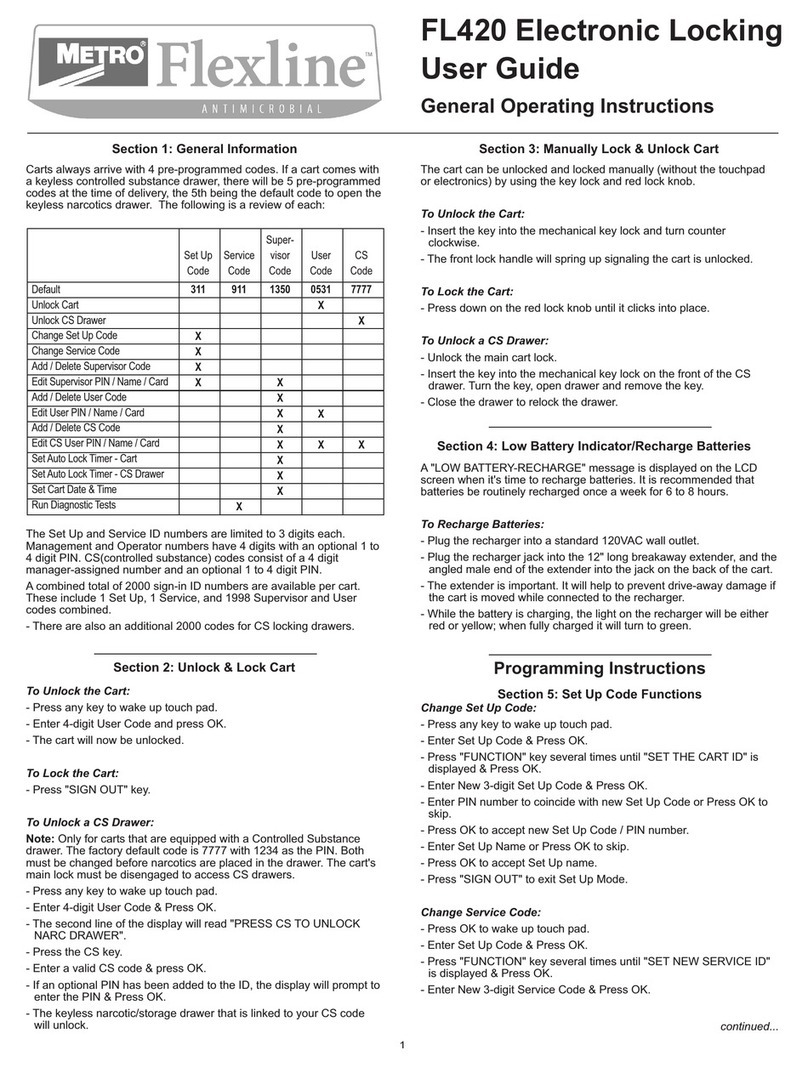

BEST ACCESS SYSTEMS

Indianapolis, Indiana

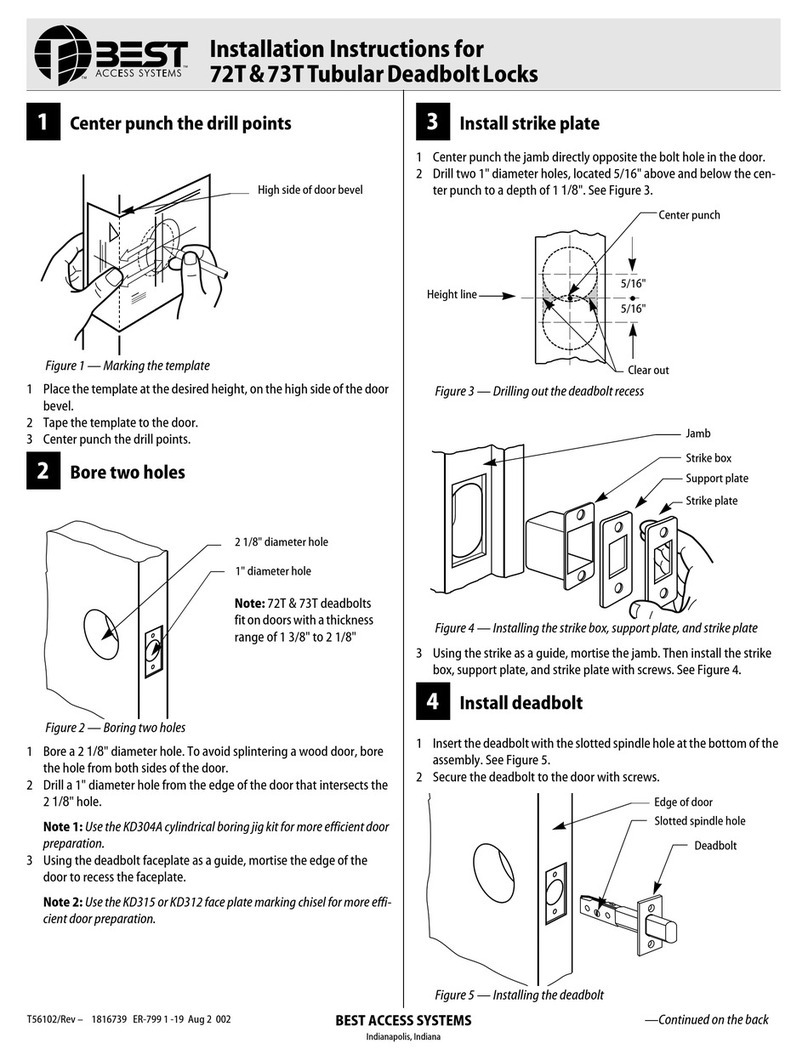

3

Using a hammer and wooden block, lightly

drive the deadbolt into the hole until the

face of the deadbolt is flush with the edge

of the door.

5

Install cylinder or cylin-

ders

For 1 3/8”thick doors only

■

Slip the spacer ring behind the outside cyl-

inder and trim assembly as shown

in

Figure 5.

Note:

Use two spacer rings for M function

deadbolts, one behind the outside cylinder

and the other behind the inside cylinder.

For single-keyed cylinder deadbolts

except ‘S’(classroom) functions

1

Extend the bolt with a screwdriver.

2

Install the cylinder and trim assembly with

the spindle in the

vertical

position as

shown in Figure 5.

For non-keyed KL functions

1

Extend the bolt with a screwdriver.

2

Slip the spacer ring behind the outside

rose.

For ‘S’(classroom) function deadbolts

1

Retract the deadbolt with a screwdriver.

2

Install the cylinder and trim assembly with

the spindle in the

horizontal

position.

For double-keyed cylinder deadbolts (‘M’

function)

1

Extend the bolt with a screwdriver.

2

Install each cylinder with its ring and rose

as shown in

Figure 6.

6

Attach inside trim

For standard mounting screws

1

Secure the cylinder to the door with the

clamp plate and mounting screws as

shown in

Figure 7.

2

Break the spindle at the appropriate notch

to suit the installation.

3

Slide the turn knob assembly over the spin-

dle and secure it with the trim screws sup-

plied.

For concealed mounting screws

1

With the inside rose and turn knob unit in

place, put the two mounting screws

through the outside cylinder as shown in

Figure 8.

2

Break the spindle at the appropriate notch

to suit the installation.

3

Screw the mounting screws into the back

of the turn knob unit.

7

Install core or cores

For double-keyed deadbolts or deadbolts

with concealed screws

■

To cover the mounting screw holes, put

the cylinder face into the ring. See

Figure 9.

For all deadbolt locks

1

Put the control key into the core and turn

the key 15 degrees clockwise as shown in

Figure 10.

2

Adjust the throw pins if needed, then put

the core into the cylinder with the control

key.

3

Turn the key 15 degrees counterclockwise

and remove the key.

Caution:

Locks that secure both sides

of the door are controlled by building

codes and the Life Safety Code®. In an

emergency exit situation, failure to

quickly unlock the door from the inside

could be hazardous or even fatal.

