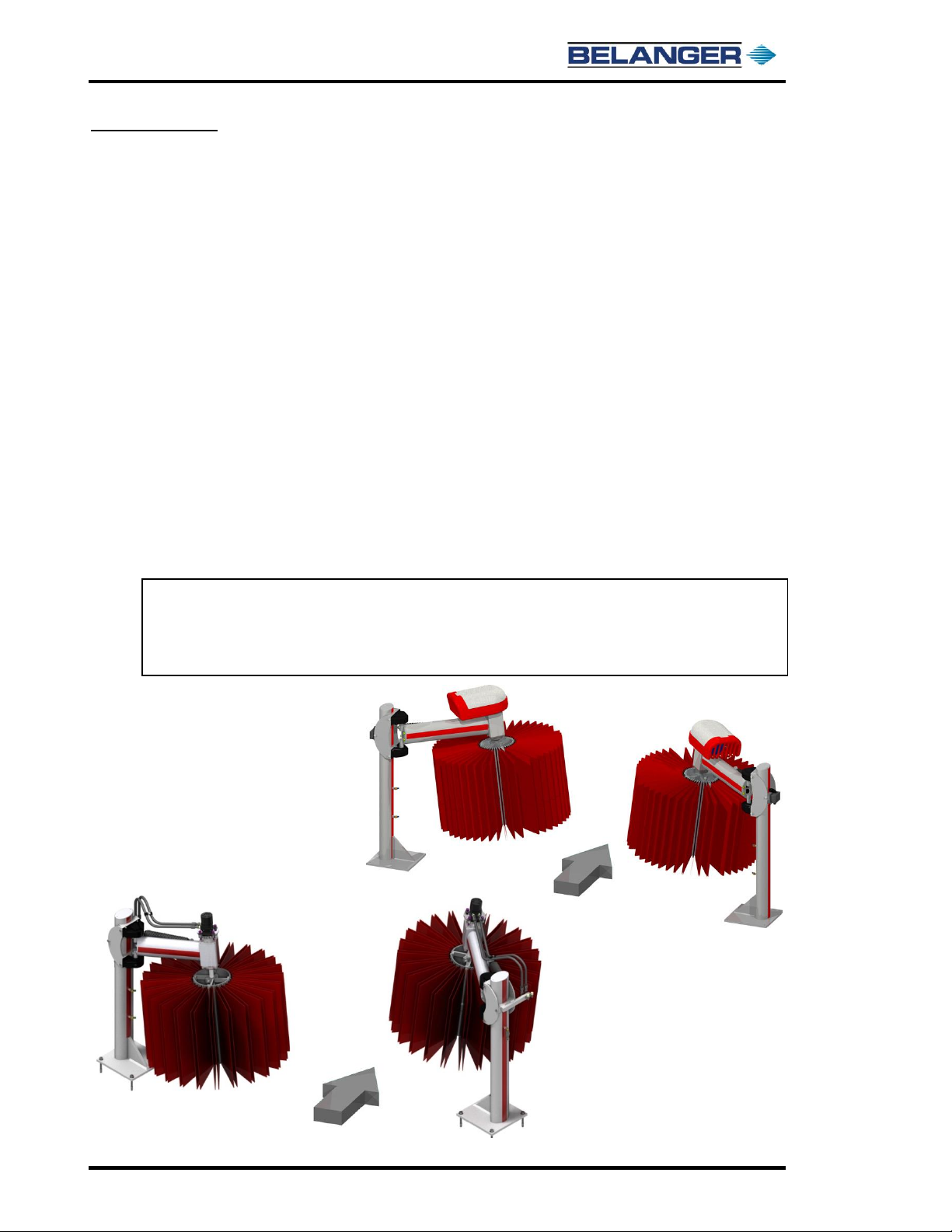

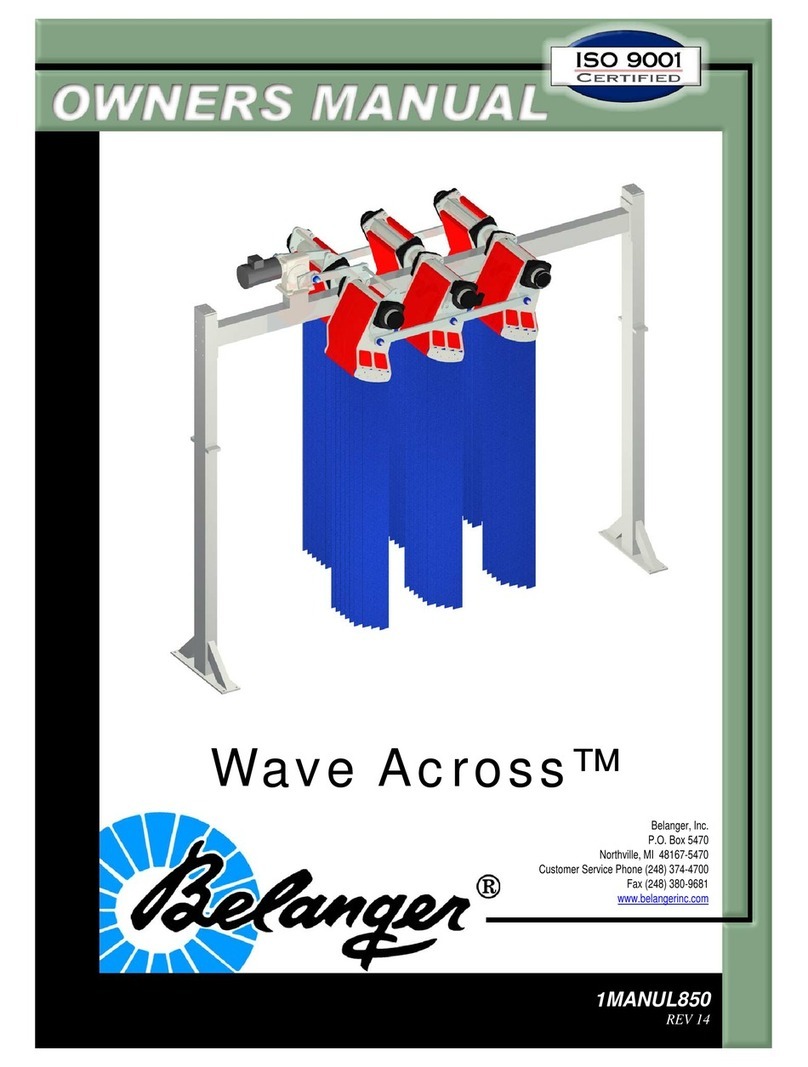

LOW SIDE WASHER Signature ®Series

1MANUL860 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 3

Belanger Incorporated® Limited Warranty

LIMITED WARRANTY:

Equipment:

Subject to the limitations stated below, Seller warrants that the Equipment sold hereunder, which is fabricated by Seller,

shall be free from defects in workmanship and material under normal use and service for a period of 1 year plus 30 days

from the date of invoice - CATPumps will be warranted for 2 years from the date of invoice.

Parts:

Subject to the limitations stated below, the Seller warrants that the Parts sold hereunder, shall be free from defects in

workmanship and material under normal use and service for a period of 90 days from the date of invoice.

Limitations On All Warranties:

The warranties contained in this Section 13 are subject to the following limitations: (1) they are void if the factory

specifications for operation and maintenance, found in original equipment manuals, and component manuals, are not

followed, or if other than factory authorized erection, alterations or modifications are made to any Parts or Equipment;

(2) defective Parts are warranted to the Purchaser only for repair or replacement through an authorized Purchaser or

Distributor of Seller, or direct with Seller for a period of 13 months from the date of invoice; however, this warranty

excludes all claims for failure resulting from normal wear and tear, improper installation, omission of factory specified

preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God and Purchaser agrees to

submit to and assist Seller or its authorized Purchaser or Distributor in conducting in-warranty inspections of the Goods

including inspection of any Equipment or Parts claimed to be defective by the Purchaser; (3) the cost of providing labor

or repair to replace Equipment and Parts warranted to Purchaser will be included within the warranty only if such claim

is made within 120 days from the date of invoice and then only during normal business hours through an authorized

Purchaser or Distributor of Seller, or direct with Seller, and labor and service provided beyond the labor warranty period

shall be subject to labor charges at the rates established by the local authorized Purchaser or Distributor or direct with

