Belanger Gyro Wrap Signature Series User manual

Gyro Wrap™ Signature Series

Gyro Wrap™ Signature Series

1MANUAL248 Rev02

Belanger Equipment Owner’s Manual

Gyro Wrap™ Signature Series

Copyright 2021

Belanger, Inc®

This manual and the accompanying equipment are protected by United States trademark, copyright, and patent laws. You

may make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form

whatsoever, in whole or in part, without the prior written permission of Belanger, Inc.®

The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is

for reference purposes only and does not imply sponsorship or approval of Belanger, Inc.®by these companies or any

companies affiliated with their respective owners.

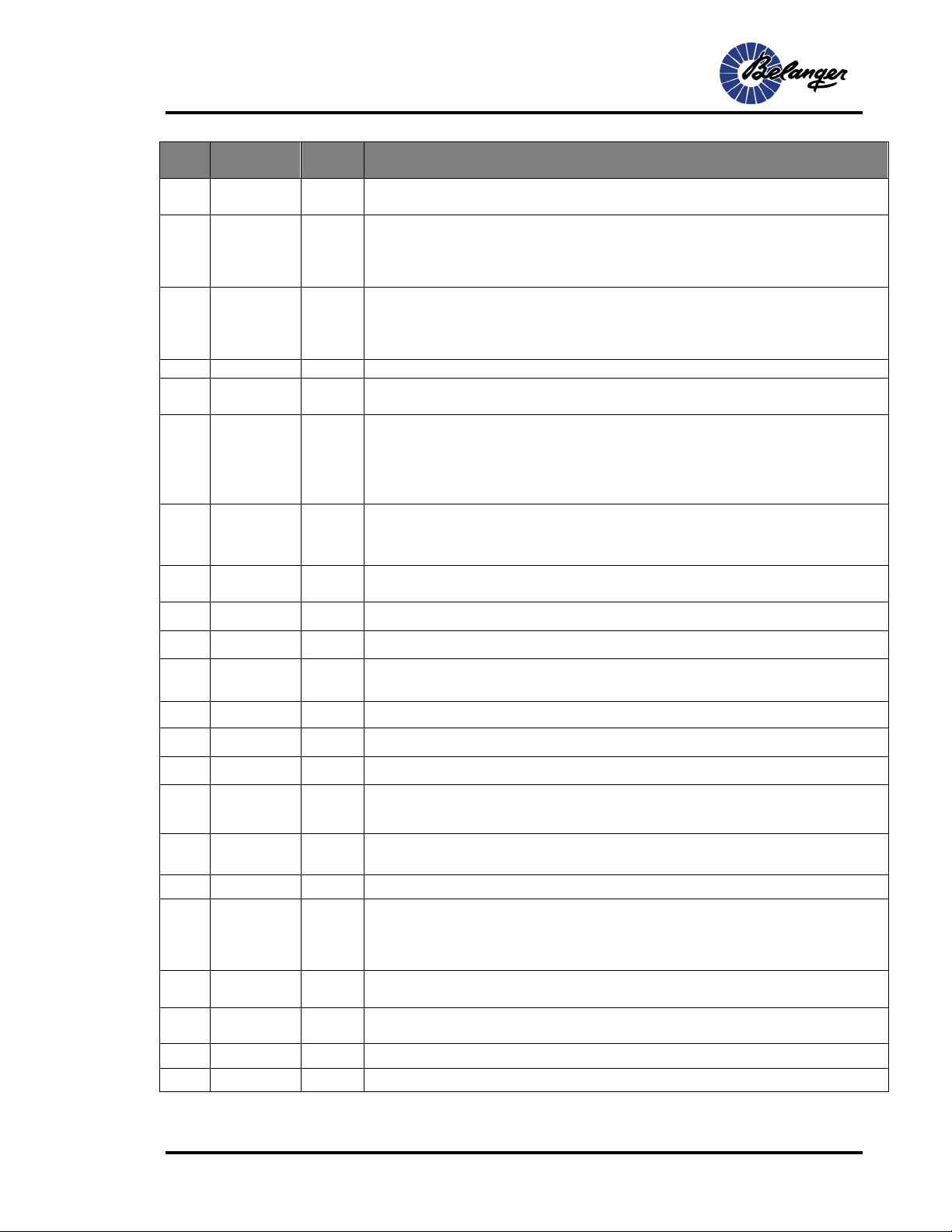

CURRENT REVISION LOG

Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL248

Rev

Release

Date

Page Description

02

Before

4/8/21

All Changed Neo-Tex to Neo-Tex™ throughout manual

3

Updated Limited Warranty

7

Added “or hydraulic” to the first sentence of the second paragraph

Removed the first sentence from the third paragraph which specified the electric motor

specifications

Removed the Neo-Tex™ Foam and cleaning information from the Introduction

In the first paragraph changed Belanger Signature Line to Belanger® Signature® and

removed “to a glossy white” after powder coated

8

Removed Gearbox from Motor-Gearbox Assemblies under Equipment included

9

Changed dimension under Tunnel space required from 129-1/2” to 139”

