Belanger Wave Across User manual

Wave Across™

1MANUL850

REV 14

Belanger, Inc.

P.O. Box 5470

Northville, MI 48167-5470

Customer Service Phone (248) 374-4700

Fax (248) 380-9681

www.belangerinc.com

Belanger Equipment Owners Manual

Wave Across

Copyright 2010

Belanger, Inc®

This manual and the accompanying equipment are protected by United States and International copyright and patent laws.

You may make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form

whatsoever, in whole or in part, without the prior written permission of Belanger, Inc.®

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1

Table of Contents

Belanger Incorporated Limited Warranty........................................................ 2

Operational Warning......................................................................................... 3

Introduction....................................................................................................... 4

Important Safety Information...................................................................................................................................4

Safety Symbols and Signal Words..........................................................................................................................4

IMPORTANT Safety Information – MUST READ....................................................................................................5

Safety Warnings......................................................................................................................................................5

Available Styles.......................................................................................................................................................6

Before You Get Started...........................................................................................................................................7

Specifications.................................................................................................... 8

Requirements..........................................................................................................................................................8

Output......................................................................................................................................................................8

Dimensions..............................................................................................................................................................9

Installation....................................................................................................... 10

Frame Assembly...................................................................................................................................................10

Tunnel Placement.................................................................................................................................................11

Utilities...................................................................................................................................................................12

Cloth......................................................................................................................................................................14

Maintenance .................................................................................................... 19

Routine Procedures............................................................................................................................................... 19

Special Attention Items.......................................................................................................................................... 20

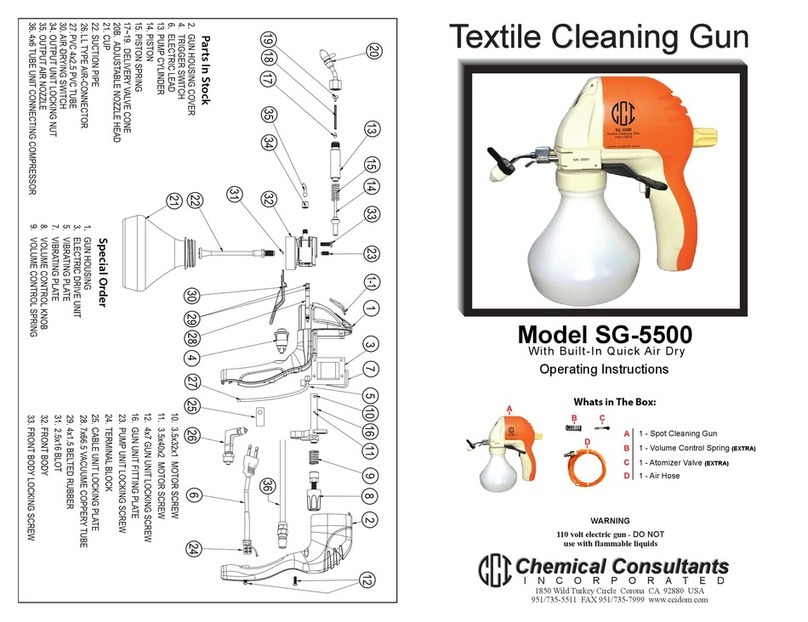

Exploded Parts View.............................................................................................................................................21

Upper Frame Assembly.........................................................................................................................................................21

Water Manifolds.....................................................................................................................................................................21

Rack Assembly......................................................................................................................................................................22

Drive Arm Assemblies...........................................................................................................................................................22

Drive Rack Assembly (1 of 2 identical assemblies)...............................................................................................................23

Follower Rack Assembly (1 of 2 identical assemblies) .........................................................................................................23

Stud/Retainer Assembly........................................................................................................................................................24

Stud Retainer with Castle Nut Assembly...............................................................................................................................24

Rack Bushing Assembly........................................................................................................................................................24

Motor/Gearbox Assembly......................................................................................................................................................25

Misc. Components.................................................................................................................................................................26

