1-3. Special Tools

1-4. Sensors

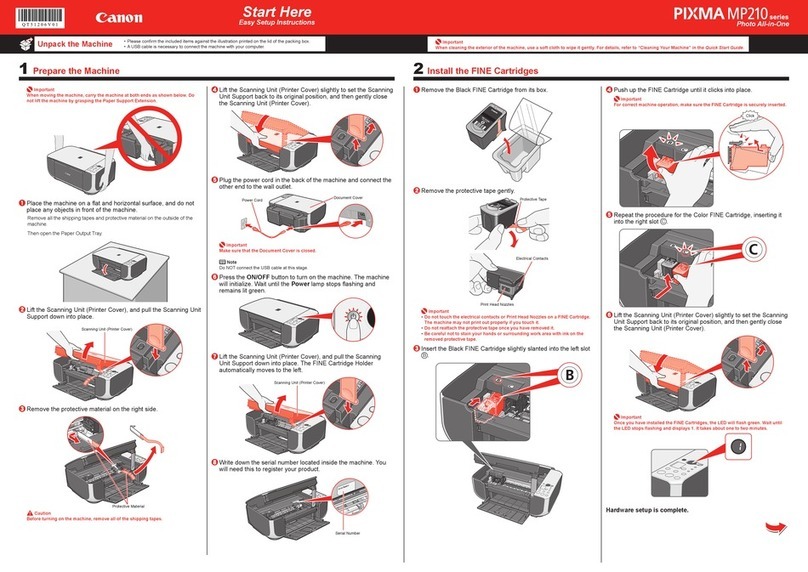

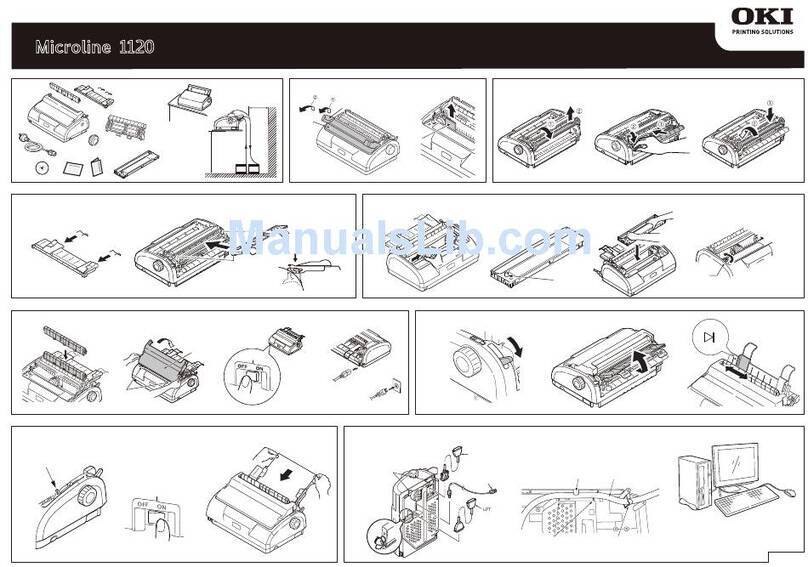

Click on the image to enlarge it.

Name Tool No. Application Remarks

FLOIL KG-107A QY9-0057-000 To the carriage rail sliding portions. In common with the MP610, etc.

No. Sensor Function Possible problems

1Scanner open sensor Detects opening and closing of the

scanning unit (cover). - The carriage does not move to the center even when

the scanning unit is opened.

2FB encoder sensor Detects rotation of the scanner motor,

and controls scanning operation. - Faulty scanner

- FB motor error

- Faulty scanned or copied images

3Inner cover sensor Detects opening and closing of the inner

cover. - The inner cover is open when it should be closed.

- The inner cover is closed when it should be opened.

4PE sensor Detects the leading and trailing edges of

paper. - No paper

- Paper jam

5ASF cam sensor Detects the position of the ASF cam (for

paper feeding from the rear tray). - ASF cam sensor error

- Paper feeding problem

6APP encoder sensor Detects rotation of the APP encoder, and

controls paper feeding and purging

operation.

- APP sensor error

- APP position error

7Carriage encoder

sensor Detects the position of the carriage. - Carriage position error

- Printing shifts from the correct position.

- Uneven printing

- Strange noise

8Temperature & Ink

amount sensor Detects the temperature of the inside of

the machine and the remaining ink

amount.

- Internal temperature error

- Low-ink or out-of-ink warning

9Ink sensor Detects the position of an ink tank. - Wrong position of an ink tank

- Installation of multiple ink tanks of the same color

- No recognition of an ink tank

10 LF encoder sensor Detects rotation of the LF encoder, and

controls paper feeding. - LF position error

- Uneven printing

11 Eject encoder sensor Detects rotation of the eject encoder, and

controls paper feeding. - LF position error

- Uneven printing

12 Valve cam sensor Detects the position of the purge valve

cam, and controls purging operation. - Valve cam sensor error

13 Pump roller sensor Detects the position of the pump roller,

and controls purging operation. - Pump roller sensor error

14 Purge cam sensor Detects the position of the purge main

cam, and controls purging operation. - PG cam sensor error