CM/XM Series User Manual Page 5/42 Ref: FDE - 3102473 / A

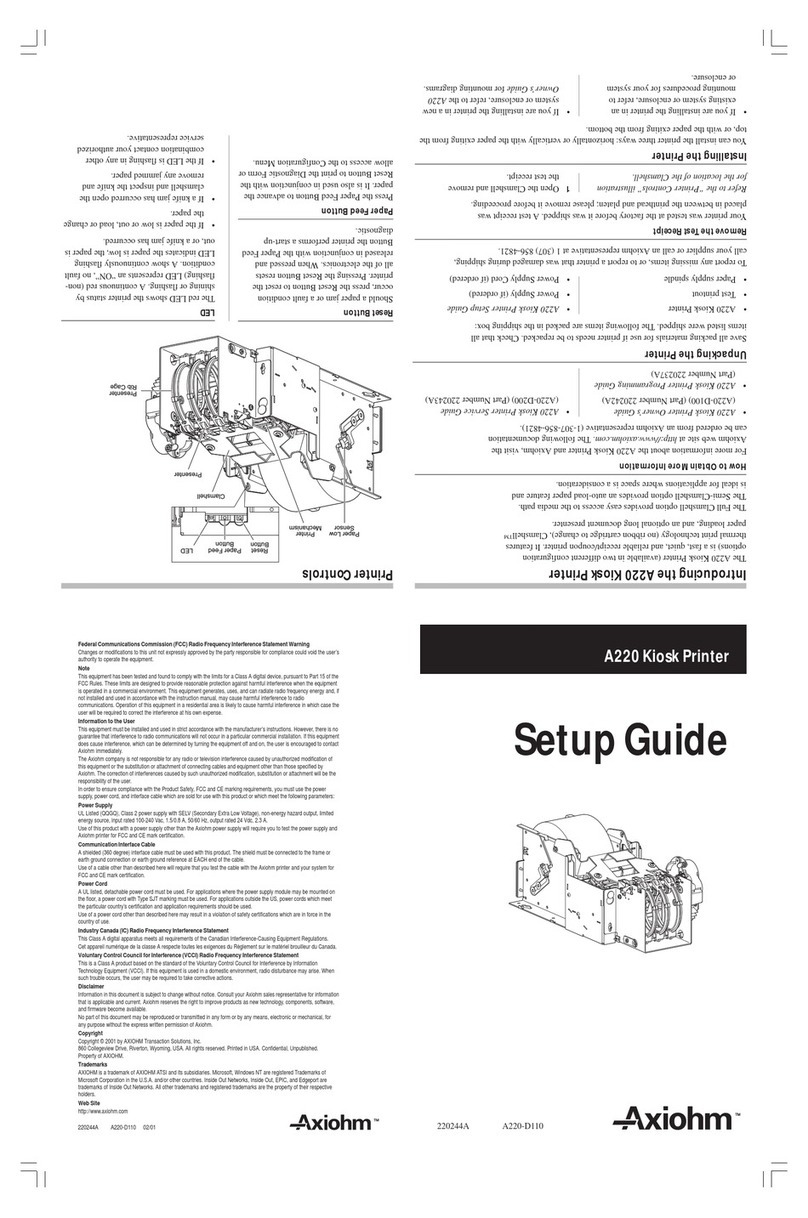

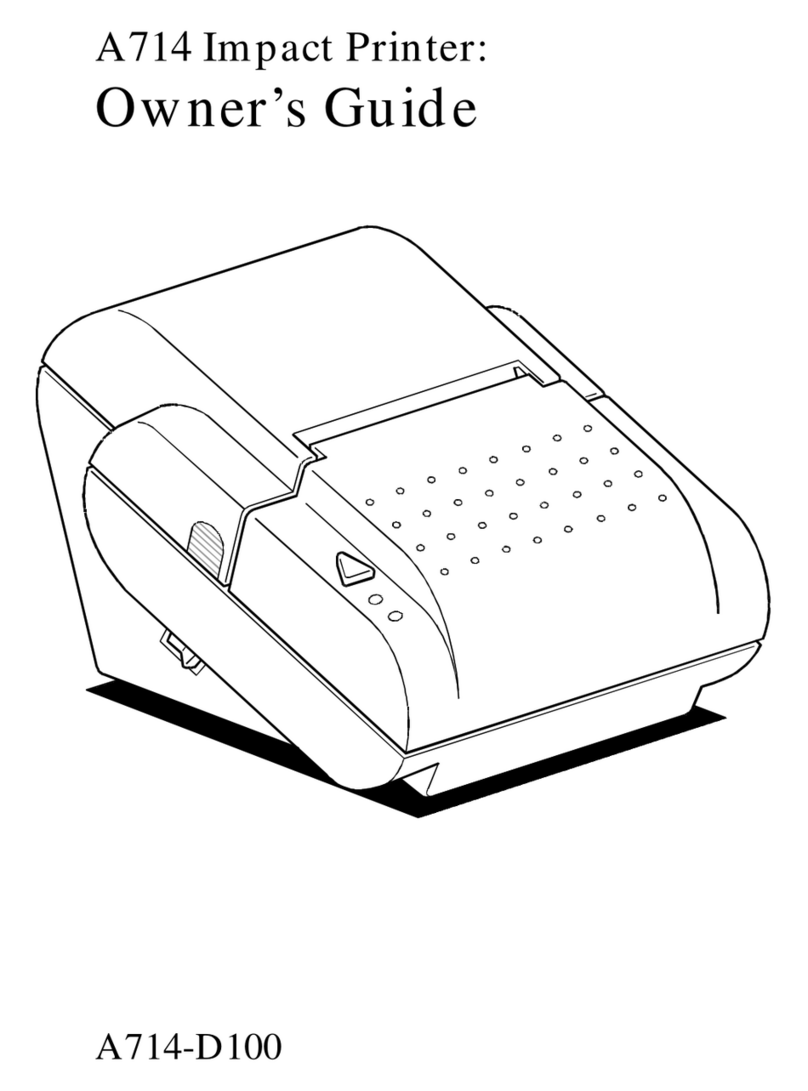

1. UNPACKING

Each printer mechanism is packaged in an antistatic bag. Observe precautions for handling in

electrostatic protected areas.