Removed “plastic” and “cover” under Unit height

Added “each motor” after each of the motor specifications

Added Hydraulic 4GPM @900 PSI to the Utility section

Added Unit Height 126”: from the floor to the top of the hoses – Hydraulic

Changed CAUTION note from …installing piece of equipment to …installing a piece of

equipment

10

Added Electric and Hydraulic to subheading

Changed dimension 129-1/2” to 139” and 135-1/2” to 145”

Added image to show Unit Height for a Hydraulic system

11

Removed “Electric” from heading Drive Considerations

Added Electric and Hydraulic to sub-heading

Added image of hydraulic motor assembly

12

Changed Electrical to Electric in subheading

Changed Note from There are driver side / passenger side labels to There is a driver side

and passenger side label…

Changed image title to Overview of the correct orientation for Gyro Head with an Electric

Motor/Gearbox

13

Added this page to describe and show the Gyro Head™ Orientation for the hydraulic

motor

14

Revised Frame Assembly steps 2-6 per the attached document

15

Added Guide Rail after Conveyor in note

19-22

Added Electric Drive Only to the sub-heading

20

Added note to verify that the overall length of the two shafts is 102”

Corrected spelling in step 1

22-25

Added Inserting the Shaft – Hydraulic Drive Only instructions and images

26-29

Added Electric Drive Only to the sub-heading Mounting the Motor/Gearbox Assembly

32-36

Revised instructions for the installation of the Neo-Tex™ Fill (per Change Request #38)

Removed installation instructions for Neo-Tex

™

with Nylon Brush fill

33

Under Installing Cleaning Material Lower Hub Fill step 5 changed 8” to 10” Wash Clips

34

Under Installing Cleaning Material for Upper Hub: Neo-Tex™ in step 5 changed “Clips” to

“Clip” and “if both packs” to “of two pieces”

37-44

Added Hydraulic to the Utilities sub-heading

Changed sub-heading to Pneumatic, Electric or Hydraulic, and Water

37

Added Note for hydraulic driven machines to disregard the electrical routing and

connection steps

Updated the Distribution Manifold – Electric images

Added images of the Distribution Manifold – Hydraulic

Added Electric and Hydraulic notes to images in step 2

38

Changed the last sentence in first paragraph from “…each end for all” to “…the end of

each” and connections to connection

Updated the images of the distribution manifold and the pneumatic connections

CURRENT REVISION LOG

Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL248

Rev

Release

Date

Page Description

40

Under Pneumatic Connections removed Passenger Side from step 4c

Changed “4 wire electrical cord” in Note to “4 conductor cable”

Under Electrical Junction Box Connections step 1 changed electrical to electrician and in

step 1c removed Passenger Side:

41

Updated the image of the distribution manifold in Step 2 of Electrical Junction Box

Connections

Removed the first word “Supplies” from the first paragraph of the Electrical Motor/Gearbox

Connections section

Added images to Electrical Motor/Gearbox Connections step 1 and in step 2 changed 4

wires to 4 conductor cable

Replaced “If you have the optional motor covers, you will need to…” with “Then…”

42

Changed “wired up” to “connected” in the first sentence under Wheel Rotation

Changed the sentence: Use the image for... to Refer to the image at the bottom of this

page for…

Changed “Turn power off swap motor leads if necessary.” to “If the wheels are rotating

incorrectly turn the power off and swap the motor leads.”

Corrected typo in Note: show to shown

Removed Water Manifold Installation section under Utilities; manifold ships secured in

position

43

Added Connecting the Hydraulic Hoses instructions and images under Utilities section

45

Changed filler strip part numbers: 8812 to 9317 and 8805 to 9310

46

Changed filler strip lengths: at base of frame legs from 7-3/4” to 7-7/8” in four places, on

top of the head assembly from 67-13/16” to 15-1/16”, on top of the passenger side arm

assembly from 43-1/4” to 33-1/2” and added a 7-3/4” filler strip

48

Removed the third sentence in the first paragraph under Swing Flow Control which stated:

On each stand, there are two such controls.

