BIG RBX5 User manual

Operation manual

Please be sure to read this manual before using the product

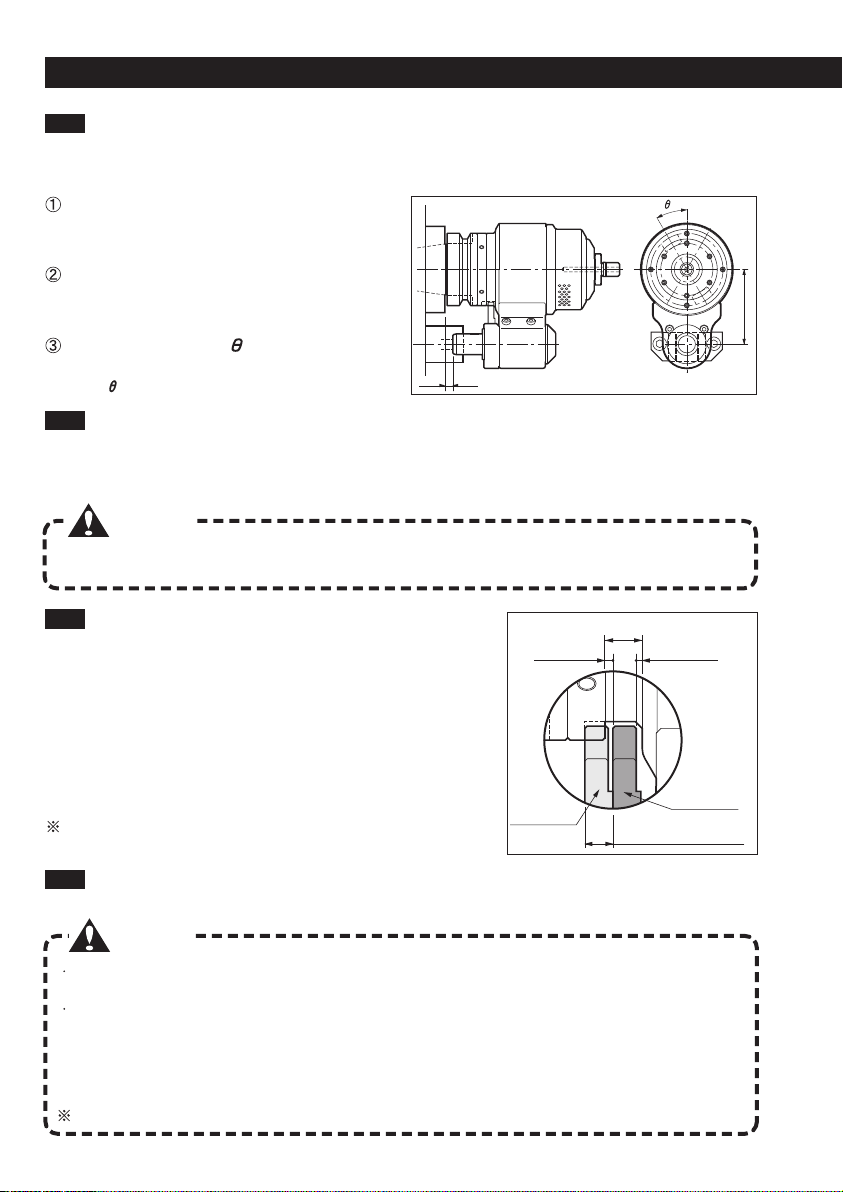

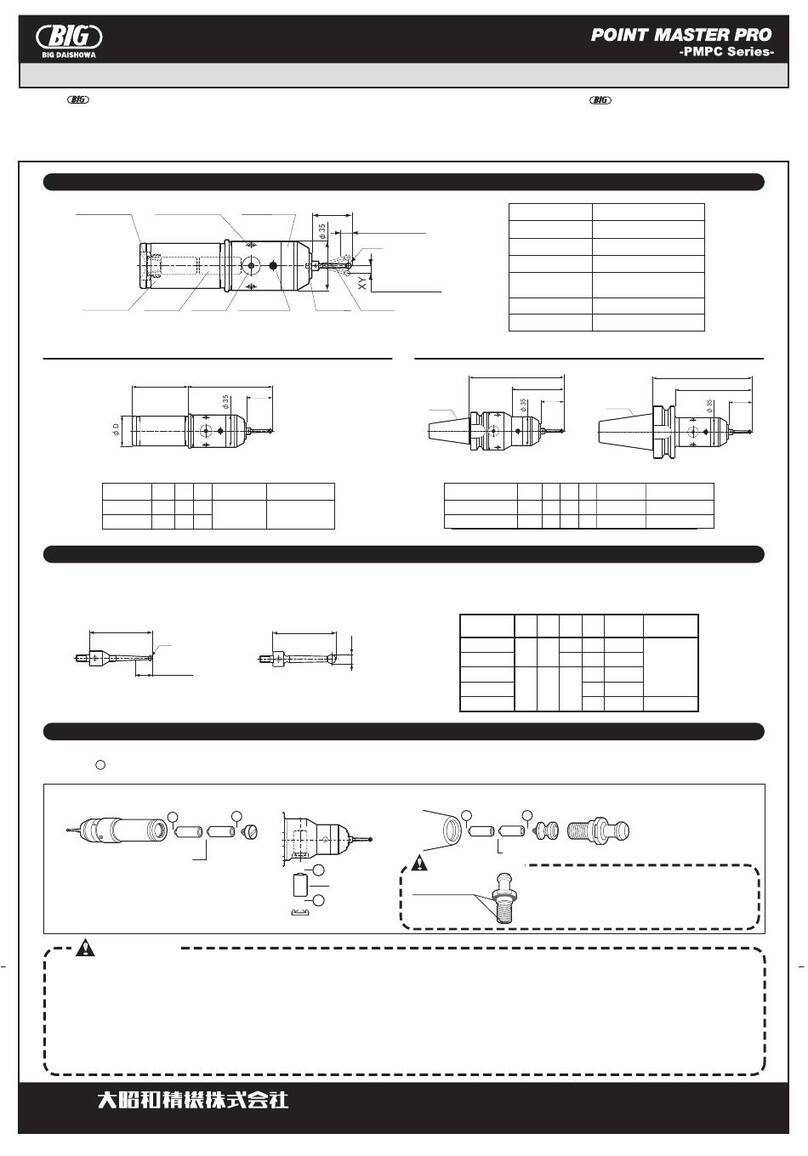

RBX5・RBX5C

RBX7・RBX7C

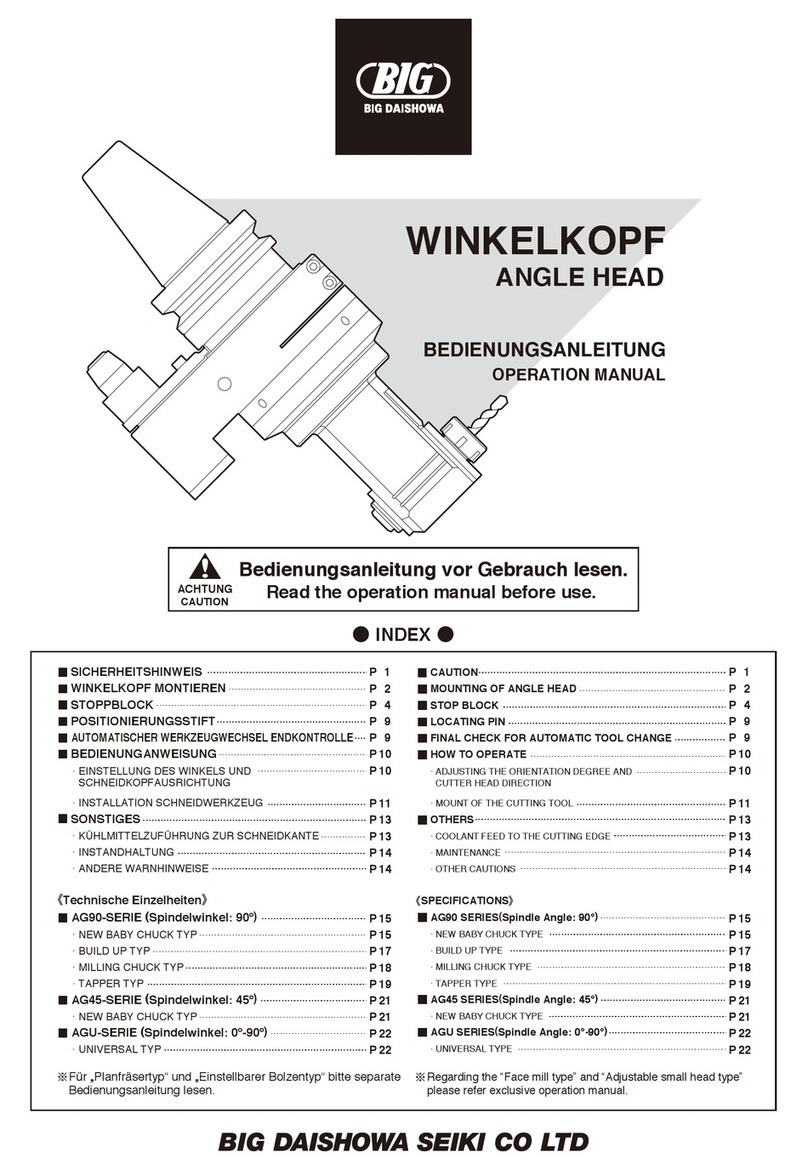

●INDEX●

SAFETY NOTES

INTRODUCTION

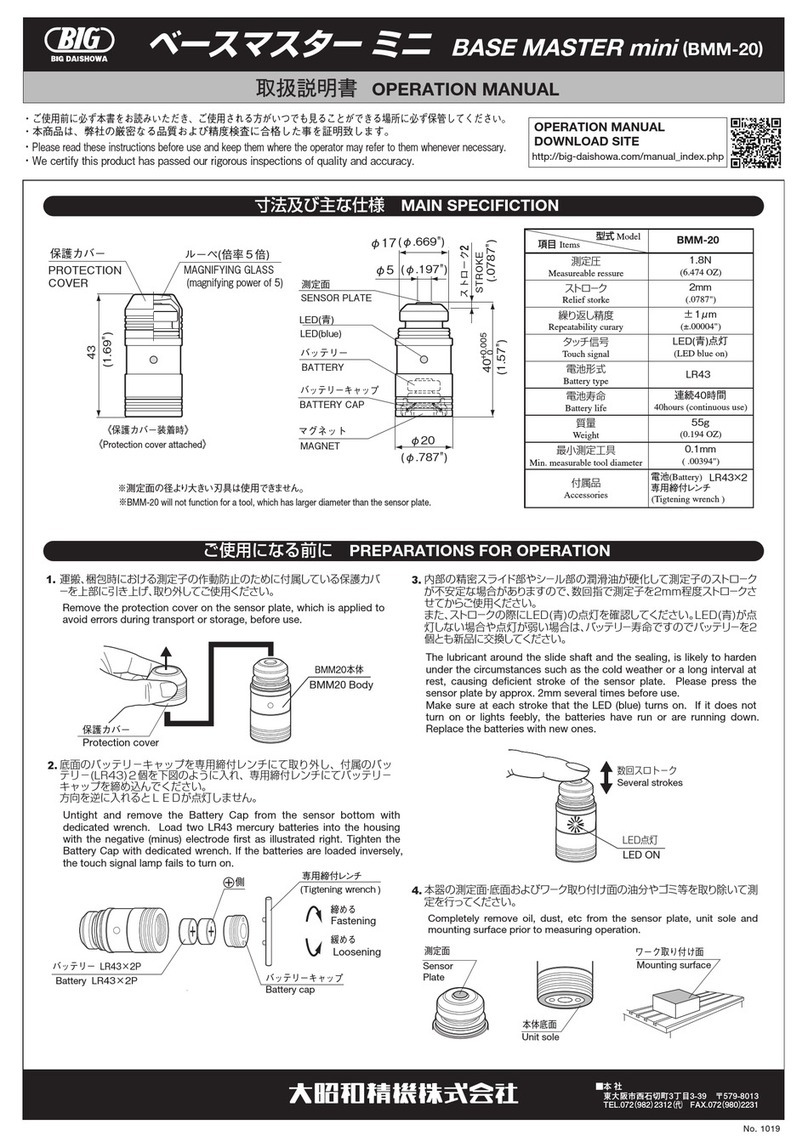

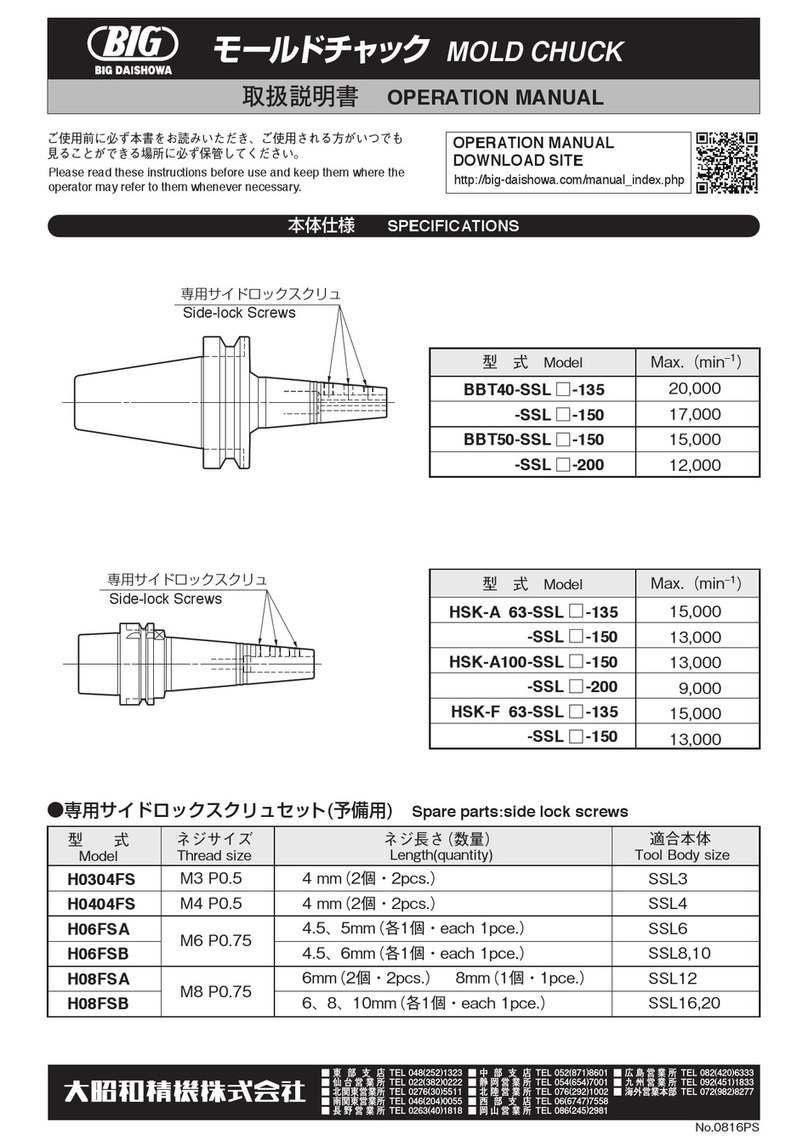

SPECIFICATIONS

UTILIZATION PROCEDURES

1. How to install / remove a cutting tool

2. Initial rotation of the air turbine

3. Spindle speed adjustment

4. Concerning the use of coolants

5. Air nozzles adjustment

6. Pull-stud bolts installation

INSTALLATION

1. Installation of the side through type

2. Installation of the center through type

3. Installation of the manual type

4. Concerning the air supply

OTHER

P 1

P 2

P 3

P 3

P 6

P 6

P 7

P 8

P 8

P 9

P15

P16

P17

P19

Thank you for your purchase of AIR TURBINE SPINDLE.

Please be sure to read this manual before using the product and also keep it in a

location where all the operators may consult it in case of necessity.

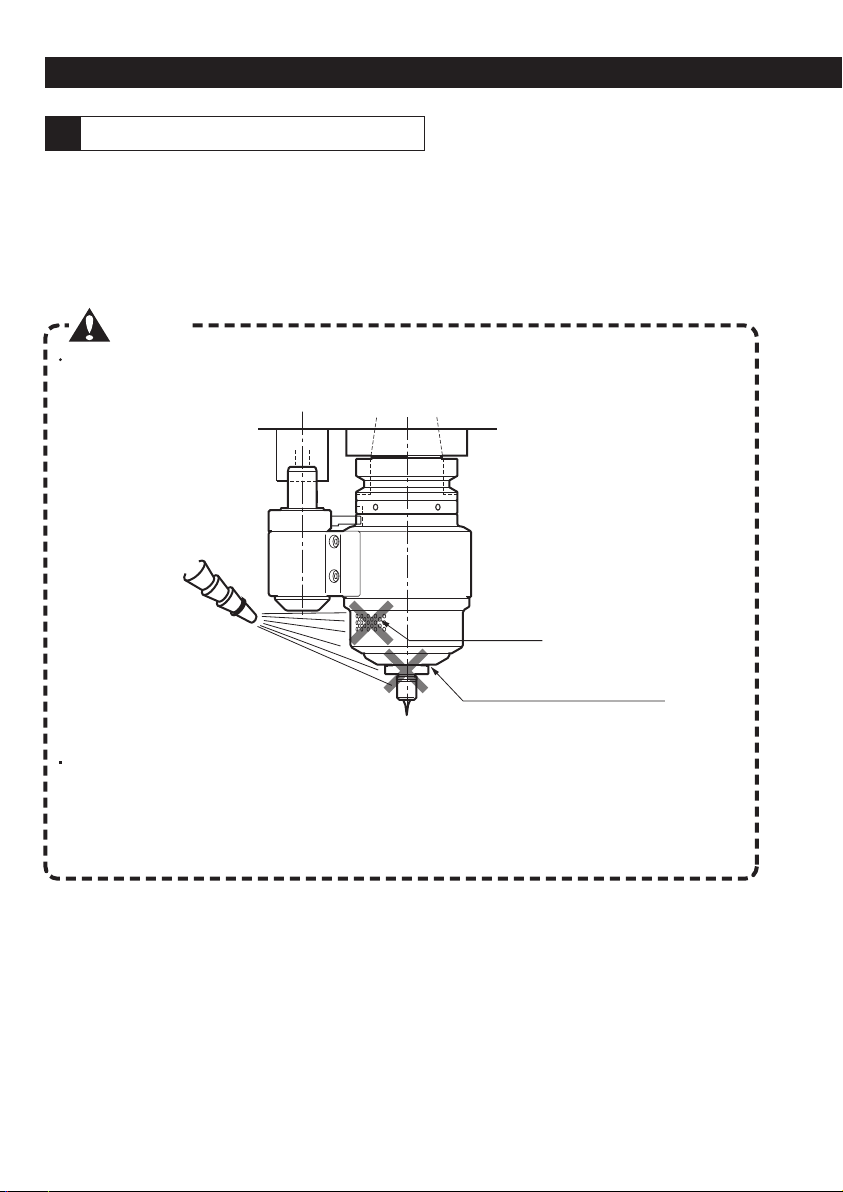

Danger

Since the Air Turbine Spindle rotates at very high speed, if the cutting tool breaks during the

process its fragments, scattering, will cause an extremely dangerous situation. During the

process, utilize a safety cover, etc. in case that fragments scatter out and please also take enough

safety measures for protect yourself. In addition, please always wear protective eyeglasses.

Do not rotate the machine spindle when the Air Turbine Spindle is installed on the machine.

(In case of utilizing the manual type, the machine spindle, by turning, may twist the air tube and

cause severe accidents.)

A low speed rotation for few seconds to orientate the side through type is not a problem.

Caution

Do not use it on machines that have previously used coolants, oil mists, etc.

(Foreign bodies invading the holder may reduce its lifespan or cause breakages.)

In case of using BBT, BCV and BDV shanks, please use pull-stud bolts provided with holes

(sold apart)

.

Caution

Please reduce the ATC speed.

(The impact with the ATC may damage the cutting tool in case of using tools with small diameter.)

Warning

Do not touch the cutting tool or the chuck part while the spindle is rotating.

Do not touch the holder rotating part immediately after have stopped the air supply.

(The holder rotating part will rotate by inertia even after have stopped the air supply. Please check