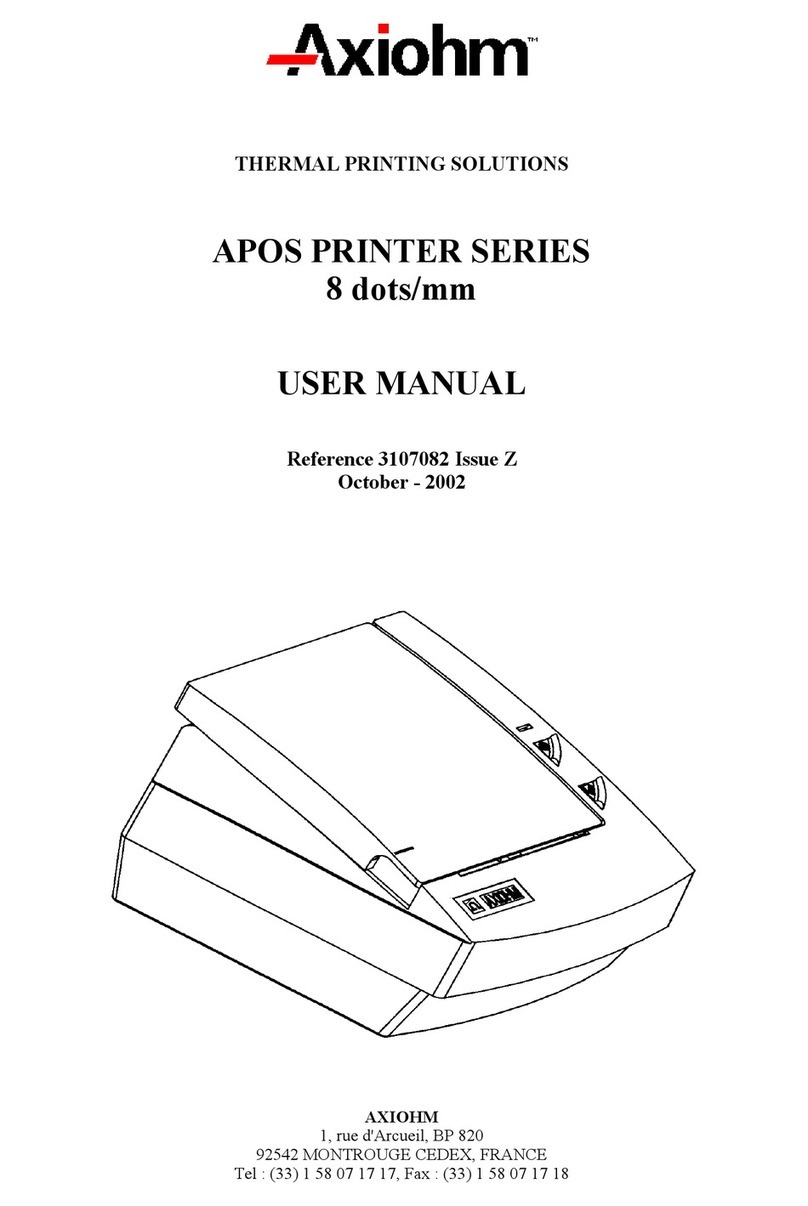

2. OVERVIEW

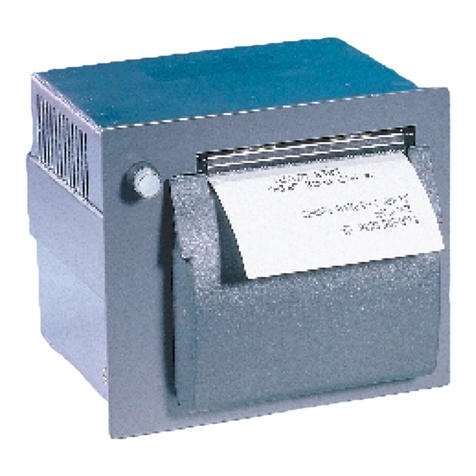

Based on static thermal printing technology, the CM/XM series is a family of user-friendly, highly

reliable devices which have been specially designed to fit in the minimum space.

CMxx : Printer only or printer with optional tear bar cover

XMxx : Printer with cutter

Very small size printer and cutter

Silent mechanism

Option of 4 dots/mm or 8 dots/mm print-heads

Optional cover with tear bar

Optional cover with Guillotine cutter (XMxx)

Easy to connect (only one connector for motor, printhead, opto-sensor and cutter)

Front and bottom paper introduction possible

Optional drive for paper rewinder

SUMMARY OF PRINTER SPECIFICATIONS

ITEM VALUE UNITS

xMBC xMDG -

Printing method Static thermal dot line printing -

Number of resistor dots 192 384 -

Resolution 4 8 Dots/mm

Printing width 48 mm

Paper width 60 mm

Head temperature detection By Thermistor -

Number of steps / dot line 2 1 -

Paper feed / dot line 0.250 0.125 mm

Paper empty detection Opto-sensor -

Operating voltage range Vcc (logic) 4.75-5.25 V DC

Operating voltage range Vch (dot) 20 - 28 20 - 26.4 V DC

Peak printhead current

(all dots ”on ” at nominal value ) 8.25 8.8 A

Current consumption:

V ch (at nominal value) 43 23 mA per resistor dot ”on ”

Current consumption:

V cc (at nominal value) 160 100 µA