50

Removed and added Daily, Weekly and Monthly Routine Procedures

Removed Quarterly Routine Procedures

50-52

Added the Powder Coating Maintenance and Powder Coating Repair Procedures

55

Added exploded views of the Head Assembly with Hydraulic Lines

56

Added exploded views of the Arm Assemblies with Hydraulic Lines

57

Changed part numbers: 1BERNG810 to 1BERNG849 in two places, 1GRMIT750 to

1GRMIT666, 8767 to 9298 and 8778 to 9299

Corrected part number: 1WASHR-LC281 to 1WASHR-LC581

58

Removed Hydraulic from the first subheading on the page

Changed second subheading from Gyro Head Assembly: Hydraulic to Gyro Cylinder

Assembly: 109721 & 109722

59

Changed subheading from Gyro Head Assembly: Hydraulic to Gyro Cylinder Assembly:

109721 & 109722

Changed subheading from Posi-Stop Mount Assembly: 109722 to Gyro Cylinder

Assembly: 109721 & 109722

Changed part number 1VALVE-HY393 to 1VALVE-HY395 (per Change Request #11)

60

Added exploded views of the electrical and hydraulic distribution manifolds

Added “see below” to component callouts

Added 109712 and 109713 to subheading and component callouts

61

Added 60 Hz into the following subheading Gyro Head Assembly: Electric 60Hz (Upper

Section)

Added the number 1 to all the plastic gear cover part numbers in chart

62

Replace with a new exploded assembly to include the 1FSTNR-SH958(4) fasteners

Corrected part numbers: 8781 was 3211, 1BERNG849 was 1BERNG810 (2 places), 8783

was 8738,

63

Added this page to show the exploded view of the Gyro Head Assembly for the 50 Hz

electric motor, drive shaft and assembled image

CURRENT REVISION LOG

1MANUL248 Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

Rev

Release

Date

Page Description

64

Added this page to show the exploded view of the Gyro Head Assembly for the hydraulic

motor, drive shaft and the exploded view of mounting the hydraulic motor

65

Changed subheadings from Air Cylinder Assembly to Water Manifold Assembly and Air-

Over-Oil Assembly to Water Manifold Assembly Components

Created new images to show the entire water manifold assembly and exploded images to

show components of the assembly

66

Changed filler strip part number 8812 to 9317 and 8805 to 9310

Changed filler strip lengths: at base of frame legs from 7-3/4” to 7-7/8” in four places, on

top of the head assembly from 67-13/16” to 15-1/16”, on top of the passenger side arm

assembly from 43-1/4” to 33-1/2” and added a 7-3/4” filler strip

68

Added part number callout 1VALVE-EL710 (per Change Request 60)

71

Added page to show part numbers for the plastic Wash Clips for Neo-Tex™ and the Neo-

Tex

™

Fill Pattern (per Change Request #38)

72

Moved line to the correct position to show the top three sections

Removed note about the bottom row of lower hub having 20 additional clips

Added: hub sizes and part numbers, single part numbers for Neo-Tex™, part numbers for

complete Neo-Tex™ fill replacement for all six colors, wash clip quantities for upper and

lower hubs (per Change Request #38)

73-75

Added Appendix A: Nylon Brush Installation for Fleet Washes. This content was

previously included within the manual, it is an offering primarily for Rental Car Fleet

Washes.

2

After

04/08/21

11 Removed the description of passenger side and driver side sticker label

12 & 13 Increased size of the driver side and passenger side identification note

14 Called out the Clevis Mount

15

Added Note: The 48-3/4” measurement is the same for both a single and a double

guiderail conveyor.

17 Identified what arm was being mounted in the image

18 Added notes about cylinder installation and how to adjust the flow control properly

26 Added note about plastic motor cover option for 60Hz Motor/Gearbox Assembly

27 Added note about loosening the Torque Studs to set the Cotter Pins when installing the

electric Motor/Gearbox then retightening the Torque Studs

54

Added not stating that the Leg Assembly Caps may have either 2 or 6 fasteners, the older

assemblies have 6 and the newer assemblies have 2

58

Updated the image of the Gyro Bearing Glide Components

61

Updated page to show 8-hole Torque Plate 108661

Added enlarged image of Torque Plate & Ring Terminals

Changed Motor/Gearbox call out from: 1GEABX-AS986: Std. Voltage, 1GEABX-AS988:

