MAINTENANCE

1MANUL222 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

Table of Contents

Chapter 1 Introduction............................................................................................................... 1-1

Operational Warning..................................................................................................................................1-1

Important Safety Information .....................................................................................................................1-2

Safety Symbols and Signal Words ............................................................................................................1-2

IMPORTANT Safety Information –MUST READ.......................................................................................1-3

Document Overview ..................................................................................................................................1-5

UL Information...........................................................................................................................................1-6

Warranty Information.................................................................................................................................1-7

Chapter 2 Preventative Maintenance........................................................................................ 2-1

Support Equipment....................................................................................................................................2-1

Daily Inspection List...................................................................................................................................2-1

Monthly Inspection List ..............................................................................................................................2-2

Periodic Inspection List..............................................................................................................................2-3

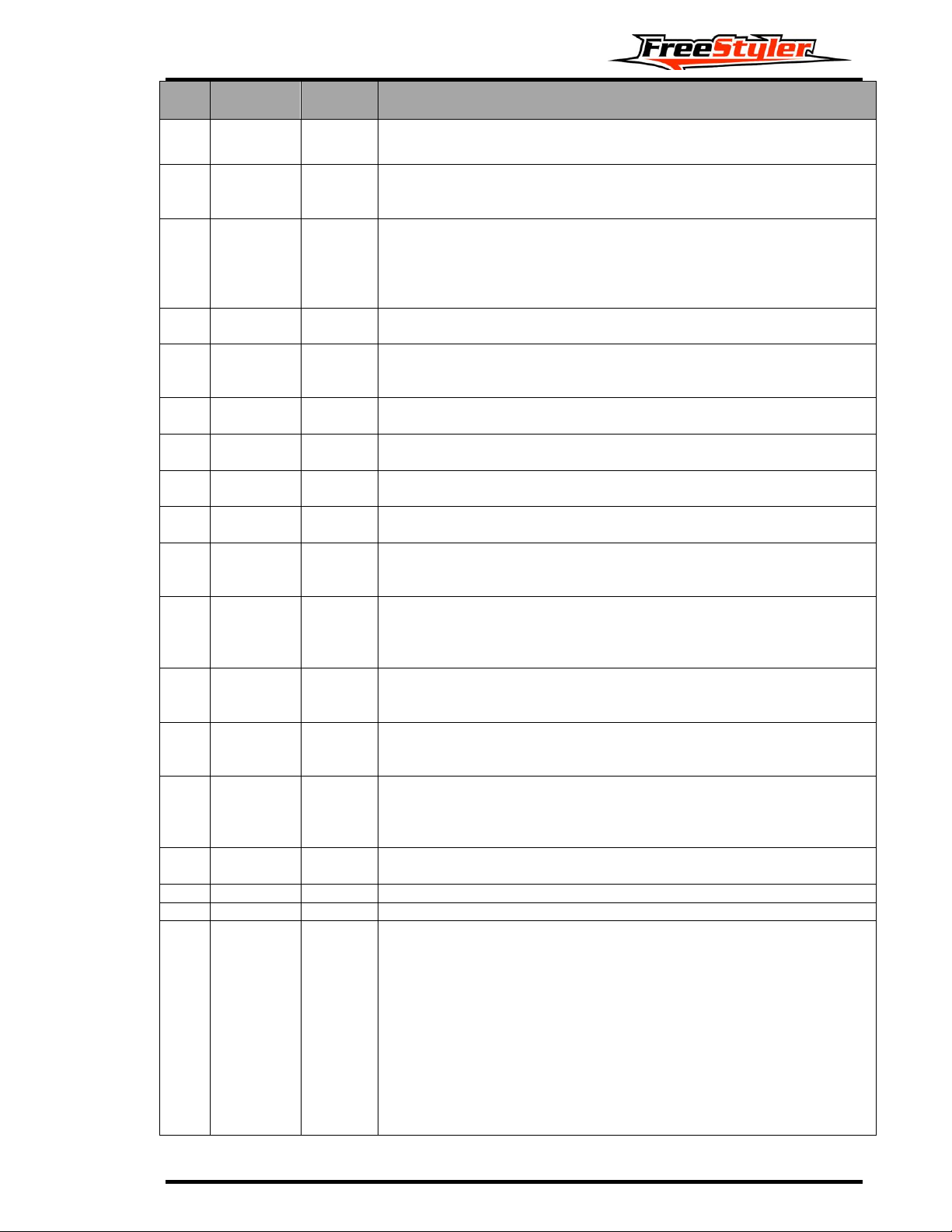

Maintenance Checklist...............................................................................................................................2-5