Drive Arm / Rack Connector Bushing Replacement .............................................................................................27

WAVE ACROSS

2Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

Belanger Incorporated Limited Warranty

LIMITED WARRANTY: Equipment: Seller warrants to the original purchaser that the goods sold hereunder, which are

fabricated by Seller, shall be free from defects in workmanship and material under normal use and service for a period of 1

year plus 30 days from the date of invoice - CAT®Pumps will be warranted for 2 years from the date of invoice. All

warranties, express, implied, or statutory, pertaining to Seller’s machinery, parts, and equipment are fully set forth

herein. This limited warranty applies to the original purchaser only and is not transferable. No addition to or

modification of any of the provisions of this stated Limited Warranty shall be binding upon the Seller, unless made

in writing and signed by a duly authorized employee of Seller. This warranty is subject to the following limitations:

(1) This warranty shall be void if the factory specifications for operation and maintenance, found in original

equipment manuals, and component manuals, are not followed, or if other than factory authorized erection,

alterations or modifications are made to any parts or equipment; (2) Defective parts are warranted to the Purchaser

for repair or replacement through an authorized distributor or value added reseller (VAR) of Seller, or direct with

Seller for a period of 13 months from the date of invoice. Parts warranty excludes all claims for failure resulting

from normal wear and tear to the depreciable parts, improper installation, omission of factory specified preventative

maintenance, misuse, abuse, negligence, third party damages, or acts of God. Purchaser agrees to submit to and

assist Seller or its authorized distributor or value added reseller (VAR) in conducting in-warranty inspections of the

machinery and equipment including inspection of any part claimed to be defective by the Purchaser; (3) Labor to

repair or replace parts is warranted to Purchaser during normal business hours through an authorized distributor or

value added reseller (VAR) of Seller, or direct with Seller, for 120 days from date of invoice. Labor warranty

excludes all claims for failure resulting from normal wear and tear to the depreciable parts, improper installation,

and omission of factory specified preventative maintenance, misuse, abuse, negligence, third party damages, or

acts of God. Seller reserves the sole right to make determinations on the above stated limitation. All labor and

service provided beyond the labor warranty period shall be subject to labor charges at the rates established by the

local authorized distributor or value added reseller (VAR) or direct with Seller; (4) This warranty shall be void for all

equipment failures and premature component wear caused by the use of corrosive chemicals in the wash process.

The following list includes some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-flouride, Bromic Acid, Muriatic Acid,

Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, Sodium Hydroxide and Chlorinated

Solvents. (5) Seller makes no warranty, express or implied, with respect to the design or operation of any entire

system, in which Seller’s goods sold hereunder are mere components. (6) In no event shall Seller be liable for any

incidental, special, consequential or exemplary damages resulting from the furnishing, performance or use of any

goods or services sold pursuant hereto, whether due to a breach of contract, breach of warranty, the negligence of

Seller or to otherwise; not for loss of business; inconvenience, or property damage of any kind; not for any

damages of whatever nature resulting in any way from the purchaser’s selection and use of any chemicals not

manufactured exclusively by seller but used with the purchased goods; or for any service not expressly provided

herein related to or arising from the equipment or goods sold. This limitation of liability extends to purchaser’s use

of any engineering recommendations, sales representations, technical assistance, advice or data supplied by seller

to purchaser in connection with the goods or services supplied, other than that information contained in Belanger

manuals.

Parts: Seller warrants to the original purchaser that the Replacement Parts sold hereunder, shall be free from

defects in workmanship and material under normal use and service for a period of 30 days from the date of invoice.

This limited warranty applies to the original purchaser only and is not transferable. (1) This warranty shall be void if

the factory specifications for operation and maintenance are not followed; (2) Parts warranty excludes all claims for

failure resulting from normal wear and tear to the depreciable parts, improper installation, omission of factory

specified preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God. (3) This

warranty shall be void for all replacements parts failures and premature component wear caused by the use of

corrosive chemicals in the wash process. The following list includes some, but not all, of the particularly corrosive

chemicals that if used in conjunction with Belanger replacement parts will void the warranty: Hydrofluoric Acid,

Ammonium Bi-flouride, Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide,

Hydrochloric Acid, Sodium Hydroxide and Chlorinated Solvents.

