6. CONFIGURATION

The BA444DF-P 8 variable PROFIBUS PA PA

indicator may be configured as a fieldbus node or

as a fieldbus listener. When used as a fieldbus

node the indicator is configured via the fieldbus

host although the instrument address may be

entered via the front panel push buttons using the

menu shown in Fig 4. For detailed node

conditioning information please refer to the BEKA

PROFIBUS PA Display – Fieldbus Interface Guide

which may be downloaded from the BEKA website

www.beka.co.uk

As a fieldbus listener, the BA444DF-P is not visible

to the fieldbus host and can only be configured via

the front panel push buttons using the menu shown

in Fig 6.

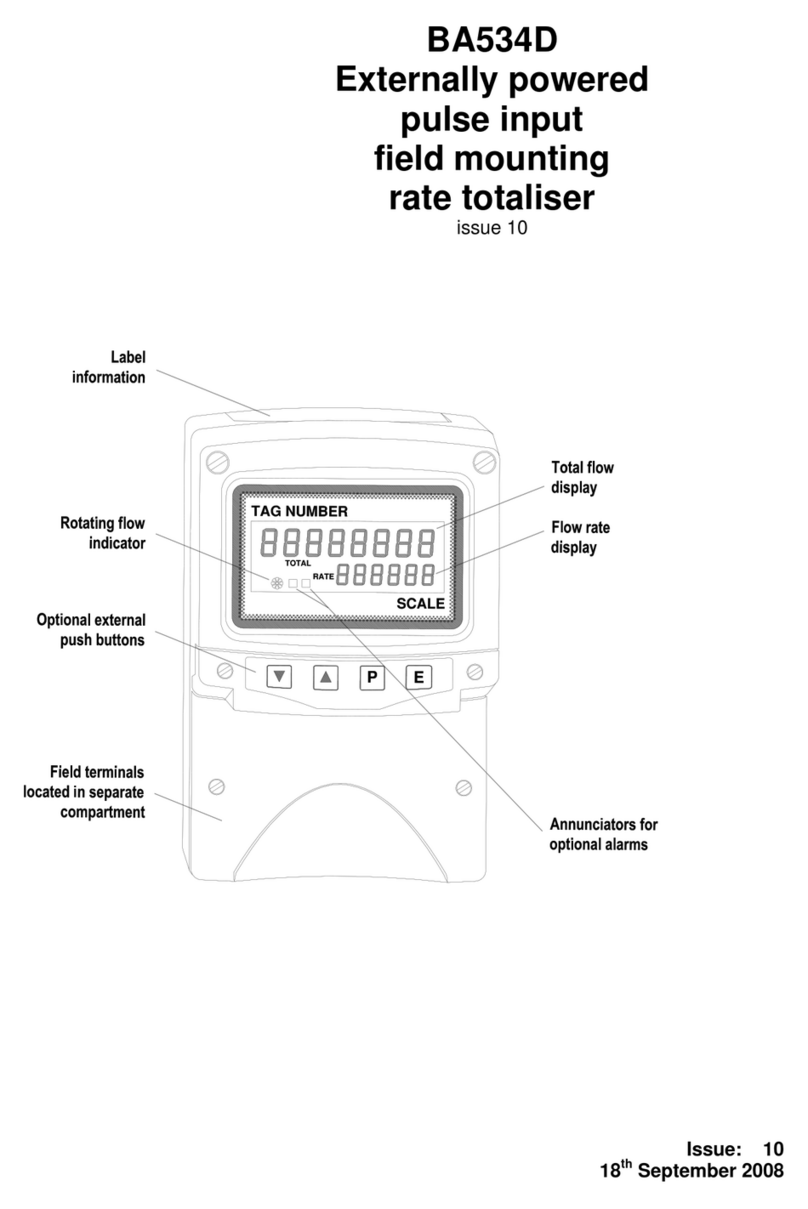

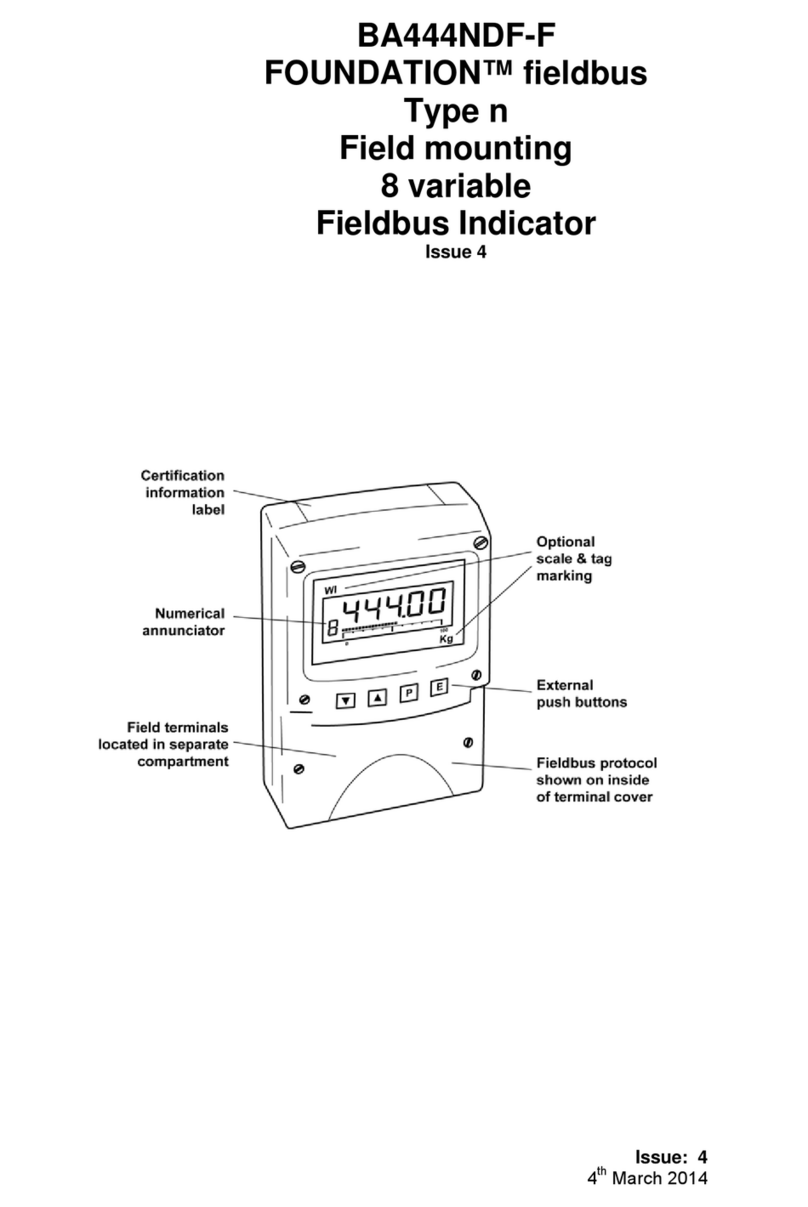

Throughout this manual the four BA444DF-P push

buttons are identified P E ▼▲and legends

displayed by the instrument are shown within

inverted commas e.g. ‘CodE’ and ‘Enb’. 6.1

Configuration menus

The configuration menus are separated into two

sections, fieldbus node and fieldbus listener. Both

contain the ‘tYPE’ function that enables transfer

between the two. Unless otherwise requested

when ordered, all PROFIBUS PA BA444DF-P

instruments are supplied as a fieldbus node with

default configuration but can easily be reconfigured

on-site.

6.2 Node configuration menu

The node configuration menu is shown in Fig 4.

Access to the menu is obtained by operating the P

and Ebuttons simultaneously. If the BA444DF-P is

not protected by an access code the first

parameter 'Addr’ will be displayed. If the

instrument is protected by an access code, ‘CodE’

will be displayed first. Pressing Pwill allow the

four digit security code to be entered digit by digit

using the ▼or ▲button to adjust the flashing digit

and Pto move control to the next digit. When the

correct code has been entered, pressing Ewill

cause the first parameter ‘Addr’ to be displayed.

If an incorrect code is entered, or no button is

pressed for ten seconds, the BA444DF-P will

automatically return to the display mode.

6.2.1 Enter fieldbus address ‘Addr’

This function enables the fieldbus address of the

BA444DF-P to be entered via the push buttons.

Select ‘Addr’ in the node menu using the ▼or ▲

button and press Pto enter the function. This will

reveal the existing three digit decimal address with

the left hand digit flashing which may be changed

by operating the ▼or ▲button. When set as

required operating the Pbutton will transfer control

