5

A4000 Operation

The following instructions apply to the

A4000 water still where the water feed to

the boiler is via the mains supply, or a

header tank.

If the boiler is to be fed with either de-

ionised or pre-treated water, please follow

the instructions on page 15.

1Before switching on either the mains

electricity or water supply, identify the

control switches and indicator lights

on the front of the cabinet.

Green Light

When illuminated this shows that

there is mains supply voltage to the

unit. Under no circumstances should

the cabinet end-panel be removed

when this light is illuminated.

White “On Off” Switch

This is the primary switch for

controlling water and electricity inside

the still. The switch illuminates when

pressed in the ON position.

Amber Light

When illuminated, this indicates that

the distillate collection reservoir is full

as detected by the level control.

White “Clean” Switch

This shuts off the heating element but

allows water to flow into the boiler

when the still is being commissioned

or cleaned. When pressed in the

CLEAN position the switch illuminates.

2Carefully check the following:–

–the appropriate electricity, water

and drain services have been

provided. If in doubt, consult the

LOCATION & SERVICES section on

page 1.

–the ON/OFF switch on the control

panel is in the OFF position.

–the CLEAN switch is pressed in the

CLEAN position.

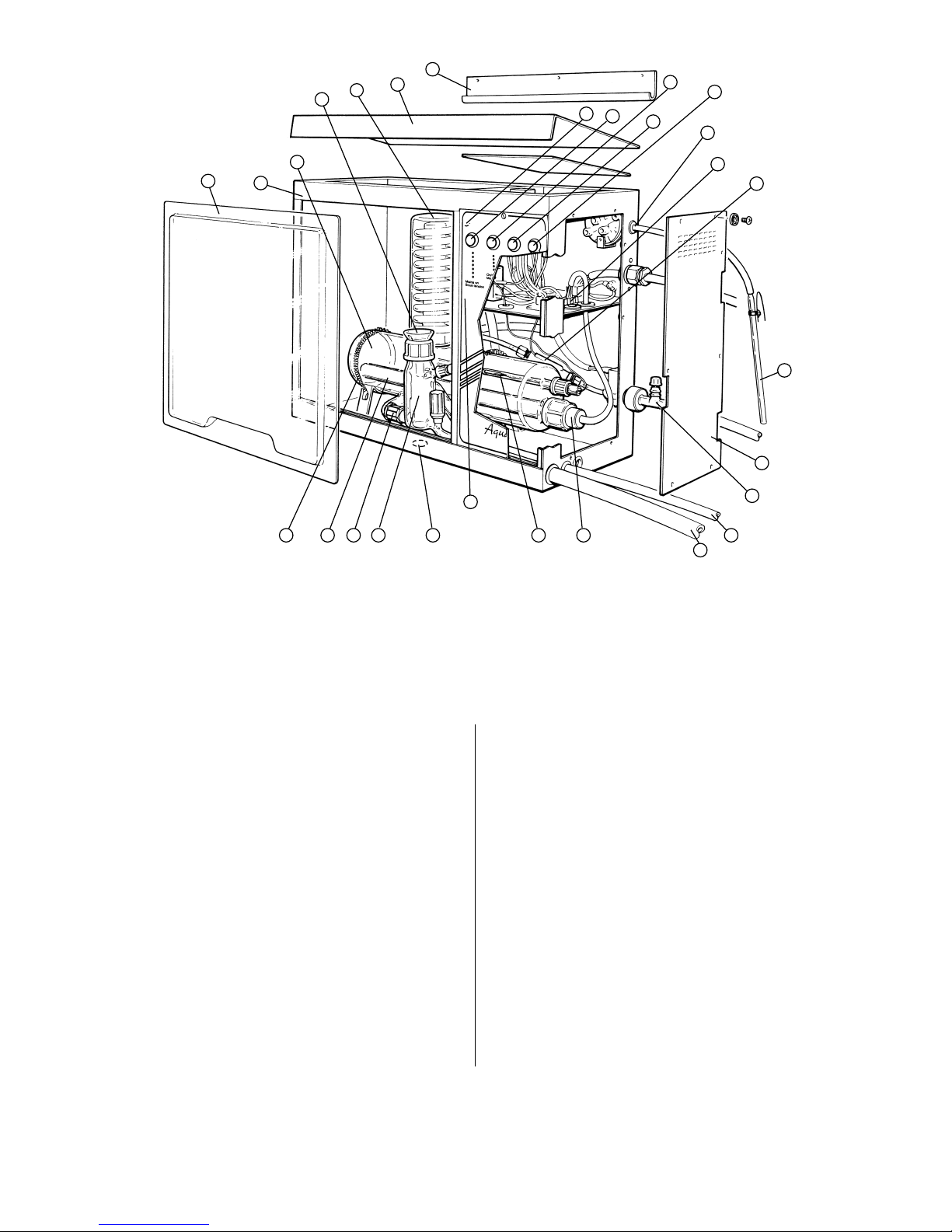

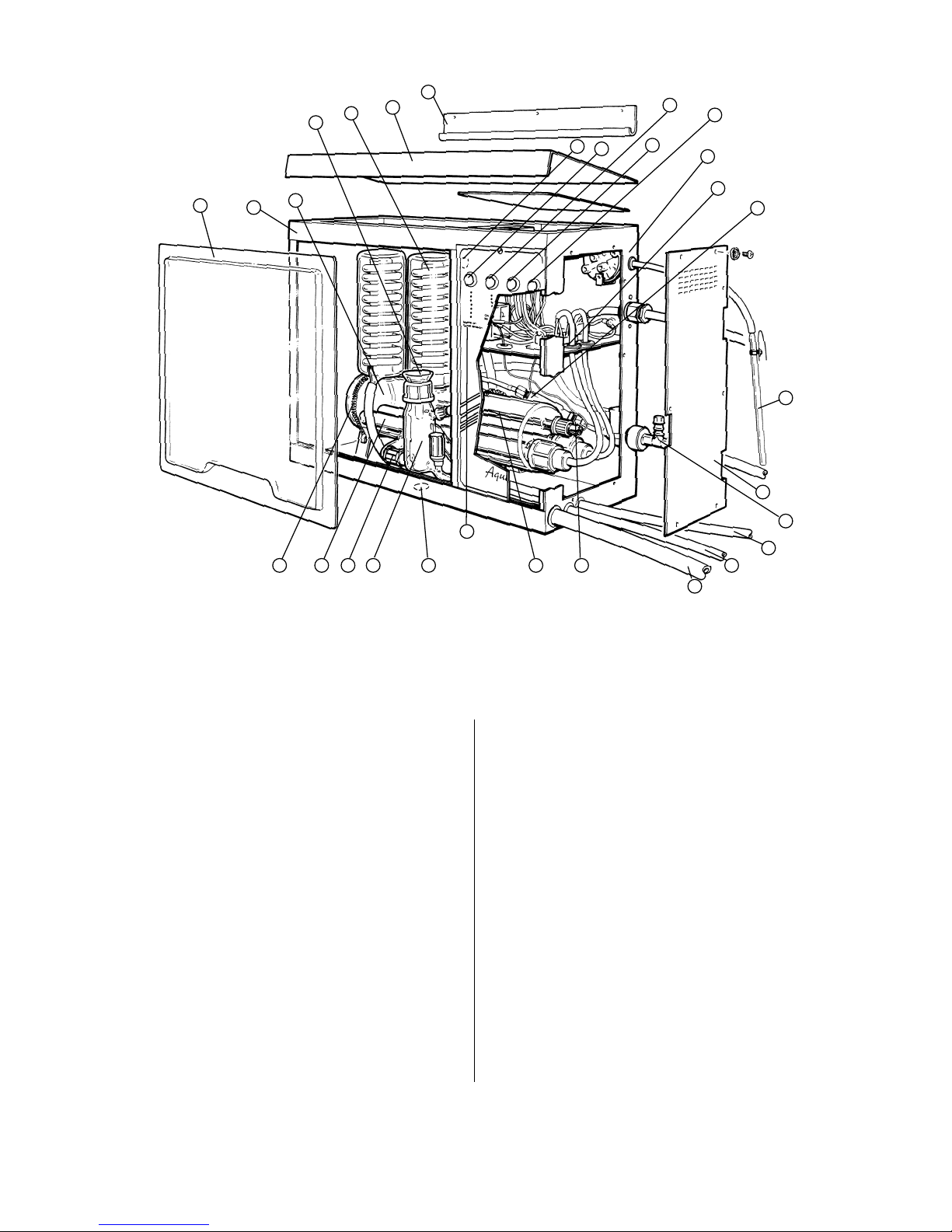

–the Rotaflo stopcock on the boiler

level control WL48 is closed.

–the Reservoir pressure switch is

fitted to the distillate collection

vessel.

–the dummy shorting plug is fitted

to socket item 8, fig. 1.

3Switch on the electricity supply – the

green indicator light will illuminate.

4Press the ON/OFF switch to the ON

position – the switch will illuminate.

5Recheck that the CLEAN switch is in

the CLEAN position and illuminated.

6Turn on the mains water supply and

using the needle valve item 18 fig. 1

on the side of the cabinet, adjust the

flow rate to approximately 1 litre/min.

Check that there are no water leaks

from the hose connections.

7Observe that the boiler is now filling

with water to cover the heating

element. When the water has reached

the pre-set level, the excess will be

discharged to drain. Check that the

drain water flows freely and does not

“back-up” into the level control.

8Switch the CLEAN button off by

pressing it for a second time – the

switch light goes out.

The heater will start to warm up and

eventually run at a red glow. If the

flow rate is insufficient, then the

heater will not switch on – this will

require the control needle valve to be

opened further. After about 2 to 3

mins. of operation distilled water will

emerge from the outlet pipe, falling

into the collection reservoir.

9To avoid excessive wastage of coolant

water, make further adjustments to

the needle valve. Slowly reduce the

flow-rate until the flow control switch,

item 15, switches off the heaters –

then increase the flow until the power

is restored.

10 Refit the perspex viewing screen.

11 Safety Cut-Outs

All Aquatron water stills are protected

by the following safety devices.

Flow Control Switch (item 15)

monitors the flow of coolant water

into the still and shuts off the heating

element, if the flow is insufficient.

Thermostat Cut-Out (item 22)

In normal operation the water within

the glass will be at 100°C. In single

fault conditions, i.e. in the event of

water supply failure, the content will

increase to 110°C where upon a

resettable thermostat will operate.

Once switched, the thermostat has to

be manually reset. This is achieved by

unscrewing the black knob, fig. 1,

item 23, located inside the cabinet

and pressing the reset button.

