3.5 Pulse input terminals

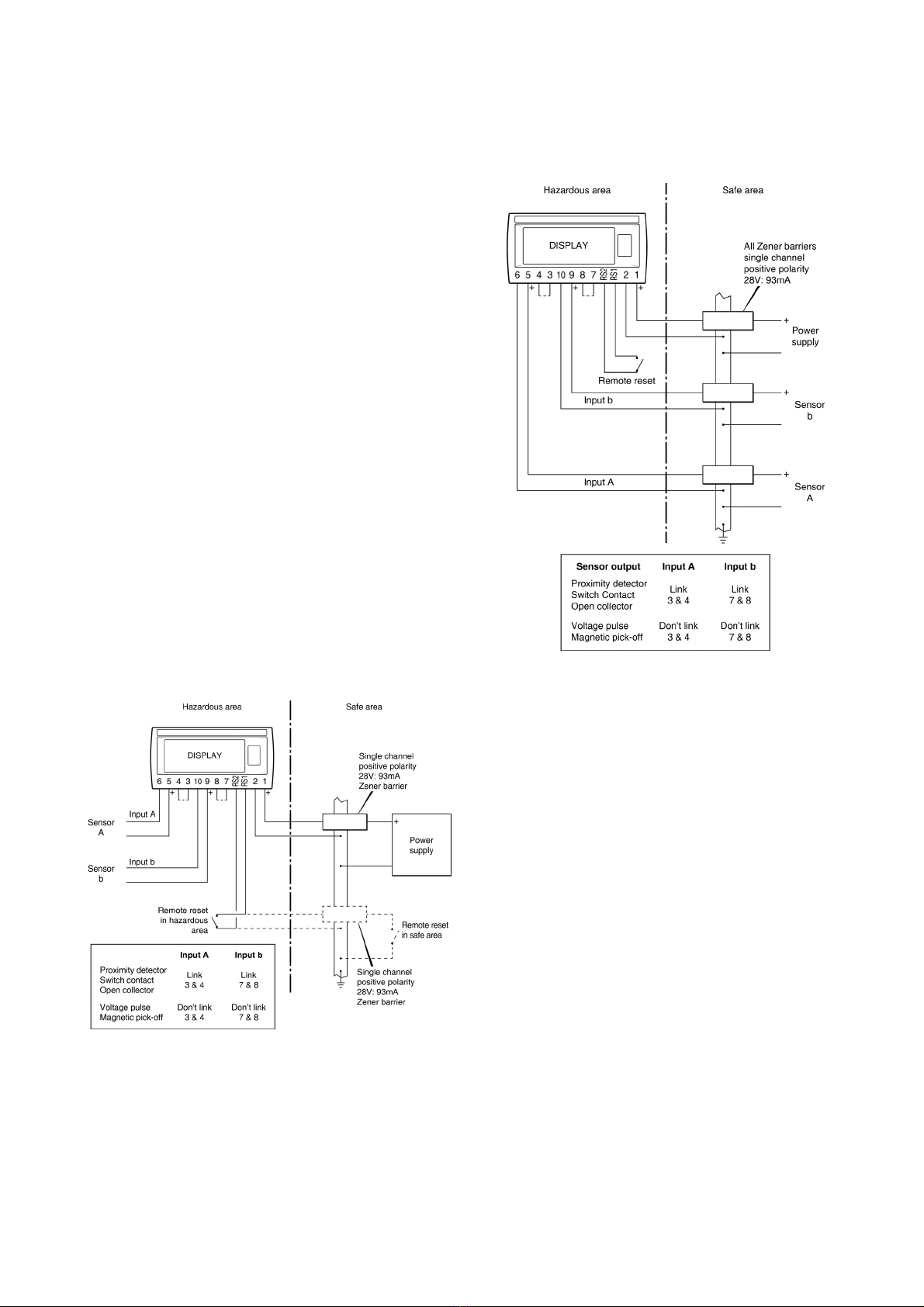

The BA368E Counter has two pulse inputs, A and b,

that may be individually configured for use with most

types of sensor. Each input is a separate

intrinsically safe circuit, although the negative side of

each input is internally connected to the negative

side of the power supply and reset terminal RS2.

See Fig 1. The two inputs should not be connected

in parallel.

Some types of sensor that may be connected to the

BA368E inputs, such as a switch contact or a 2-wire

proximity detector, require energising to determine

their state. For sensors requiring energising fitting

an external link between terminals 3 & 4 of the

BA368E for input A and between terminals 7 & 8 for

input b, connects an internal 7V, 6mA supply to the

respective input. Energising is not required when a

BA368E input is connected to a voltage source.

Fitting an energising link changes the output safety

parameters of each BA368E input as shown in the

following table which also shows the types of sensor

requiring energising (link fitting).

Output safety

parameters of each

input.

Type of input Link* Uo Io Po

Switch contact Yes 10.5V 9.2mA 24mW

Proximity detector Yes 10.5V 9.2mA 24mW

Open collector Yes 10.5V 9.2mA 24mW

Magnetic pick-off No 1.1V 0.5mA 0.2mW

Voltage input (low) No 1.1V 0.5mA 0.2mW

Voltage input (high) No 1.1V 0.5mA 0.2mW

*For input A link terminals 3 and 4

*For input b link terminals 7 and 8

3.5.1 sensors that do not require energising

Magnetic pick-offs and voltage pulse inputs do not

require energising, see section 3.5. For intrinsic

safety purposes, sources of energy with output

parameters less than 1.5V; 100mA and 25mW are

considered to be simple apparatus (Clause 5.7 of

EN60079-11), which allows them to be ignored and

not documented when assessing an intrinsic safe

system.

When terminals 3 & 4 and terminals 7 & 8 are not

linked, the associated BA368E Counter input

complies with the requirements for simple

apparatus. This allows the output parameters of the

pulse input to be ignored when assessing the safety

of the sensor connected to a Counter.

This allows almost any certified intrinsically safe

voltage pulse or certified magnetic pick-off to be

directly connected to one of the BA368E Counter

inputs.

The BA368E EC-Type Examination Certificate

specifies that the equivalent capacitance and

inductance of each BA368E Counter input are:

Ci = 2nF

Li = 4H

To determine the maximum permissible cable

parameters these figures should be subtracted from

the maximum permitted cable parameters specified

for the sensor connected to the input terminals of the

Counter. However, the Counter input parameters

are very small and they are unlikely to make any

significant difference to the allowable cable

parameters.

3.5.2 sensors that require energising

Switch contacts, proximity detectors and open

collector inputs require energising as described in

section 3.5. When energised, the output parameters

of each BA368E Counter input are:

Uo = 10.5V

Io = 9.2mA

Po = 24mW

These parameters do not comply with the

requirements for simple apparatus and should be

included when assessing the safety of the circuits

connected to the inputs of the BA368E Counter.

Any certified intrinsically safe sensor or simple

apparatus may be connected to an energised

BA368E Counter input providing that the sensor's

input parameters are equal to, or greater than, the

output safety parameters of the BA368E Counter

input which are shown above. This is not restrictive

and most sensors will comply.

This allows most mechanically operated switch

contacts, open collector transistors and certified

intrinsically safe NAMUR proximity detectors to be

directly connected to a BA368E Counter input

providing the sensor and associated wiring can

withstand a 500V rms insulation test to earth and

both are located within the same hazardous area as

the Counter.

The maximum capacitance and inductance that may

be safely connected to each Counter input when

energised (link connected) is:

Co = 2.4µF

Lo = 200mH

Again this is not restrictive and most sensors will

comply.

7