BD-S / BD-S-UL, ED-S / ED-S-UL, FD-S / FD-S-UL (E1) 03/2022 page 2/60

Content

1. SAFETY.................................................................................................................. 4

1.1 Personnel Qualification .......................................................................................................................4

1.2 Operating manual................................................................................................................................4

1.3 Legal considerations ...........................................................................................................................4

1.3.1 Intellectual property ...................................................................................................................5

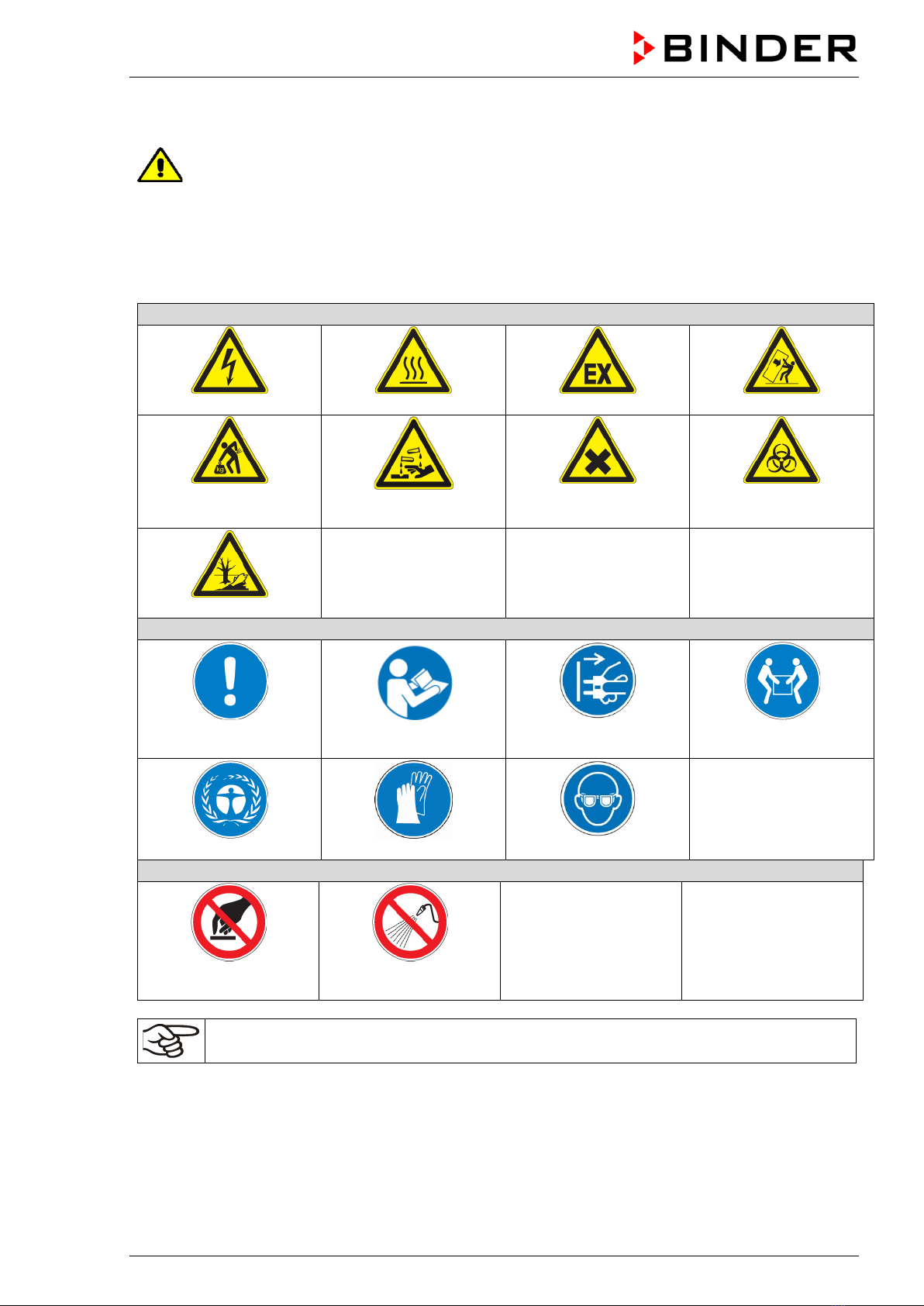

1.4 Structure of the safety instructions......................................................................................................5

1.4.1 Signal word panel......................................................................................................................5

1.4.2 Safety alert symbol ....................................................................................................................6

1.4.3 Pictograms.................................................................................................................................6

1.4.4 Word message panel structure .................................................................................................7

1.5 Localization / position of safety labels on the chamber ......................................................................7

1.6 Type plate............................................................................................................................................8

1.7 General safety instructions on installing and operating the chambers ...............................................9

1.8 Intended use .....................................................................................................................................10

1.9 Foreseeable Misuse..........................................................................................................................12

1.10 Residual Risks ..................................................................................................................................12

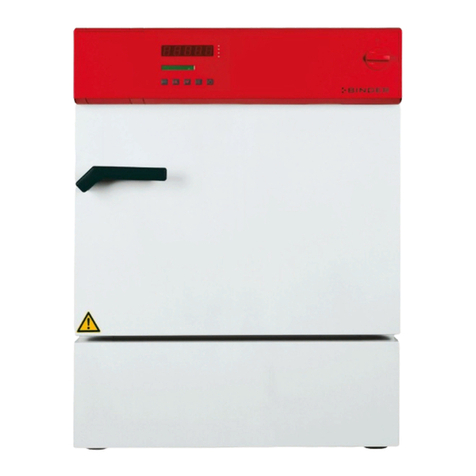

2. CHAMBER DESCRIPTION .................................................................................. 14

2.1 Chamber overview ............................................................................................................................14

2.2 Triangular instrument panel ..............................................................................................................15

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION.................................................................................................... 16

3.1 Unpacking, and checking equipment and completeness of delivery ................................................16

3.2 Guidelines for safe lifting and transportation.....................................................................................16

3.3 Storage..............................................................................................................................................17

3.4 Location of installation and ambient conditions ................................................................................17

4. INSTALLATION.................................................................................................... 18

4.1 Installing the racks ............................................................................................................................18

4.2 Connection to an exhaust/ventilation system (optional) ...................................................................18

4.3 Electrical connection .........................................................................................................................19

5. R-S CONTROLLER OVERVIEW.......................................................................... 20

5.1 Menu structure overview ...................................................................................................................21

6. START UP ............................................................................................................ 21

6.1 Adjusting air change..........................................................................................................................21

7. TEMPERATURE SET -POINT ENTRY ................................................................ 22

8. SELECTING THE TEMPERATURE UNIT............................................................ 22

8.1 Setting the temperature unit..............................................................................................................22

9. OVERTEMPERATURE PROTECTION ................................................................ 23

9.1 Overtemperature protective device (class 1) ....................................................................................23

9.2 Safety controller ................................................................................................................................23

9.2.1 Setting the safety controller.....................................................................................................23

9.2.2 Alarm message and proceeding in case of an alarm ..............................................................24

10. TIMER FUNCTION “DELAYED OFF” ................................................................. 25

10.1 Setting the timer run-time..................................................................................................................25