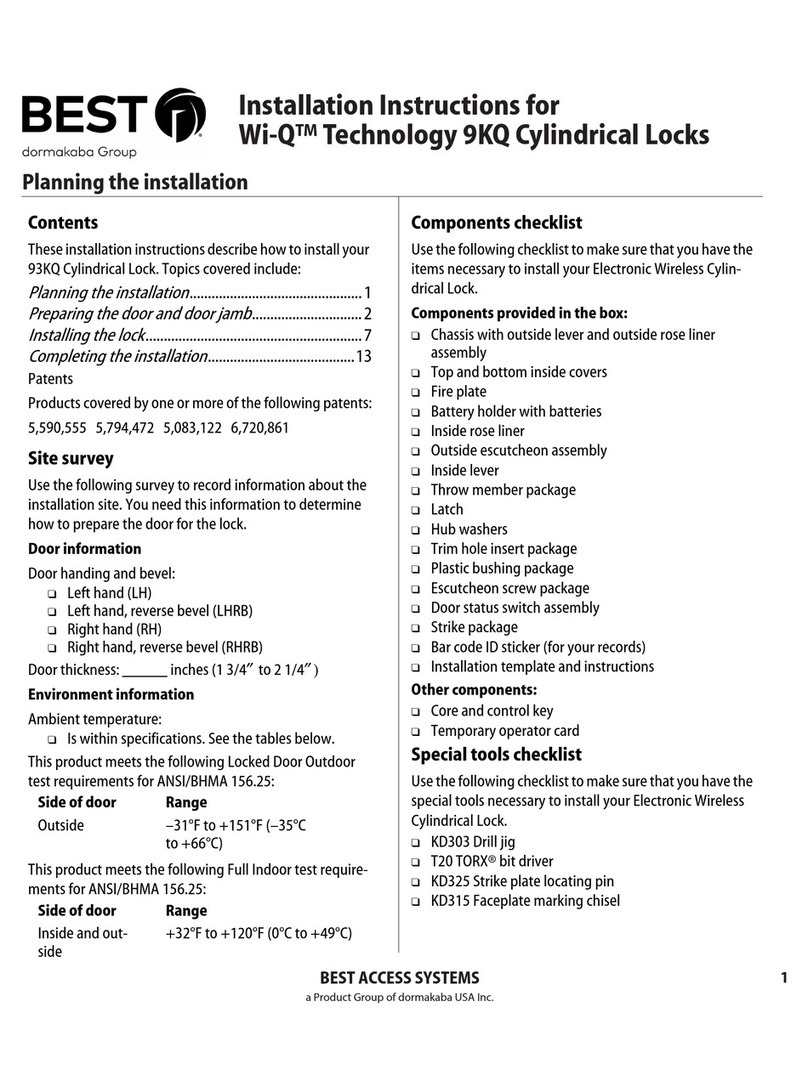

Patents

Products are covered by one or more of the

following patents:

U.S. Patents

D290085, 4444034, 4424693, 4386510,

4294093, 4301667, 4655063, 4843852

Other patents pending.

.

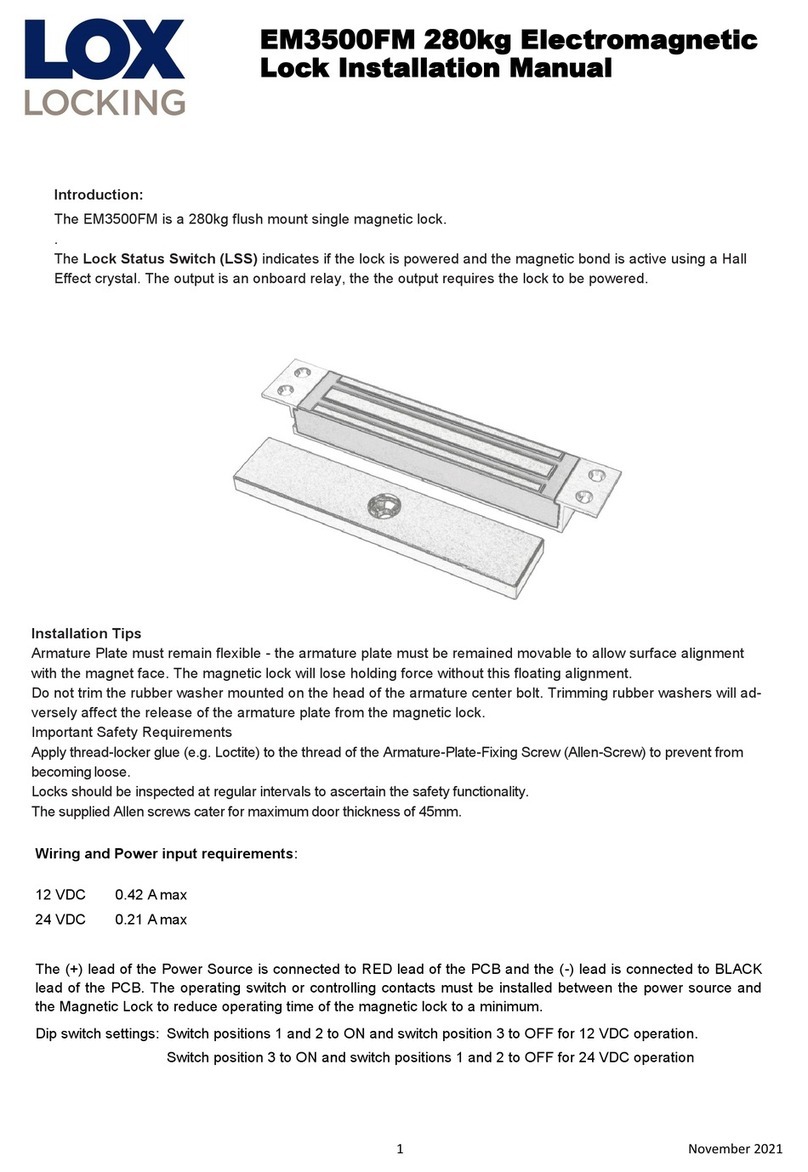

Figure 5

Installing the cylinder and trim

assembly

Spindle

Cylinder & trim assy

Extend or retract bolt

with screwdriver here

Spacer ring (1 3/8”

thick doors)

Figure 6

Side view of a double-keyed deadbolt

Figure 7

Standard trim mounting

Figure 8

Concealed trim mounting

Both spindles fit

through slotted

spindle hole

p

n

e

Clamp plate

Mounting screws

Trim screws

Turn knob assy

Outside cylinder,

ring, and rose

Inside rose

Turn knob unitMounting screw

Figure 9

Installing the cylinder face for double-

keyed deadbolts and deadbolts with

concealed screws

Figure 10

Installing the core on standard

deadbolts

Ring

Mounting screw holes

Cylinder face

Throw pins

Core

Rotate 15 degrees