that the rotating part is not moving in case of touching it.)

Please also respect the below notes in case of using the center through type (RBX5C, RBX7C).

SAFETY NOTES

The following safety notes are arranged in order to use correctly our product and to protect the operator

and other people from possible injuries and damages. In order to distinguish the severity of the injury or

damage, the safety notes are divided in three categories “Caution”, “Warning” and “Danger”. Please be

sure to respect the safety notes since any of them contain important safety matters.

This note indicates that the wrong handling of the product may injury people or

cause material damages.

This note indicates a dangerous situation that if not avoided may cause death or

severe injuries.

This note indicates that the wrong handling of the product may cause death or

severe injuries.

Caution

Warning

Danger

:

:

:

1

2

INTRODUCTION

Caution

About the specifications

About the process, the cutting tool installation, the air adjustments, etc

About the installation on the machine tool and the air supply

About the storage, maintenance

How to install / remove a cutting tool P3

-

P5

1

Maintenance P19

2

Long period storage and re-use P19

1

Pull-stud bolts installation P8

6

Air nozzles adjustment P8

5

Concerning the use of coolants P7

4

Spindle speed adjustment P6

3

Initial rotation of the air turbine P6

2

Specifications P3

1

Concerning the air supply P17

4

In order to be able to use the Air Turbine, it is necessary to install the

machine tool, air supply, etc. Please consult the below

and conduct the installation correctly.

SPECIFICATIONS

INSTALLATION

UTILIZATION PROCEDURES

OTHER

INSTALLATION

321 Installation of

the side

through type

Installation of

the center

through type

Installation

of the manual

type

P9

-

P14 P15 P16

Caution

Before installing a cutting tool, always use, on the internal diameter of the chuck, the internal and

external surfaces of the collet and on the shank of the cutting tool, kerosene or other degreasing

agents and wipe the dirty parts with a cloth.

Warning

The Air Turbine Spindle rotates at very high speed. In case of using cutting tools with a big

unbalance or tools with small diameter and long overhang, due to the centrifugal force, the

cutting tool may break creating an extremely dangerous situation. Use a cutting tool with high

rigidity and make it short as much as possible.

