AB-6569

10

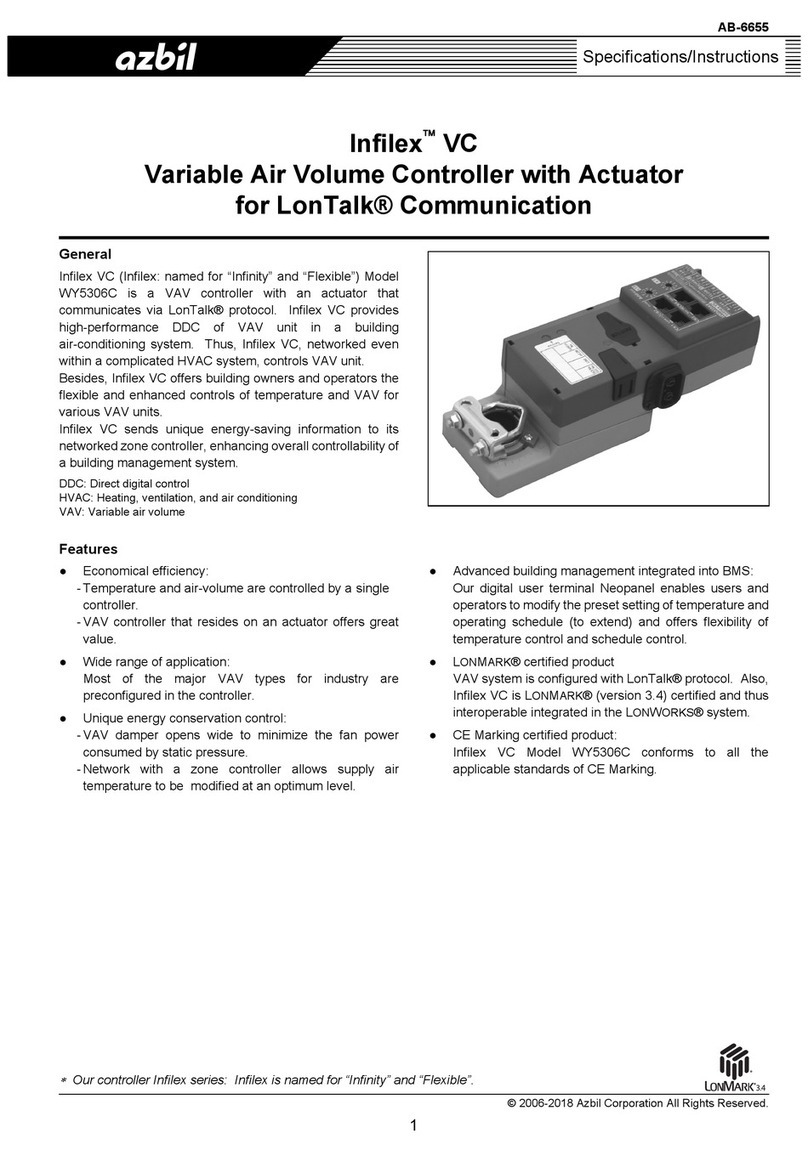

Mount Infilex FC with the front surface facing horizontal

direction unless it is protected in a dust-proof housing.

(See ‘B’ in Fig. 13.) If the Infilex FC is mounted with its

front surface facing the vertical direction (upwards), dust

may accumulate on the connectors. (See ‘A’ in Fig. 13.)

.

Figure 13. Mounding direction

After a modular plug is inserted into the corresponding

modular jack, lightly pull the modular cable to make sure

the modular plug is completely connected to the modular

jack.

Recommended wires and cables

For recommended wires and cables, refer to the wiring

specifications of Input/output specifications section.

Wire connection for FCU ON/OFF output, control valve

output, and other inputs

Quick-fit screwless terminals are provided for ON/OFF output,

control valve output, status input, and trip alarm input. Follow

the procedure below for connecting these wires. (Refer to Fig.

9.)

1) Remove covers of the terminals to which wires are

connected.

2) Strip the 5-6 mm wire sheath to be connected to. (Scale

is indicated on the front surface. If a bare wire is longer

or shorter than 5-6 mm, it may get exposed or may come

off from the connector.) Make sure that any wire fiber

goes out of the bare wire.

3) Insert a slotted screwdriver into a smaller square hole

(for clamp release) on the terminal blocks located on the

upper and the lower sides of the front surface.

To insert the screwdriver to deep end (approx. 10 mm

deep), push and tilt it (towards the front surface) along

the curving surface inside the square hole.

When the screwdriver is correctly inserted to the deep

end, the clamp is completely released and the

screwdriver remains inserted position by itself.

Notes:

A slotted screwdriver with the blade 3.5 mm wide and 0.5 mm

thick (straight type) is applicable. A screwdriver with the blade

end narrower than the beginning (shaft side) may not be

applicable.

Applicable screwdriver (an example):

Vessel’s Model 9900 (3 mm wide 100 mm long) or

Model 910 (3 mm wide 75 mm long)

Since the terminal blocks have the inclined surfaces, required

maintenance clearance varies depending on the length of the

screwdriver to be used. Note that a long screwdriver (80 mm or

longer) may not be usable for the Infilex FC replaced from IFC or

Microstat since IFC or Microstat requires smaller maintenance

clearance.

4) After the a bare wire is fully inserted, remove the

screwdriver with the bare wire inserted.

5) Lightly pull the wires connected to make sure it is completely

held by clamp.

Note for connecting stripped wire of 1.8 mm2 or smaller

cable

1.8 mm2 or thinner cable connected to a quick-fit screwless

terminal may cause short-circuit due to dust accumulated in

clearance of the terminal. (See Fig. 14.)

To prevent short-circuit, put the tubes* through the wires so

that the wire connected terminals are covered. (See Fig. 15.)

Tubes are not supplied with Infilex FC and commercially

available. See Fig. 24 for tube specifications.

Tubes are also available at Azbil Corporation.

(Part No. 83167219-001, 6 pieces/set)

Figure 14. Dust accumulated in quick-fit screwless terminals

Figure 15. Tubes covering quick-fit screwless terminals

Connection to user terminal / temperature sensor

Wires from user terminal / temperature sensor are connected

to Infilex FC with modular connection. For correctly crimping

modular plugs on LAN cables, refer to the following section.

Dust

Vertical

direction

Horizontal

direction

A: Incorrect B: Correct

Dust

Tubes