THIS LIMITED WARRANTY FOR EQUIPMENT AND REPLACEMENT PARTS IS EXPRESSLY IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

Copyright © 2000 by Belanger, Inc. All rights reserved. No part of this work may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying and recording, or by any information storage or retrieval system,

except as may be expressly permitted by the 1976 Copyright Act. Revised as of 8-15-01. Belanger reserves the right to change or

modify the Belanger Inc. Limited Warranty without notice.

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 3

Operational Warning

Formulations containing the chemicals listed below are particularly dangerous and should not

be used even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-flouride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc., does not endorse or condone the use of chemicals that are potentially

dangerous to human health, the environment or property. Belanger recognizes that it is the

right and sole decision of the end user operators of our equipment as to the type and dilution

ratio of the chemicals used in their facilities. We strongly recommend that the end user does

not select products containing any of the chemicals listed above as an ingredient in the wash

solutions. The chemicals listed above are potentially dangerous to human health, and have a

detrimental, deteriorating effect on the equipment and the facility. Be advised that a portion of,

or all of your warranty will be voided if you determine to use any of the chemicals listed above

as an ingredient in the wash solutions in conjunction with your Belanger automatic car wash

equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger Terms and Conditions of

Sales describes the potential limitation of warranty due to your chemical selection:

(4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes

some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-flouride,

Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric

Acid, and Chlorinated Solvents. The Purchaser also agrees to accept the responsibility and

liability for the selection and use of any chemicals listed above;

However, should the end user decide to use formulations containing any of the above

ingredients, the end user should institute a comprehensive training program and implement

detailed operational parameters within their organization for the proper handling and treatment

of such products to minimize the potential dangers involved. Consult your chemical supplier for

assistance in establishing operational guidelines in the use of their products. MSDS (Material

Safety Data Sheet) should be obtained from the chemical supplier before using any chemical

formulation.

CAUTION

During the installation process the installer is responsible for re-tightening ALL

lugs, set screws and terminals located in the electrical panels. Components may

vibrate loose during shipping.

WAVE ACROSS

4Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

Introduction

Important Safety Information

This section introduces the hazard and safety precautions associated with installing, maintaining or servicing this product.

Before performing any task on this product, read this safety information and the applicable sections in this manual, where

additional hazards and safety precautions for your task may be found. Electrical shock could occur and cause death or

serious injury if these safe service procedures are not followed.

Safety Symbols and Signal Words

Alert Symbol

This safety alert symbol is used in this manual and on warning labels to alert you to precautions which

must be followed to prevent potential personal safety hazards. Obey safety directives that follow this

symbol to avoid possible injury or death.

Signal Words

The signal words used in this manual and on warning labels tell you the seriousness of particular safety hazards. The

precautions that follow must be followed to prevent death, injury or damage to the equipment.

DANGER

This signal word is used to alert you to a hazard or unsafe practice which WILL RESULT IN

DEATH OR SERIOUS INJURY

This alerts you to a hazard or unsafe practice which COULD RESULT IN DEATH OR

SERIOUS INJURY

CAUTION

This signal word designates a hazard or unsafe practice, which MAY RESULT IN MINOR

INJURY

CAUTION

When used by it self, CAUTION designates a hazard or unsafe practice which MAY RESULT

IN PROPERTY OR EQUIPMENT DAMAGE

Before You Begin

Only trained or authorized individuals knowledgeable in the related procedures should install, inspect, maintain or

service this equipment.

Read the Manual

Read, understand and follow this manual and any other labels or related materials supplied with this equipment. If

you do not understand the procedure, call a Belanger, Inc. representative at 248-349-7010. It is imperative to your

safety and the safety of others to understand the procedures before beginning work.

