Thank you for buying this product. Our Company is sure that you will be

more than satised with the performance of the product. This product is

supplied with a “WARNINGS” leaet and an “INSTRUCTION MANUAL”.

These should both be read carefully as they provide important informa-

tion about safety, installation, operation and maintenance. This product

complies with recognised technical standards and safety regulations. We

declarethatthisproductisinconformitywiththefollowingEuropeanDirec-

tives:89/336/CEE, 73/23/EEC,98/37/EECand subsequent amendments.

1) GENERAL OUTLINE

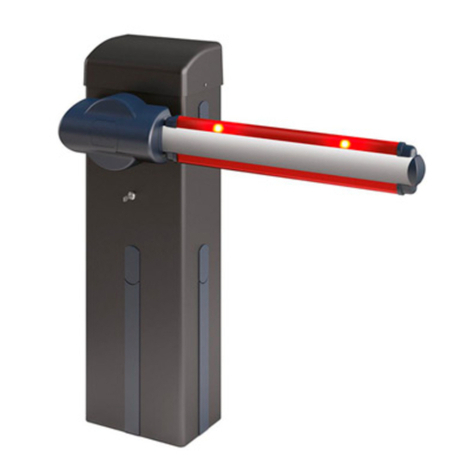

Compact electromechanical barrier suitable for limiting private areas,

parkings, access areas for vehicles only. Available for passageways

from 3 to 6 metres. Adjustable electromechanical limit devices ensuring

a correct stop position for the boom. In case of intensive use, a thermal

sensor activates the cooling fan.

The emergency release device for manual manoeuvre is controlled by a

personalised key lock.

The actuator is always supplied for left-hand side tting. However, when

necessary, the opening direction can be reversed by means of simple

operations.

The CBO mod. foundation base (on request) makes barrier installation

easier.

Appropriate ttings make it easy to install accessories without needing

to drill any holes.

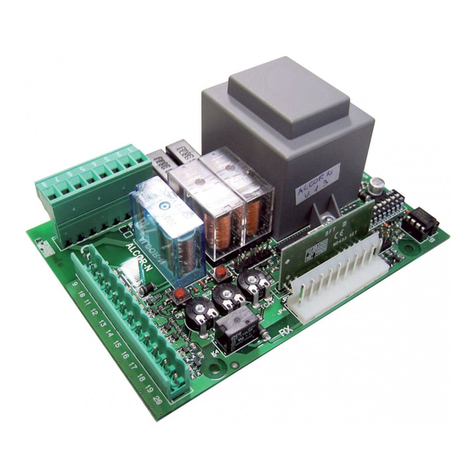

TheLEO-MV-D control panelis supplied bythe manufacturer with standard

setting. Any alteration must be set by means of the incorporated display

programmer or by means of Universal palmtop programmer. The Control

unit completely supports the EELINK protocol, including the programmer

self-supply from the control unit.

Its main characteristics are:

- Closing / opening limit-switch inputs

- Separate inputs for safety devices

- Clock input

- Serial protocol connection input

- Incorporated radio receiver

The board is provided with a terminal board which can be pulled out for

easier maintenance or replacement. The board is supplied with a series

of pre-wired jumpers to facilitate the installer’s work.

Thejumpers relate to thefollowingterminals: 21-23, 21-24 and 21-30.If the

above-mentioned terminals are in use, remove their respective jumpers.

2) GENERAL SAFETY

WARNING! An incorrect installation or improper use of the product

can cause damage to persons, animals or things.

• The “Warnings” leaet and “Instruction booklet” supplied with this

product should be read carefully as they provide important information

about safety, installation, use and maintenance.

• Scrap packing materials (plastic, cardboard, polystyrene etc) according

tothe provisionsset out bycurrentstandards. Keepnylon or polystyrene

bags out of children’s reach.

• Keep the instructions together with the technical brochure for future

reference.

• This product was exclusively designed and manufactured for the use

specied in the present documentation. Any other use not specied

in this documentation could damage the product and be dangerous.

• The Company declines all responsibility for any consequences resulting

from improper use of the product, or use which is different from that

expected and specied in the present documentation.

• Do not install the product in explosive atmosphere.

• The construction components of this product must comply with the

following European Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC

andsubsequent amendments. Asfor all non-EEC countries,the above-

mentioned standards as well as the current national standards should

be respected in order to achieve a good safety level.

