75.5959.01 LZR-FLATSCAN SW QSG 20180627 Page 3 of 475.5959.01 LZR-FLATSCAN SW QSG 20180627 Page 3 of 4

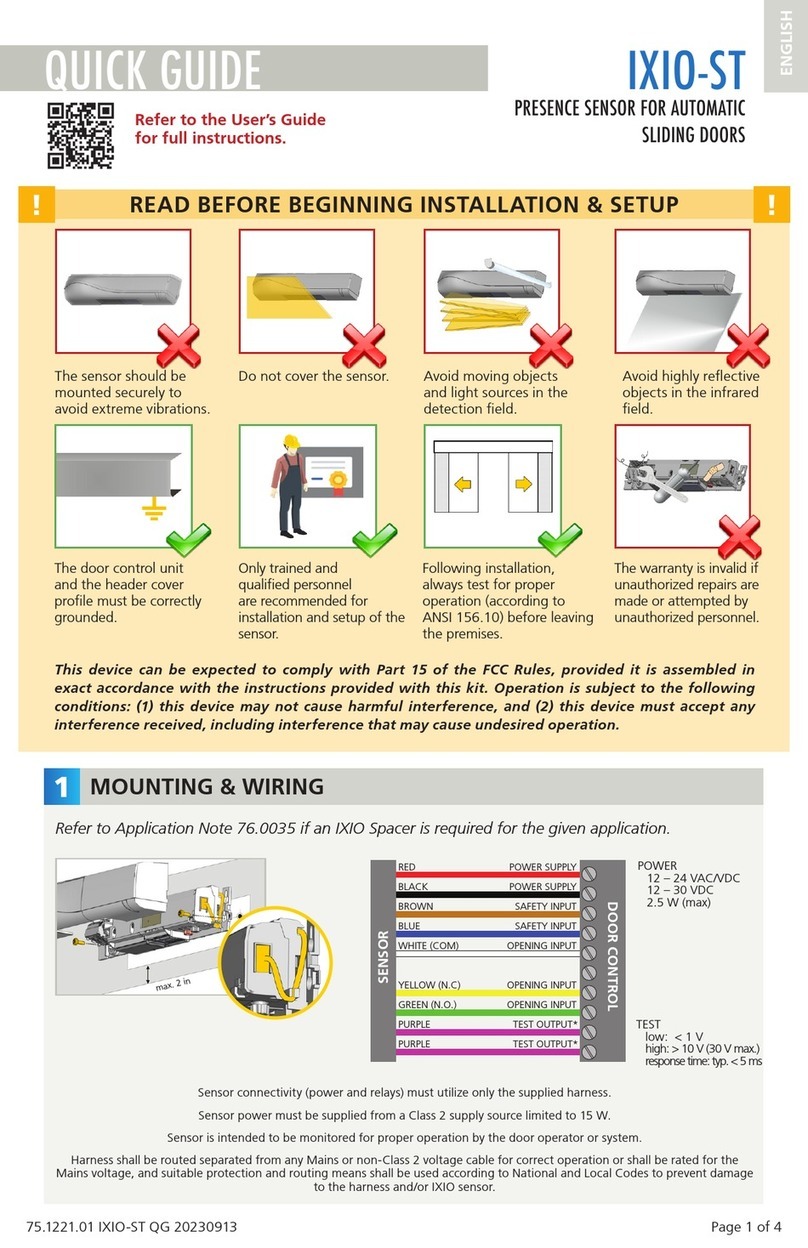

Before launching a teach-in, ensure the following:

• door is closed (use Service Mode if needed − see page 4)

• both relays are connected to door control and master/slave cable is connected between sensors

