Bistos BT-500 User manual

Keep this manual for future reference

P/N : 500-ENG-OPM-EUR-R07

BT-500

BT-500

Infant Incubator

BT-500 Operation Manual 1

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Proprietary Material

Information and descriptions contained in this manual are the property of Bistos Co., Ltd. and

may not be copied, reproduced, disseminated, or distributed without express written

permission from Bistos Co., Ltd

Information furnished by Bistos Co., Ltd is believed to be accurate and reliable. However, no

responsibility is assumed by Bistos for its use, or any infringements of patents or other rights

of third parties that may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Bistos.

Revision R07

Mar,2018

Copyright © Bistos Co., Ltd. 2018. All rights reserved.

7th FL., A Bldg., Woolim Lions Valley 5-cha, 302, Galmachi-ro, Jungwon-gu, Seongnam-si,

Gyeonggi-do, Korea

Telephone: ++82 31 750 0340

Fax: ++82 31 750 0344

Printed in Korea

BT-500 Operation Manual 2

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Table of Contents

1. SAFETY............................................................................................4

1.1 Instructions for the Safe Operation and Use of the BT-500................................4

1.2 Warnings.............................................................................................................5

1.3 Shockh azards...................................................................................................12

1.4 General precaution on environment..................................................................13

1.5 Definitions and symbols ...................................................................................15

2. INTRODUCTION..........................................................................16

2.1 General..............................................................................................................16

2.2 Breif Device Description ..................................................................................16

2.3 Intended Use.....................................................................................................16

2.4 Operating Principles..........................................................................................16

2.5 Essential performance.......................................................................................17

2.6 Options and Accessories ...................................................................................17

2.7 Appearance of BT-500......................................................................................19

2.7.1 BT-500 Front view..................................................................................................19

2.7.2 BT-500 Front view Detail .......................................................................................20

2.7.3 BT-500 Rear view...................................................................................................20

2.7.4 BT-500 Side view....................................................................................................21

2.8 Description of each part....................................................................................22

2.8.1 Control shell............................................................................................................22

2.8.2 Hood .......................................................................................................................23

2.8.3 Mattress tray ...........................................................................................................23

2.8.4 Stand .......................................................................................................................24

3. INSTALLATION & CONNECTION...........................................25

3.1 IV pole Assembly..............................................................................................26

3.1.1 IV Extenal Monitor................................................................................................27

3.1.2 IV plate ..................................................................................................................28

3.1.3 IV ringer ploe.........................................................................................................29

3.2 Air Filter Assembly...........................................................................................30

3.3 Connection of Power and Cable........................................................................31

3.3.1 Power Connection..................................................................................................31

3.3.2 Cable Connection...................................................................................................31

3.3.3 Sensor Module Connection....................................................................................32

3.4 Placement Infant ...............................................................................................32

3.5 Movement and Innstallation .............................................................................32

4. OPERATION..................................................................................34

4.1 System Start-up.................................................................................................34

4.2 LED...................................................................................................................36

4.3 Key and knob operation....................................................................................37

4.3.1 Key.........................................................................................................................37

4.3.2 Knob ......................................................................................................................37

4.4 Displays ............................................................................................................38

4.5 Temperature Measurement and Control............................................................40

BT-500 Operation Manual 3

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

4.6 Humidity Measurement and Control.................................................................42

4.7 O2 Measurement...............................................................................................43

4.8 Weighting Scale Measurement..........................................................................44

4.9 SpO2 and PR(pulse rate) Measurement............................................................44

4.10 Menu functions ...............................................................................................44

4.11 Pulse Oximeter................................................................................................50

4.12 External Monitor.............................................................................................53

4.13 Shut down.......................................................................................................55

4.14 Calibration of O2 module ...............................................................................56

5.ALARMS.........................................................................................58

5.1 System alarms...................................................................................................58

5.2 Temperature alarms...........................................................................................59

5.3 Humidity alarms ...............................................................................................61

5.4 Oxygen alarms..................................................................................................61

5.5 Weighting Scale alarms.....................................................................................61

5.6 Alarm self-test...................................................................................................62

6. CLEANING & MAINTENANCE.................................................63

6.1 General cleaning method and precuations ........................................................63

6.2 Hood .................................................................................................................64