575 Volts to 112286 Std. VAC, 112297: 380/400/415 VAC, 112288: 575VAC per

62

Updated the Electric 60Hz Head Assembly to clarify the B-Ball Assembly 109725 &

Motor/Gearbox Assembly, specified black powder coated parts

63

Updated the Electric 50Hz Head Assembly to clarify the B-Ball Assembly 110245 &

Motor/Gearbox Assembly 110246, specified black powder coated parts

64

Updated the Hydraulic Motor/B-Ball Head Assembly 110342, specified black PC parts

69

Changed part number 1FSTNR-HH045 to 1FSTNR-HH056

GYRO WRAP™ Signature ®Series

1MANUL248 Belanger, Inc. *PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1

Table of Contents

Belanger Incorporated Limited Warranty........................................................ 3

Operational Warning......................................................................................... 4

Introduction ....................................................................................................... 5

Important Safety Information................................................................................................................................... 5

Safety Symbols and Signal Words.......................................................................................................................... 5

Safety Warnings...................................................................................................................................................... 6

Before You Get Started........................................................................................................................................... 8

Specifications.................................................................................................... 9

Requirements.......................................................................................................................................................... 9

General Dimensions: Electric and Hydraulic......................................................................................................... 10

Drive Considerations ...................................................................................... 11

Wash Module ........................................................................................................................................................ 11

Electric and Hydraulic Motor Assembly Component Orientation........................................................................... 11

Installation ....................................................................................................... 12

Gyro Head™ Orientation - Electric........................................................................................................................ 12

Gyro Head™ Orientation - Hydraulic..................................................................................................................... 13

Tunnel Placement ................................................................................................................................................. 14

Frame Assembly ................................................................................................................................................... 14

Attaching the Arms and Cylinders......................................................................................................................... 16

Attaching the Spherical Bearing Assembly – Electric Drive Only.......................................................................... 19

Inserting the Shaft – Electric Drive Only................................................................................................................ 20

Inserting the Shaft – Hydraulic Drive Only ............................................................................................................ 22

Mounting the Motor/Gearbox Assembly – Electric Drive Only .............................................................................. 26

Installing Side Wheel Hubs ................................................................................................................................... 30

Lower Hub Installation Overview...........................................................................................................................................30

Lower Hub Installation...........................................................................................................................................................30

Upper Hub Installation...........................................................................................................................................................31

Installing Cleaning Material ................................................................................................................................... 31

Cleaning Material Orientation................................................................................................................................................31

Lower Hub Fill........................................................................................................................................................................33

Upper Hub: Neo-Tex™..........................................................................................................................................................34

Utilities: Pneumatic, Electric or Hydraulic, and Water ........................................................................................... 37

Installing the Remaining Filler Strips..................................................................................................................... 45

Adjusting the Positive Stops.................................................................................................................................. 47

Operational Performance and Controls ........................................................ 48

Understanding Air-Over-Oil ................................................................................................................................... 48

Understanding Regulator Adjustments.................................................................................................................. 48

Initial Start Up.................................................................................................. 49

GYRO WRAP™ Signature ®Series

2Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL248

Table of Contents

Maintenance .....................................................................................................50

Routine Procedures ...............................................................................................................................................50

Powder Coating Maintenance................................................................................................................................50

Powder Coating Repair..........................................................................................................................................51

Trouble Shooting....................................................................................................................................................52

Exploded Parts View..............................................................................................................................................53

Frame Main Components ......................................................................................................................................................53

Leg Assembly: 109717 ..........................................................................................................................................................54

Arm Weldments .....................................................................................................................................................................54

Head Assembly with Hydraulic Lines ....................................................................................................................................55

Arm Assemblies with Hydraulic Lines....................................................................................................................................56

Arm Mounting Components ...................................................................................................................................................57

Head Mounting Components.................................................................................................................................................57

Head Mounting & Gyro Bearing Glide Components..............................................................................................................58

Gyro Cylinder Assembly: 109721 & 109722..........................................................................................................................58

Distribution Manifold Assembly..............................................................................................................................................60

Posi-Stop Mount Assembly....................................................................................................................................................60

Gyro Head Assembly: Electric 60Hz (Lower Section) ...........................................................................................................62

Gyro Head Assembly: Electric 50Hz .....................................................................................................................................63

Gyro Head Assembly: Hydraulic............................................................................................................................................64

Water Manifold Assembly ......................................................................................................................................................65

Water Manifold Assembly Components ................................................................................................................................65