to the next digit that may be adjusted in the same

way. When all digits are set as required operating

the Ebutton will enter the new address and the

indicator will restart in the display mode after

completing the initialisation sequence. If the

address is not changed, operating the Ebutton will

return the display to the ‘Addr’ prompt in the node

configuration menu.

6.2.2 Access code for configuration menu

‘CodE’

Access to the node configuration menu may be

protected by a four digit security code which must

be entered to gain access. New instruments are

supplied configured with the default code 0000

which disables this protection and allows

unrestricted access to the configuration menu.To

enter a new access code select ‘CodE’ in the node

configuration menu by operating the ▼or ▲

button. To enter the function press Pwhich will

reveal the current access code with one digit

flashing. The code may be changed using the ▼or

▲button to adjust the flashing digit and the P

button to move control to the next digit. When the

required code has been selected, press Eto enter

the selection and return to the ‘CodE’ prompt in the

configuration menu. The revised access code will

be activated when the transmitter is returned to the

display mode.

If the access code is lost please contact BEKA

associates.

6.2.3 Change from node to listener ‘tYPE’

This function enables the instrument to be changed

from a fieldbus node to a fieldbus listener. Select

‘tYPE’ in the node configuration menu using the ▼

or ▲button. To enter the function press Pwhich

will show that the instrument is configured as a

fieldbus node, to change to a fieldbus listener

press the ▼or ▲button which will toggle the

display to ‘LStnr’ To prevent accidental changes

this request must be confirmed by operating the P

button and entering ‘5urE’. The instrument will

display ‘0000’ with the first digit flashing, using the

▼or ▲button set the flashing digit to ‘5’ and press

the Pbutton to move control to the next digit which

should be set to ‘u’. When the four letters of ‘5urE’

have been entered, operating the Ebutton will

cause the instrument to restart as a fieldbus

listener in the display mode.

CAUTION

All the instrument’s node configuration

information will be lost when it is

changed from a fieldbus node to a

fieldbus listener.

Please refer to the quick set-up procedure in the

BEKA PROFIBUS PA Display – Fieldbus Interface

Guide.

8