6.3 Shell, Sensor module, Scale module, Basket....................................................64

6.4 Water tankt........................................................................................................64

6.5 Skin temperature sensors and SpO2 sensors.....................................................65

6.6 Drain of residual water......................................................................................65

6.7 Regular Inspection............................................................................................66

6.8 Battery Replacement and Disposal ...................................................................67

6.9 Disposal of the BT-500.....................................................................................67

7. SPECIFICATION...........................................................................68

8. TROUBLESHOOTING.................................................................72

8.1 General Checking .............................................................................................72

8.2 Alarm Message Checking .................................................................................72

9. MANUFACTURER’S DECLARATION .....................................75

9.1 Electromagnetic emissions................................................................................75

9.2 Recommended separation distances between portable and mobile

RF communications equipment and the EUT...................................................75

9.3 Electromagnetic immunity................................................................................76

WARRANTY ......................................................................................78

BT-500 Operation Manual 4

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Section 1

Safety

1.1 Instructions for the Safe Operation and Use of the

BT-500 Incubator

Examine the incubator and any accessories periodically to ensure that the

cables, line cords and instruments do not have visible evidence of damage that

may affect patient safety or performance. The recommended inspection

interval is once per week or less. Do not use the incubator if there is any

visible sign of damage.

Only the AC line cord supplied with the BT-500 is approved for use with the

Unit.

Do not attempt to service the BT-500 incubator. Only qualified service

personnel by Bistos Co., Ltd. should attempt any needed internal servicing.

The BT-500 is not specified or intended for operation during the use of

defibrillators or during defibrillator discharge.

The BT-500 is not specified or intended for operation in the presence of

electrosurgical equipment.

The BT-500 is not specified or intended for operation in conjunction with any

other type of equipment except the specific devices that have been identified

for use in this Operator’s Manual.

Perform periodic safety testing to insure proper patient safety. This should

include leakage current measurement and insulation testing. The recommended

testing interval is once per year.

Do not operate the BT-500 incubator if it fails to pass the power on self-test

procedure.

WARNING

Be informed that it may cause serious injury or death to

the patient, property damage, material losses against the

“WARNING” sign.

CAUTION

Be informed that it may cause no harm in life but lead to

injury against the “CAUTION” sign.

SHOCK HAZARD

Be informed that it may cause serious electrical shock to

the patient or operator, property damage, material losses

against the “SHOCK HAZARD” sign.

BT-500 Operation Manual 5

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

1.2 Warnings

WARNING

Thoroughly read and understand the manual prior to use of the

incubator. Failure to do so could result in personal injury or

equipment damage.)

Incubator misuse may result in harm to an infant. Only properly

trained personnel should use the incubator as directed by an

appropriately qualified attending physician aware of currently

known risks and benefits.

Use of accessories other than those listed and approved for use in

this product as original or replacement items may result in

increased emissions or decreased immunity.

The total electrical current leakage of all items powered through

the incubator, including devices on the outlet strip, must be less

than 300uAfor 120VAC/ 100VAC systems and less than 500uA

for 230VAC systems. Otherwise, personal injury or equipment

damage could occur.

The use of accessory equipment not complying with the

equivalent safety requirements of this equipment may lead to a

reduced level of safety of the resulting system. Consider the use

of the accessory in the patient’s vicinity and evidence that the

safety certifications of the accessory have been performed in

accordance with the appropriate International Electrotechnical

commission (IEC) 60601-1 harmonized national standard.

Personal injury or equipment damage could occur.

Devices connecting to the serial data port must be compliant with

EN 60601-1-2, the EMC requirement for Medical Devices.

Failure to do so could result in personal injury or equipment

damage.

Medical electrical equipment needs special precautions regarding

EMC and needs to be installed and put into service according to

the EMC information provided in this manual. In addition,

portable and mobile RF communications equipment can effect

medical electrical equipment.

The equipment shall not be used adjacent to or stack with other

devices unless verification of normal operation in the

configuration in which it is to be used can be achieved.

Use only Bistos recommended fuel cells for proper operation.

Failure to do so could result in personal injury or equipment

damage.

Higher incubator relative humidity at any given temperature

BT-500 Operation Manual 6

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

decreases an infant’s evaporative heat loss, and may cause an

increase in the infant temperature. Routinely monitor the infant’s

rectal and/or axillary temperature according to the attending

physician’s orders or Nursery Standing Orders. Failure to do so

could result in personal injury.