Filler Strips.............................................................................................................................................................................66

Gyro Wrap Air Panel..............................................................................................................................................................67

Aluminum Hub Assembly (Overview) ....................................................................................................................................68

Aluminum Hub Assembly (Upper Section): 106782 ..............................................................................................................69

Aluminum Hub Assembly (Lower Section): 106026 ..............................................................................................................70

Neo-Tex™ Wash Clips ..........................................................................................................................................................71

Aluminum Hub Neo-Tex™ Fill ...............................................................................................................................................72

Appendix A: Nylon Brush Installation for Fleet Washes ..............................73

Installing Cleaning Material....................................................................................................................................73

Overview for Neo-Tex™ with Nylon Brush Packs .................................................................................................................73

Exploded Parts View..............................................................................................................................................75

Aluminum Hub Neo-Tex™ Fill with Nylon Brush Packs ........................................................................................................75

GYRO WRAP™ Signature ®Series

1MANUL248 Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-96813

Belanger Incorporated Limited Warranty

LIMITED WARRANTY:

Equipment:

Subject to the limitations stated below, Seller warrants that the Equipment sold hereunder, which is fabricated by

Seller, shall be free from defects in workmanship and material under normal use and service for a period of 1 year plus

30 days from the date of invoice - CATPumps will be warranted for 2 years from the date of invoice.

Parts:

Subject to the limitations stated below, Seller warrants that the Parts sold hereunder, shall be free from defects in

workmanship and material under normal use and service for a period of 90 days from the date of invoice.

Limitations on All Warranties:

The warranties contained in this Section 13 are subject to the following limitations: (1) they are void if the factory

specifications for operation and maintenance, found in original equipment manuals, and component manuals, are not

followed, or if other than factory authorized erection, alterations or modifications are made to any Parts or Equipment;

(2) defective Parts are warranted to the Purchaser only for repair or replacement through an authorized Purchaser or

Distributor of Seller, or direct with Seller for a period of 13 months from the date of invoice; however, this warranty

excludes all claims for failure resulting from normal wear and tear, improper installation, omission of factory specified

preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God and Purchaser agrees to

submit to and assist Seller or its authorized Purchaser or Distributor in conducting in-warranty inspections of the

Goods including inspection of any Equipment or Parts claimed to be defective by the Purchaser; (3) the cost of

providing labor or repair to replace Equipment and Parts warranted to Purchaser will be included within the warranty

only if such claim is made within 120 days from the date of invoice and then only during normal business hours

through an authorized Purchaser or Distributor of Seller, or direct with Seller, and labor and service provided beyond

the labor warranty period shall be subject to labor charges at the rates established by the local authorized Purchaser

or Distributor or direct with Seller; (4) the warranties shall be void for all Equipment failures and premature Part wear

caused by the use of corrosive chemicals in the wash process, and the following list includes some, but not all, of the

particularly corrosive chemicals that if used in conjunction with Equipment or Parts will void the warranty: Hydrofluoric

Acid, Ammonium Bi-fluoride, Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide,

Hydrochloric Acid, Sodium Hydroxide and Chlorinated Solvents; (5) Seller makes no warranty, express or implied, with

respect to the design or operation of any entire system, in which Seller’s Equipment or Parts sold hereunder are mere

components;(6) in no event shall Seller be liable for any incidental, special, consequential, punitive or exemplary

damages resulting from the furnishing, performance or use of any Goods or services sold pursuant hereto, whether

due to a breach of contract, breach of warranty, negligence or any other claim at law or equity. Seller shall not be

liable for any damages of any kind, including, but not limited to, loss of business; inconvenience, or property damage

of any kind; nor for any damages of whatever nature resulting in any way from the Purchaser’s selection and use of

any chemicals not manufactured exclusively by Seller but used with the purchased Equipment or Parts; or for any

service not expressly provided herein related to or arising from the Equipment or Parts sold. Seller shall not be liable

for damages resulting from Purchaser’s use of any engineering recommendations, sales representations, technical

assistance, advice or data other than that information contained in Belanger manuals; (7) all warranties, express,

implied, or statutory, pertaining to the Equipment and Parts apply to the Purchaser only; are not transferable; are fully

set forth herein; and no addition to or modification thereto shall be binding upon the Seller, unless made in writing and

signed by a duly authorized employee of Seller.

No Other Warranties:

THIS LIMITED WARRANTY FOR EQUIPMENT AND PARTS IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE – SALES ARE EXPRESSLY

DISCLAIMED.