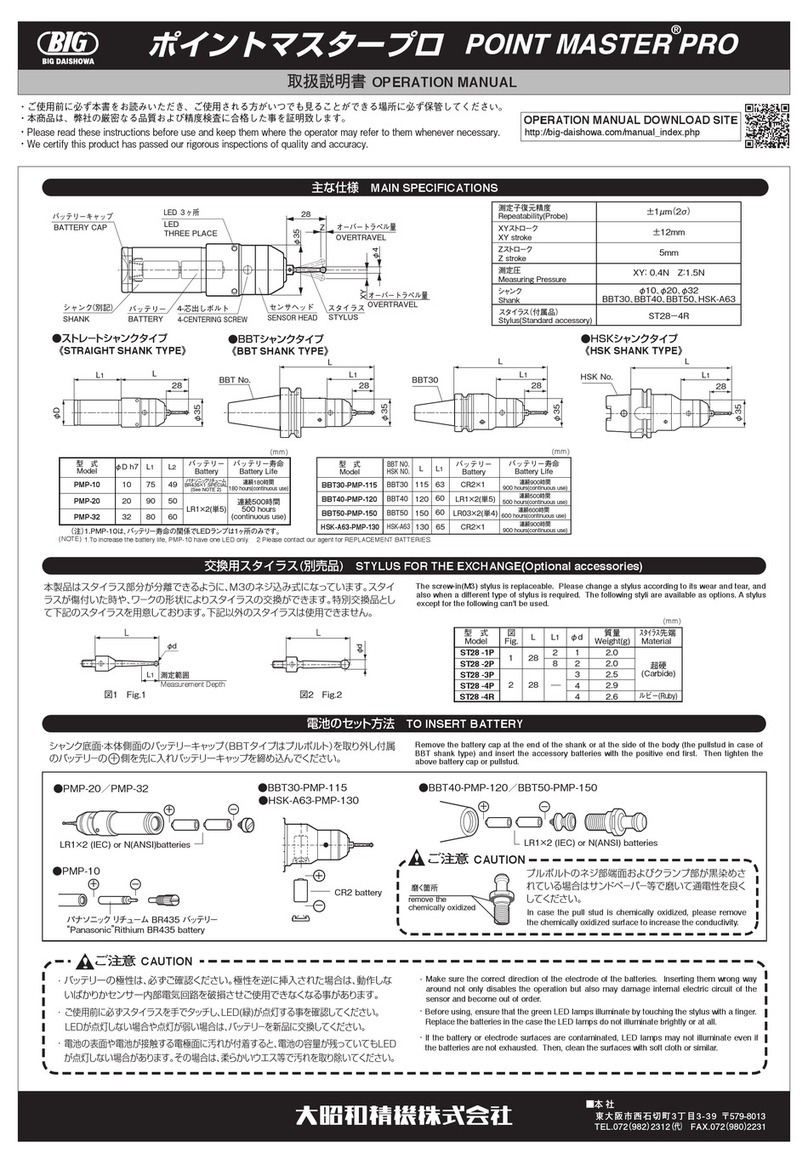

SPECIFICATIONS

UTILIZATION PROCEDURES

Clamping range (mm)

Tool diameter (mm)

Minimum spindle speed (min-1)

Maximum spindle speed (min-1)

Collet

ø0.45

-

4.05

ø1.5 or smaller

About 40,000 (0.3MPa)

About 50,000 (0.6MPa)

NBC4S-dAA (Option)

ø0.45

-

4.05

ø1.5 or smaller

About 60,000 (0.3MPa)

About 80,000 (0.6MPa)

NBC4S-dAA (Option)

Type RBX5 / RBX5C RBX7 / RBX7C

BIG-PLUS is a standard product of BIG Daishowa Seiki. Use machine tools with the

BIG-PLUS trademark to obtain a correct double face contact. BIG-PLUS holders are

also compatible with spindles of standard machines. In this case, check that there

are not projecting objects in the machine spindle’s surface and in the holder’s surface.

How to install / remove a cutting tool

1

Specifications

1

About BIG-PLUS (BBT, BDV, and BCV)

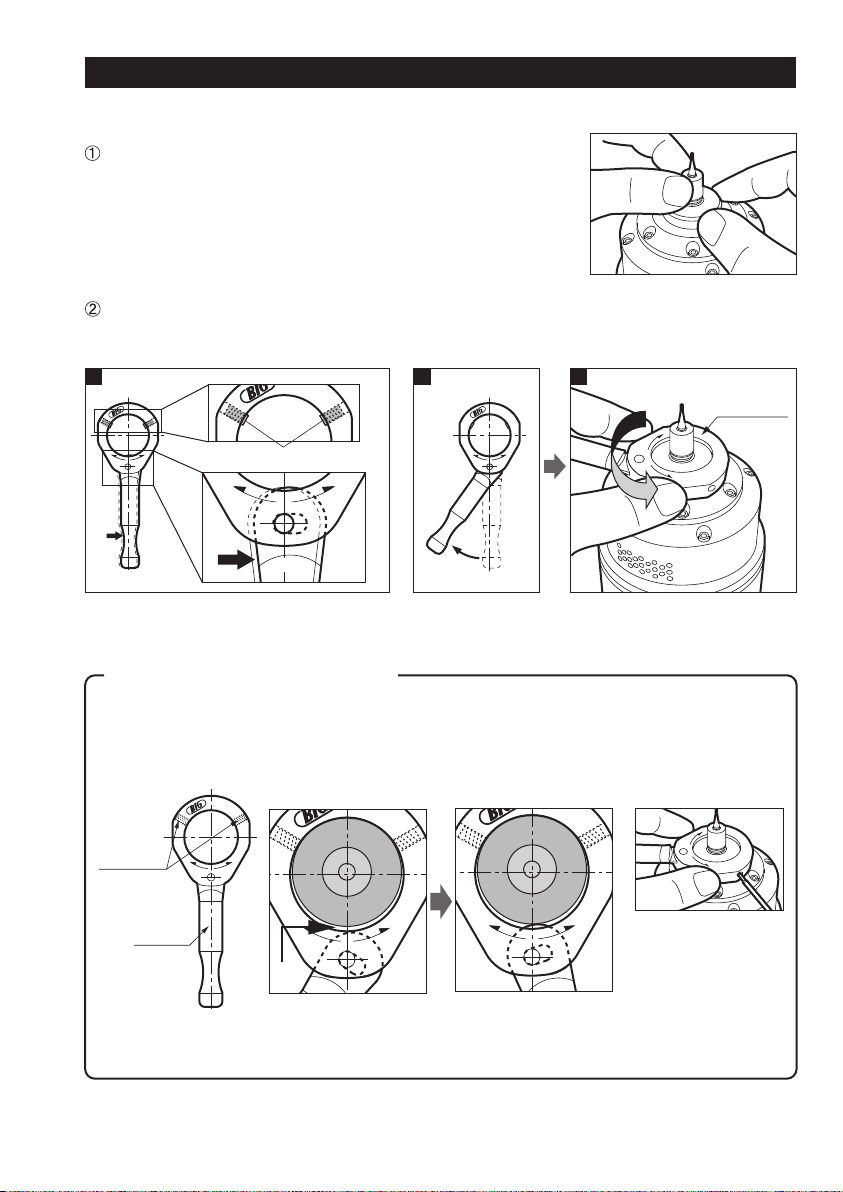

Use the X-Wrench and the Mega Wrench for install/remove the cutting tool. Please consult P4 “How

to use the X-Wrench” regarding how to use the X-Wrench.

Always install the collet in the chuck body

after have inserted it into the nut.

Caution

Insert the collet from the rear part of the nut

and push it until the ribbed part of the collet is

set with a “click”.

It is possible to remove the collet from the nut

by pulling the collet straight along the spindle.

[Collet installation procedures]

[Collet removal procedures]

3

UTILIZATION PROCEDURES

Insert the cutting tool in the collet – nut and tight it lightly with

your hands. Reduce the overhang of the cutting tool as much

as possible. (It greatly influences the T.I.R. and Rigidity.)

Let project a little bit both side-lock screws of the X-Wrench, shift the handle on the “LOCK” side

and move the handle to the left as shown in the picture FIG 2. Then insert the wrench on the

flange part of the spindle and lock the spindle by moving the handle.

OPEN

LOCK

X

W

2

7

C

O

L

K

E

O

P

N

C

O

L

K

E

O

P

N

Let project a little bit both side-lock screws and

shift the handle on the “LOCK” side.

Shift the handle as

shown in the picture.

Insert the wrench on the flange part of the

spindle and move it on the "LOCK"side.

X

W

2

7

C

O

L

K

E

O

P

N

1 2 3

X-Wrench

(XW27)

[How to install a cutting tool]

The X-Wrench is a wrench that secures the spindle of the Air Turbine when tightening the

collet. It clamps the spindle thanks to the eccentric cam structure of the handle.

Please adjust the 2 side-lock screws if it is not possible to lock.

Please adjust the

side-lock screws on the

wrench if it is not

possible to lock.

OPEN

LOCK

How to use X-Wrench (XW27)

X

W

2

7

C

O

L

K

E

O

P

N

Side-lock

screws

Side-lock screws

Handle

When the wrench is

inserted in the spindle When the nut is tighten

X

W

2

7

C

O

L

K

E

O

P

N

Gap

X

W

2

7

C

O

L

K

E

O

P

N

X

W

2

7

The spindle’s flange is

secured thanks to the

side-lock screws and

to the handle’s tip.

4

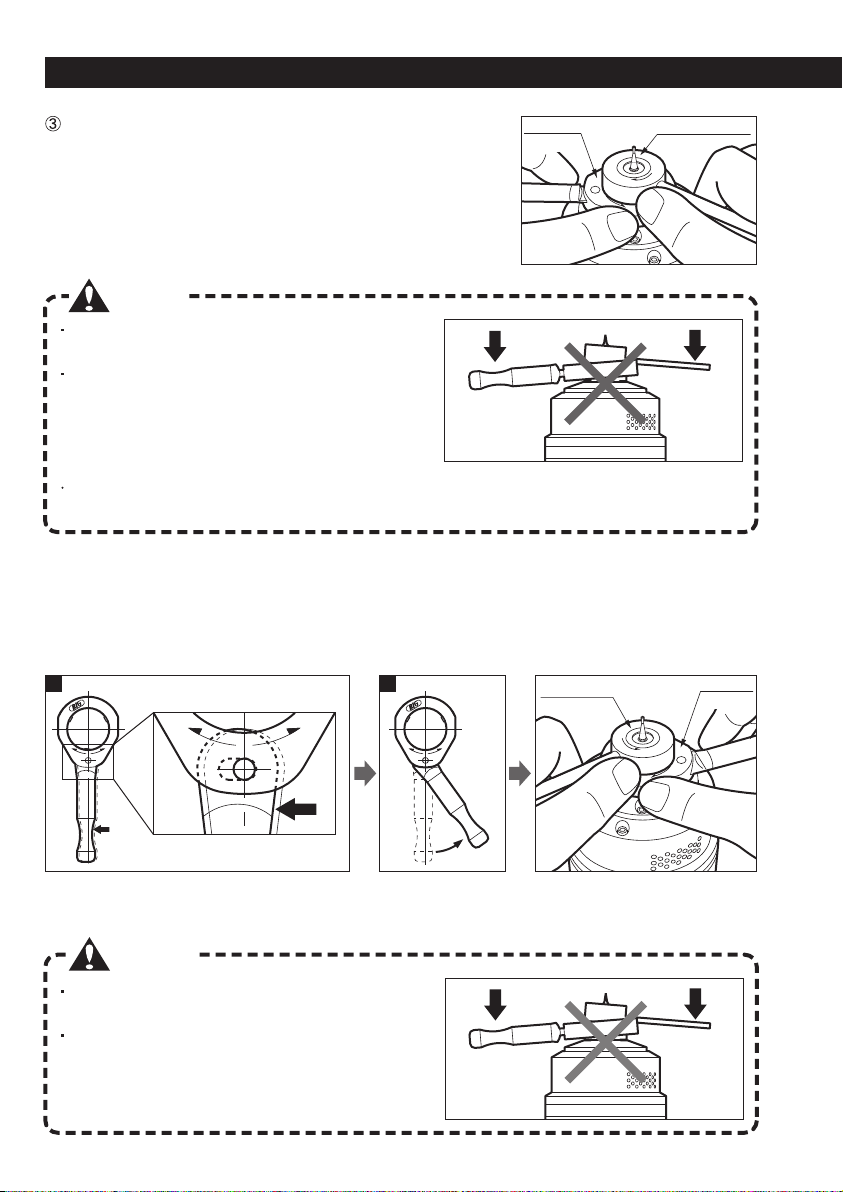

Caution

Be careful to not damage the cutting tool when

inserting the wrench.