Higher relative humidity will, at any given time, decrease an

infant’s evaporative water loss, and may cause an increase in

infant temperature. This effect is greatest n very low birth-weight,

premature infants. The attending physician should prescribe

Temperature Control mode, temperature setting, and humidity

output level setting. Routinely monitor the infant’s rectal and/or

axillary temperature according to the attending physician’s orders

or Nursery Standing Orders. Failure to do so could result in

personal injury.

Fill the reservoir to the Maximum Filing Limit line. Do not

overfill. Water spillage may result, and personal injury could

occur.

Use distilled water only (<10 ppm total dissolved solids). The

use of sterile water is not acceptable. Equipment damage could

occur.

For proper operation of the incubator, use only skin temperature

probes from Bistos Co. Ltd. Using other probes could result in

personal injury or equipment damage.

Never place the skin temperature probe under the infant or use it

rectally. Personal injury could occur.

BT-500 cannot differentiate between an increase in core

temperature with a cold skin (fever) and a low core and skin

temperature (hypothermia). The temperature of the infant is

monitored separately.

When in skin mode, the skin temperature probe must be in direct

contact with the skin to provide accurate monitoring of the

infant’s skin temperature. When in skin mode, failure to maintain

direct skin contact can result in overheating. Routinely check the

infant’s condition for correct sensor attachment, and feel the

infant’s skin for signs of overheating.

When an x-ray is taken through the hood, the hood could show

up on the x-ray as a radiolucent shadow and could result in

incorrect diagnosis.

Do not use in the presence of flammable anesthetics. Personal

injury or equipment damage could occur.

BT-500 Operation Manual 7

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Keep matches, and all other sources of ignition, out of the room

in which the incubator is located. Textiles, oils, and other

combustibles are easily ignited and burn with great intensity in

air enriched with oxygen. Personal injury or equipment damage

could occur.

Small quantities of flammable agents, such as ethyls and alcohol,

left in the incubator may cause a fire in connection with oxygen.

Personal injury or equipment damage could occur.

A fire and explosion hazard exists when performing cleaning or

maintenance procedures in an oxygen-enriched environment.

Make sure that oxygen supply is turned Off and the oxygen hose

to the incubator is disconnected when performing cleaning and

maintenance procedures. Turn off or disconnect oxygen supplies

during periods of non-use. Failure to do so could result in

personal injury or equipment damage.

If it is necessary to administer oxygen in an emergency, notify the

attending physician immediately. Failure to do so could result in

personal injury or equipment damage.

Improper use of supplemental oxygen may be associated with

serious side effects including blindness, brain damage, and death.

The risks vary with each infant. The qualified attending physician

should prescribe the method, the concentration, and the duration

of oxygen administration.

Administration of oxygen may increase the noise level for the

infant within the infant incubator.

An oxygen analyzer shall be used separately when oxygen is

delivered to the infant.

Measure the oxygen concentrations to verify delivery of the

prescribed oxygen concentration. Failure to do so could result in

personal injury or equipment damage.

If the patient’s arterial oxygen levels cannot be maintained when

the oxygen control setting is set to maximum, the attending

physician should prescribe alternate means of oxygenation.

Failure to do so could result in personal injury or equipment

damage.

The oxygen concentration inspired by an infant does not

accurately determine the partial pressure of oxygen(pO2) in the

blood. When deemed advisable by the attending physician,

measure blood pO2by accepted clinical techniques. Failure to do

so could result in personal injury or equipment damage.

BT-500 Operation Manual 8

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Disconnect the incubator from the hospital oxygen source when

oxygen is not in use. Failure to do so could result in personal

injury or equipment damage.

As oxygen use increases the danger or fire, do not place auxiliary

equipment that produces sparks in an incubator. Personal injury

or equipment damage could occur.

Use of anesthetic agents can interfere with oxygen analyzer

accuracy.

Inspect gas/oxygen service components at regular service

intervals for signs of corrosion or damage. Failure to do so could

result in personal injury or equipment damage.

A dirty air intake micro filter could affect performance or cause

carbon dioxide(CO2) build-up. Ensure that the filter is checked

on a routine basis commensurate with local conditions.