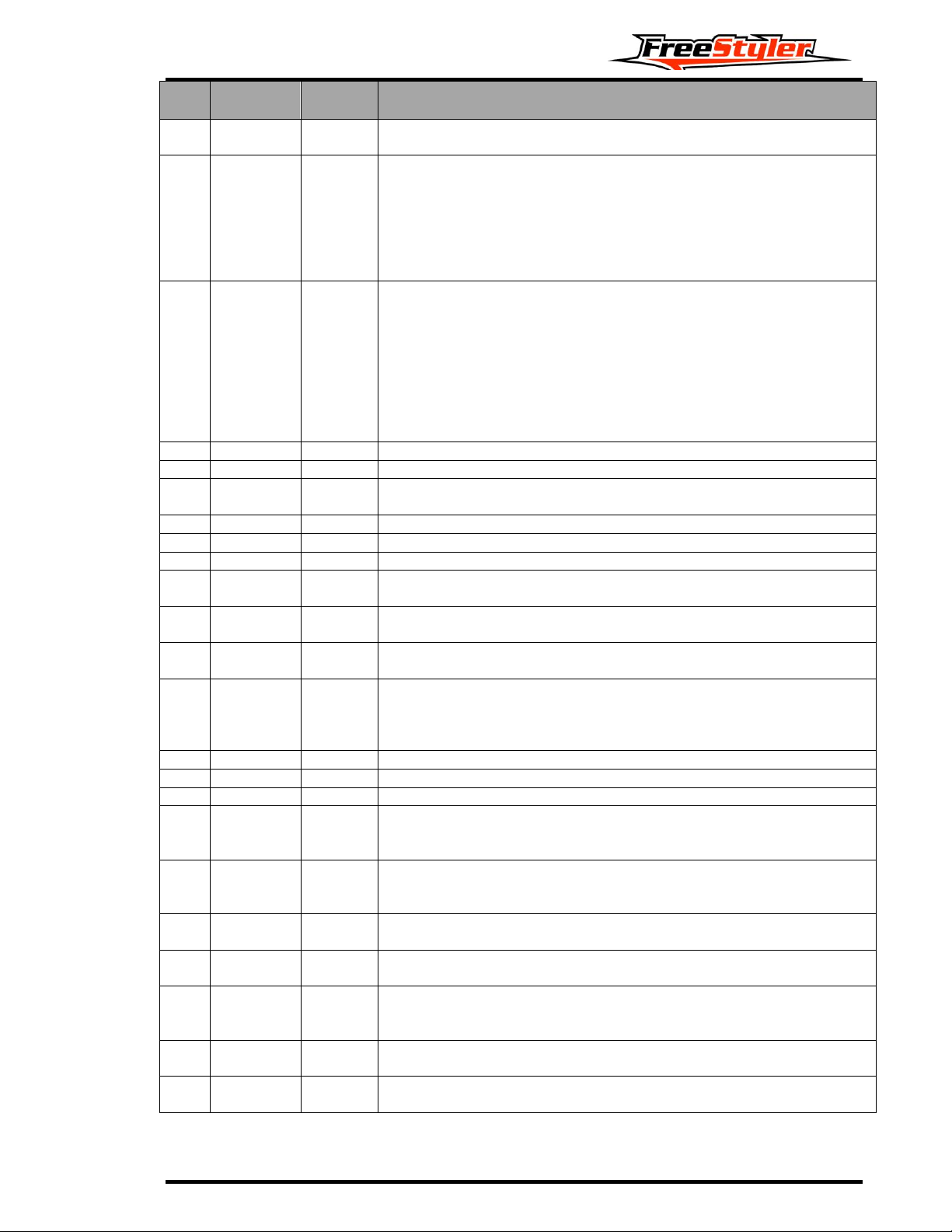

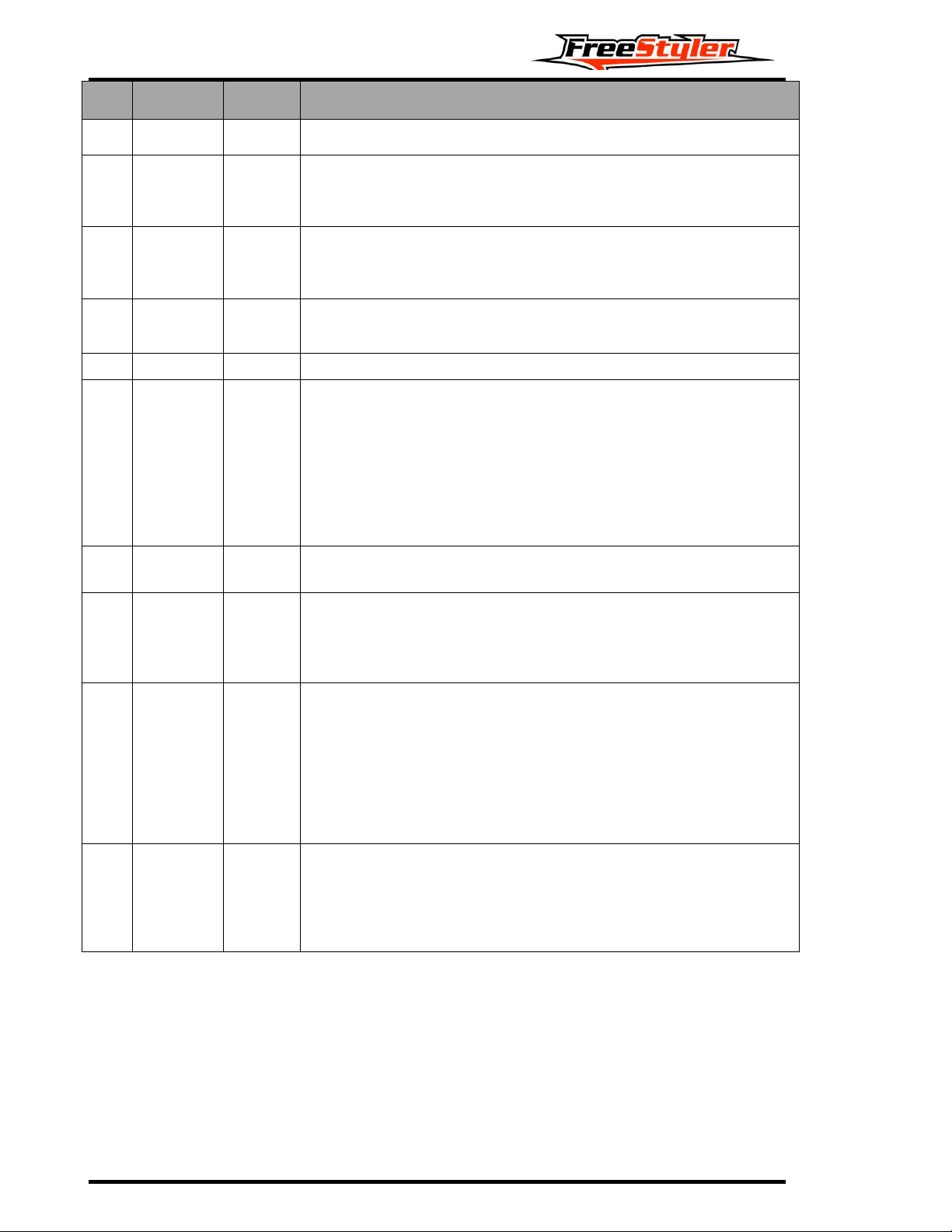

Maintenance Management Report ............................................................................................................2-6

VPS® Photo-Eye.....................................................................................................................................2-15

General Input Locations ..........................................................................................................................2-15

Main and Coalescent Filters....................................................................................................................2-17

Greasing the Bearings.............................................................................................................................2-18

Inspecting the Carriage Rollers ...............................................................................................................2-19

Pumping Station Drive Belt Replacement and Tightening.......................................................................2-20

Pumping Station Float Valve ...................................................................................................................2-23

Pumping Station Float Valve Seal Replacement Kit #105884.................................................................2-24

Hydraulic Hose Information .....................................................................................................................2-33

Foaming Pod Connections ......................................................................................................................2-34

Chapter 3 General Repairs......................................................................................................... 3-1

Torque Values ...........................................................................................................................................3-1

Gearboxes.................................................................................................................................................3-2

Powder Coating Maintenance....................................................................................................................3-2

Powder Coating Repair..............................................................................................................................3-3

Pumping Station ........................................................................................................................................3-5

Repair Section Overview...........................................................................................................................3-7

Top View of the Carriage with all Wired Components ...............................................................................3-7

View of Water/Chemical Valves ................................................................................................................3-9

Bearing Replacement..............................................................................................................................3-10

How to Disassemble the Top Wheel for Repairs.....................................................................................3-12

Top Wheel Troubleshooting ....................................................................................................................3-15

Changing a Roller or Drive Shaft.............................................................................................................3-18

Replacing a Bent Shaft or Wheel Bearing...............................................................................................3-21

Replacing a Motor/Gearbox Assembly ....................................................................................................3-23

Replacing an Arm Rotation Bearing ........................................................................................................3-27

Replacing a Pivot Shaft Assembly...........................................................................................................3-27

Inside the Pods........................................................................................................................................3-30

Manifolds and Wiring...............................................................................................................................3-38

Spot Free (RO)........................................................................................................................................3-38

Pulsatron™Suction and Discharge Valve - Replacement Procedure.....................................................3-55

Metering Pumps.......................................................................................................................................3-56

Wheel Cleaning Pump.............................................................................................................................3-76

Water Softener ........................................................................................................................................3-90

Torque Plate and Electric Motor Replacement......................................................................................3-110

Optional On-Board Dryer.......................................................................................................................3-114

Optional On-Board Dryer Motor Maintenance Supplied by Baldor®......................................................3-119