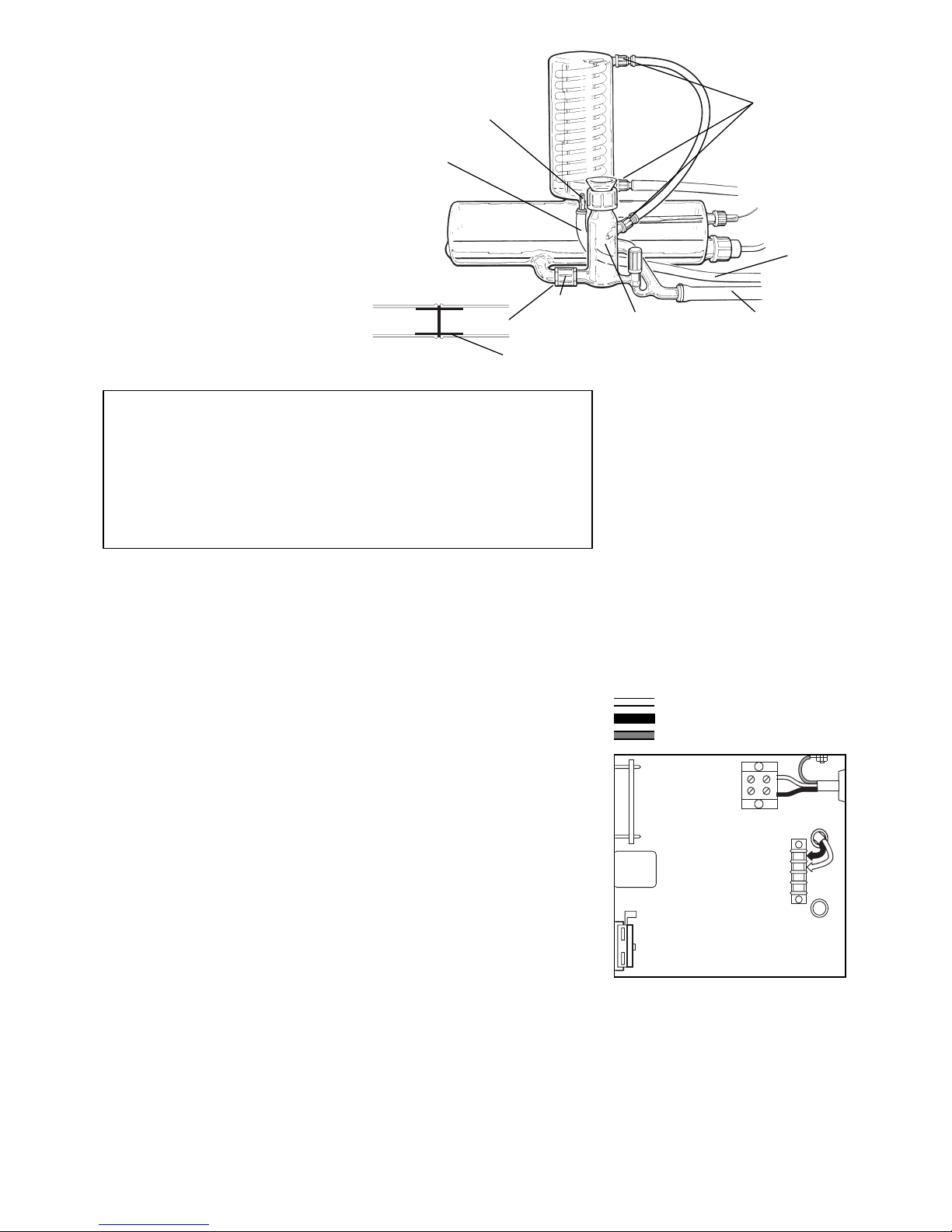

Reservoir Control (fig. 11)

is positioned on the collection

reservoir and switches off both the

electricity and water supply when the

reservoir is full of distilled water. The

water supply is only shut off around 7

minutes after the reservoir is full to

allow the heating element to cool.

It is recommended that the operation

of the flow switch and reservoir

control be checked on a regular basis.

a) Simulation of Mains Water

Supply Failure

Turn off the mains water supply at

the tap. This should switch off the

heating element. Turning the tap on

again will switch the heater on.

b) Simulation of Reservoir Full

Condition

Lower the glass pressure bell WPB,

(fig. 11), into the distillate to a

depth of 150mm. This will switch

off the heating element

immediately and the cooling water

after 7 minutes. Raising the bell will

cause both to be re-supplied.

12 Switching Off

Push the CLEAN switch to the ON

position. Wait until the residual heat

contained in the heating element has

dispersed and no boiling is evident.

Turn off water supply. Push ON/OFF

switch to OFF position. Isolate from

mains electricity supply.