Particularly, if the unit is used in an unusually dusty environment,

more frequent replacements may be necessary. Failure to do so

could result in infant injury or equipment damage.

After each change of oxygen flow, allow at least 30 min to

achieve new concentrations. Failure to do so could result in

personal injury or equipment damage.

Compressed gas cylinders, such as oxygen cylinders, can become

hazardous projectiles if the gas is released rapidly due to damage

or other causes. Securely fasten the cylinder. Failure to do so

could result in personal injury or equipment damage.

Oxygen levels within the incubator hood environment may be

affected when the access doors or access panels are opened.

Make sure all hood access door gaskets and tubing ports are

properly installed. Any open gaps in the incubator hood may

reduce the incubator’s internal oxygen. Personal injury could

occur.

Make sure all hood access door gaskets and tubing ports are

properly installed. Any open gaps in the incubator hood will

reduce the incubator’s internal relative humidity. Personal

injury or equipment damage could occur.

The use of infant seats, or other accessories within the incubator

that can alter the airflow pattern, may affect temperature

uniformity, temperature variability, the correlation of the

incubator temperature reading to center mattress temperature and

infant skin temperature. Personal injury could occur.

Phototherapy units located too close to the incubator may affect

BT-500 Operation Manual 9

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

hood wall temperature, incubator hood temperature, and infant

skin temperature. Personal injury of equipment damage could

occur.

Phototherapy lamps placed over the top of the incubator hood

may interfere with upward travel of the vertical height adjustable

stand. To prevent this interference, always remove the

phototherapy lamp prior to positioning the stand.

If airflow passages are not kept clear of obstructions, such as

blankets and stuffed animals, during clinical usage, patient safety

and incubator performance may be compromised.

To avoid overheating the infant due to direct radiation, do not

position the incubator in direct sunlight or under other sources of

radiant heat.

Do not place surgical covers or blankets over the infant and warm

air curtain or side vents simultaneously. This may cause heat-

induced injury and burns.

To prevent accidental disconnection, secure all patient leads,

infusion lines, and ventilator tubing to the mattress with sufficient

excess length to allow for the full range of mattress height

adjustment.

Only connect equipment to the serial port that complies with the

relevant IEC standard; and use data cables with plastic body

connectors.

Do not raise the hood at any time while the infant is in the

incubator. Gain access to the infant by the access panels and

access doors. Failure to do so could result in personal injury or

equipment damage.

When the front access panel (or optional rear) is open, the

temperature display may not accurately reflect the incubator

temperature. Do not leave the front access panel (or optional rear)

open longer than essential. Personal injury could occur.

Positively secure all access panel latches to avoid accidental

opening, Failure to do so could result in personal injury or

equipment damage.

For infant safety, do not leave the infant unattended when the

access panels are open. Personal injury could occur.

Always use two people when moving the incubator and patient

together. When moving the incubator within the same floor

space, check that the patient is secured safely in the unit and

BT-500 Operation Manual 10

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

either remove or secure all loose system components to prevent

possible patient injury or equipment damage. If the move

involves varying floor heights or a complete floor level change

(i.e. thresholds, ramps, elevators), remove all items either not

being used or not necessary for the move, lower the VHA, IV

poles and shelves to their lowest position, place all drawers in

their locked state, and remove all accessories from the front and

rear rail position.

Never place objects taller than the top of the wheel casters

beneath the incubator stand. Placement of objects there could

interfere with the stability of the vertical height adjustable stand.

Personal injury of equipment damage could occur.

To avoid possible tip-over or damage to adjacent carts, IV stands,

shelves, etc., keep at least a 12” (30 cm) perimeter area clear

around the vertical height adjustable stand.

For optimum incubator stability, always lock all stand wheels, Do

not leave the unit unattended when parking on an incline. Failure

to do so could result in personal injury or equipment damage.

When raising or lowering the incubator, the operator should

ensure that both equipment and appendages are clear of the unit’s

travel path. Patient and incubator connections must also be

checked before adjusting the incubator height. Never place any

objects on top of the drawer assembly and always check before

lowering the VH that there is sufficient clearance between the

incubator and stand assembly. Do not raise or lower the unit

while installing or removing medical gas tanks from the tank

holder assembly. Failure to do so could result in personal injury

of equipment damage.