Handle the wrenches horizontally. If a force is

applied in the axis direction, the spindle’s bearings

will endure a great load that may rapidly decrease

the lifespan of the spindle.

X-Wrench

MEGA

Wrench

X-Wrench

MEGA

Wrench

UTILIZATION PROCEDURES

[How to remove a cutting tool]

Always respect the recommended tightening torque when clamping a cutting tool.

Over-tightening may worsen the T.I.R. accuracy and damage the collet and the nut.

In case of micro-diameter cutting tools processes, check, after the installation of the cutting tool,

the T.I.R. at the base of the cutting tool’s shank.

Insert the MEGA Wrench on the nut with the “LOCK” seal

facing up and execute the tightening process with both hands.

(Recommended tightening torque: 3N・m)

OPEN

LOCK

MEGA Wrench

(MGR12)

MEGA Wrench

(MGR12)

C

O

L

K

E

O

P

N

X

W

2

7

C

O

L

K

E

O

P

N

X

W

2

7

C

O

L

K

E

O

P

N

21

LOCK

LOCK

OPEN

OPEN

Shift the handle to the “OPEN” side. Shift the handle as

shown in the picture.

Caution

Be careful to not damage the cutting tool when

inserting the wrench.

Handle the wrenches horizontally. If a force is

applied in the axis direction, the spindle’s bearings

will endure a great load that may rapidly decrease

the lifespan of the spindle.

X-Wrench

(XW27)

X-Wrench

(XW27)

To remove a cutting tool, invert “LOCK” and “OPEN” and unfasten the nut with both wrenches

following the same procedures.

5

6

Caution

The cutting tool and the chuck while rotating are extremely dangerous. Do not touch them.

40,000

45,000

50,000

60,000

70,000

80,000

30 sec.

25 sec.

20 sec.

Target speed

(min-1)

RBX5 / RBX5C RBX7 / RBX7C

[Warming-up operation]

[Acceleration time]

It is recommended to execute a warming-up operation

to lubricate with grease the internal parts of the

bearings when the unit is used for the first time or if the

unit is not used for more than 1 week. Perform the

warming-up operation according to the air pressure

indicated on the table.

After have started the air supply, it is necessary to

wait several seconds to reach the selected speed.

Start the process according to the time indicated

on the table. (The table indicates the time

required to reach the target speed after have

adjusted the air pressure and started the air

supply.)

Air pressure for the

warming-up operation

Warming-up time

0.3MPa

More than 10 min.

Time required

for reaching the

target speed

Initial rotation of the air turbine

2

38,000

40,000

43,000

45,000

47,000

48,500

50,000

58,000

62,000

66,000

70,000

73,000

77,000

80,000

0.30

0.35

0.40

0.45

0.50

0.55

0.60

Spindle speed (min-1)

RBX5 / RBX5C RBX7 / RBX7C

Air pressure

(MPa)

Caution

The air pressure should be above 0.3MPa.

If the air pressure is low, the torque will be insufficient and the process unstable.

Spindle speed adjustment

3

It is possible to adjust the speed of the Air Turbine Spindle by controlling the air pressure with a

regulator. Please consult the below table. (The values indicated in the below table are reference

values. Depending on the model, the speed may differ by 5%.)

Please refer to the table indicating the air pressure and the spindle speed on the body of the Air

Turbine Spindle.

7

Caution

Since the air purge does not work when the air is not supplied to the Air Turbine Spindle,

under this situation, coolants, etc. may be able to invade the internal parts. For this reason,

start supplying the air to the turbine before starting the application of coolants and oil mists. In

case of stopping the application of the coolant, please execute the operation continuing to

supply the air to the turbine.

The Air Turbine Spindle, by using air purge for moving the turbine, is built to prevent coolants and oil

mists from invading the internal parts of the holder. However, if the coolant is applied directly on the

spindle body, it may invade its internal parts.

Pay attention to not apply the coolant directly on the body of the Air Turbine Spindle.

Coolants and foreign bodies, by invading the internal parts of the unit, will reduce the lifespan of the

bearings.

Concerning the use of coolants

4

UTILIZATION PROCEDURES

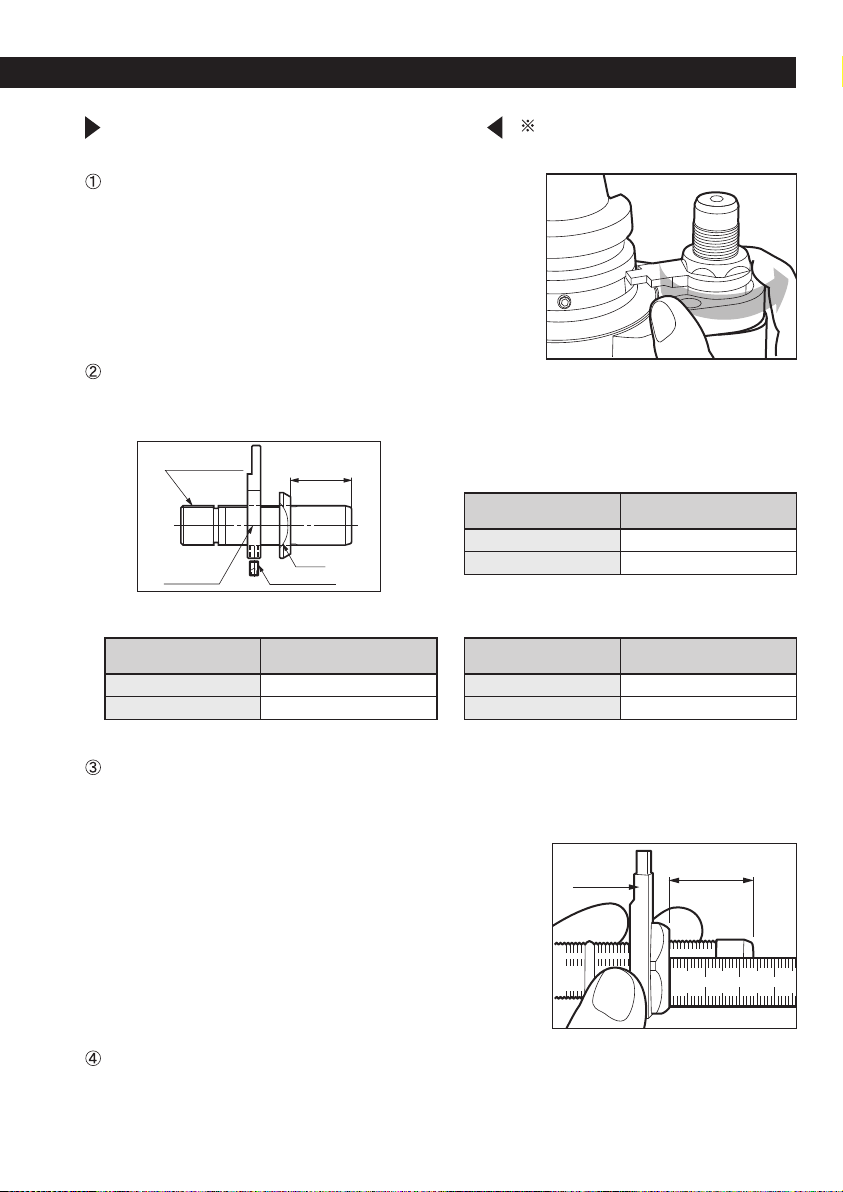

Air vents

Gap between the case and

the flange of the spindle

Pay attention to not apply the coolant directly on the Air Turbine Spindle. In particular

do not apply the coolant on the air vents and on the gap between the case and the

flange of the spindle.

8

BBT30

BBT40

BBT50

15

-

20

45

-

65

85

-

115

BT No. Tightening torque (N m)

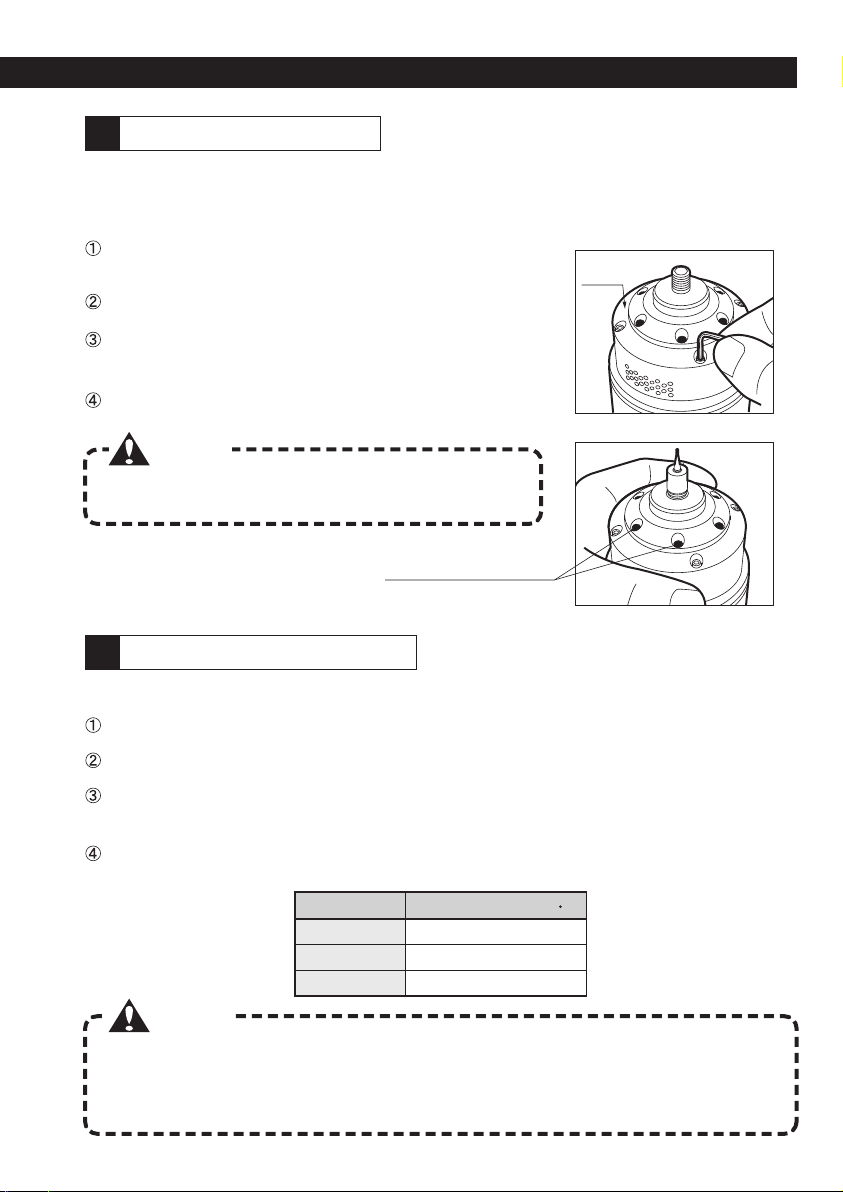

Caution

Caution

Do not loosen the 6 red-painted bolts. It may become

cause of damages or worsen the accuracy.

