Page 4 of 96 01-37A2-7D0006_py_Manual_Exp-Control-Unit_20210923_a_en.docx Rev. 0

3Product description.................................................................................................. 19

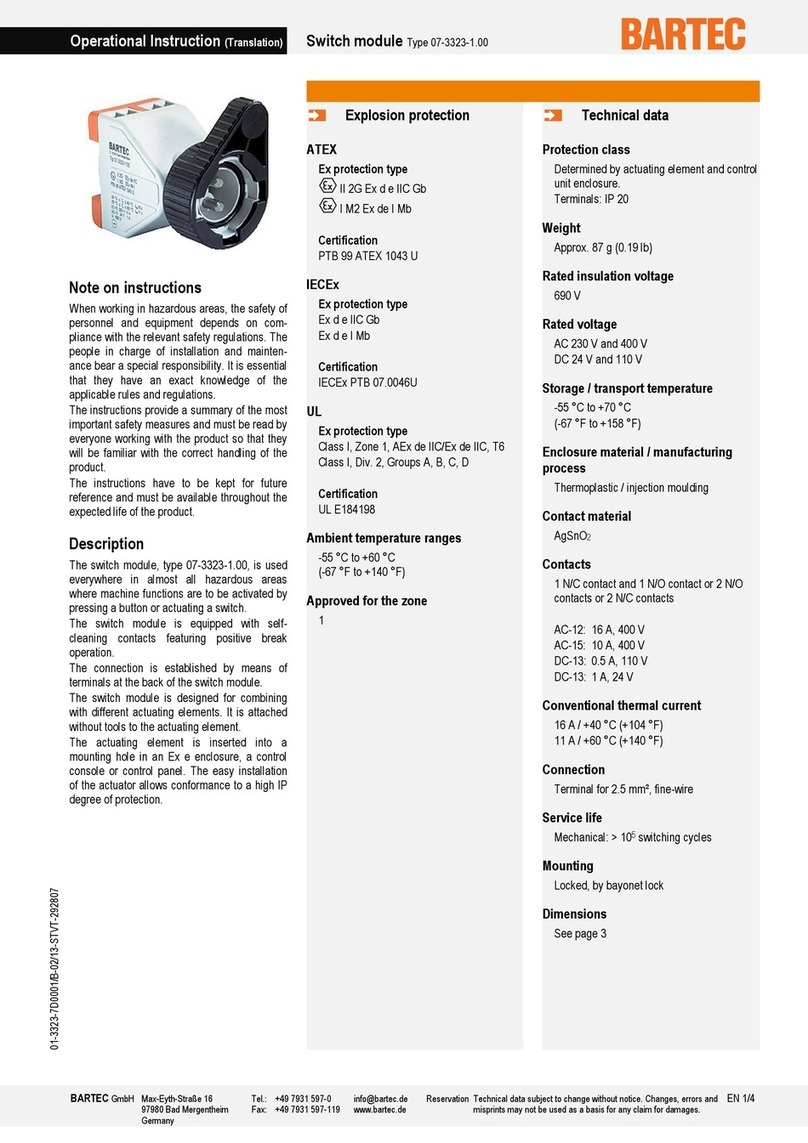

General information ..................................................................................................... 19

Ex p control units APEX ................................................................................................ 19

APEX design, type 07-37A2-2111/*520......................................................................... 20

Accessories.................................................................................................................. 21

Valve fuse..................................................................................................................... 21

Pressure monitor.......................................................................................................... 21

Purge gas valve ............................................................................................................ 21

p-operator panel .......................................................................................................... 21

Programming switch .................................................................................................... 22

Programming cable ...................................................................................................... 22

4Transport and storage .............................................................................................. 23

Scope of delivery.......................................................................................................... 23

Packaging..................................................................................................................... 23

Transport ..................................................................................................................... 23

Storage ........................................................................................................................ 24

Disposal ....................................................................................................................... 24

5Installation............................................................................................................... 25

Installation Ex p control unit, type 07-37A2-2111/*520................................................ 25

Installation of the pressure monitor ............................................................................. 25

Assembly "Internal mounting kit, type 05-0091-0275" ................................................. 26

Assembly "External mounting kit, type 05-0091-0280"................................................. 27

Installation purging gas supply..................................................................................... 28

Version G1/4” ............................................................................................................... 29

Version G1/2” ............................................................................................................... 30

Version G1/4” (Dust application)................................................................................... 31

Pneumatic Connections ............................................................................................... 32

Pneumatic connections APEX, type 07-37A2-2111/*520 .............................................. 32

Typical installations ..................................................................................................... 32

Typical arrangement - outside installation / gas application ........................................ 33

Typical arrangement - inside installation / gas application .......................................... 34

Typical arrangement - outside installation / dust application....................................... 35

Typical arrangement - inside installation / dust application......................................... 36

6Electrical connections .............................................................................................. 37

General ........................................................................................................................ 38

Connection notes ......................................................................................................... 38

EMC-compliant connection.......................................................................................... 39

Pre-Fuse ...................................................................................................................... 40

Inductive loads............................................................................................................. 41

Electrical wiring APEX .................................................................................................. 42

“Ex e” connection terminals ......................................................................................... 43

Connection terminals “Ex i”.......................................................................................... 47