The UART port is for debugging purposes only. It does not allow

connections with other devices.

Prior to placing the infant in the incubator, pre-warm the

incubator to the temperature prescribed by the attending

physician, or according to nursing protocol.

Only one monitor shelf should be used per incubator. When using

the monitor shelf, always place the monitor in the center of the

shelf, ensure that the monitor fits within the border of the shelf,

and avoid stacking monitors on the shelf. Personal injury or

equipment damage could occur.

Attach the incubator to the stand or the vertical height adjustable

stand using the bolts provided. Failure to do so could result in the

incubator separating from the stand if sufficiently tilted,

particularly with the hood open. Personal injury or equipment

BT-500 Operation Manual 11

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

damage could occur.

This product has been validated with the accessories and options

listed in this manual and found to comply with all relevant safety

and performance requirements applicable to the device. It is

therefore the responsibility of that person or organization who

makes an unauthorized modification, or incorporates an

unapproved attachment to the device, to ensure that the system

still complies with those requirements.

Apulse oximeter should NOT be used as an apnea monitor

Pulse rate measurement is based on the optical detection of a

peripheral flow pulse and therefore may not detect certain

arrhythmias. The pulse oximeter should not be used as a

replacement or substitute for ECG based arrhythmia analysis.

Apulse oximeter is an early warning device. Use lab co-oximeter

to completely understand the patient’s condition.

Do not use the MS board pulse oximeter in the presence of

flammable anesthetics or other flammable substance in

combination with air, oxygen enriched environments, or nitrous

oxide.

Do not remove the monitor cover except to replace the battery.

An operator may only perform maintenance procedures

specifically described in this manual. Refer servicing to Masimo

in repair of this equipment.

Leakage current must not exceed 100 microamperes; measure

when an external device is connected to the serial port.

Do not use Masimo oximetry sensors during MRI scanning as it

could potentially cause burns.

Inaccurate measurements may be caused by incorrect application

or use.

Inaccurate measurements may be caused by significant levels of

dysfunctional hemoglobin (HbCO or MetHb).

Inaccurate measurements may be caused by intravascular dyes

such as indocyanine green or methylene blue.

Inaccurate measurements or loss of pulse signal may be caused

by excessive illumination.

Inaccurate measurements may be caused by excessive patient

BT-500 Operation Manual 12

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

movement.

Inaccurate measurements may be caused by venous pulsation.

Inaccurate measurements or loss of pulse signal may be caused

by placement of a sensor on an extremity with a blood pressure

cuff, arterial catheter or intravascular line.

The MS board pulse oximeter can be used during defibrillation,

but the readings may be inaccurate for a short time.

Loss of pulse signal can occur when the sensor is too tight.

Loss of pulse signal can occur when the patient has hypotension,

severe vasoconstriction, severe anemia, or hypothermia.

Loss of pulse signal can occur when there is arterial occlusion

proximal to the sensor.

Loss of pulse signal can occur when the patient is in cardiac

arrest or is in shock.

Use only Masimo sensors for SpO2 measurements.

Tissue damage can occur due to incorrect placement of sensor.

1.3Shock hazards

SHOCK

HAZARD

Unplug the unit from its power source prior to cleaning or

maintenance. For units equipped with an uninterruptible power

supply(UPS) system, also remove the battery pack prior to

cleaning or maintenance. Failure to do so could result in personal

injury or equipment damage.

Some chemical cleaning agents may be conductive and leave a

residue that may permit a build-up of conductive dust or dirt. Do

not allow cleaning agents to contact electrical components, and do

not spray cleaning solutions onto any of these surfaces. Personal

injury or equipment damage could occur.

To ensure grounding reliability, plug the AC power cord only into

a properly grounded 3-wire hospital-grade or hospital-use outlet.

Do not use extension cords. If any doubt exists as to the

grounding connection, do not operate the equipment. Personal

injury or equipment damage could occur.

Do not expose the unit to excessive moisture that would allow for

liquid pooling. Personal injury or equipment damage could occur.

BT-500 Operation Manual 13

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Due to the risk of electrical shock hazard, only qualified

personnel with appropriate service documentation should service

the unit.

Batteries can present a risk of electric shock. The following

precautions should be taken when working on batteries: remove

watches, rings or other metal objects; use tools with insulated

handles.