The direction of the air nozzles can be set in 4 directions at 90˚ each. If, due to the emitted air, the

application of the coolant is inadequate, please follow the below procedures to adjust the direction of

the air nozzles.

Loosen the 4 fixing bolts of the muffler case.

(Refer to the below safety notes)

Remove the 4 bolts.

Adjust the direction of the air nozzles by rotating the

muffler case matching the positions of the bolts’ holes.

Re-tight firmly the bolts.

Muffler

case

Never loosen the (6) bolts.

Air nozzles adjustment

5

Pull-stud bolts installation

6

Always respect the recommended torque when clamping the pull-stud bolts. In particular for

BBT30, exceeding the recommended values will easily bulge the taper, due to the thickness of

the small part of the taper. Since, when the Air Turbine Spindle is used, the spindle of the

machine does not rotate, the clamping torque of the pull-stud bolts is a little lower than normal.

Follow the below procedures to install the pull-stud bolts.

Check if the machine and the pull-stud bolts are compatible.

Clean the installation holes of the taper and remove the grease of the pull-stud bolts.

Apply an anti-loosening solution. (Refer to the operation manual of the anti-loosening manufacturer

for details regarding the application method.)

Always use the torque wrench (available on the market) and clamp following the below

recommended torque.

9

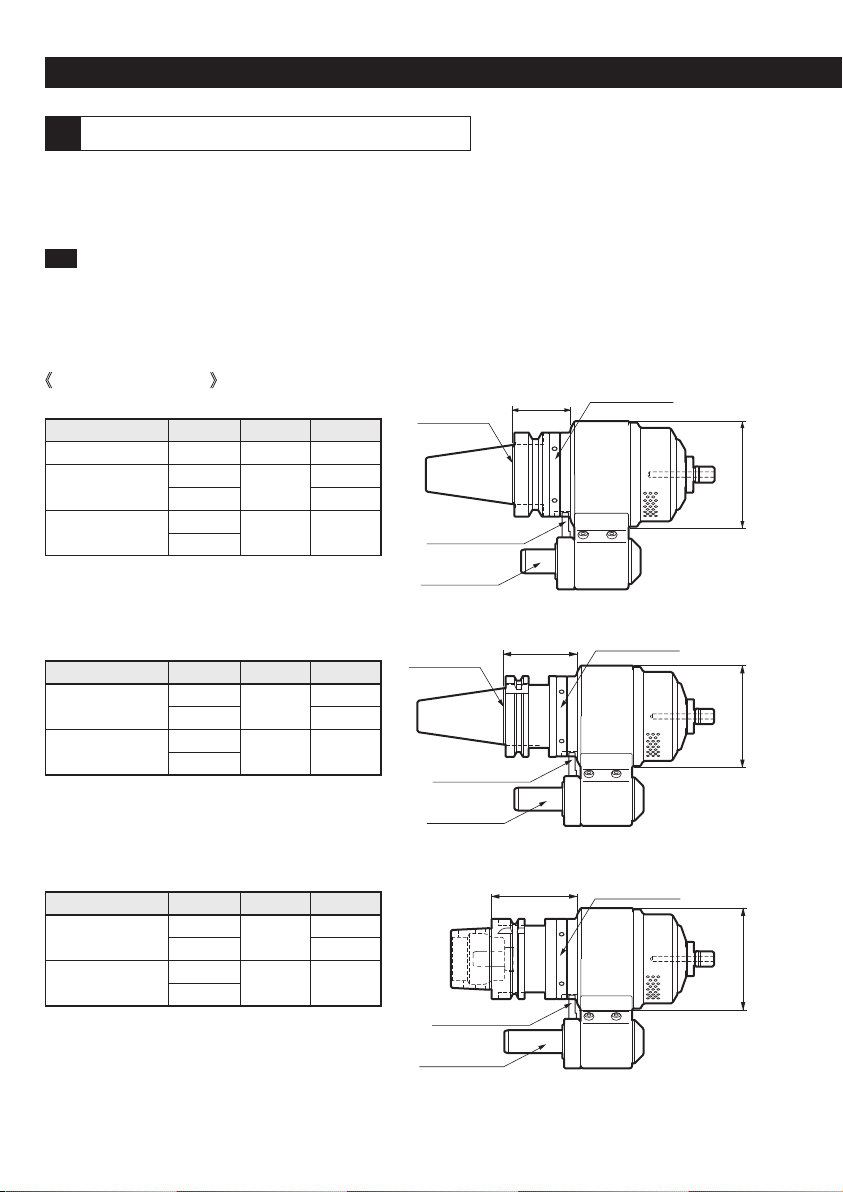

INSTALLATION (Side through type)

RBX7

RBX7

RBX5

RBX7

RBX5

80

80

96

100

BBT30

BBT40

BBT50

28

43

58

TypeShank Size K1øD

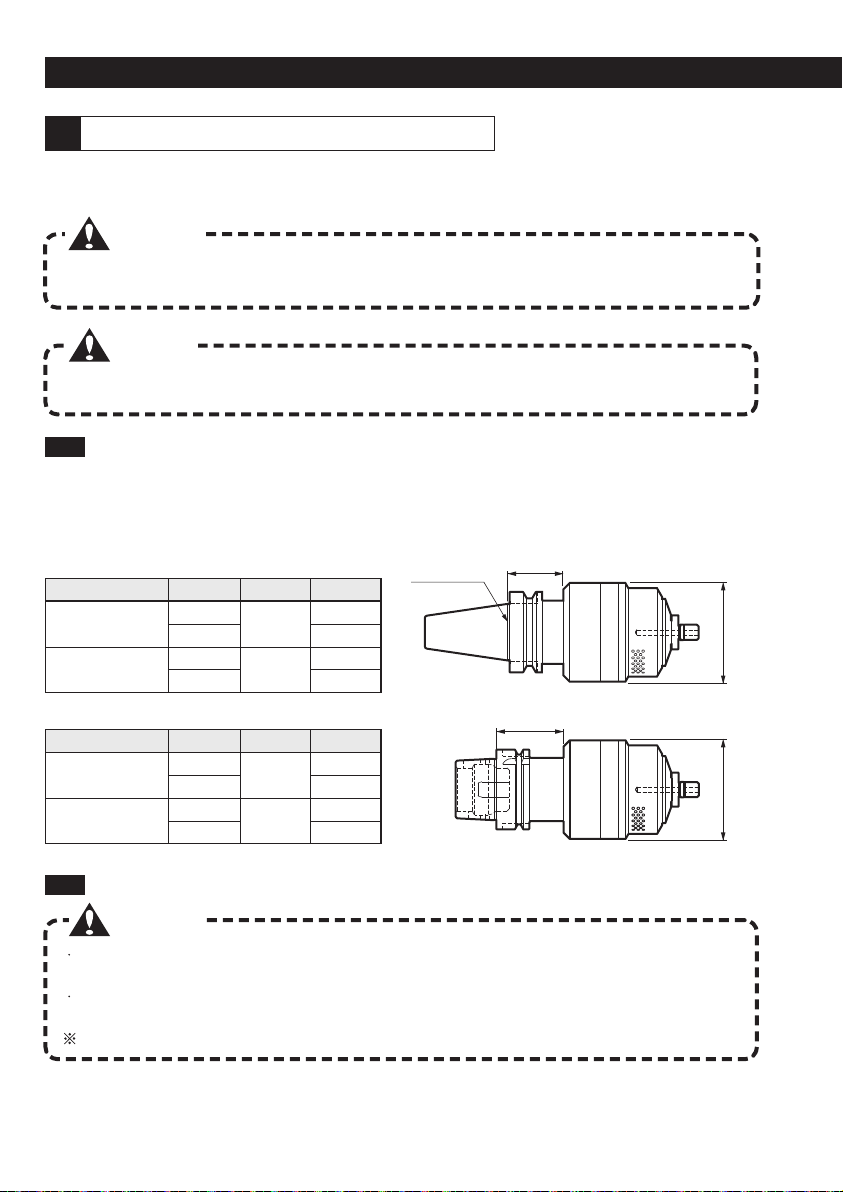

The Air Turbine Spindle is set and shipped following the machine model indicated at the

moment of the purchase and consulting our past results. However, for safety reasons, be

sure to check the following notes before the installation on the machining center.

Use as base the interference values written in the operation manual of the machining center and the

measures of K1and øD of the Air Turbine Spindle to check that there is no interference between the

ATC arm of the machining center and the Air Turbine Spindle. Please inquiry the machine

manufacturer in case of unclear interference.

1-1 ATC arm interference check

Side through type

RBX7

RBX5

RBX7

RBX5

80

96

100

#40

#50

57

62

RBX7

RBX5

RBX7

RBX5

80

96

100

HSK-A63

HSK-A100

67

72

øDøDøD

K1

K1

K1

Gauge line

Indexing ring

Indexing ring

Indexing ring

Installation of the side through type

1

Locating collar

Locating pin

Gauge line

Locating collar

Locating pin

Locating collar

Locating pin

TypeShank Size K1øD

TypeShank Size K1øD

BBT shank

BCV, BDV shank

HSK shank

1-2 Locating block of the machine spindle

10

The locating block is necessary for the air supply. Since the measures and the shape of the locating

block depend on the model of the machining center, control, by checking the operation manual,

drawing and materials of the machine that the block is actually suitable for the machine’s spindle.

Caution

A tap hole for plumbing laterally the air is always necessary for the locating block.

When installing the air to the locating block, use an air filter. An air rich with moisture and

foreign particles may damage the bearings.

In case of using the ATC, before installing the Air Turbine Spindle release one time the air

for clean the ditches and the internal parts of the block.

To the customers that currently use our High Jet Holder, High Spindle, etc and

have already installed the locating block in the machines

Even if the locating block for the Air Turbine Spindle and the locating block for the holder of the

High Jet Holder, High Spindle, etc have the same shape, please avoid a shared use. In case of

the Air Turbine Spindle, the air supplied from the locating pin has to be pure. If a locating block

that has used in the past coolants, is used for the Air Turbine Spindle, the coolant invading the

Air Turbine Spindle, may reduce its efficiency and life due rust, etc.

18+0.03

+0.01

19.6±0.02

9±0.1

9±0.1

13±0.02

10˚

10˚

10˚

10˚

1.3

12

ø9.9

ø5

ø6.7

O ring’s ditch

O ring’s ditch

+0.03

+0.01

0

-0.1

ø16.6 0

-0.1

ø12+0.1

0

ø7

+0.1

0

0

-0.1

20

-0.1

For #30

For #40 - #50

PT tap hole

Air supply port

PT tap hole

Air supply port

11

Caution

Be sure to do the checks when performing the manual installation.

If there are errors in the settings, the Air Turbine Spindle may be damaged during the ATC.

INSTALLATION (Side through type)

After the orientation (M19) of the machining center’s spindle, fix the drive key’s position and install

manually the Air Turbine Spindle on the machine. At this time check that the drive key and the

locating pin enter without problems.

Execute the ATC after have checked the procedures from 1-1 (P9) to 1-5 (P11) and the below attention notes.

Caution

Please reduce the ATC speed.The impact with the ATC may damage the tool in case of using

tools with small diameter.

Do not rotate the machine’s spindle at high speed or for a long time when the Air Turbine

Spindle is installed in the machine.

(When the unit is fixed on the case with the locating pin, since it is built to let rotate only the

internal part of the holder even if the machine’s spindle is rotated, high speed and long time

rotations will lead to damages due being stuck, etc.)

