NE216

www.baumer.com 29

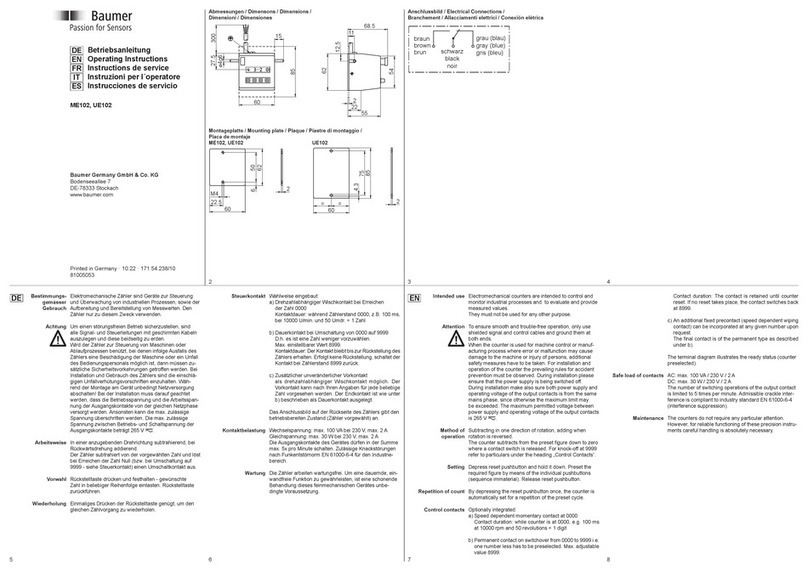

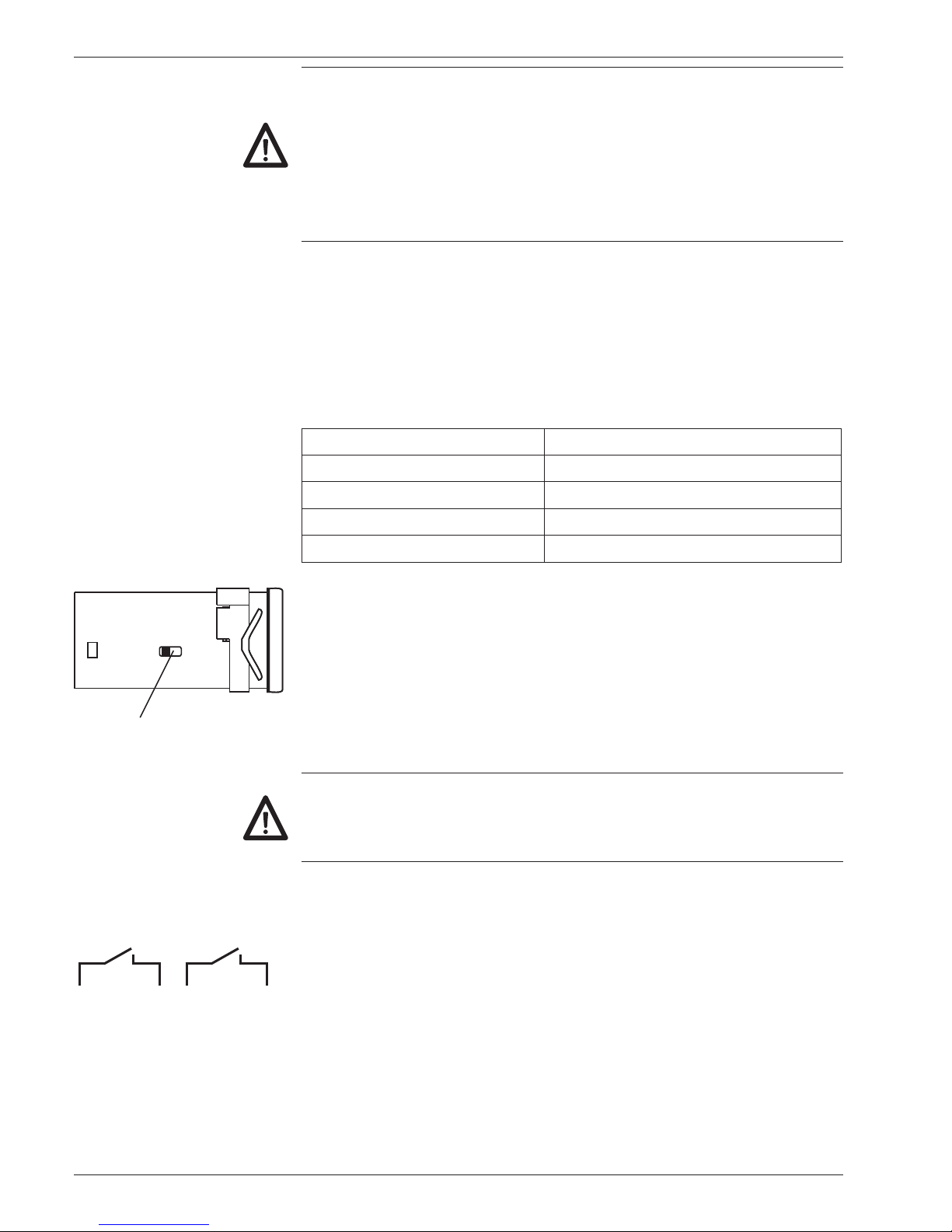

Max. rating Max. voltage Max. current

150 VA/30 W 250 V 1 A

The user must take care that, in case of disturbance, the contact

rating of 8 A / 150 VA (W) is not exceeded. Internal spark suppressi-

on by means of zinc-oxide varistor (275 V). The output relays of the

instrument (1 relay or several) may in total switch 5 x per minute at

the most. Admissible clicks according to interference suppression

standard for the industrial sector. In case of higher switching rate,

the operator will be responsible to take care of local interference

suppression in consideration of the contact rating.

