3. CERTIFICATION

The BA367NE has ATEX and IECEx Ex nA gas and

Ex tc dust certification. The main sections of this

instruction manual describes ATEX gas certification.

ATEX dust certification is described in Appendix 1, d

IECEx gas and dust certification in Appendix 2 and

ETL & cETL certification in Appendix 3.

3.1 ATEX Ex nA certification

Notified Body Intertek Testing and Certification Ltd

have issued the BA367NE with a Type Examination

Certificate number ITS16ATEX48409X. This has

been used to confirm compliance with the European

ATEX Directive for Group II, Category 3G

equipment. The instrument carries the Community

Mark and, subject to local codes of practice, may be

installed in any of the European Economic Area

(EEA) member countries and in the EEA EFTA

states, Iceland, Liechtenstein and Norway. ATEX

certificates are also acceptable in Switzerland and

Turkey. The European Commission's Blue Guide

lists the member states, overseas countries and

territories that have adopted harmonisation

legislation.

This section of the instruction manual describes

ATEX installations in explosive gas atmospheres

conforming with EN 60079-14 Electrical installations

design, selection and erection. When designing

systems for installation outside the UK the local

Code of Practice should be consulted.

3.2 Zones, gas groups and T rating

The Counter has been certified as Group II Category

3G Ex ic nA IIC T5 Gc apparatus. This is non-

sparking apparatus complying with EN 60079-15

Equipment protection by type of protection 'n' that

minimises the risk of arcs or sparks capable of

creating an ignition hazard occurring during

conditions of normal operation.

The Counter's front panel push button contacts are

non incendive and have been certified intrinsically

safe Ex ic without an external Zener barrier or

galvanic isolator, as shown on the Type Examination

Certificate. This allows the Counter to be adjusted

and configured live when installed in a Ex n panel

enclosure located in Zone 2.

When connected to a suitable system and correctly

mounted in a panel enclosure complying with the

requirements for Type of protection 'n', the panel

enclosure containing the BA367NE Counter may be

installed in:

Zone 2 explosive gas air mixture not

likely to occur, and if it does

will only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

In gases that may safely be used with equipment

having a temperature classification of:

T1 450oC

T2 300oC

T3 200oC

T4 135oC

T5 100oC

At ambient temperatures between -40 and +60oC.

This allows use with all commonly used industrial

gases except carbon disulphide CS2.

3.3 Special conditions for safe use

Special conditions for safe use are specified by the

Ex nA certificate indicated by the certificate number's

'X' suffix. These state that the BA367NE Counter

should be:

a. Mounted such that the instrument terminals

are protected by at least an IP54 enclosure

certified to IEC 60079-0 or IEC 60079-15 as

appropriate.

b. Be supplied from limited energy circuits with

output parameters in normal operation equal

to, or less than the instruments input

parameters.

These special conditions for safe use can be

satisfied by mounting the BA367NE in an Ex n, Ex e

or Ex p panel enclosure. For ATEX Category 3

installations in Zone 2, self or third party certified

Ex n, Ex e or Ex p panel enclosures may be used.

Additional requirement apply for non-metallic panel

enclosures.

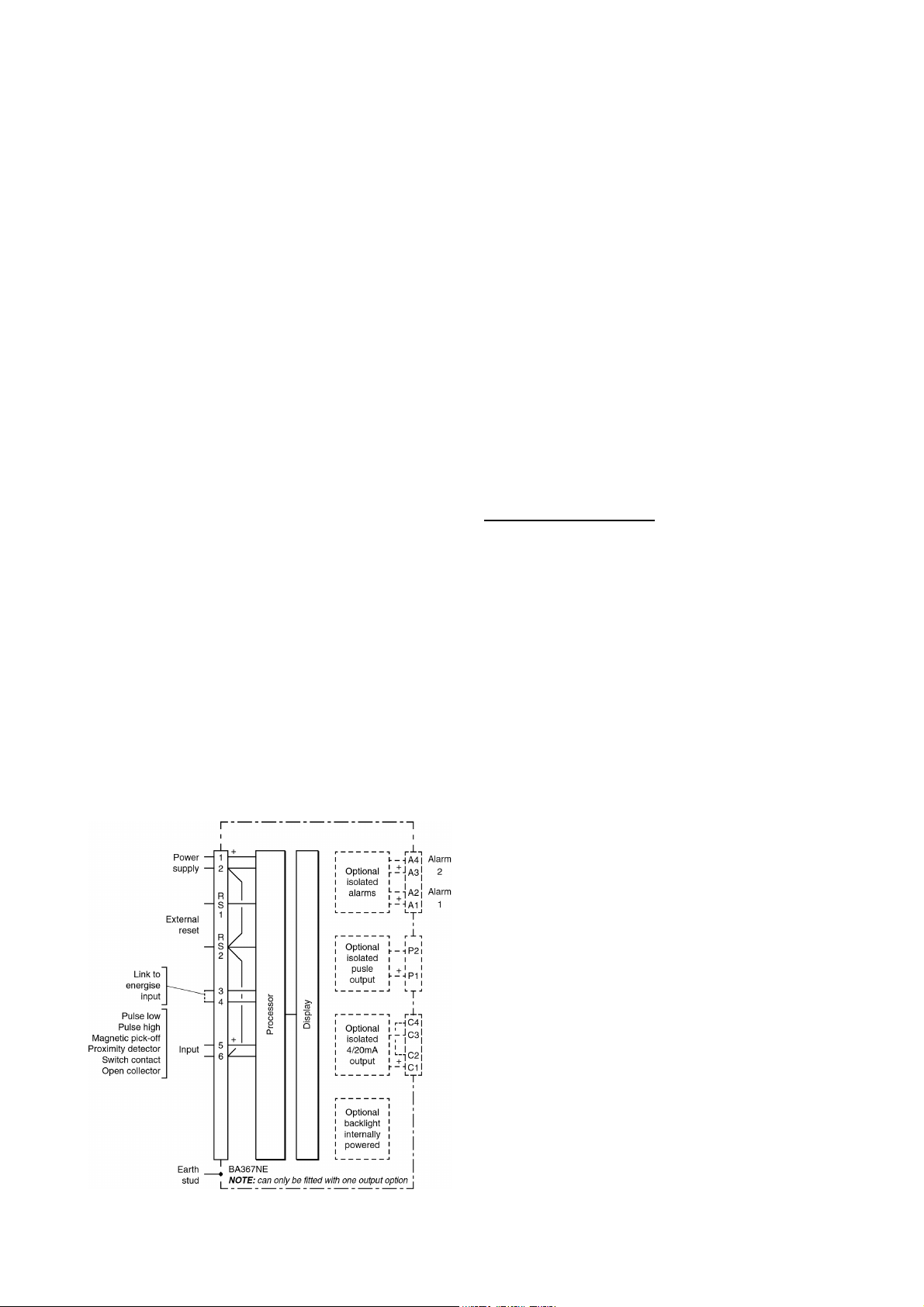

3.4 Power supply

The input safety parameters for the power supply

terminals 1 and 2 are:

Ui = 30dc

Ii = 100mA

This allows the BA367NE to be powered from any dc

supply which in normal operation has an output

voltage of less than 30V. See section 4.1 for power

supply recommendations.

3.5 Pulse input

The BA367NE Counter has a single pair of pulse

input terminals 5 and 6 that may be configured for

use with different types of sensor.

For sensors that require energising to determine

their state, such as switch contacts or a 2-wire

proximity detector, an external link between

terminals 3 & 4 of the BA367NE connects an internal

7V, 6mA supply to the input terminals. Energising is

6