It is not a problem to rotate the machine’s spindle for the orientation at the moment of the ATC.

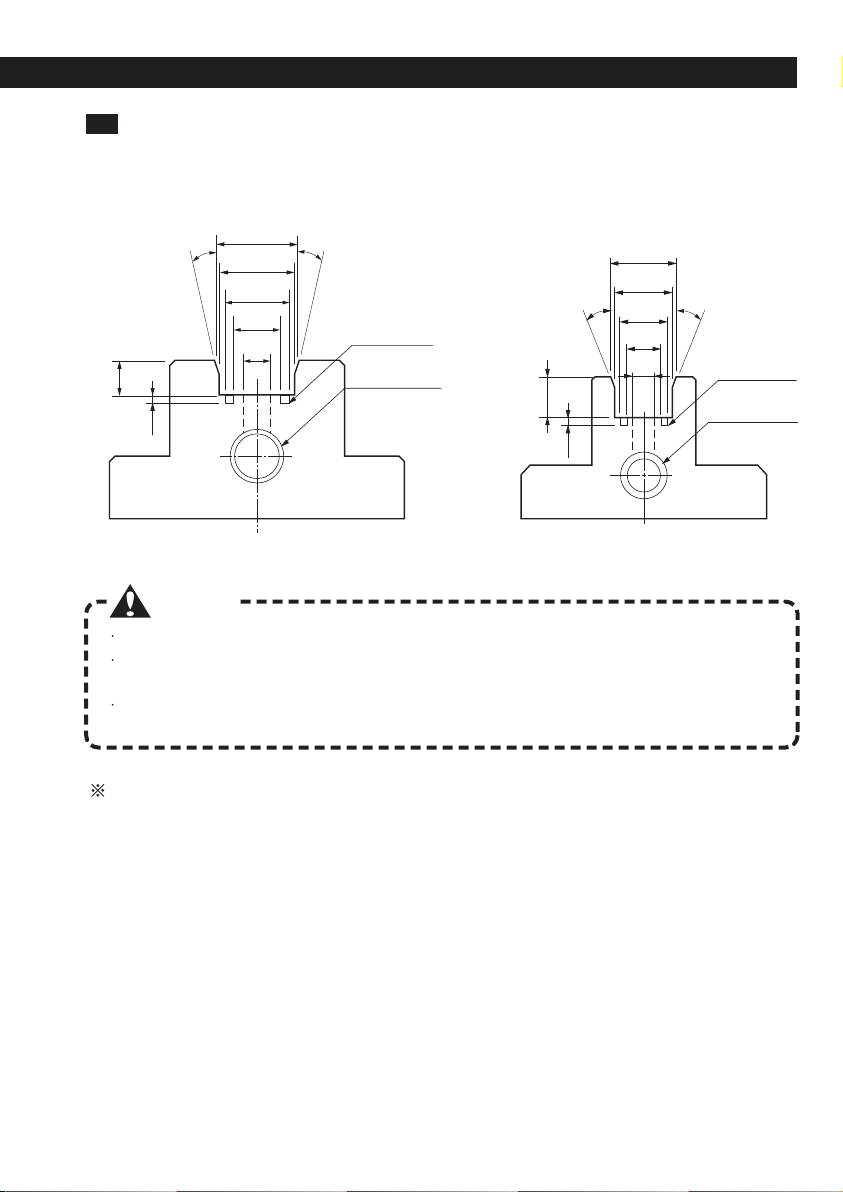

Pay attention that a clutch movement of the locating pin higher

than the prescribed amount (6mm) will exert an eccentric load

on the case and add an anomalous load to the bearings leading

to heat and a reduction of the lifespan. Pay also attention that

a movement of the locating pin inferior to the prescribed

amount will not release the lock mechanism. If the spindle is

rotated in this situation the Air Turbine Spindle may be

damaged. The correct position has a gap of 2mm and 1mm on

each side of the clutch. (See the figure on the right)

Check that the setting measures of the “Inspection sheet” included with the Air Turbine Spindle

match the values of the machine’s spindle nose.

1-3

Please return the product to us since the

modifications cannot be done by the customer.

Please read at P12 “How to adjust the setting

length H” and proceed with the adjustments.

Please read at P13 “How to adjust the setting

angle ” and proceed with the adjustments.

S

H

Gap 8mm

Gap 2mm Gap 1mm

Before the

installation

Settings check

1-4 Checking by actual installing

1-5 Length settings check

1-6 Regarding the ATC

If the pitch S is different

If the setting length H is different

If the setting angle is different

If the gaps differ, please read at P12 “How to adjust the

setting length H” and proceed with the adjustments.

Amount of the clutch

movement 6mm

After the

installation

12

BBT40

BBT50

B(mm)=32-H

B(mm)=47-H

Shank size Length of B

HSK-A63

HSK-A100

B(mm)=56-H

B(mm)=61-H

Shank size Length of B

#40

#50

B(mm)=46-H

B(mm)=51-H

Shank size Length of B

How to remove the locating pin

Keeping pushed the locating pin (to release the lock

mechanism), manually rotate the taper until the tip of the

locating collar is located in the large notch of the indexing

ring. Rotate the locating pin until it is positioned in the large

notch of the indexing ring and pull it out. Also remove at the

same time the locating collar and the spring.

How to calculate the length of the locating pin

Substitute the setting length H of the used machine with the following formula and calculate the

length B of the locating pin.

How to adjust the length of the locating pin

Loosen the set screw of the locating collar then loosen the nut and the locating collar itself.

Adjust the nut and set the pin length to B ±0.3mm (Refer to the above figure).

After the adjustment, fix the nut and tighten the locating

collar. Apply the anti-loosening solution (Toagosei:

Arontight US equivalent) to the set screw of the locating

collar, insert a brass shim and tighten the screw completely

with an L-wrench.

How to install the locating pin

Install the locating pin by inverting the removal procedures.

In case of BBT shanks

In case of BCV, BDV shanks In case of HSK shanks

Locating pin

Nut

Set screw

B(mm)

10 20 30

B

How to adjust the setting length H It is not possible to

adjust the #30 type

Locating

collar

Locating

collar

13

INSTALLATION (Side through type)

Caution

If the 4 lock bolts are not uniformly and gradually clamped, the indexing ring will be loose causing

ATC problems.

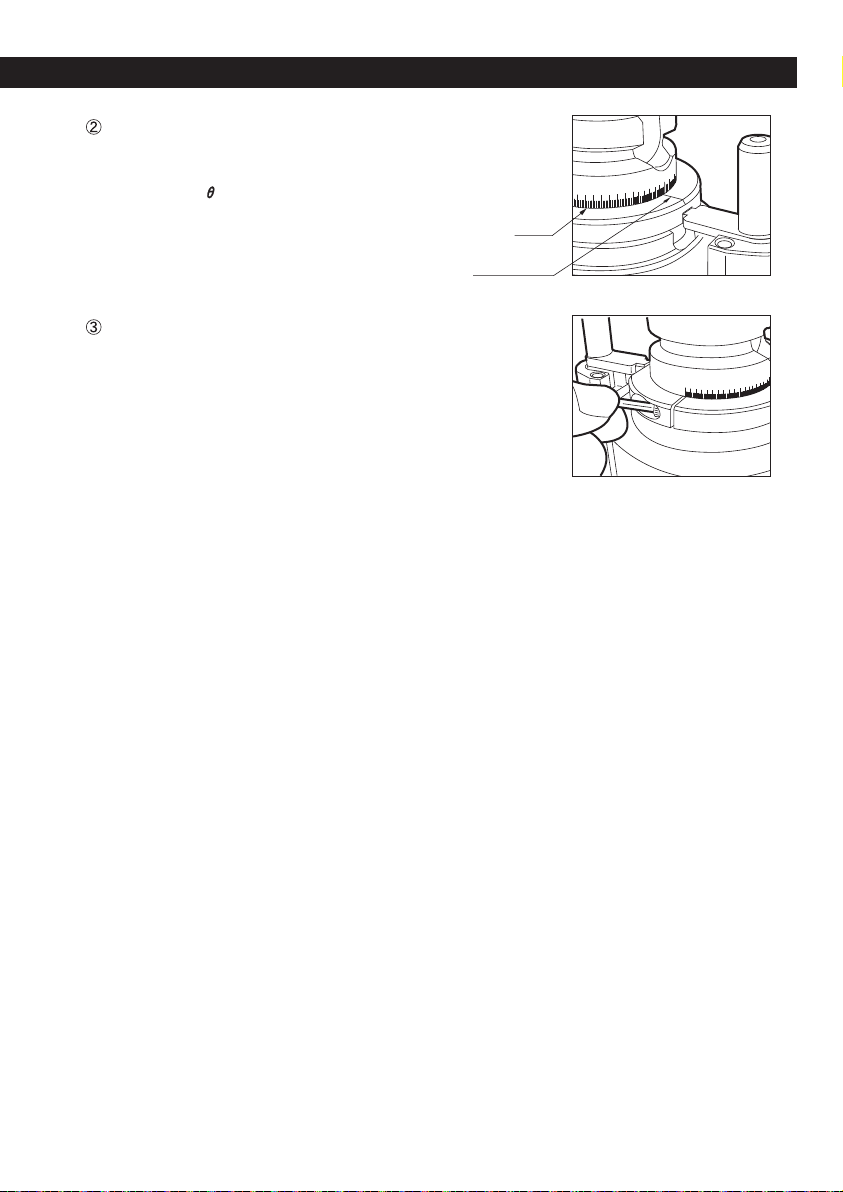

Side lock removal

Loosen the 4 lock bolts of the indexing ring.

(Refer to the figure on the right)

Setting angle adjustment

Check that the indexing ring rotates around the

circumference. Adjust the scale of the indexing ring to

the setting angle used on your machine by matching

exactly the line marker on the main body.

(Refer to the figure on the right)

Tightening the side lock

After the adjustment, apply the anti-loosening solution (Toagosei: Arontight US equivalent) to the

lock bolts and tighten firmly and uniformly the 4 lock bolts. In this moment, gradually clamp the 2

opposite locations.

#40, #50 types

Side lock removal

Loosen the 2 lock bolts of the indexing ring.

(Refer to the figure on the right)

+30゜

-

30゜

-

60゜

-

90゜

How to adjust the setting angle

#30type

Line

marker

Lock bolts

Indexing ring

line marker

14

Setting angle adjustment

Check that the indexing ring rotates around the

circumference. Adjust the scale of the indexing ring to the

setting angle used on your machine by matching exactly

the line marker on the main body.

(Refer to the figure on the right)

Tightening the lock bolts

After the adjustment, apply the anti-loosening solution

(Toagosei: Arontight US equivalent) to the lock bolts and

tighten firmly and uniformly the 2 lock bolts.

Scale

2-1 ATC arm interference check

2-2 Regarding the ATC

15

INSTALLATION (Center through type, Manual type)

Caution

Please reduce the ATC speed. The impact with the ATC may damage the tool in case of

using tools with small diameter.

Do not rotate the machine’s spindle at high speed or for long time when the Air Turbine

Spindle is installed in the machine.

It is not a problem to rotate the machine’s spindle for the orientation at the moment of the ATC.

RBX7C

RBX5C

RBX7C

RBX5C

78

96

78

96

HSK-A63

HSK-A100

53

58

RBX7C

RBX5C

RBX7C

RBX5C

78

96

78

96

BBT40

BBT50

43

53

TypeShank size K1øD

TypeShank size K1øD

BBT shank

HSK shank

øD

K1

K1

øD

Gauge line

For safety reasons, be sure to check the following notes before the installation on the

machining center.

