1

<Contents>

1. Precautions for Use..........................................................................................................................2

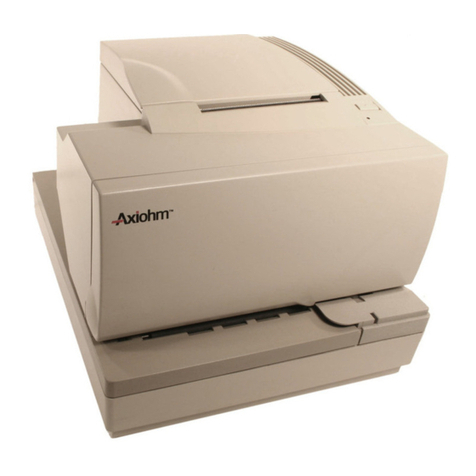

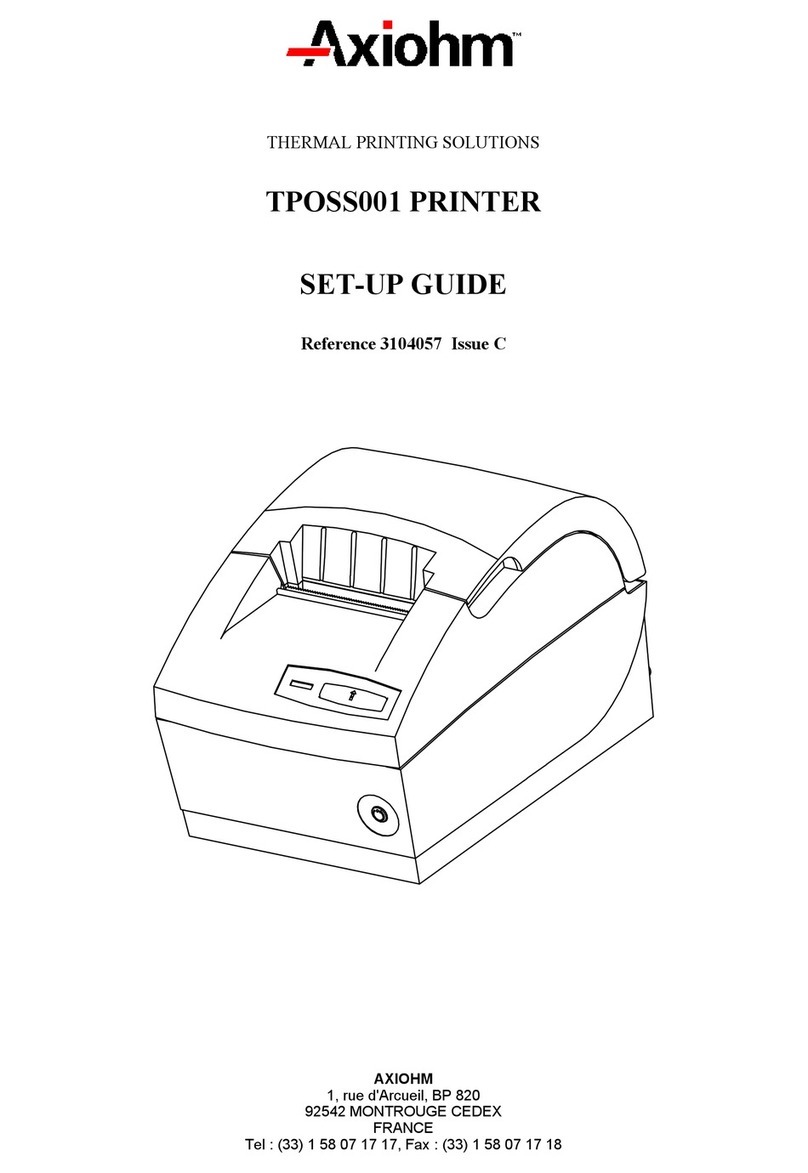

2. Unpacking........................................................................................................................................5

2.1 Unpacking ..................................................................................................................................5