Copyright ©2020 by Belanger, Inc. All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage

or retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Belanger reserves the right to

change or modify the Belanger Inc. Limited warranty without notice.

GYRO WRAP™ Signature ®Series

4Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL248

Operational Warning

Formulations containing the chemicals listed below are particularly dangerous and should not

be used even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-fluoride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc., does not endorse or condone the use of chemicals that are potentially

dangerous to human health, the environment or property. Belanger recognizes that it is the

right and sole decision of the end user operators of our equipment as to the type and dilution

ratio of the chemicals used in their facilities. We strongly recommend that the end user does

not select products containing any of the chemicals listed above as an ingredient in the wash

solutions. The chemicals listed above are potentially dangerous to human health, and have a

detrimental, deteriorating effect on the equipment and the facility. Be advised that a portion of,

or all of your warranty will be voided if you determine to use any of the chemicals listed above

as an ingredient in the wash solutions in conjunction with your Belanger automatic car wash

equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger Terms and Conditions of

Sales describes the potential limitation of warranty due to your chemical selection:

(4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes

some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride, Bromic

Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid,

and Chlorinated Solvents. The Purchaser also agrees to accept the responsibility and

liability for the selection and use of any chemicals listed above.

However, should the end user decide to use formulations containing any of the above

ingredients, the end user should institute a comprehensive training program and implement

detailed operational parameters within their organization for the proper handling and treatment

of such products to minimize the potential dangers involved. Consult your chemical supplier for

assistance in establishing operational guidelines in the use of their products. MSDS (Material

Safety Data Sheet) should be obtained from the chemical supplier before using any chemical

formulation.

During the installation process the installer is responsible for re-tightening

ALL lugs, set screws and terminals located in the electrical panels. Components

may vibrate loose during shipping.

GYRO WRAP™ Signature ®Series

1MANUL248 Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-96815

Introduction

Important Safety Information

This section introduces the hazard and safety precautions associated with installing, maintaining or

servicing this product. Before performing any task on this product, read this safety information and

the applicable sections in this manual, where additional hazards and safety precautions for your task

may be found. Electrical shock could occur and cause death or serious injury if these safe service

procedures are not followed.

Safety Symbols and Signal Words

Alert Symbol

This safety alert symbol is used in this manual and on warning labels to alert you to

precautions, which must be followed to prevent potential personal safety hazards.

Obey safety directives that follow this symbol to avoid possible injury or death.

Signal Words

The signal words used in this manual and on warning labels tell you the seriousness of

particular safety hazards. The precautions that follow must be followed to prevent death, injury

or damage to the equipment.

This signal word is used to alert you to a hazard or unsafe practice which WILL RESULT IN

DEATH OR SERIOUS INJURY

This alerts you to a hazard or unsafe practice which COULD RESULT IN DEATH OR

SERIOUS INJURY

This signal word designates a hazard or unsafe practice, which MAY RESULT IN MINOR

INJURY

When used by itself, CAUTION designates a hazard or unsafe practice, which MAY RESULT

IN PROPERTY OR EQUIPMENT DAMAGE

Before You Begin

Only trained or authorized individuals knowledgeable in the related procedures should install,

inspect, maintain or service this equipment.

Read the Manual

Read, understand and follow this manual and any other labels or related materials supplied with

this equipment. If you do not understand the procedure, call a Belanger, Inc. representative at

248-349-7010. It is imperative to your safety and the safety of others to understand the

procedures before beginning work.

GYRO WRAP™ Signature ®Series

6Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL248

Introduction

IMPORTANT Safety Information – MUST READ

Safety Warnings

DISCONNECT MAIN POWER SUPPLY PRIOR TO

SERVICING OR MAINTAINING EQUIPMENT

Belanger recommends that all workers observe the OSHA (U.S. Department

of Labor Occupational Safety & Health Administration) Lockout / Tagout

procedure prior to performing service or maintenance on machinery and

equipment. Doing so will prevent unexpected energization, startup, or

release of hazardous energy while maintenance and servicing activities are

being performed.

BE SURE TO OBSERVE OPERATING ENVELOPE.

EQUIPMENT MAY START UNEXPECTICALLY. OVERHEAD,

ROTATING AND/OR MOVING COMPONENTS COULD

RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF FOREIGN OBJECTS IN THE AREA

SURROUNDING A ROTATING PIECE OF EQUIPMENT.