Use as base of the interference values written in the operation manual of the machining center and

the measures of K1and øD of the Air Turbine Spindle to check that there is no interference between

the ATC arm of the machining center and the Air Turbine Spindle. Please inquiry the machine

manufacturer in case of unclear interference.

Installation of the center through type

2

Caution

Do not use it on machines that have previously used coolants, oil mists, etc.

(Foreign bodies invading the holder may reduce its lifespan or cause breakages)

Caution

In case of using BBT, BCV and BDV shanks, please use pull-stud bolts provided with holes

(sold apart).

3-1 Anti-rotation bar installation

3-2 Installation on the machine

16

Warning

Be sure to stop the rotation.

When using the Air Turbine Spindle, it is not necessary to fix it using an anti-rotation bar,

however, if the machine’s spindle is rotated by mistake, this may twist the air tube causing severe

accidents.

Insert, as shown in the figure on the

right, the anti-rotation bar with its flat

part facing up in the anti-rotation block

and perform a side lock.

Make a “stop bar” and install it on the machine surface.

Installation of the manual type

3

Anti-rotation

block

Anti-rotation

bar

Stop bar

NameName

NumberNumber

FunctionFunction

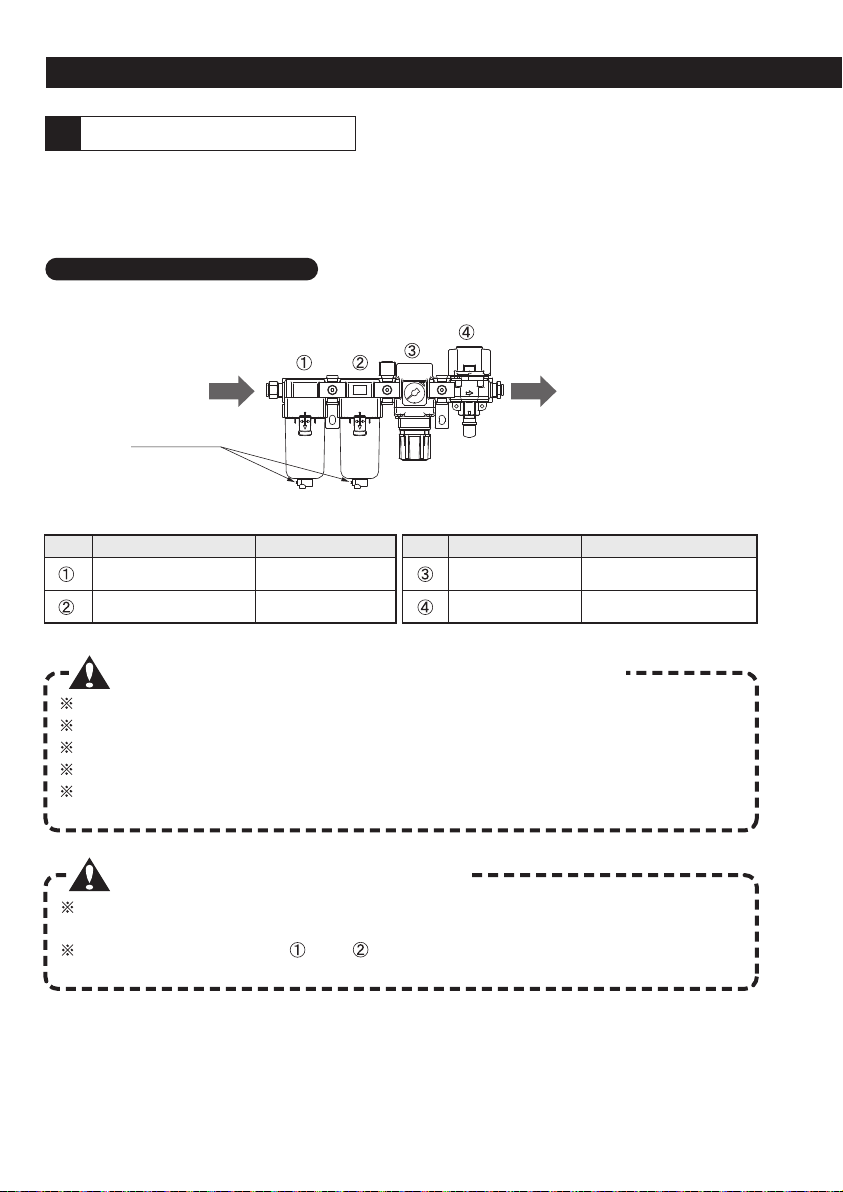

Do not use air that contains large quantities of drain (moisture, oil, dust).

Install the device vertically in order to have the drain valves pointing downward

Arrange enough space under the “Air filter regulator” for changing the elements and for draining.

Before doing the plumbing, clean the tubes removing chips, coolants and foreign bodies.

Prevent tensional and bending moments on the “Air filter regulator” other than its own weight.

(Pay attention in particular when using pipes like steel pipes, etc., that do not have flexibility.)

Cautions regarding the maintenance

Since the Air Turbine Spindle uses compressed air as driving source, if an air rich with moisture and

foreign bodies is used, the bearings may rust or get stuck reducing the tool life. In order to use pure

air, the following device is recommended. Even when using the center through type, always use a

filter (mesh: 0.01mm or above) to supply pure air from the machine’s spindle.

Mist separator Mesh: 0.3µm

Mesh: 0.01µmMicro mist separator

Precision regulator

ON/OFF valve

Air pressure adjustment

(spindle speed)

Open/close the air

(no-grease type)

Before using the device always check the amount of drain inside the regulator and the dirt of

the plastic cases. If the plastic cases are very dirty clean them using a neutral detergent.

Replace the filter elements and with new ones after 2 years of use or if the air

pressure is lower than 0.1MPa. (Consult P18 Element replacement)

INSTALLATION

Concerning the air supply

4

17

Cautions regarding the installation and the plumbing

IN OUT

Drain valves

Air filter regulator (Model: XF1)

This device is necessary to remove foreign bodies from the air supplied to the spindle

and to regulate the air pressure.

Shop’s air

(Tube diameter:ø10)

To the Air Turbine Spindle

(Tube diameter:ø8)

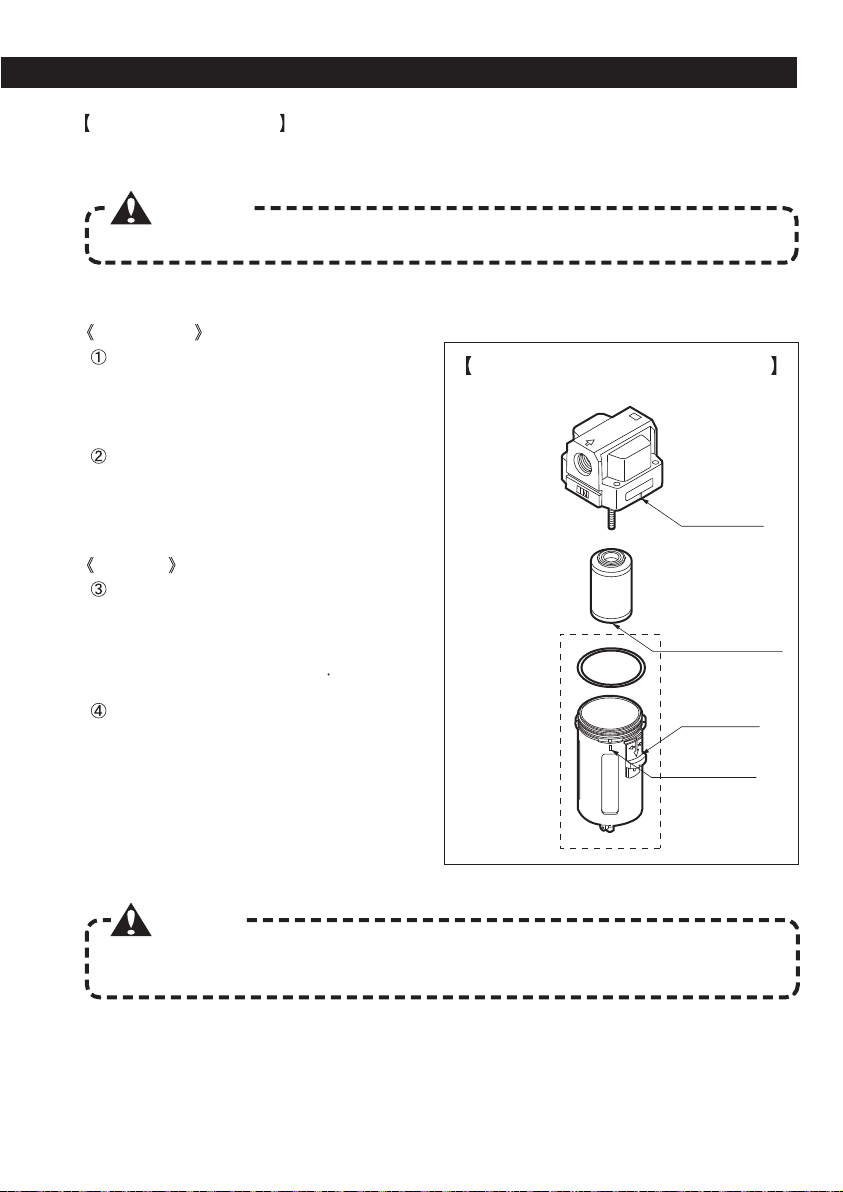

Warning

Before replacing the elements always check that there is no pressure inside the device.

Warning

After have done the replacement work, please always check that there are no external leaks

and that the functions are adequate before carrying out the installation.

In case of not being able to drain a great volume due to low pressure, the element of the (micro) mist

separator is stuck. Replace the element assembly (sold apart) following the below procedures.

Procedures

Case assembly removal

Push down the lock button while pulling

up the case assembly and then rotate it

in one direction for 45° to remove it.

Element removal

Apply round pincers to the cylindrical

part of the element and turn them to the

left for removing the element.

Element installation

Apply round pincers to the cylindrical

part of the element and turn them to the

right for installing the element.

Clamping torque 0.35±0.05 [N m]

Case assembly installation

Insert the case assembly in the body

assembly aligning the respective line

markers and then rotate it in one

direction for 45° (until the lock button

slides up) to mount the case assembly.

Be sure to check that the lock button

is in the upper position.

Body

assembly

Element

assembly

Case

assembly

Line marker

Line marker

Cylindrical part

for the round pincers

Lock button

18

Element replacement

Disassembly

Assembly

Mist separator assembly drawing

No.0217

Caution

Do not apply the anti-rust oil on the body (muffler case, locating pin, etc.) of the unit.

The oil invading the unit may lower the life of the bearings.

Protect the air inlet so that foreign bodies, dust, etc. do not penetrate.

Apply anti-rust oil on the internal and external diameters of the chuck and on the taper shank.

Check that the pull-stud bolts, the internal and external diameters of the chuck and the taper

shank are not affected by rust.

Remove completely the anti-rust oil.

Before connecting the air tube to the unit, release the air to check that moisture, etc. is not

present inside the tube.

Perform a warming-up operation.

It is not necessary to oil the internal parts of the unit. We will grease the unit when doing the

overhaul.

Never disassemble or modify the unit. Otherwise, it will be considered outside the normal

overhaul or repairs.

It is recommended to perform the overhaul after 1 year from the first operation or when the

operation time exceeds 2000 hours. The overhaul is also recommended if the unit is not used

for a long period of time (1 year or more). Return the unit through our distributors for the

overhaul. The overhaul is charged.