The total power of all equipment connected to the convenience

outlet strip on the pedestal / stand must me within the electrical

requirements shown on the rear of the pedestal / stand. Otherwise,

personal injury or equipment damage could occur.

Make sure the Building power source is compatible with the

electrical specifications shown on the column of the pedestal /

stand and on the incubator. Failure to do so could result in

personal injury or equipment damage.

To prevent equipment damage or accidental power

disconnections, do not plug an incubator power cord directly to

an AC wall socket when the incubator is mounted on a pedestal

/stand. Always provide power to the incubator by using the power

cord coming directly from the pedestal /stand.

1.4 General precaution on environment

Do not keep or operate the equipment under the environment listed below.

Avoid placing in an area

exposed to moisture. Do

not touch the equipment

with wet hand.

Avoid exposure to

direct sunlight

Avoid placing in an area

where there is a high

variation of temperature.

Operating temperature

ranges from 20°C to

30°C. Operating

humidity ranges from 0%

to 95%.

Avoid in the vicinity

of Electric heater

Avoid placing in an area

where there is an

excessive humidity rise

or ventilation problem.

Avoid placing in an

area where there is an

excessive shock or

vibration.

BT-500 Operation Manual 14

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

1.5Definitions and symbols

Symbol

Description

Used to identify safety information.

Be well-known this information thoroughly before using BT-500.

During the operation, do not disconnect any cable.

Indicate the warning for hot surface.

Type BF Applied part

Refer to operation manual. Read manual before placing the device.

Skin temperature sensor #1, to be connected to infant’s abdomen for baby

(controlled) mode

Skin temperature sensor #2, to be connected to other than infant abdomen

IPX0

IPX0 Non-protected against ingress of water with harmful effects.

(Device)

IPX1

IPX1 Protected against the vertically dripping water

(Skin temperature sensor_2EA)

IPX2

IPX2 Protected against the dripping water

(SpO2sensor)

IPX6

IPX6 Protected against the powerful jetting

(Foot switch_2EA)

Indicates the weight limit

This symbol indicates the manufacturer.

This symbol indicates the serial number of the device.

This symbol indicates the authorized representative in the European

Community of manufacturer.

Avoid placing in an area

where chemicals are

stored or where there is

in danger of gas leakage.

Avoid dust and

especially metal

material into the

equipment.

Do not disjoint or

disassemble the

equipment.

BISTOS Co., Ltd. does

not take responsibility of

it.

Power off when the

equipment is not fully

installed.

Otherwise, the

equipment could be

damaged.

BT-500 Operation Manual 15

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

This symbol indicates to keep the device dry.

This symbol indicates to keep the correct upright position on the transport

package.

This symbol indicates the device is fragile.

This symbol indicates the temperature limitation for operation, transport

and storage.

This symbol indicates the humidity l

imitation for operation, transport and

storage.

This symbol indicates the packing material is recyclable.

External Signal IN/OUT Port

This symbol indicates the compliance with the essential requirements and

provisions of the Medical Device Directive 93/42/EEC as amended by

2007/47/EEC.

This symbol indicates to not dispose the device together with unsorted

municipal waste(for EU only). The solid bar symbol indicates that mains

adapter is put on the market after 13August 2005.

BT-500 Operation Manual 16

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Section 2

Introduction

2.1 General

This chapter provides a general description of the BT-500 infant incubator including.

Brief Device Description

Product Features

Model Configurations

2.2 Brief Device Description

A mains electricity (AC-powered) unit designed to provide an enclosed controlled

environment to maintain appropriate temperature and humidity levels mainly for premature

infants and other newborns who cannot effectively regulate their body temperature. It

typically consists of a clear removable plastic hood with a mattress. It typically includes a

means to warm the infant such as providing heated air; temperature controls that work

automatically either by measuring the air temperature or through a temperature sensor

attached to the infant skin; and humidity controls. The device is intended to use in a hospital.

2.3 Intended Use

BT-500 is an infant incubator for non-invasively measuring and showing graphically

humidity, air temperature, skin temperature, O2 Module, weight and SpO2. This data is

intended to aid the maintaining life of a premature baby or a precocious baby under 2kgs.

