Table of contents

7.4.1 Customer-specific limits ......................................................................................................36

7.4.2 Customer-specific visual inspection....................................................................................37

7.4.3 Customer-specific test procedures......................................................................................37

7.4.4 Customer-specific device templates ...................................................................................37

7.4.5 Customer-specific templates...............................................................................................38

7.4.6 Update.................................................................................................................................38

7.4.7 Factory settings...................................................................................................................38

7.5 General test procedure ......................................................................................................38

7.5.1 Automatic testing ................................................................................................................39

7.5.2 Manual testing ....................................................................................................................40

7.5.3 Terminology used in test procedures..................................................................................40

7.6 Device information ..............................................................................................................42

7.7 Individual tests ....................................................................................................................42

7.7.1 Protective conductor resistance..........................................................................................42

7.7.2 Insulating resistance ...........................................................................................................43

7.7.3 Protective conductor current ...............................................................................................44

7.7.4 Contact current....................................................................................................................44

7.7.5 Device leakage current (medical electrical devices) ...........................................................44

7.7.6 Patient leakage current (medical electrical devices)...........................................................45

7.7.7 Functional test.....................................................................................................................45

7.7.8 Cable continuity test............................................................................................................46

7.7.9 Safety extra-low voltage......................................................................................................46

7.7.10 Voltage of the welding circuit ..............................................................................................46

7.7.11 Contact current of the welding circuit..................................................................................47

7.7.12 PRCD..................................................................................................................................47

7.7.13 Power distributors ...............................................................................................................48

7.8 Remote control....................................................................................................................48

7.9 Optional accessories...........................................................................................................49

7.9.1 Three-phase testing with the BENNINGMA4....................................................................49

7.9.2 Three-phase testing with the BENNINGMA3....................................................................50

7.9.3 Three-phase testing with the BENNINGMA2-16...............................................................50

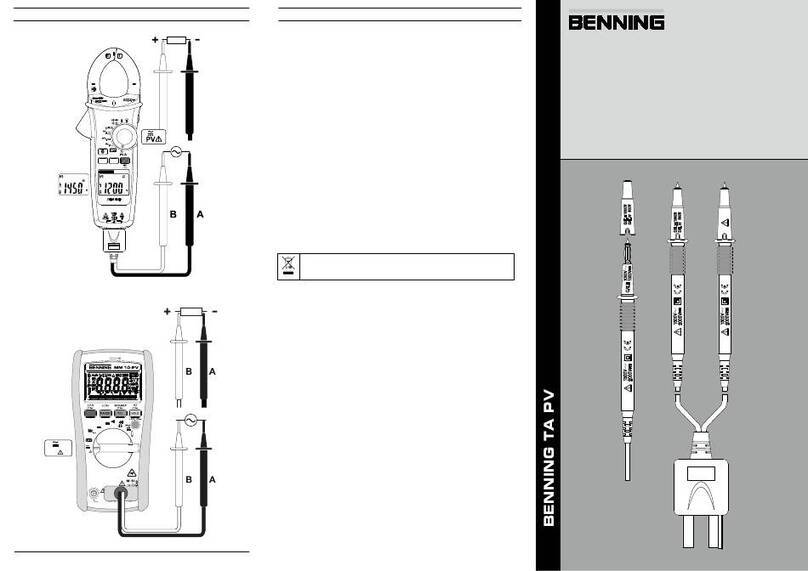

7.9.4 Single-phase and three-phase testing with the leakage current clamp...............................51

7.9.5 Barcode scanner (optional).................................................................................................51

7.9.6 RFIDscanner (optional)......................................................................................................53

7.9.7 Printer (optional)..................................................................................................................54

7.9.8 Keyboard (optional).............................................................................................................55

8 Configuration ...........................................................................................................................................56

8.1 Setting the system data.......................................................................................................56

8.2 Setting the device data........................................................................................................58

8.3 Managing the network settings ...........................................................................................58

8.3.1 Establishing a connection via WLAN ..................................................................................59

8.3.2 Establishing a connection via Bluetooth..............................................................................59

8.4 Managing the expert settings..............................................................................................60

8.4.1 Managing customer-specific limits ......................................................................................60

8.4.2 Creating a customer-specific visual inspection ...................................................................61

5284 / 08/2023 enBENNING ST 755+ / ST 760+4