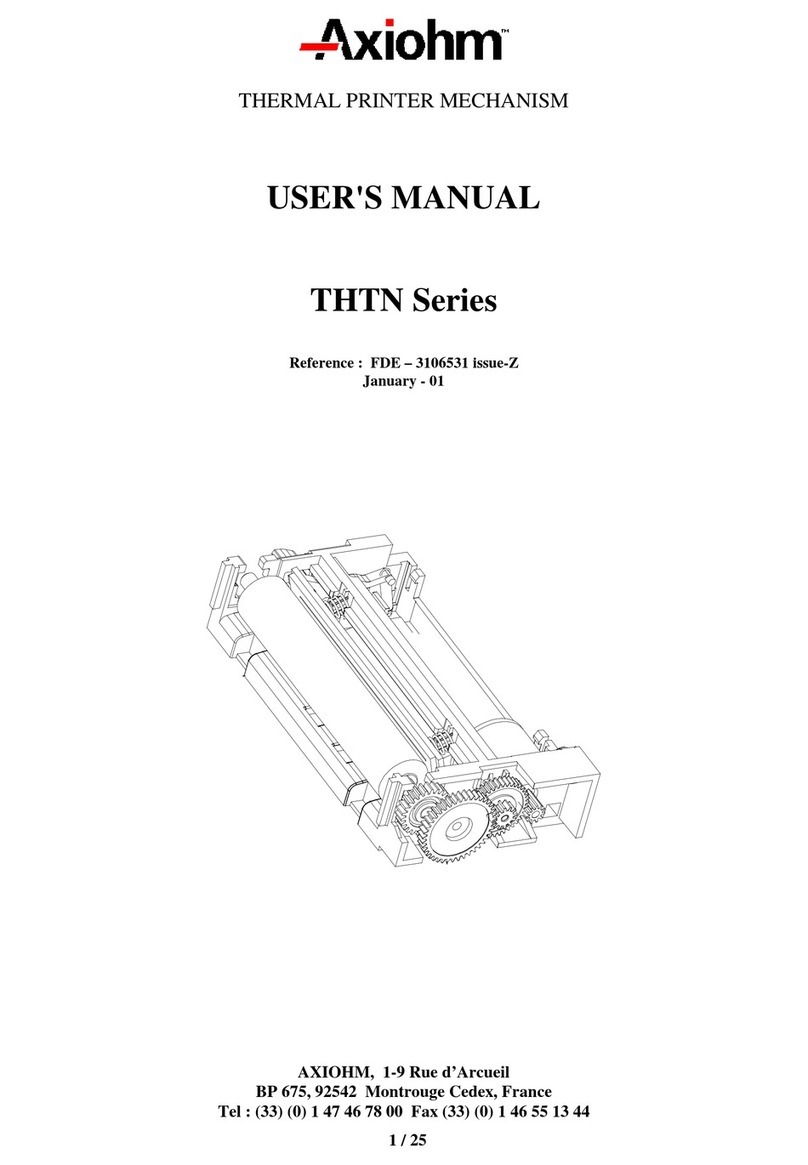

2.2 Names of Each Part.....................................................................................................................6

3. How to Operate................................................................................................................................7

3.1 Preparation..................................................................................................................................7

3.2 Paper Setting...............................................................................................................................7

3.3 Test Printing...............................................................................................................................7

3.4 DIP Switch Setting .....................................................................................................................8

3.5 Cable Connection .....................................................................................................................10

4. How to Treat This Product.............................................................................................................11

4.1 Paper Empty Detection .............................................................................................................11

4.2 Paper End Signal......................................................................................................................11

4.3 Error Signal..............................................................................................................................11

5. Specifications.................................................................................................................................13

5.1 General Specifications ..............................................................................................................13

5.2 Interface Specifications.............................................................................................................14

6. Control Codes................................................................................................................................18

6.1 List of Control Codes................................................................................................................18

6.2 Function of Each Control Code ................................................................................................21

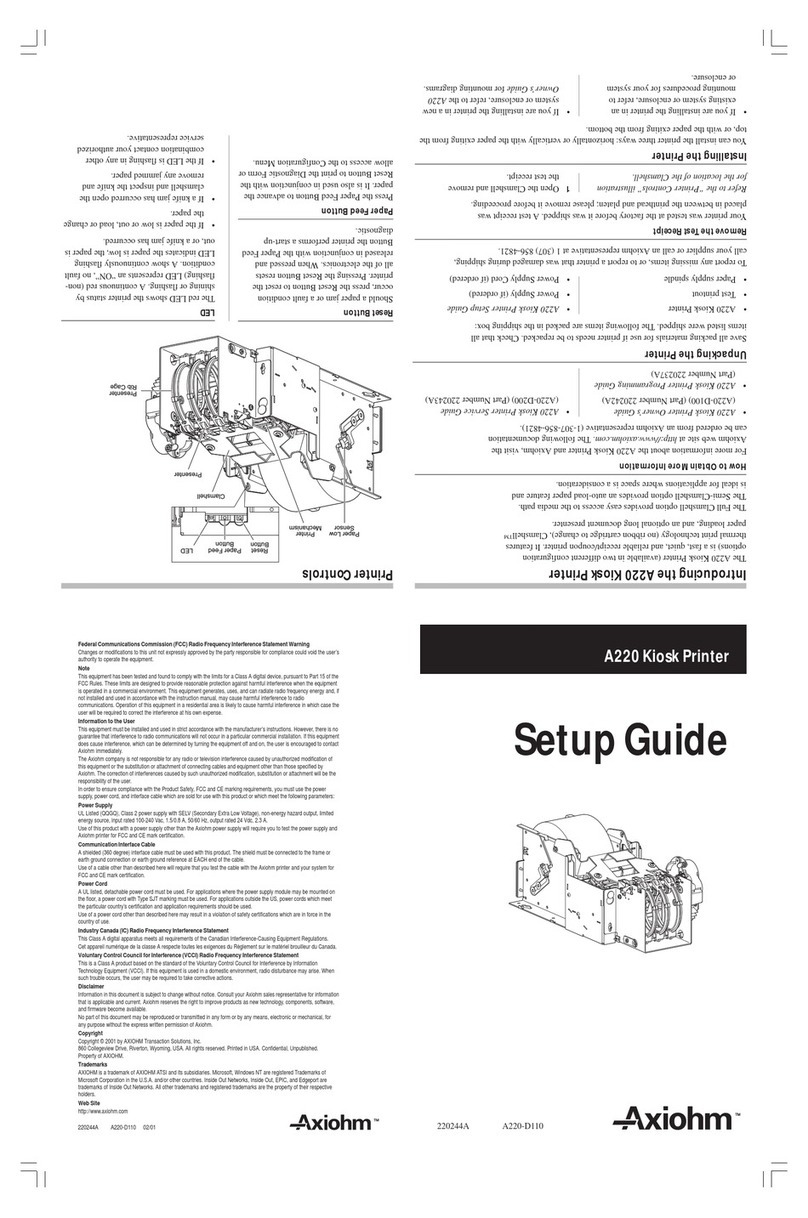

7. Trouble Shooting of the Printer......................................................................................................42

Appendix 1: Character Code Table....................................................................................................43

Appendix 2: Dimensions and Panel Cut Dimensions.........................................................................45