This device is for use only by trained medical personnel located in hospital. Also this device

can be used in the all departments of the hospital which offers a neonatal care service such

as NICU(Neonatal Intensive Care Unit), special nursery unit and pediatrics.

2.4 Operating Principles

- Air and skin temperature measurement and Control: Internal cartridge heater raises the

temperature. The infant environmental temperature value is determined by air a skin

temperature that is measured by the sensor module. Through the main fan, the air is

circulated within the hood and adjusts the temperature.

- Humidity measurement and control: The steam of humidity module vaporizes the water

particles. It Adjust the humidity mixed with air within the hood. Sterilized by heating the

water to 100℃.

- O2 Module(Optional):It is available to control the oxygen concentration in the hood when

putting the module option of oxygen concentration.

- SpO2 measurement (Optional):The probe sensor is wear at the end of an infant’s finger. By

measuring the intensity of reflected light, depending on the concentration of dissolved

oxygen in the blood determines the oxygen saturation.

BT-500 Operation Manual 17

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

- Pulse rate measurement(SpO2):During the heart beats, the infrared light is from the light

source.

It is on the arteriole, such as fingers. The intensity of the light is reflected to the sensor is

measured.

2.5 Essential performance

Air temperature measurement and incubator air temperature control.

Skin temperature measurement and infant Skin temperature control.

Humidity measurement and control inside the incubator.

An alarm occurs if the difference between the set temperature and the control

temperature is more than a certain level.

System must remain in a safe condition acc. IEC 60601-1, IEC 60601-2-19

WARNING

Do not use the skin temperature control on babies who are in shock

or who have high temperatures

2.6 Options and Accessories

Picture

Name

Description

Qty

Control shell

(Standard)

Hold up the hood and be composed

with instruments and parts that control

the temperature and humidity 1ea

Hood

(Standard)

Made of double framed clear acrylic

panel to watch inside, and to minimize

heat loss 1ea

Fixed Stand

(Standard) Movable incubator cradle with wheels 1ea

Basket

(Optional) Storage of medical equipment and

items which infant needs 1ea

Basket Partition

(Optional) Partition of Basket 1ea

Sensor module

(Standard)

Measures temperature and humidity

inside the hood and infant’s body

temperature 1ea

BT-500 Operation Manual 18

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

Mattress tray

(Standard) Baby desk with X-ray tray 1ea

mattress

(Standard)

Accommodate infant stably with

bouncy mattress 1ea

Skin

temperature

sensor

(Standard)

Measures infant’s skin temperature 2ea

IV-pole

(Optional) IV hanger. 1ea

AC power code

(Standard) AC Power cord(AC Power cord for

operating the equipment) 1ea

External LCD

Monitor

(Optional)

Displays measured values from the

control and video of infant inside the

hood.1ea

CCD Camera

(Optional) Takes video of infant inside the hood 1ea

Masimo SpO2

sensor probe

(Optional) Measures infant’s SpO2 1ea

Masimo

Extension for

SpO2 sensor

(Optional)

Extend sensor cable 1ea

IV plate

(Optional) Plate to place items which infant needs 1ea

Shelf

(Optional) Plate to place items which infant needs 1ea

BT-500 Operation Manual 19

P/N : 500-ENG-OPM-EUR-R07

Bistos Co., Ltd.