• detection field is free of environmental obstructions, objects, and people

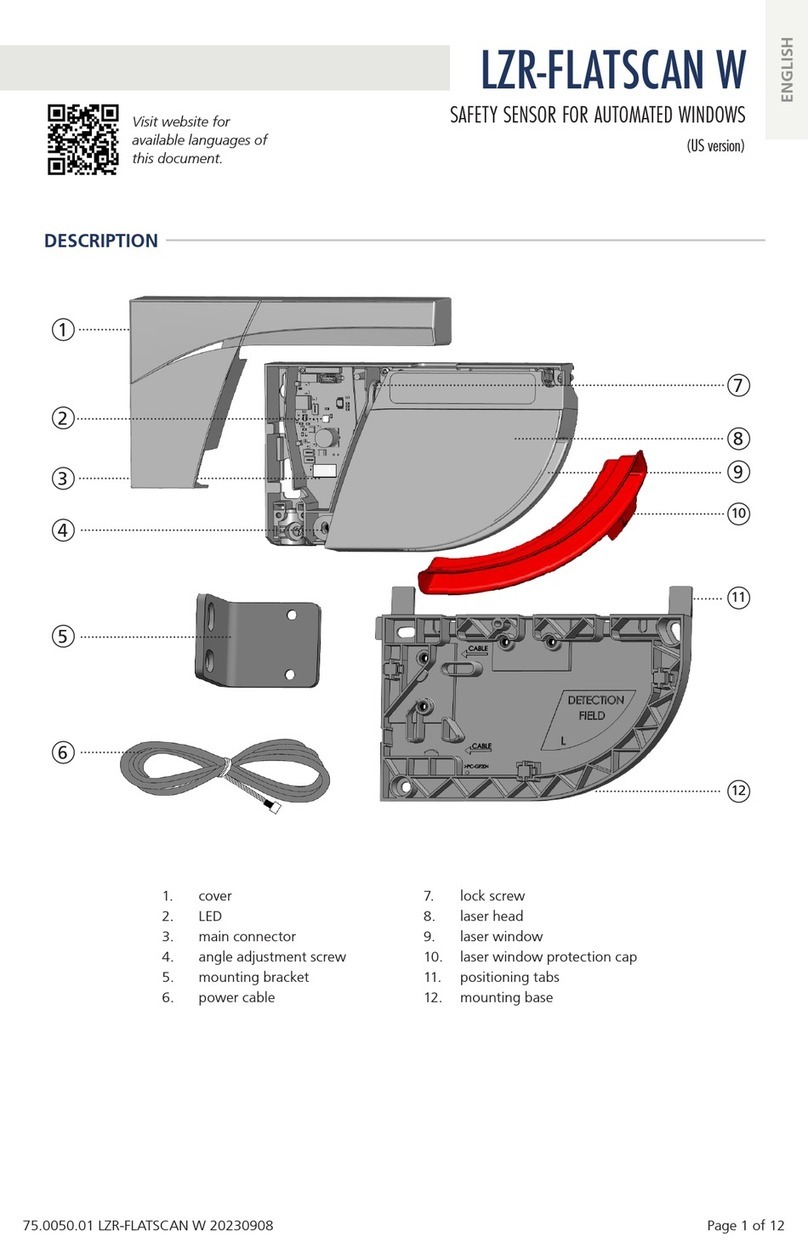

• laser window protector is removed

< 1 sec.

1. 2. 4.

3.

1. Press the Master sensor push-button briefly. The LED will begin quickly flashing red/green. When installing the

sensor on a pair of doors, repeat this on the second Master sensor.

2. When both sensors flash green, position yourself in front of the door and stretch out your arm in front of you.

Make an up-and-down motion at the leading-edge to mark the limit of the detection zones. The LED will flash

red while calculating the width of the door leaves.

3. When the sensors flash green again, remove yourself from the detection field and cycle the door open to allow

the sensors to learn the environment. The sensors will flash red during the closing of the door.

4. Once the door is completely closed again and the LED is off, the teach-in is complete.

NOTE: A teach-in on the master configures both the master and the slave. A teach-in on the slave only configures the

slave. In case the master and slave sensor are not aligned, first launch a teach-in on the master and then on the

slave.

MASTER

TEACH-IN

TESTING / ADJUSTING

4

5

B

A

B

A

Always launch a teach-in and test the correct positioning of the detection fields after making adjustments to

the angle, sensor position, or environment.

Check the correct positioning of the

safety fields by walk-testing according

to ANSI 156.10 standards.

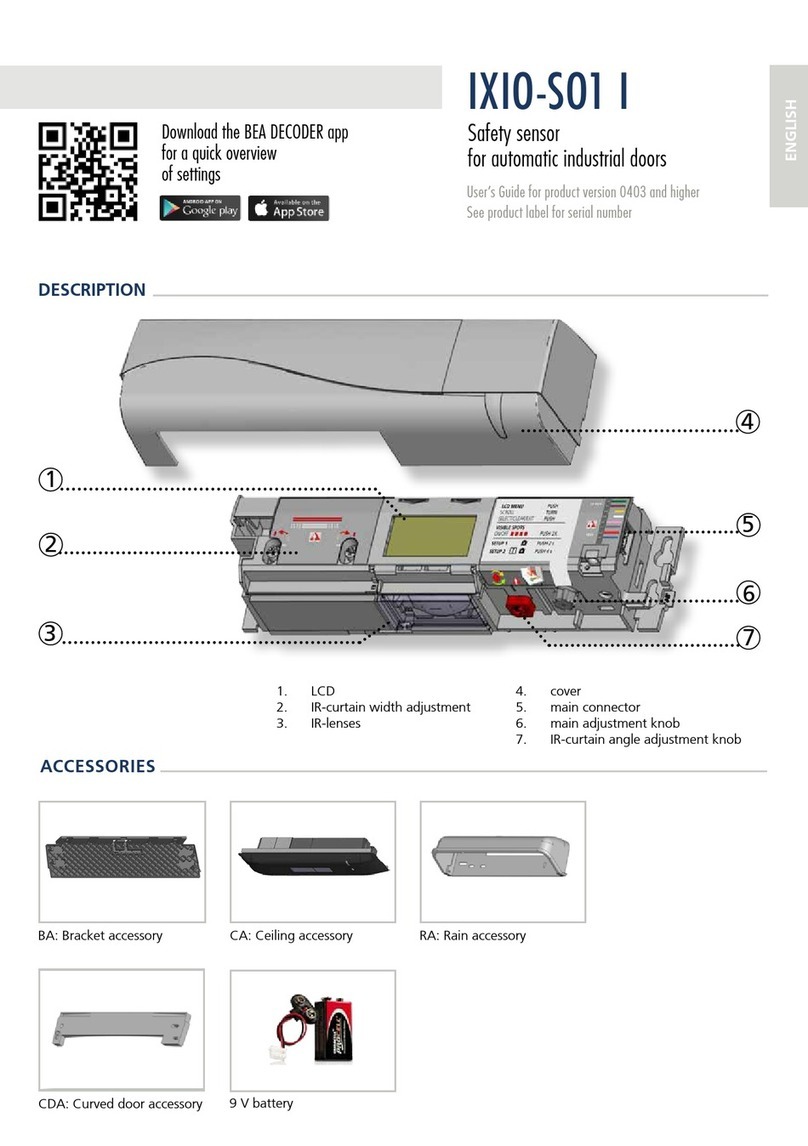

If necessary, adjust the tilt angle of the laser curtain by turning the tilt

angle adjustment screw (from 2° to 10°).