sec, to operates RESET.

ON

AUTO/MANUAL selection

Operation mode (auto control/manual control) of the power controller can be

selected with the external AUTO/MAN contact.

In the manual control mode, the manual control indicator on the front turns on. ON/OFF

When the power is supplied, this function is able to

protect the load when it controls load (molybdan,

white gold, infrared lamp) with inrush current or the

width of rising temperature in big (SV is big).

SOFT START set time (T) is the required time that

output reaches to 100%, and it is differentiated by

OUT ADJ set value.

Unlike SOFT START which operates only once at

supplying power, this function protects load from the

inrush current in the RUN mode. When reached to

the target output value, operation stops.

Output high limit/low limit value [H-L/L-L]

This function is to limit output range to protect load.

It compensates the offset between actual input value

and measured input value.

E.g.) When input monitoring value is 5% at 4mA in

DC4-20mA control input, setting INB to -5

calibrates the input monitoring value to 0%.

Measured input signal [%] Output [%] Output [%] Output [%]

Measured input signal [%]

SOFT START set time

SOFT DOWN set time

SOFT UP set time

Time

Time

When output applied to load is 100%,

This function will be [Control input (%) × OUT ADJ (%) =

Output] and it controls the power supplied into the load.

Although control input is 100% (5V or 20mA), the output

is the 50% which is proportioned with OUT ADJ.

0 50 100

Control input [%]

Setting value = 50%

Setting value = 100%

100

75

50

25

: Actual input signal (%)

: Input corrected signal (%)

: Actual input signal (%)

: Input corrected signal (%)

Actual input signal [%]

It compensates the gain of the measured 100% input

for actual 100% input value.

Calibrated monitoring value=Monitoring value+ Monitoring value

×SPN

100- SPN

E.g.) When the input monitoring value is 99% at 4mA in

DC4-20mA control input,

setting SPN to 1

calibrates

the input monitoring value to 100%.

SOFT START [S-T]

When output applied to load is 50%,

0

100

50

0

100

50

SOFT START set time

A: SOFT START function nished.

B: SOFT UP function nished.

C: SOFT DOWN function nished.

100

100

100

100

80

80

75

75

60

60

40

40

50

50

20

20

25

25

0

0

※

※This function can not be used for ON/OFF control method.

※

※This function can not be used for ON/OFF control method.

※

※This function can not be used for ON/OFF control method.

Alarm

Type Error Operation Clear alarm

Display priority

SCR error alarm※1SCR

Output stops.

(SCR OFF)

- Re-supply the power.

- RESET

- Switch to STOP mode

1

Overcurrent alarm※1O-C 2

Fuse break alarm FUS 3

Heatsink overheat alarm TEM 4

Overvoltage alarm※1O-V 5

Heater break alarm※1H-B Continues

operation

Automatically cleared when

returning within the setting range. 6

※

1: This is only for feedback control models.

※

For models with alarm output, the error message and alarm indicator ash at the same time, and alarm output turns on.

※

When multiple alarms occur at the same time, the highest priority error message will be displayed based on priority.

1) SCR error alarm

Even though output is 0%, if the current of 10% or more of the rated load current ows for over 3 sec

continuously, SCR error alarm occurs and output stops.

2) Overcurrent alarm [OCU/OCT]

This function protects the load from overcurrent.

If the current ows over the overcurrent alarm setting value and setting delay time, overcurrent alarm

occurs and output stops.

3) Heatsink overheat alarm

When the temperature of a heatsink is over 85℃, heatsink overheat alarm occurs and output stops.

4) Overvoltage alarm [OVV/OVT]

This function protects the load from overvoltage.

If the current ows over the overvoltage alarm setting value and setting delay time, overvoltage alarm

occurs and output stops.

5) Heater break alarm [HBV]

Comparing the full load resistance value and the current load resistance value, if the current load

resistivity is maintained under the setting value for over 3 sec

continuously

, heater break alarm occurs.

Output does not stop and operates normally.

Current load resistivity(%) = Full load resistance value ×100

Current load resistance value

※1: : Press any key among , , .

※2: Press the key once after changing the setting value, to save

the setting value and move to the next parameter

※Hold the key for 3 sec to save the setting value and return to

RUN mode after changing the setting value.

※Dotted parameters may not appear by model type or other

parameter settings.

Monitoring group

RUN mode

Control input

IN 0

※1

Load voltage

between U-V line

U-V 380

V-W 380

Load voltage

between V-W line

Load voltage

between W-U line

W-U 380

U-phase

load current

U-A 50

V-phase

load current

V-A 50

W-phase

load current

W-A 50

※2

Measuring range: 0 to 100%

※

Displayed only for feedback control models.

Measuring range: 0 to rated power range[VA]

Measuring range: Percentage [%] of the currently measured

resistance value compared to the set

resistance value of full load auto recognition.

Load power

L-W 10

Load resistance

L-R 50

Heatsink temp.

TMP 25

Power supply

frequency

FRQ 60

Measuring range: 0 to 100℃

Measuring range: 50, 60Hz

Measuring range: 0 to rated voltage range[V]

Measuring range: 0 to rated current range[A]

Parameter 2 group

Setting range: 0 to 120%

Setting range: 0 to 100 sec

Setting range: 0 to 120%

Setting range: 10 to 100%

Setting range: 0 to 100 sec

Setting range: -99 to 99%

Setting range: -99 to 99%

3 sec

4 sec

RUN mode

Control input DC4-20mA 1-5VDC 5-12VDC

ON/OFF contact

INT 420

Control method

C-M

E-R OFF

External output

limit adjuster

OVV 120

Overvoltage alarm value

DIS IN

Front display

HBV 010

Heater break alarm value

Input correction

INB 00

Overvoltage

alarm delay time

OVT 005

Overcurrent alarm value

OCV 120

Input slope correction

SPN 00

Full load auto recognition

F-L OFF

Overcurrent

alarm delay time

OCT 005

1-5 512 ONF

※2

PR2

RS485 comm.

COM

Load voltage

between

U-V line

Load voltage

between

V-W line

Load voltage

between

W-U line

U-V V-W W-U

ON

ON

Resistance

and input

※1

※Displayed only for feedback control models.

Setting range: Normal control PA, F-C, ONF

Feedback control (normal/constant current/

constant voltage/constant power control)

PA, V-F, C-F, W-F,

F-C, ONF

Phase -

Constant

voltage

U-phase

load current

Phase -

Constant

current

V-phase

load current

Phase -

Constant

power

W-phase

load current

Load power

ON/OFF

V-F

U-A

C-F

V-A

W-F

W-A L-W

ONF

Cycle-Fixed

F-C

PA

Phase -

Normal

Setting range: Normal control IN

Feedback control (normal/constant current/

constant voltage/constant power control)

IN, U-V, V-W, W-U,

U-A, V-A, W-A, L-W

EVE ODD

1

Setting range: 1 to 99

※Displayed only formodelswithRS485comm.output.

Setting range: 5 to 99ms

Setting range:

Enables Disables

PRT NON

Comm. parity bit

CM.W EN.A

Comm. write

Comm. stop bit

STP 2

Comm. address

ADR 001

Lock

LOC OFF

Comm. response

waiting time

RW.T 020

Comm. speed

BPS 96

Parameter reset

INI NO

LC1

YES

DsA

LC2

PR1 PR2

OFF

LC1

LC2

9,600bps 19,200bps 38,400bps 2,400bps 4,800bps

192 384 24 48

: Available to check/set

: Available to check/Unavailable to set

※

Hold the , , keys for 5 sec, to enter parameter reset parameter.