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 5

Introduction

IMPORTANT Safety Information – MUST READ

Safety Warnings

DANGER

DISCONNECT MAIN POWER SUPPLY PRIOR TO

SERVICING OR MAINTAINING EQUIPMENT

Belanger recommends that all workers observe the OSHA (U.S. Department of

Labor Occupational Safety & Health Administration) Lockout / Tagout procedure

prior to performing service or maintenance on machinery and equipment. Doing

so will prevent unexpected energization, startup, or release of hazardous energy

while maintenance and servicing activities are being performed.

BE SURE TO OBSERVE OPERATING ENVELOPE.

EQUIPMENT MAY START UNEXPECTICALLY. OVERHEAD,

ROTATING AND/OR MOVING COMPONENTS COULD

RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF FOREIGN OBJECTS IN THE AREA

SURROUNDING A ROTATING PIECE OF EQUIPMENT.

OBJECTS MAY BECOME TANGLED WITH EQUIPMENT AND

COULD RESULT IN SERIOUS INJURY OR DEATH.

CAUTION

BE AWARE OF HAZARDS ASSOCIATED WITH

EQUIPMENT INSTALLED ON THE FLOOR

THAT MAY BE A TRIP HAZARD.

It is imperative to your safety and the safety of others to always follow

safe work procedures.

WAVE ACROSS

6Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

Introduction

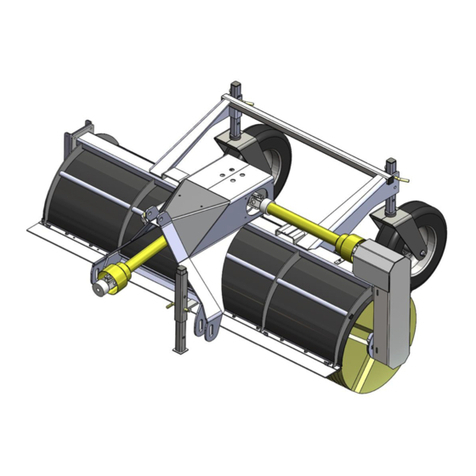

Congratulations on your purchase of the Belanger, Inc. Wave Across®. The Belanger, Inc. Wave Across®is designed to

operate in only 84” (213.4 cm) of tunnel space. If followed by a rinse arch, an envelope of 116” (294.6 cm) is required.

Available Styles

Part Number Description

WAVE A CROSS-386 Wave Across Wave Mitter, 380V, 60Hz

WAVE A CROSS-50 Wave Across Wave Mitter, 380V, 50Hz

WAVE A CROSS-60 Wave Across Wave Mitter, Standard Voltage

WAVE A CROSS-75 Wave Across Wave Mitter, 575V, 60Hz

The replacement cloth is available in the standard colors: Black, Blue, Green and Red.

The plastic pieces that hold the mitter cloth (“Mitter Waves”) come in Black, Blue, Green, Red and Yellow.

The cloth pieces or the “Mitter Waves” (plastic fins) can be purchased in complete sets or individually.

Contact your local distributor for details.

The purpose of this manual is to familiarize you with the way that the Wave Across®is installed.

The “Installation” section will be used in conjunction with the location diagram, and the Wave Across®drawings. All of

these combined are your guides to installation.

The “Maintenance” section will be used to make sure you can keep your car wash component looking and

functioning like new.

Whether you have already operated a car wash or you are new to our industry, you know the importance of the

appearance of a car wash and its equipment to the customer. Keeping the equipment clean will not only make the

equipment easier to maintain, it will act as an example to your customer to keep their equipment (their vehicle) clean

as well. Replacing the cloth in your tunnel as necessary will also help the image of your wash and keep the customer

coming back.

Read through the entire manual to familiarize yourself with the Wave Across®before installation. When installation is

completed, you will want to keep this manual as a guide to proper maintenance.