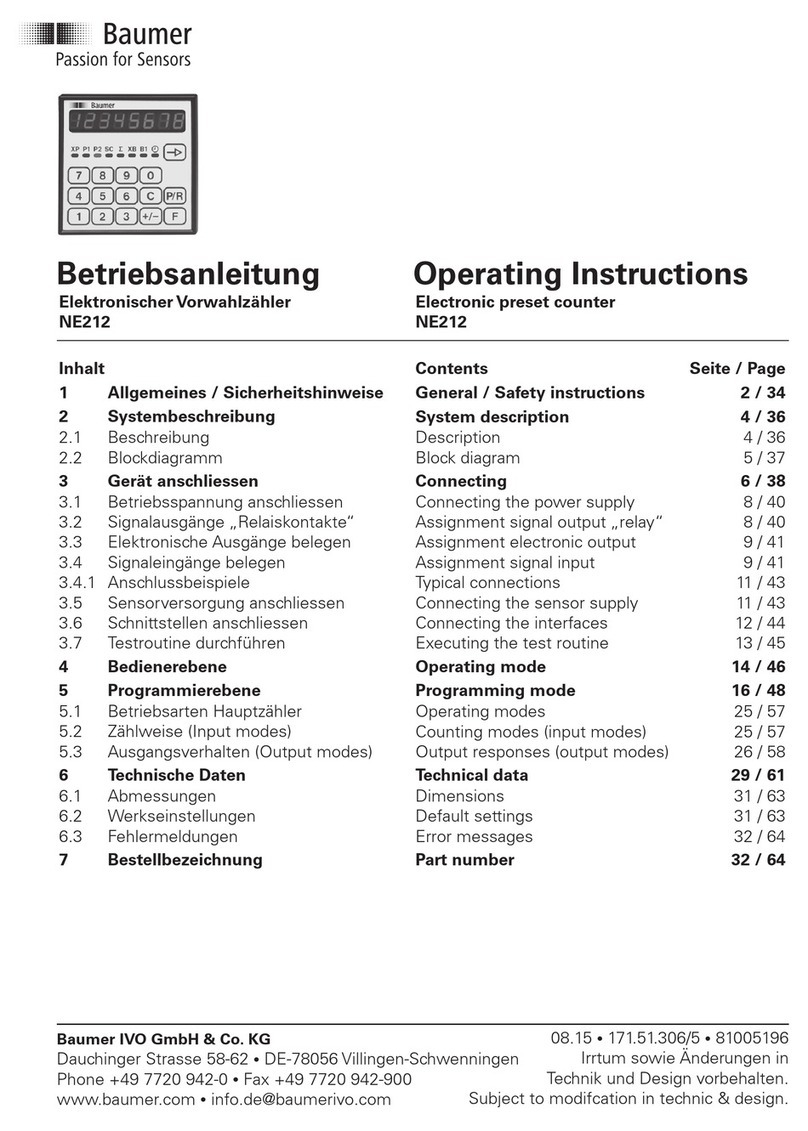

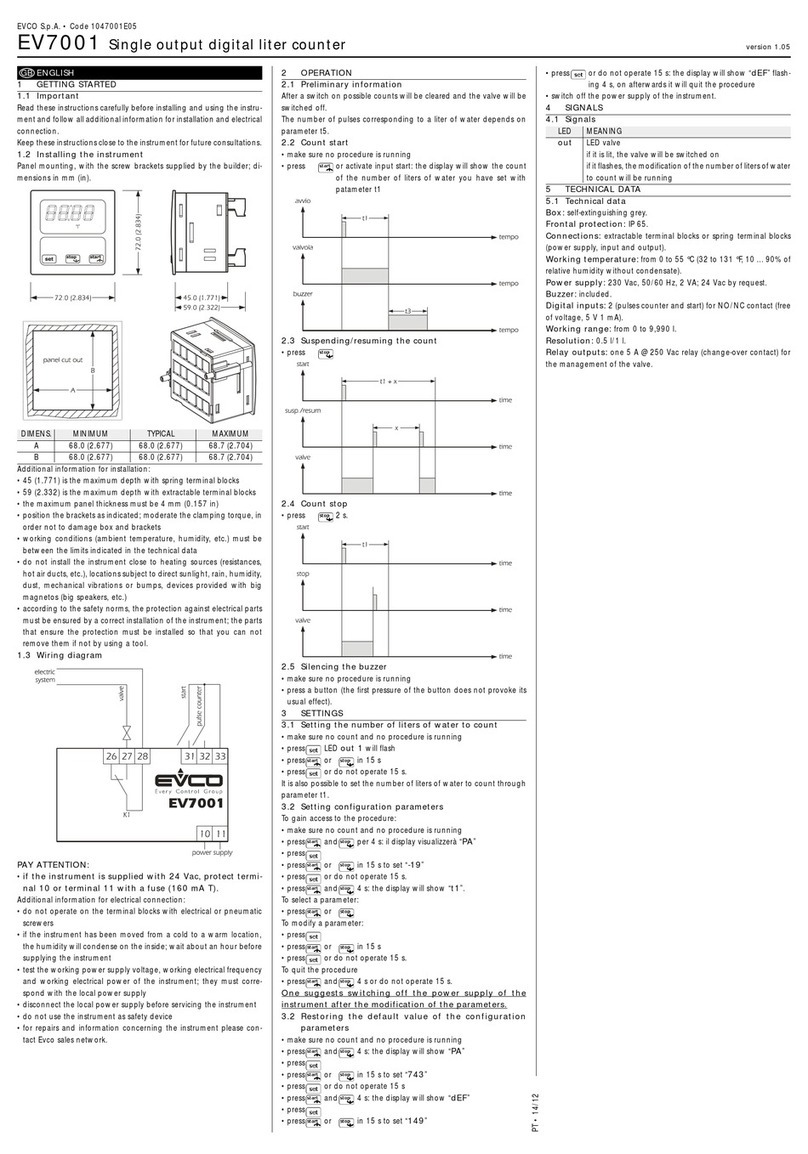

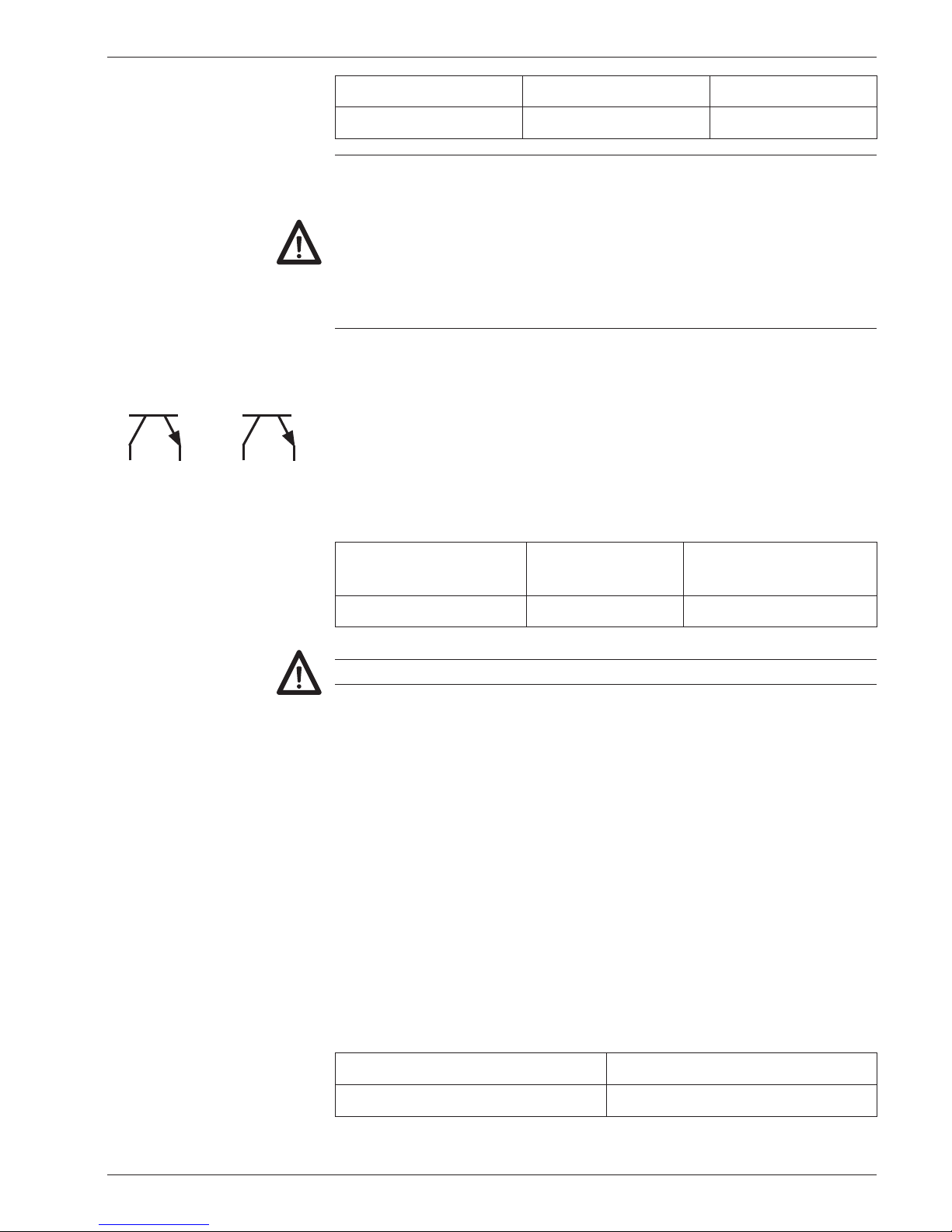

3.3 Assignment of signal outputs (electronic)

4 36 5

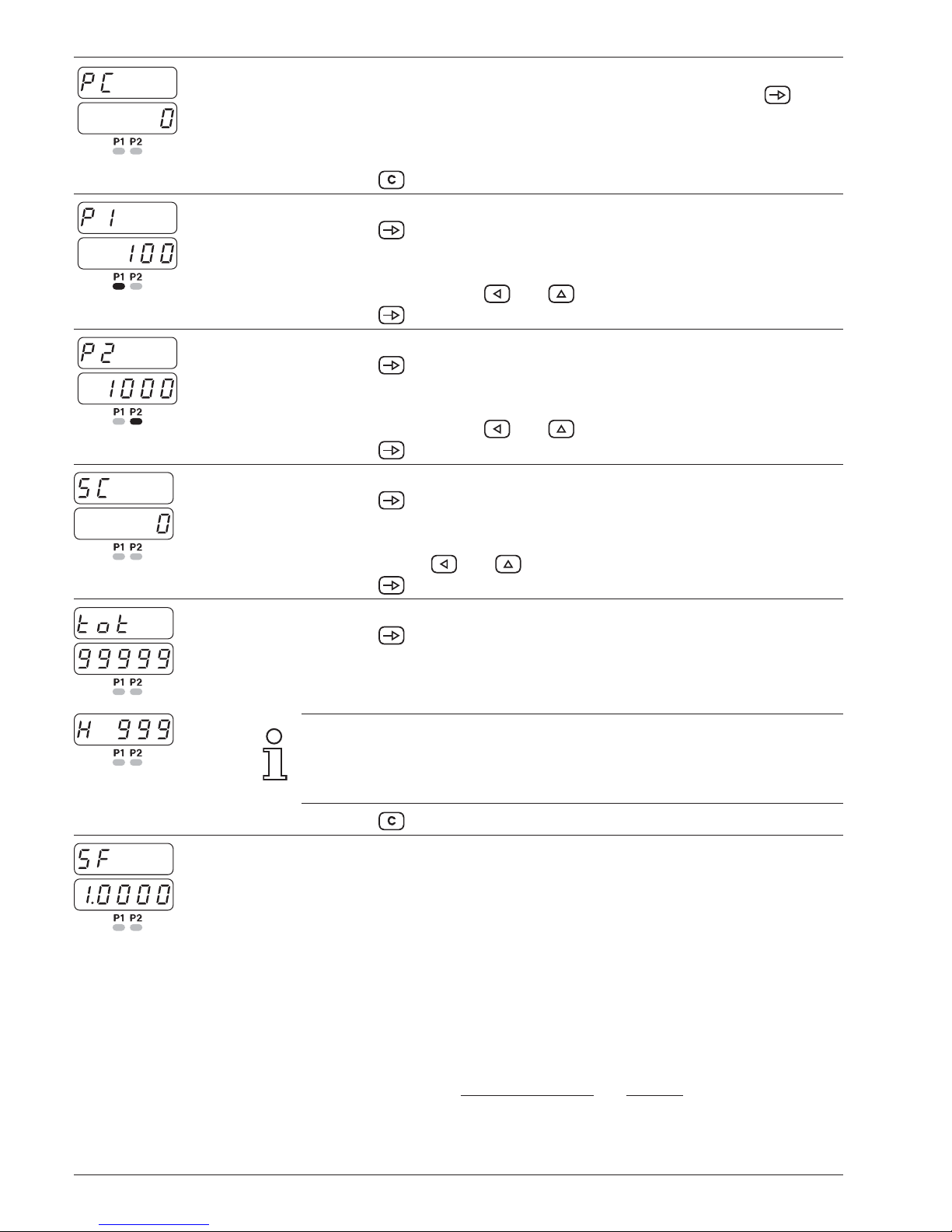

Output P2 Output P1 The electronic outputs (contacts 3, 4 and 5, 6) are optocoupler

outputs. The signal outputs can be assigned as per the adjacent

terminal diagram.

The type of output, as momentary or latched signal, can be chosen

in the programming lines 41/42.

Their function, as normally open or closed, is selected in program-

ming line 40.

Max. switching

voltage

Max. switching

current

Max. residual voltage

+40 VDC 25 mA at 25 mA <1 V

The electronic outputs are not short-circuit-proof.

3.4 Assignment of signal inputs

Choice of PNP or NPN The contacts 7 to 10 are comparator signal inputs.

They can be triggered either by PNP or NPN sensors. The input logic

as well as the operating threshold are correspondingly chosen in pro-

gramming line 33.

The contacts 7 (Track A) and 8 (Track B) are counting inputs for a

counting range between 3 Hz, 25 Hz or 10 kHz. The counting rate is

determined in programming lines 31 and 32.

The contacts 9 and 10 are 2 control inputs for Reset, Stop, Hold,

Print, Keylock etc. The function of these control inputs is selected in

the programming lines 34 and 36.

The minimum pulse duration of control input 1 can be switched in

programming line 35 from 30 ms to 100 s. For control input 2, 30

ms are generally valid.

Input resistance Selectable operating threshold

approx. 3 kΩ 3 V and 6 V