OBJECTS MAY BECOME TANGLED WITH EQUIPMENT AND

COULD RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF HAZARDS ASSOCIATED WITH

EQUIPMENT INSTALLED ON THE FLOOR

THAT MAY BE A TRIP HAZARD.

It is imperative to your safety and the safety of others to always follow safe work procedures.

GYRO WRAP™ Signature ®Series

1MANUL248 Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-96817

Introduction

Congratulations on your purchase of the Belanger® Signature® Gyro Wrap. All the main frame

components and the arm components are constructed of aluminum and then powder coated. The

powder coat finish will give the machine a fresh new look for many years and is easier to maintain

and clean. The hub shafts are constructed of a high strength stress proof steel and then cadmium

plated for added corrosion resistance.

The Signature® Gyro Wrap is offered as an electric or hydraulic drive machine. The arms are

controlled by a single air panel which is then connected to a single air-over-oil system for each arm

assembly. The air-over-oil system then utilizes a flow control valve on the extend and retract ports of

the cylinder to ensure a smooth and consistent stroke every cycle.

Whether you have already operated a car wash, or you are new to our industry, you know the

importance of the appearance of a car wash and its equipment to the customer.

Read through the entire manual to familiarize you with the Gyro Wrap™ before installation. When

installation is completed, you will want to keep this manual as a guide to proper maintenance.

It is imperative that wheels are spinning during any period that the

conveyor is activated.

GYRO WRAP™ Signature ®Series

8Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL248

Introduction

Before You Get Started

Tools needed for installation:

Forklift (with side shift if available) C-Clamps

Hammer drill with 5/8” bit Tin snips

Tape measure (25 foot or greater) Safety glasses

Miscellaneous hand tools Work gloves

Level 50-foot extension cord

Ladder

Equipment included: Qty

Head Beam Frame Assembly 1

Driver Side Arm Assembly 1

Passenger Side Arm Assembly 1

Leg Assemblies 2

Large Diameter Hub Assemblies: 28-1/4” long 2

Small Diameter Hub Assemblies: 42-1/4” long 2

Steel hub Shafts 2

Spherical Bearing Assemblies 2

Motor Assemblies 2

Lower Hub Neo-Tex™ Clips 1 box

Upper Hub Neo-Tex™ Clips 1 box

Filler Strip Kit 1

Neo-Tex™ Cleaning Material 8 boxes

Accessory box 1

Note: Uncrate and inspect shipment for damage, and to verify that all pieces are there. If there is

any damaged equipment, file a claim with the trucking company immediately. Receiving

party is responsible for filing claim with trucking company. Notify your local distributor or

Belanger, Inc. immediately If shipment is determined damaged or incomplete.

GYRO WRAP™ Signature ®Series

1MANUL248 Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-96819

Specifications

Requirements

Physical

Tunnel space required

Unit Length: entrance side of the base plate to the outermost tip of

Neo-Tex™ on the passenger side wheel – 139”

Unit width

151-1/2”: outside to outside of base plates

Unit height

120”: from the floor to the top of the motor - Electric

126”: from the floor to the top of the hydraulic hoses - Hydraulic

Vehicle height clearance

90”

Utility

Electrical

1 HP; 208-230/460 V; 60 Hz – each motor

1 HP; 575 V; 60 Hz – each motor

2 HP; 208-230/460 V; 50 Hz – each motor

Pneumatic

0.3 CFM @ 90-120 PSI maximum

Hydraulic

4 GPM @ 900 PSI

Water

2.8 GPM total or 1.4 GPM per side @ 40 PSI

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE SERVICING ANY

EQUIPMENT!

Always wear safety glasses when performing maintenance on any equipment

It is recommended that a licensed electrician is contracted to perform all electrical installations.

YOUR HYDRAULIC SYSTEM MUST BE CAPABLE OF ADJUSTMENT TO 76 RPM AT

900 PSI (62.1 BAR) WHILE LOADED AGAINST VEHICLE. PLEASE VERIFY YOUR

SYSTEMS CAPABILITY TO MEET THESE SETTING WHILE RUNNING A VEHICLE

PRIOR TO INSTALLING A PIECE OF EQUIPMENT

A compressed Air System should be set correctly to support 90 PSI necessary to operate

equipment but should never be set to deliver more than 120 PSI air pressure to the Belanger

specified equipment.