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 7

Introduction

Before You Get Started

Tools needed for installation:

Fork lift (with side shift if available) Lifting straps

Hammer drill with 5/8” bit 50 foot extension cord

Tape measure (25 foot or greater) Safety glasses

Pry bar Work gloves

Level Miscellaneous hand tools

Ladder Tin snips

Equipment included: Qty

Head assembly 1

Support legs 3

Accessory box 1

Cloth 1 complete set

Note: Uncrate and inspect shipment for damage, and to verify that all pieces are there. If there

is any damaged equipment, file a claim with the trucking company immediately. Receiving

party is responsible for filing claim with trucking company. Notify your local distributor

or Belanger, Inc. immediately if shipment is determined damaged or incomplete.

WAVE ACROSS

8Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

Specifications

Requirements

Physical

Tunnel space required 84” minimum

Unit height 126”

Unit width 146”

Utility

Electrical 208/230 – 480 VAC

Water (2) 3/4” pipe @ 6 GPM @ 40 PSI

Output

Physical

Vehicle clearance, height 90”

Vehicle clearance, width 127”

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE SERVICING ANY

EQUIPMENT.

CAUTION

Always wear safety glasses when performing maintenance on any equipment.

CAUTION

It is recommended that a licensed electrician is contracted to perform all electrical installations.

CAUTION

A compressed Air System should be set correctly to support 90 PSI necessary to operate

equipment, but should never be set to deliver more than 120 PSI air pressure to the Belanger

specified equipment.

Note: YOUR HYDRAULIC SYSTEM MUST BE CAPABLE OF ADJUSTMENT TO 76 RPM

AT 900 PSI WHILE LOADED AGAINST VEHICLE. PLEASE VERIFY YOUR

SYSTEMS CAPABILITY TO MEET THESE SETTING WHILE RUNNING A

VEHICLE PRIOR TO INSTALLING PIECE OF EQUIPMENT!