Seller; (4) the warranties shall be void for all Equipment failures and premature Part wear caused by the use of corrosive

chemicals in the wash process, and the following list includes some, but not all, of the particularly corrosive chemicals

that if used in conjunction with Equipment or Parts will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride,

Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, Sodium Hydroxide

and Chlorinated Solvents; (5) Seller makes no warranty, express or implied, with respect to the design or operation of

any entire system, in which Seller’s Equipment or Parts sold hereunder are mere components;(6) in no event shall Seller

be liable for any incidental, special, consequential, punitive or exemplary damages resulting from the furnishing,

performance or use of any Goods or services sold pursuant hereto, whether due to a breach of contract, breach of

warranty, negligence orany other claim at law or equity. Seller shall not be liable for any damages of anykind, including,

but not limited to, loss of business; inconvenience, or property damage of any kind; nor for any damages of whatever

nature resulting in any way from the Purchaser’s selection and use of any chemicals not manufactured exclusively by

Seller but used with the purchased Equipment or Parts; or for any service not expressly provided herein related to or

arising from the Equipment or Parts sold. Seller shall not be liable for damages resulting from Purchaser’s use of any

engineering recommendations, sales representations, technical assistance, advice, or data other than that information

contained in Belanger manuals; (7) all warranties, express, implied, or statutory, pertaining to the Equipment and Parts

apply to the Purchaser only; are not transferable; are fully set forth herein; and no addition to or modification thereto

shall be binding upon the Seller, unless made in writing and signed by a duly authorized employee of Seller.

No Other Warranties:

THIS LIMITED WARRANTY FOR EQUIPMENT AND PARTS IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE –SALES ARE EXPRESSLY

DISCLAIMED.

Copyright ©2020 by Belanger, Inc. All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage or

retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Belanger reserves the right to change

or modify the Belanger Inc. Limited warranty without notice.