Stop immediately the operation and contact us in case of strange noises and nasty smells

coming from the Air Turbine Spindle or in case of strong vibrations.

In addition do not continue to operate with strong vibrations (chattering process).

19

Long period storage and re-use

1

Maintenance

2

OTHER

In case of storing the device for a long period of time

Greasing

Disassembly and modifications

Overhaul

In case of strange noises, nasty smells and vibrations

In case of re-use the unit after a long period of storage

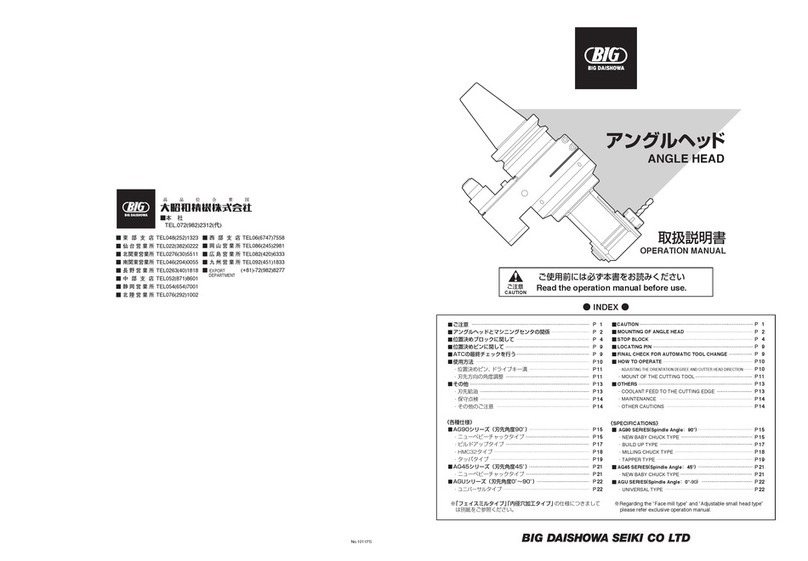

EXPORT DEPARTMENT

TEL (+81)-72-982-8277

E-mail [email protected]

This manual suits for next models

3

Table of contents

Other BIG Industrial Equipment manuals

BIG

BIG Point Master Pro User manual

BIG

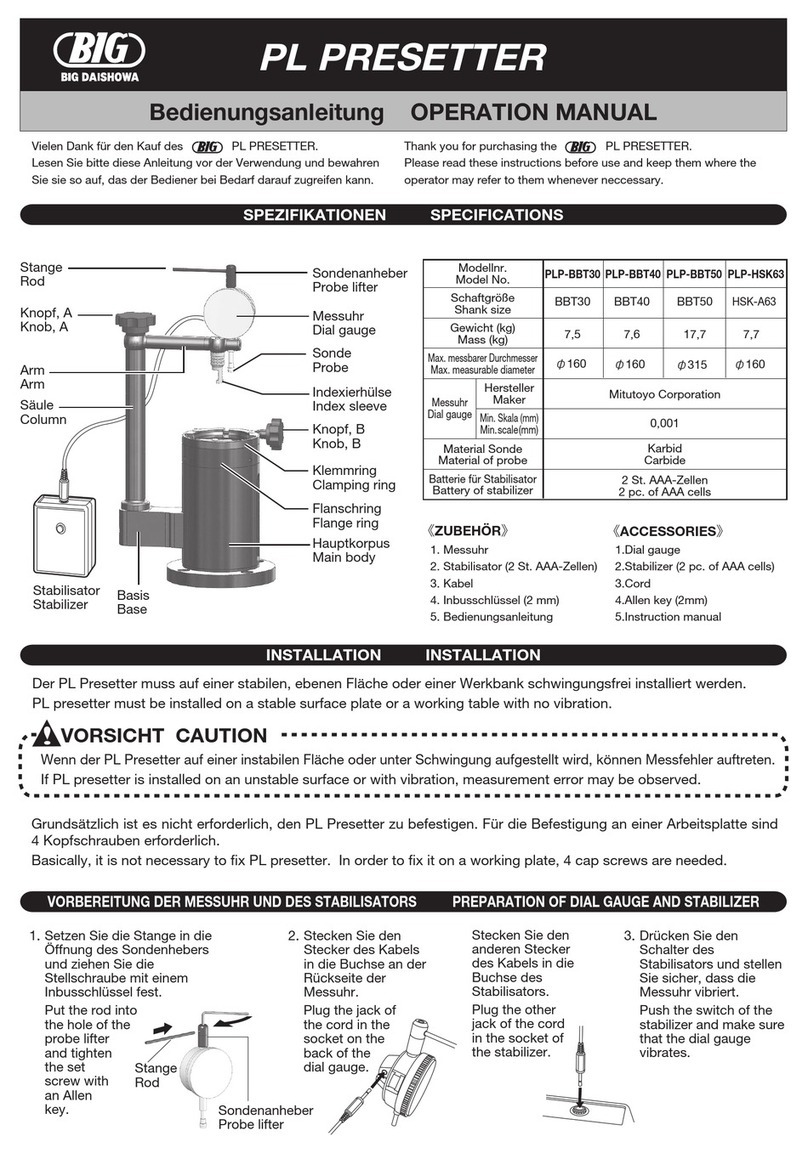

BIG BBT40 User manual

BIG

BIG Point Master Pro PMPC Series User manual

BIG

BIG PLP-BBT30 User manual

BIG

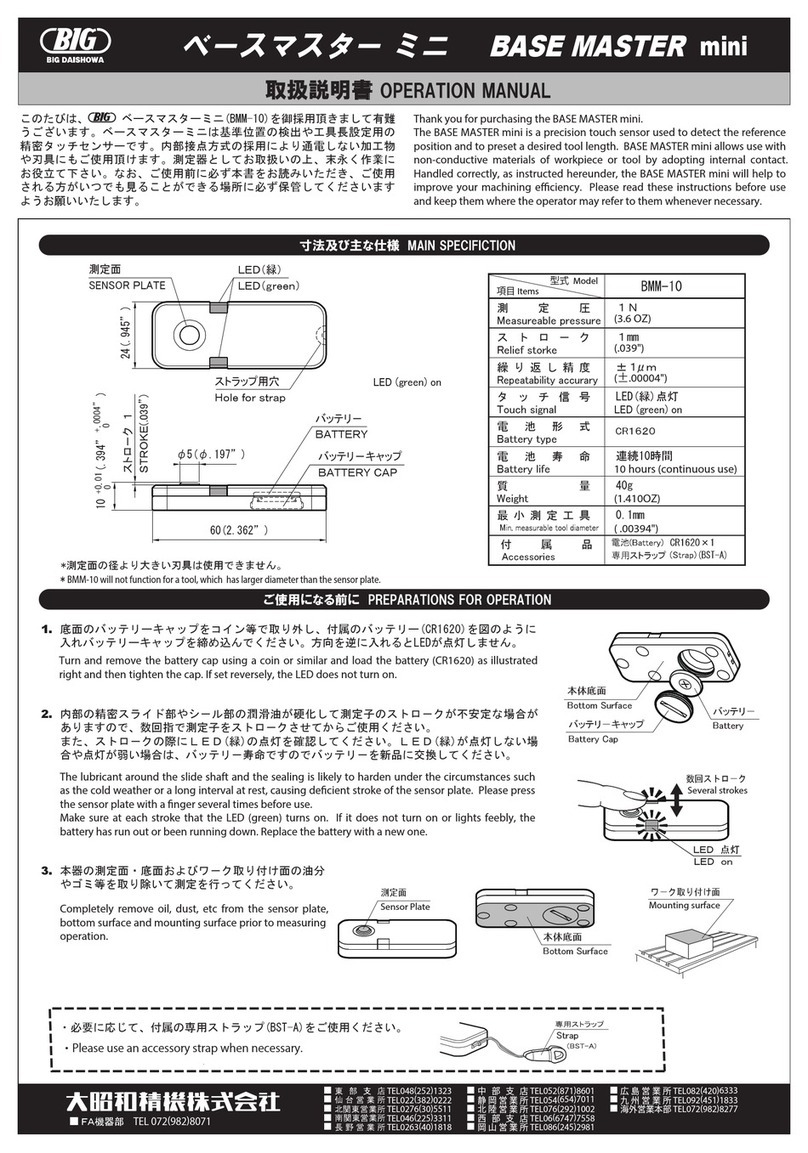

BIG Base Master Mini User manual

BIG

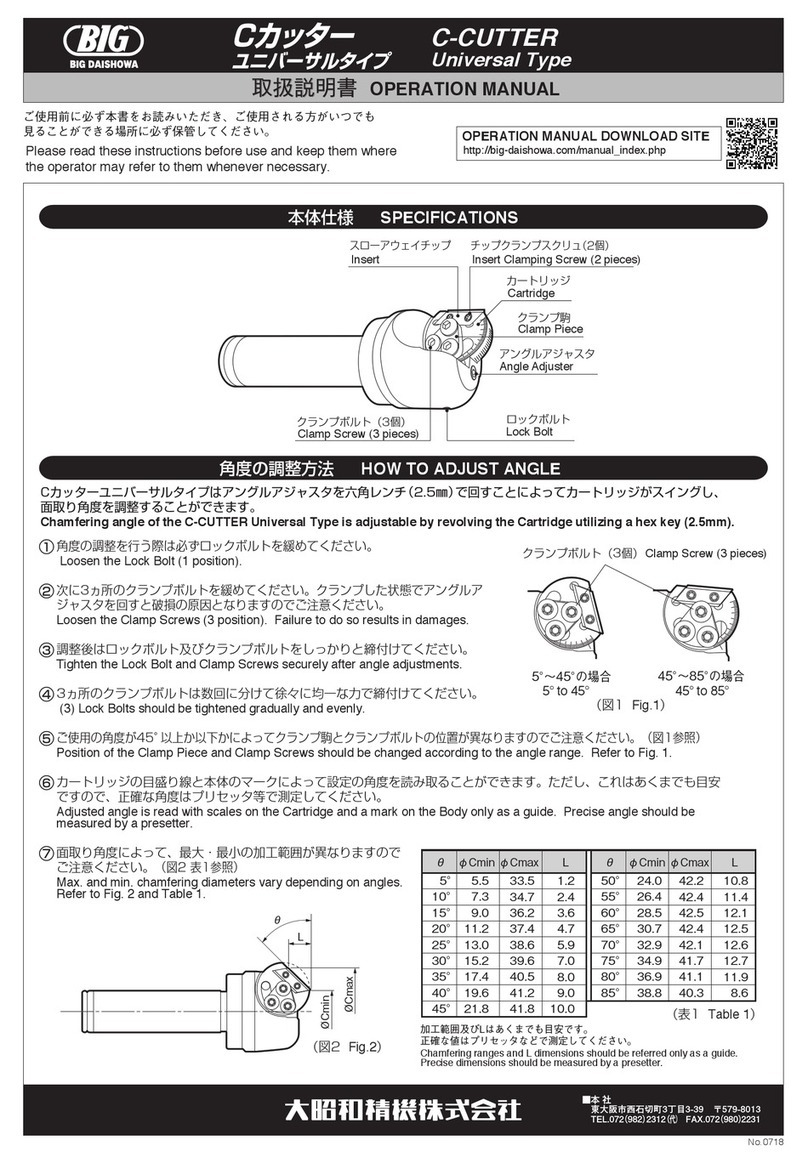

BIG C-Cutter Universal Type User manual

BIG

BIG FCR User manual

BIG

BIG Base Master Mini User manual

BIG

BIG HSK-A63 User manual

BIG

BIG BBT40-SSL -135 Series User manual