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 9

Specifications

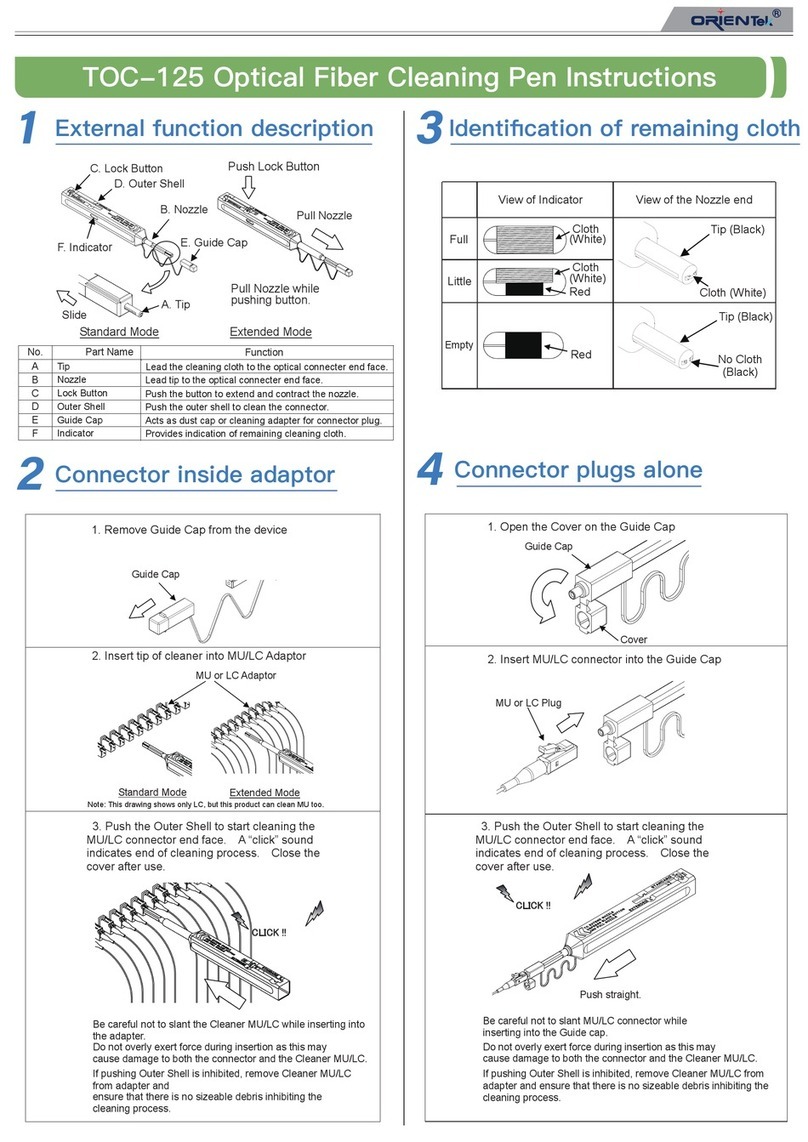

Dimensions

Operating envelope when followed by rinse

Standard envelope

The 126” dimension is taken from the floor to the top of the gearbox

126”

116”

84”

146”

WAVE ACROSS

10 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

Installation

Frame Assembly

1) Place the head assembly in its approximate tunnel location. Using a forklift, strap the head

assembly securely to the forks and raise above the height of the support legs.

Note: Be sure to clamp or strap equipment securely to the forks of the forklift before lifting

equipment. Do not stand under load while fork lift is in operation

2) Locate the leg assemblies and secure them to the head assembly using the supplied bolts,

washer and nuts.

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 11

Installation

Tunnel Placement

When placing a piece of equipment, tunnel depth will vary from site to site. Be sure to allow an adequate operating

envelope. The Wave Across®can be installed facing either direction as there is no entrance or exit side.

1) Position the assembled unit in its permanent tunnel location.

2) While placing a level on the vertical surface of one of the legs, place shims under the base

plate as needed to make the assembly level in both directions. Repeat this leveling process

on the other leg.

Note: Shims not supplied by Belanger, Inc.

3) Once the assembly is positioned correctly and level, lag it to the floor using the supplied lag

bolts.

The 45” dimension is taken from the inside edge of the inside conveyor guide rail to the outside edge of the equipment leg.

Although the main water feed is shown on the driver side, it can be installed on eitherside.