• The Company declines all responsibility for any consequences result-

ing from failure to observe Good Technical Practice when constructing

closing structures (door, gates etc.), as well as from any deformation

which might occur during use.

• The installation must comply with the provisions set out by the follow-

ing European Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC and

subsequent amendments.

• Disconnect the electrical power supply before carrying out any work

on the installation. Also disconnect any buffer batteries, if tted.

• Fit an omnipolar or magnetothermal switch on the mains power supply,

having a contact opening distance equal to or greater than 3,5 mm.

• Check that a differential switch with a 0.03A threshold is tted just

before the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for

closure (doors, gates etc.) and all system components provided with

an earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are

needed to protect the area from any danger caused by squashing,

conveying and shearing, according to and in compliance with the ap-

plicable directives and technical standards.

• Position at least one luminous signal indication device (blinker) where

it can be easily seen, and x a Warning sign to the structure.

• The Company declines all responsibility with respect to the automation

safety and correct operation when other manufacturers’ components

are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorised

by the company.

• Instruct the product user about the control systems provided and the

manual opening operation in case of emergency.

• Do not allow persons or children to remain in the automation operation

area.

• Keep radio control or other control devices out of children’s reach, in

order to avoid unintentional automation activation.

• The user must avoid any attempt to carry out work or repair on the

automation system, and always request the assistance of qualied

personnel.

• Anything which is not expressly provided for in the present instructions,

is not allowed.

• Installation must be carried out using the safety devices and controls

prescribed by the EN 12978 Standard.

3) TECHNICAL SPECIFICATIONS

MOOVI 30S

Power supply:..........................................................220-230V 50/60Hz(*)

Absorbed power: ............................................................................300W

Motor: .........................................................................2800 min-1 2 poles

Capacitor: ..........................25µF 450V (220-230V): 100µF 250V (110V)

Absorption: .......................................................................... 0.8 A - 1.6 A

Insulation class:.....................................................................................F

Ventilation intervention temperature:.............................110 °C (winding)

Circuit-breaking intervention temperature: ........... 130 °C (self-resetting)

Reduction gear lubrication:.........................................Permanent grease

Max torque:.....................................................................................72Nm

Minimum opening time: .................................................................. 1.5 s

Boom (aluminium) length:.......................................................... 3m max.

Impact reaction:............................. Obstacle detection device (Encoder)

Limit devices:.................................Electric, incorporated and adjustable

Manual manoeuvre:.....................................................Quick key release

Type of use:...................................................................... semi intensive

Working temperature:.....................................................-10°C to +55 C°

Degree of protection:........................................................................IP24

Operator weight (without boom): ................................... 356N (~35.6 kg)

Dimensions:..............................................................................See g. 1

(*) Special supply voltages available on request.

MOOVI 30 RMM - MOOVI 60 RMM

Power supply:............................................................. 220-230V 50/60Hz

Absorbed power: ............................................................................300W

Motor: ........................................................................1400 min-1, 4 poles

Capacitor: ...............................8µF 450V (220-230V):32µF 250V (110V)

Absorption: ............................................................................ 0.8 A:1.6 A

Insulation class:.....................................................................................F

Ventilation intervention temperature:..............................110°C (winding)

Circuit-breaker intervention temperature:.............. 130°C (self-resetting)

Reduction gear lubrication:.........................................Permanent grease

Max torque:...................................MOOVI-30 85Nm: MOOVI-60 250Nm

Opening time: ........................................... MOOVI-30 4s : MOOVI-60 8s

(Aluminium) bar length: ..................................MOOVI-30 3m max: MOOVI-60 6m max

Max Impact reaction:...................... Obstacle detection device (Encoder)

Limiting devices:............................Electric, incorporated and adjustable

Manual manoeuvre:.....................................................Quick key release

Working temperature:.......................................................-10°C ÷ +55°C

Degree of protection:........................................................................IP24

Actuator weight (without bar):........................................ 356N (~35.6 kg)

Dimensions:...............................................................................See g.1

(*) Special power voltages available on request.

4) FOUNDATION PLATE (Fig.2)

- Prepare a foundation hole suitable for the particular kind of ground.

- Layout several raceways for the electric cables to pass through.

- Position the screws supplied with the CBO mod. base into the 4 xing

holes with the thread facing upwards. Weld the 4 screw heads to the

base and protect the welds with rust preventer. Position the base so

INSTALLATION MANUAL

ENGLISH

16 - MOOVI 30S-30RMM-60RMM Ver. 01

All manuals and user guides at all-guides.com