CURRENT REVISION LOG

1MANUL854 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

Updated Belanger Limited Warranty

Changed Bi-floride to Bi-fluoride

Added Overview for Neo-Tex™fill diagram (per Change Request #35)

Changed the order of these pages and updated the Upper Neo-Tex™fill diagram (per Change Request #35)

Deleted unnecessary part number callouts

Added Neo-Tex™Wash Clips and Fill Pattern

Updated the Neo-Tex™fill diagram to include the part numbers for the Black Neo-Tex™, changed 24 Piece

Set to 48 Piece Set on the lower hub part number callouts (per Change Request #35)

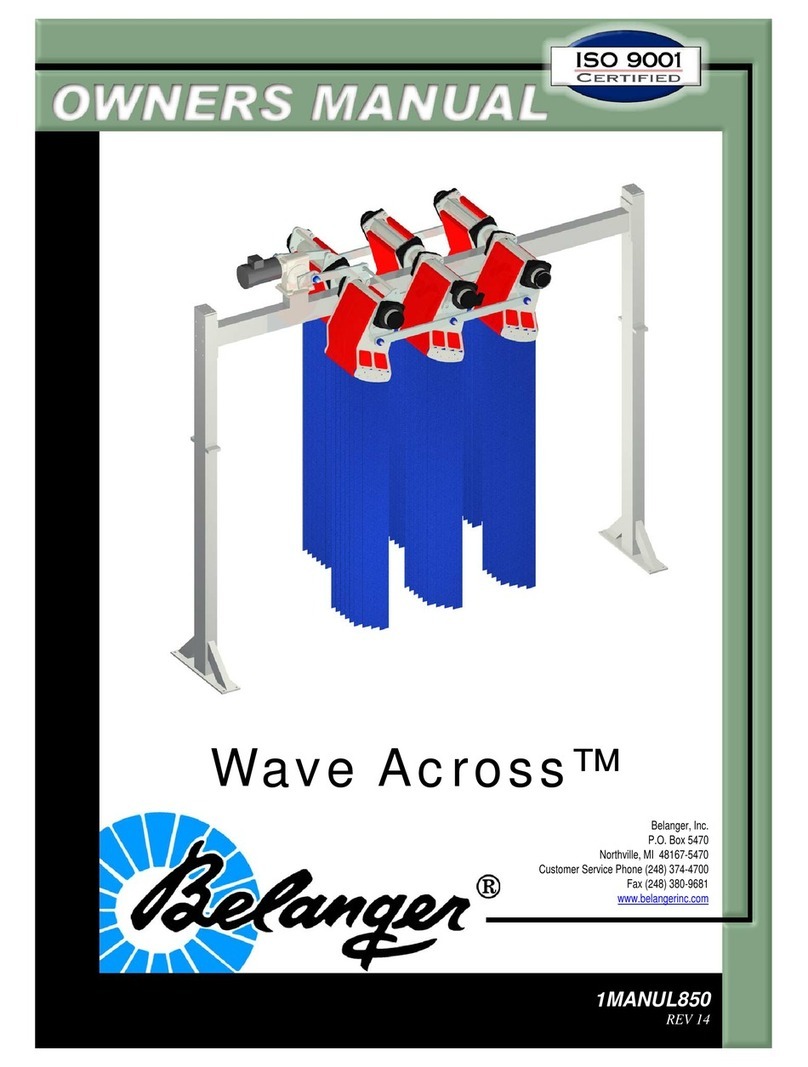

Updated Cover to the new layout

Updated Copyright date from 2014 to 2020

Updated Back Cover to the new layout

Changed Gearbox Assembly numbers from 1GEABX-AS986 to 112286 and 1GEABX-AS988 to 112288 (per

ECN #5131)

Changed Belanger Limited Warranty on Parts from 30 days to 90 days

Added page Installation: Identify Conveyor

Added Note that 13” conveyor is shown in the images in this manual (per Project #32-523)

Updated dimension to driver side FSW 13” Conveyor: 56” and 14-1/2” Conveyor: 57-1/2”

Added to note under image: (13” Conveyor: 56”/14-1/2” Conveyor: 57-1/2”) (per Project #32-523)

Updated dimension to driver side FSW 13” Conveyor: 56” and 14-1/2” Conveyor: 57-1/2”

Added to note under image: (13” Conveyor: 56”/14-1/2” Conveyor: 57-1/2”) (per Project #32-523)

Removed note for dimension 170”from under the image

Added Step 6 to Initial Startup: Connect water lines to the Water Manifold Assemblies attached to the leg of

each FSW assembly

Update Step 8 to state: remove the eight (8) (older equipment has four (4)) flat head fasteners

Changed image to show the current torque plate with eight holes and fasteners

Updated Step 7 to state torque all eight (8) fasteners (four (4) on older equipment) to 25 ft-lbs.

Changed bearing 791 to 1BERNG848 in 2 places

Changed 1FSTNR-HH810 to 1FSTNR-HH811 in 2 places

Added Hydraulic Motor Assembly 100109 and Torque Channel Assembly: 101229

Changed bearing 1609 to 1BERNG848

Changed bearing 791 to 1BERNG848

Changed cover 17 to 1PLSTC-EX082 (per Change Request #95)

Removed 1FSTNR-SM500 (4) (per Change Request #95)

Changed bearing 791 to 1BERNG848 in 2 places

Changed 1FSTNR-HH810 to 1FSTNR-HH811 in 2 places

Added 112297: 380/400-415 Volts to Motor/Gearbox callout (per Project #10038)

Updated exploded views of Head Assembly to show current Torque Plate 108661 with 8-holes

Added enlarged exploded view of Torque Plate Assembly108661 to show 1GRMIT222 (2)

Corrected 1FSTNR-FH025 to 1FSTNR-FH075 and changed quantity from 4 to 8

Changed 1FSTNR-SM500 (2) to 1FSTNR-PH040 (2)

Added 1GEABX-KT250 and 1ELECT-FS855 (4) to the exploded view

Updated enlarged views in the chart –added 1FSTNR-PH040 & 1ELECT-FS855

Updated exploded view of Head Assembly to show Filler Strip, Torque Plate, and fasteners

Added 1WASHR-LC581 (4) in 2 places

Changed cover 17 to 1PLSTC-EX082 (per Change Request #95)

Removed 1FSTNR-SM500 (4) (per Change Request #95)

Added Arm & Stand Assembly (Hydraulic) part numbers for DS & PS

Adde Lagbolt and Leveling Bolt part numbers and quantities

Added FSW Arm Assembly and FSW Stand Assembly (Electric) part numbers for DS & PS

Updated the Full Side Washer Air Panel (Electric) assembly 108489

Added Lagbolt & Leveling Bolt part numbers and quantities

Added page Leg Water Manifold Assembly

Changed 1FSTNR-HH045 to 1FSTNR-HH056

Changed (2 per Spider Half) to (8 per Hub Assembly) for the hub fasteners in 3 places

Added a quantity of (2) to1141 and 101141

Changed 1FSTNR-HH162 (1 per Spider Half) to 1FSTNR-HH162 (2)

Changed 1WASHR-LC270 (1 per Spider Half) to 1WASHR-LC270 (2)

Changed (per Wheel) to (per Hub) in 2 places

Added note: Upper Hub 106782 is used on the driver & passenger side FSW assemblies