45” Center

Line

DIRECTION

of

TRAVEL

WAVE ACROSS

12 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

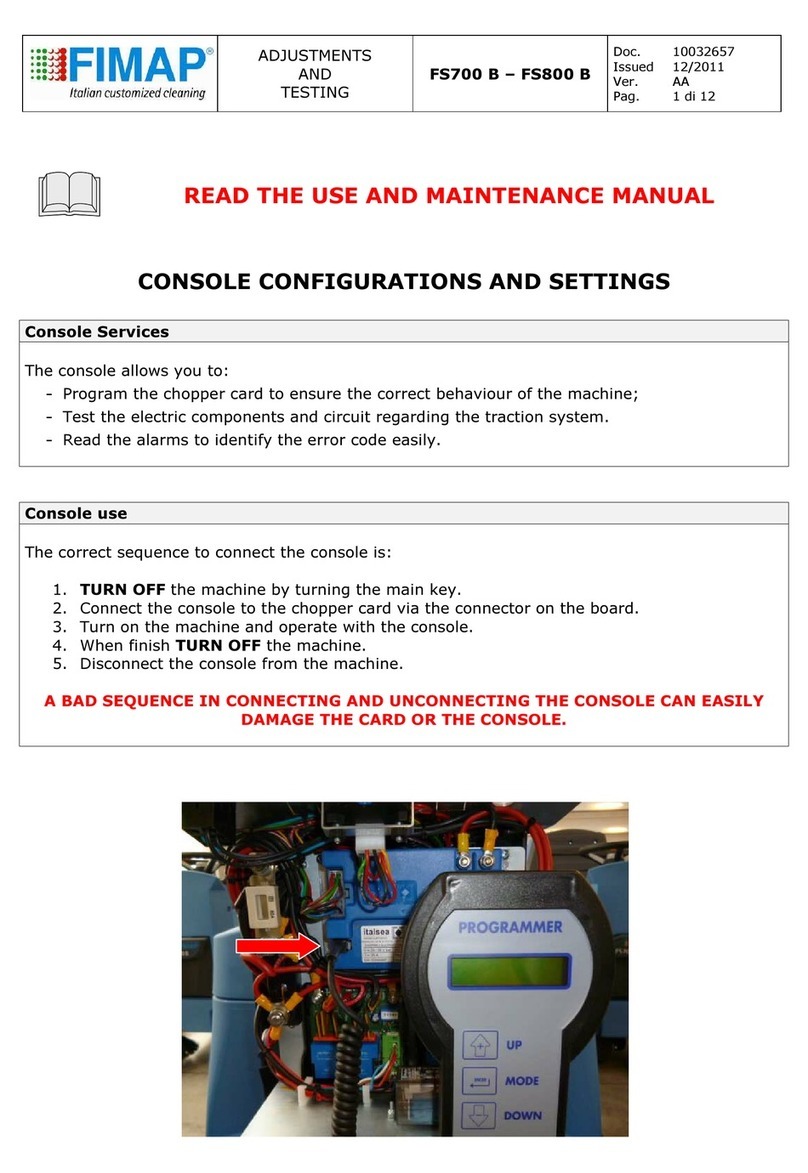

Installation

Utilities

Locate the following items:

(2) Copper manifolds, one with a vertical water feed and one without

(1) Section of water hose

(3) Barbed hose fittings

(3) Hose clamps

Water Manifolds Assembly

CAUTION

It is recommended that a licensed plumber is contracted to perform all water installations.

1) Determine the side in which you would like to supply the unit with water.

2) Secure the manifolds to the clamps on the underside of the crossbeam as shown.

Overhead View

3) Locate the barbed hose fittings. Secure one to opening on the underside of each manifold. This is

how one manifold will be fed from the other.

4) Secure the other fitting to the end of the vertical manifold. This is the main water feed.

Note: Fittings require a water sealant. We recommend using Teflon®tape, pipe dope or an

equivalent.

5) Locate the hose clamps and slide two of them onto the supplied 3/4” water hose. Use the water

hose to connect the two manifolds together and slide the hose clamps into position.

6) Slide the third hose clamp onto the hose being used as a main water feed and secure the main

water feed hose to the vertical manifold. Slide the hose clamps into position.

Clamp (typical)Crossbeam

Barbed

hose fitting

(typical)

Teflon®tape

(typical)

Hose Clamp

(typical)

Water feed

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 13

Installation

Utilities

Electrical

CAUTION

It is recommended that a licensed electrician is contracted to perform all electrical

installations.

1) Supply 3-phase power to the motor on top of the frame assembly.