GYRO WRAP™ Signature ®Series

10 Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL248

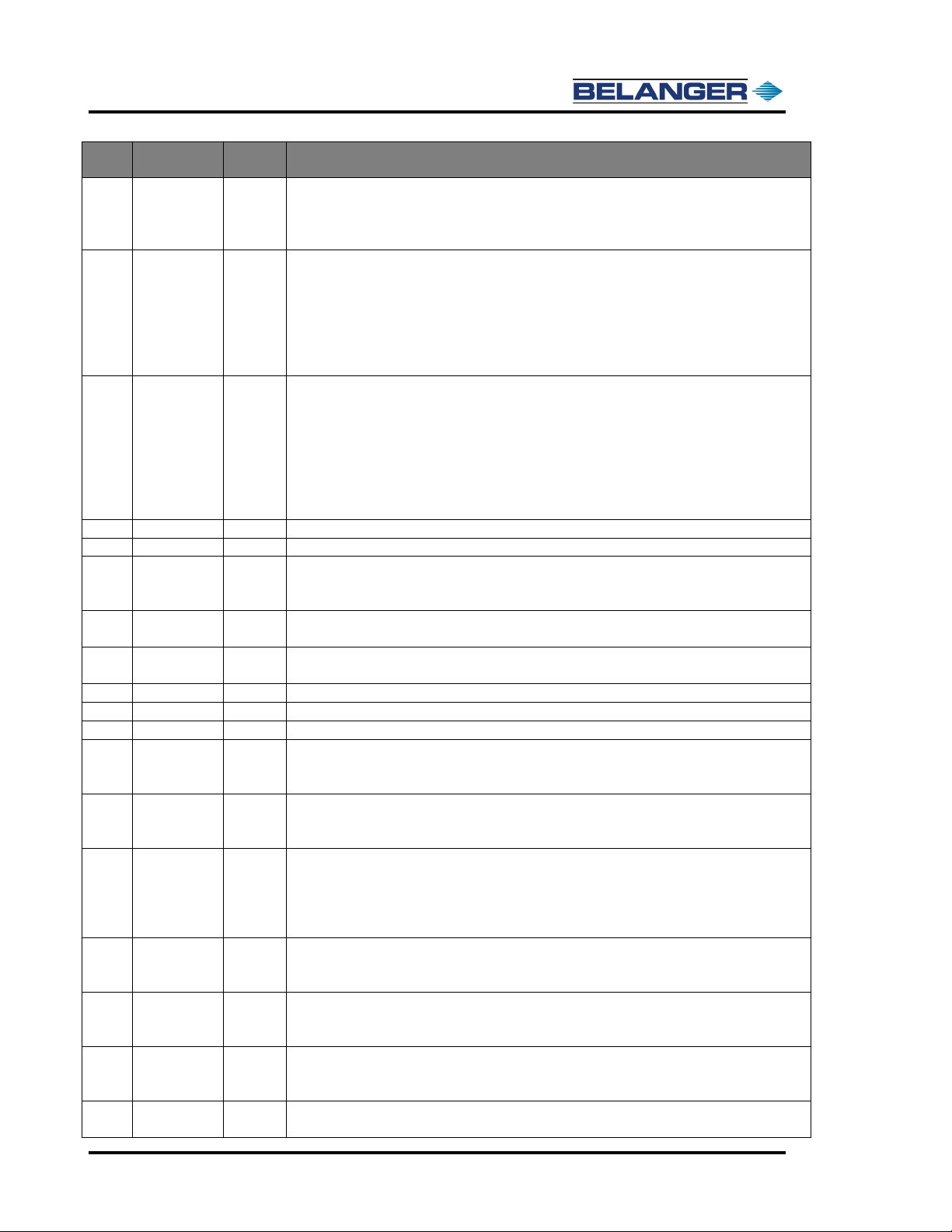

Specifications

General Dimensions: Electric and Hydraulic

145" dimension allows 6” clearance from the cleaning material

Unit Height for

Hydraulic Only

151-1/2”

145”

48-3/4”

This dimension is taken from the outside edge

of the Base Plate to the inside edge of the

inside Conveyor Guide Rail

139”

126”

120”

Table of contents

Other Belanger Cleaning Equipment manuals

Belanger

Belanger DuoScrubber User manual

Belanger

Belanger FreeStyler E-1032 User manual

Belanger

Belanger DuoScrubber HP User manual

Belanger

Belanger Wave Across User manual

Belanger

Belanger FreeStyler User manual

Belanger

Belanger Full Side Washer User manual

Belanger

Belanger QuickFire User manual

Belanger

Belanger QuickFire Wrap Around Signature Series User manual

Belanger

Belanger DURAJET ARCH User manual

Belanger

Belanger SUDZAMELEON ARCH User manual