B / E 01/2011 page 6/30

Content

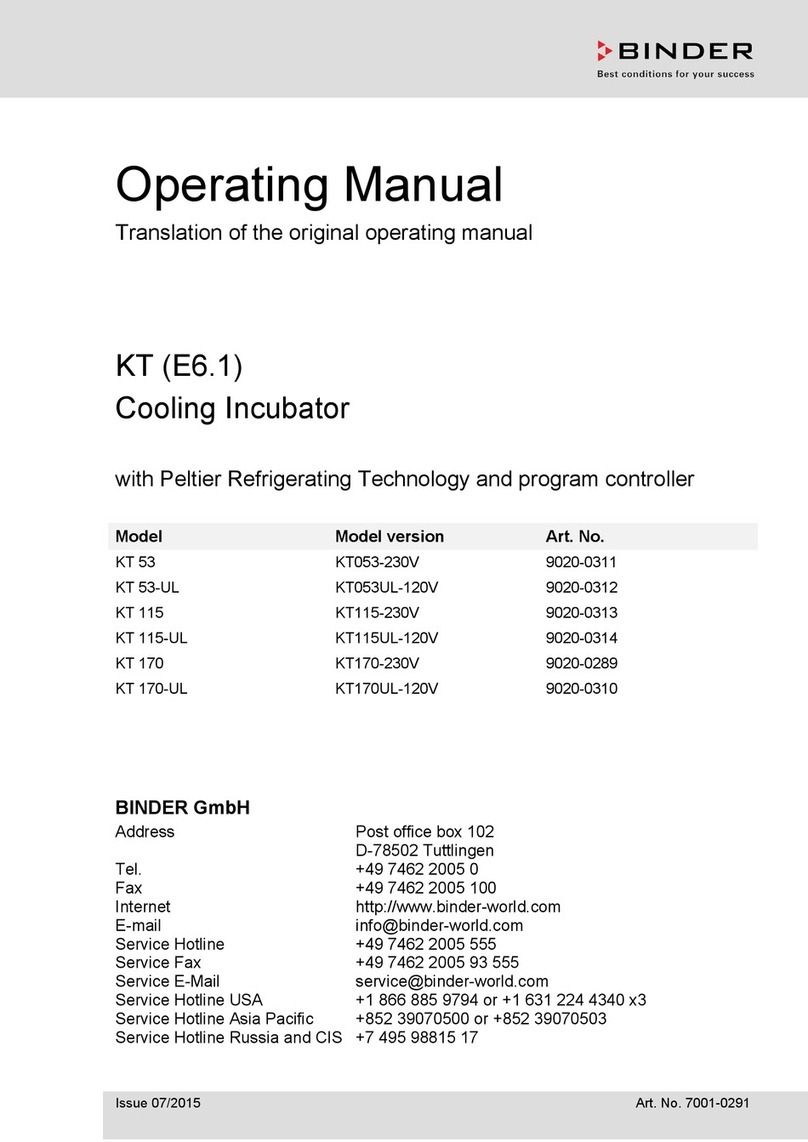

1. SAFETY..................................................................................................................7

1.1 Legal considerations...........................................................................................................................7

1.2 Structure of the safety instructions......................................................................................................7

1.2.1 Signal word panel......................................................................................................................7

1.2.2 Safety alert symbol....................................................................................................................8

1.2.3 Pictograms.................................................................................................................................8

1.2.4 Word message panel structure.................................................................................................9

1.3 Localization / position of safety labels on the unit...............................................................................9

1.4 Type plate .........................................................................................................................................10

1.5 General safety instructions on installing and operating the B incubators and E heating ovens

..........................................................................................................................................................10

1.6 Intended use .....................................................................................................................................12

1.6.1 B 28 incubators........................................................................................................................12

1.6.2 E 28 heating ovens..................................................................................................................12

2. UNIT DESCRIPTION............................................................................................12

2.1 B 28 unit overview.............................................................................................................................13

2.2 E 28 unit overview.............................................................................................................................14

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION....................................................................................................14

3.1 Unpacking, and checking equipment and completeness of delivery................................................14

3.2 Guidelines for safe lifting and transportation ....................................................................................15

3.3 Storage..............................................................................................................................................15

3.4 Location of installation and ambient conditions................................................................................15

4. INSTALLATION OF THE EQUIPMENT ...............................................................16

4.1 Electrical connection.........................................................................................................................16

5. START UP............................................................................................................17

5.1 Turning on the unit............................................................................................................................17

5.1.1 Turning on the B 28 incubator by the main power switch.......................................................17

5.1.2 Turning on the E 28 heating oven by the 0-120 minutes timer...............................................17

5.2 Temperature setting..........................................................................................................................17

5.3 Fresh air supply.................................................................................................................................18

5.4 Using the E 28 for hot-air sterilization...............................................................................................18

6. TEMPERATURE SAFETY DEVICE CLASS 1 (OPTION)....................................18

7. MAINTENANCE, CLEANING, AND SERVICE ....................................................19

7.1 Maintenance intervals, service..........................................................................................................19

7.2 Cleaning and decontamination .........................................................................................................19

7.3 Sending the unit back to BINDER GmbH.........................................................................................21

8. DISPOSAL............................................................................................................21

8.1 Disposal of the transport packing .....................................................................................................21

8.2 Decommissioning..............................................................................................................................21

8.3 Disposal of the unit in the Federal Republic of Germany .................................................................22

8.4 Disposal of the unit in the member states of the EC except for the Federal Republic of Germany.23

8.5 Disposal of the unit in non-member states of the EC .......................................................................24

9. TECHNICAL DESCRIPTION................................................................................24

9.1 Factory calibration and adjustment...................................................................................................24

9.2 Definition of usable volume...............................................................................................................24

9.3 B 28 technical data............................................................................................................................25

9.4 E 28 technical data............................................................................................................................26

9.5 Equipment and Options ....................................................................................................................27

9.6 Accessories and spare parts.............................................................................................................27

10. CONTAMINATION CLEARANCE CERTIFICATE ...............................................28