Overhead View

Gearbox

Motor

Main electrical

feed

WAVE ACROSS

14 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

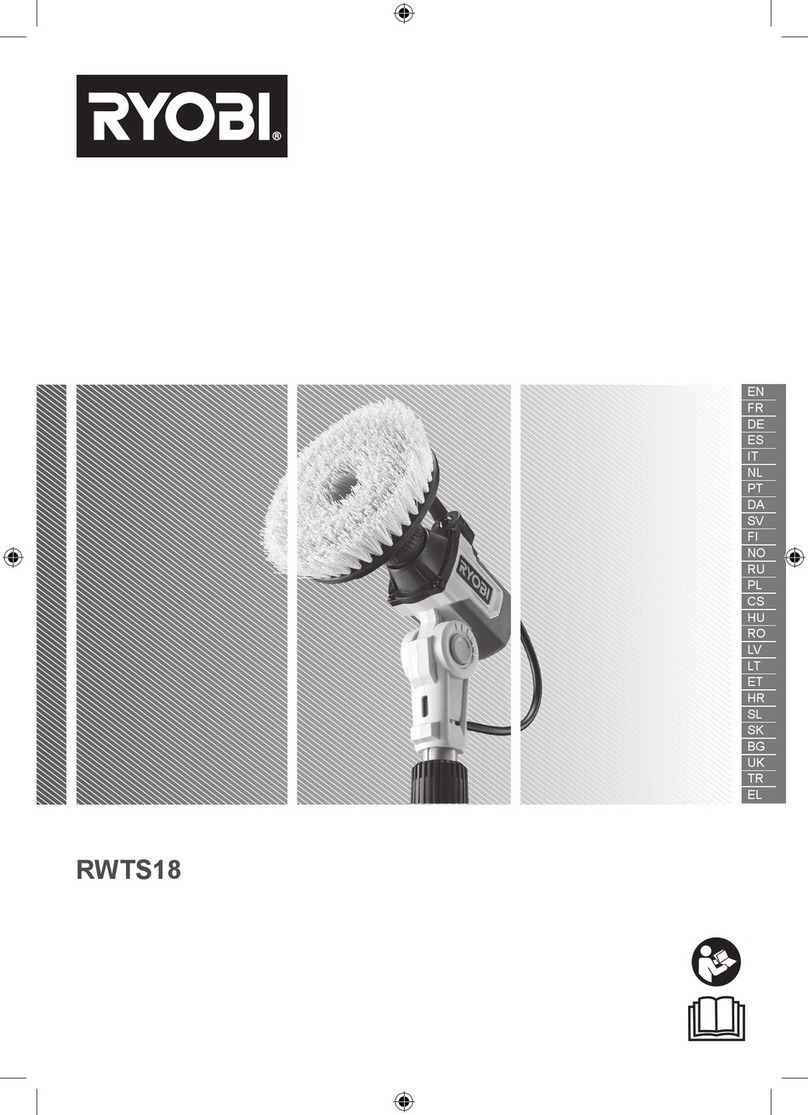

Installation

Cloth

This section will explain the cloth installation procedure.

Note: Do not install any cloth until all equipment has been installed, turned on and checked for

hydraulic, pneumatic and water leaks.

Locate the following hand tools:

1-1/8” wrench 9/16” socket

5/16” hex wrench Work gloves

3/16” hex wrench Safety glasses

Ladder

Parts Identification Entrance View

Upper drive arm

Lower drive arm

Drive rack Passenger side

follower rack

Center

follower rack

1-1/8” bolt,

(remove for cloth installation, typical)

Retainer pin

(typical)

Pitman

arm

WAVE ACROSS

1MANUL850 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 15

Installation

Cloth

Helpful Hint

Collar Placement

Placement typical on all six bearings (Overhead view of Head Frame)

DO NOT LOOSEN ANY OF THE SIX

COLLARS DURING CLOTH

INSTALLATION OR REPLACEMENT!

If circumstances require doing, so see

dimensions below

Overhead View

Collar Assembly

Collars are to be butted up

against the side-plates Collars are to be butted up

against the side-plates

WAVE ACROSS

16 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL850

Installation

Cloth

In order to install the cloth, some disassembly is necessary. Pay attention to how the machine is taken apart.

1) Loosen the upper locking collar on the drive rack with a 3/16” hex wrench and slide it over against

the flat washer.

2) Loosen lower locking collar of the drive rack using a 5/16” hex wrench.

3) Slide lower locking collar out away from rack and butt it against the plastic end cap.

Side View

Lower locking

collar (typical)

1-1/8” bolt,

(remove for cloth installation, typical)

Cloth

(typical)

Plastic end cap

(typical)

Upper drive arm

Upper locking collar 1-1/8” bolt,

(remove for cloth installation, typical)

Shaft

bearing

(typical)

Table of contents

Other Belanger Cleaning Equipment manuals

Belanger

Belanger QuickFire User manual

Belanger

Belanger H2AIR ARCH User manual

Belanger

Belanger FreeStyler User manual

Belanger

Belanger SUDZAMELEON ARCH User manual

Belanger

Belanger FreeStyler User manual

Belanger

Belanger FreeStyler E-1032 User manual

Belanger

Belanger QuickFire Wrap Around Signature Series User manual

Belanger

Belanger DuoScrubber User manual

Belanger

Belanger QuickFire Plus User manual

Belanger

Belanger Full Side Washer User manual