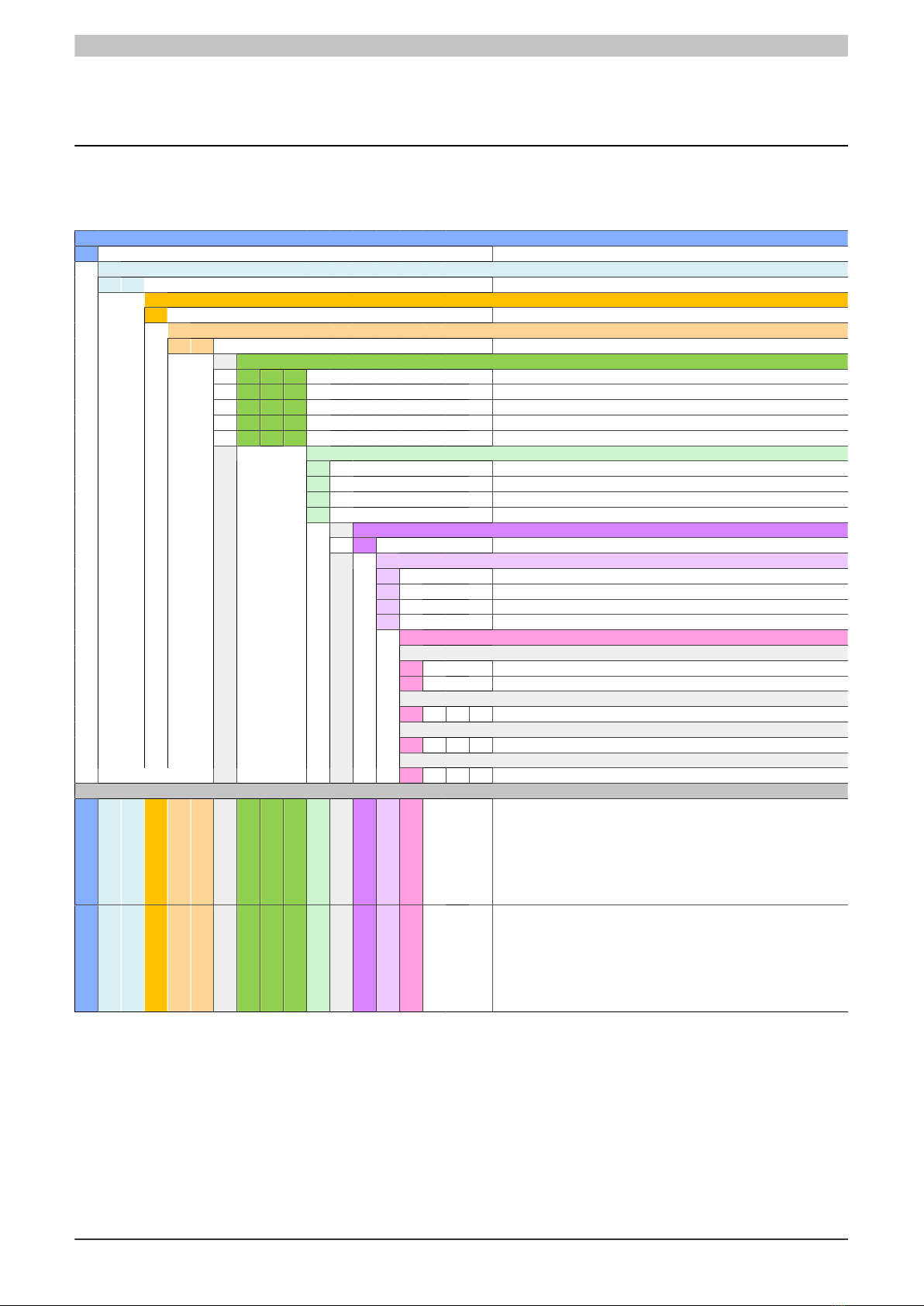

Table of contents

1 Introduction................................................................................................................6

1.1 Manual history.................................................................................................................................................6

1.2 Information about this document.................................................................................................................... 6

1.2.1 Organization of notices..............................................................................................................................6

1.2.2 Guidelines.................................................................................................................................................. 6

2 General safety guidelines........................................................................................ 7

2.1 Intended use................................................................................................................................................... 7

2.2 Protection against electrostatic discharge...................................................................................................... 7

2.2.1 Packaging.................................................................................................................................................. 7

2.2.2 Regulations for proper ESD handling....................................................................................................... 7

2.3 Regulations and measures............................................................................................................................. 7

2.4 Transport and storage.................................................................................................................................... 8

2.5 Installation....................................................................................................................................................... 8

2.6 Operation.........................................................................................................................................................8

2.6.1 Protection against contact with electrical parts.........................................................................................8

2.6.2 Ambient conditions - Dust, moisture, aggressive gases........................................................................... 8

2.6.3 Programs, viruses and malicious programs..............................................................................................9

2.7 Cybersecurity disclaimer for products............................................................................................................ 9

3 System overview..................................................................................................... 10

3.1 Order number key.........................................................................................................................................10

3.2 System characteristics.................................................................................................................................. 11

3.2.1 Type overview..........................................................................................................................................11

3.3 Overview........................................................................................................................................................11

4 Device description.................................................................................................. 12

4.1 Order overview..............................................................................................................................................12

4.1.1 Content of delivery.................................................................................................................................. 12

4.1.2 Optional accessories............................................................................................................................... 12

4.2 Technical data...............................................................................................................................................13

4.2.1 Specific technical data of the display variants........................................................................................ 15

4.2.2 Technical data of the interface variants.................................................................................................. 16

4.3 Technical information.................................................................................................................................... 17

4.3.1 Dependencies to hardware upgrades and Automation Runtime............................................................ 17

4.3.2 Practical example of writing load in an application................................................................................. 17

4.3.3 Projected capacitive touch (PCT)............................................................................................................17

4.3.4 Viewing angles........................................................................................................................................ 18

4.3.5 Surface resistance...................................................................................................................................18

4.4 Temperature/Humidity diagrams...................................................................................................................19

4.5 Dimensions....................................................................................................................................................22

4.5.1 5.7" variants.............................................................................................................................................22

4.5.2 7.0" variants.............................................................................................................................................23

4.5.3 10.1" variants...........................................................................................................................................24

4.5.4 12.1" variants...........................................................................................................................................25

4.5.5 15.6" variants...........................................................................................................................................26

4.6 Environmental properties.............................................................................................................................. 27

4.6.1 Spacing for air circulation........................................................................................................................27

4.6.2 Temperature sensor positions.................................................................................................................28

4.6.3 Derating the ambient temperature.......................................................................................................... 28

4.7 Device interfaces and slots...........................................................................................................................29

4.7.1 Interface overview................................................................................................................................... 29

4.7.2 Power supply........................................................................................................................................... 29

4.7.3 Grounding................................................................................................................................................ 30

4.7.4 USB interfaces.........................................................................................................................................30

4.7.5 LED status indicators.............................................................................................................................. 31

4.7.6 Fieldbus interfaces.................................................................................................................................. 32

Power Panel C80 User's manual V1.02 3