2018,03

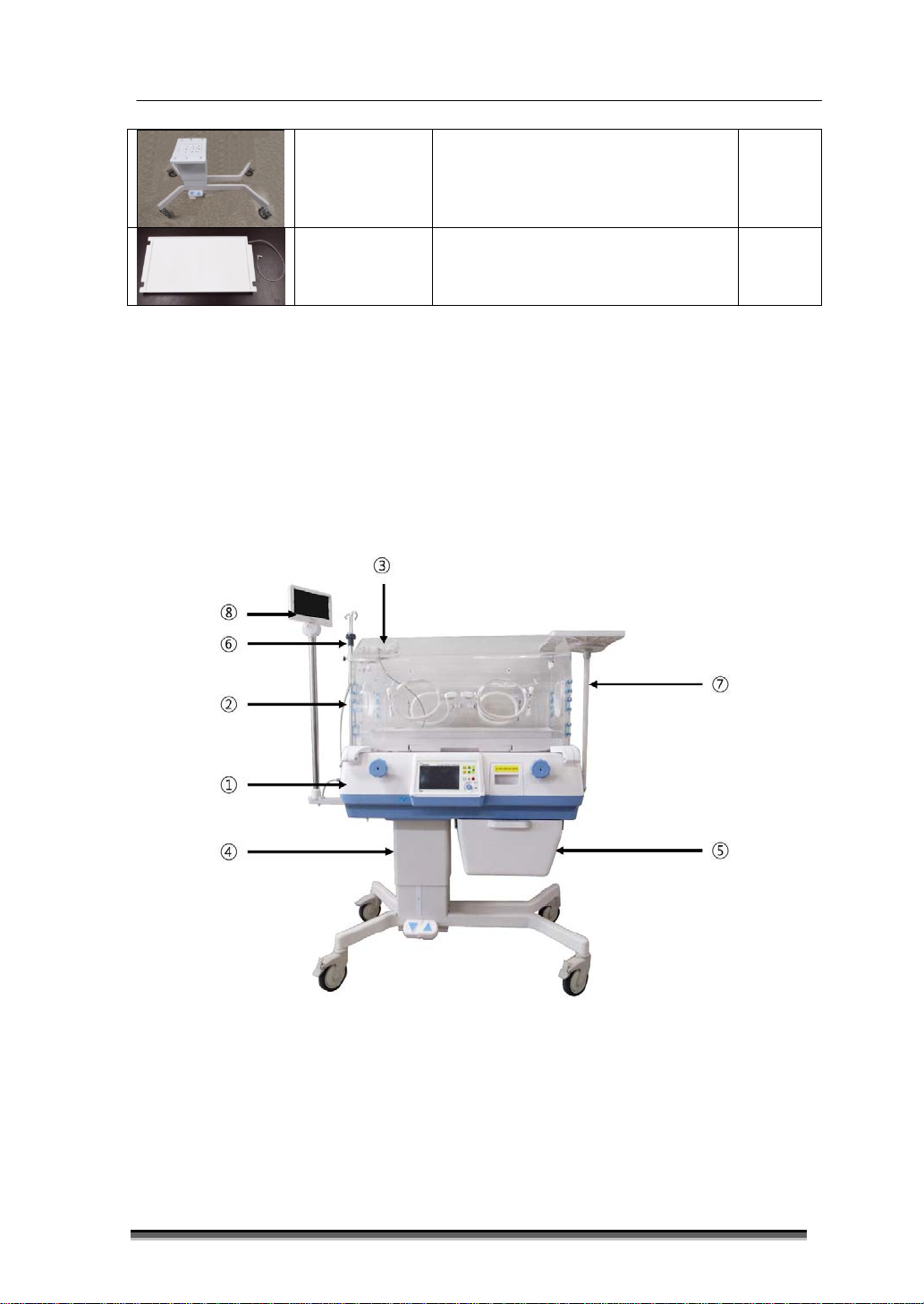

Lift Stand

(Optional)

Movable incubator cradle with wheels

(VHA- Variable Height Adjustable) 1ea

Weighting

Scale

(Optional)

Measures Infant’s weight 1ea

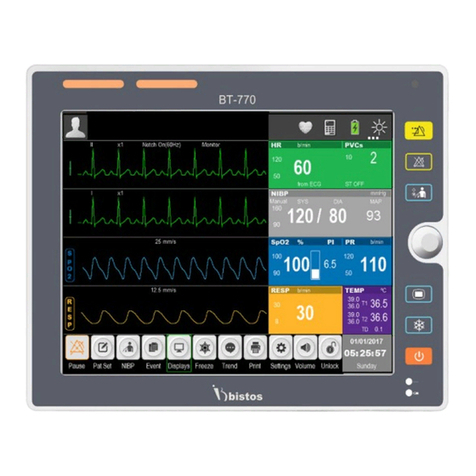

2.7 Appearance of BT-500

2.7.1 BT-500 Front View

Figure 2-1. BT-500 Front view

①Control Shell ②Hood

③Sensor module ④Moving Stand

⑤Basket ⑥IV pole

⑦IV plate ⑧External monitor

Notes;

* The built-in air filter requires periodic replacement to maintain clean air periodic

replacement of the pads according to the maintenance schedule is recommended.

**Oxygen control module is also available as an optional component.

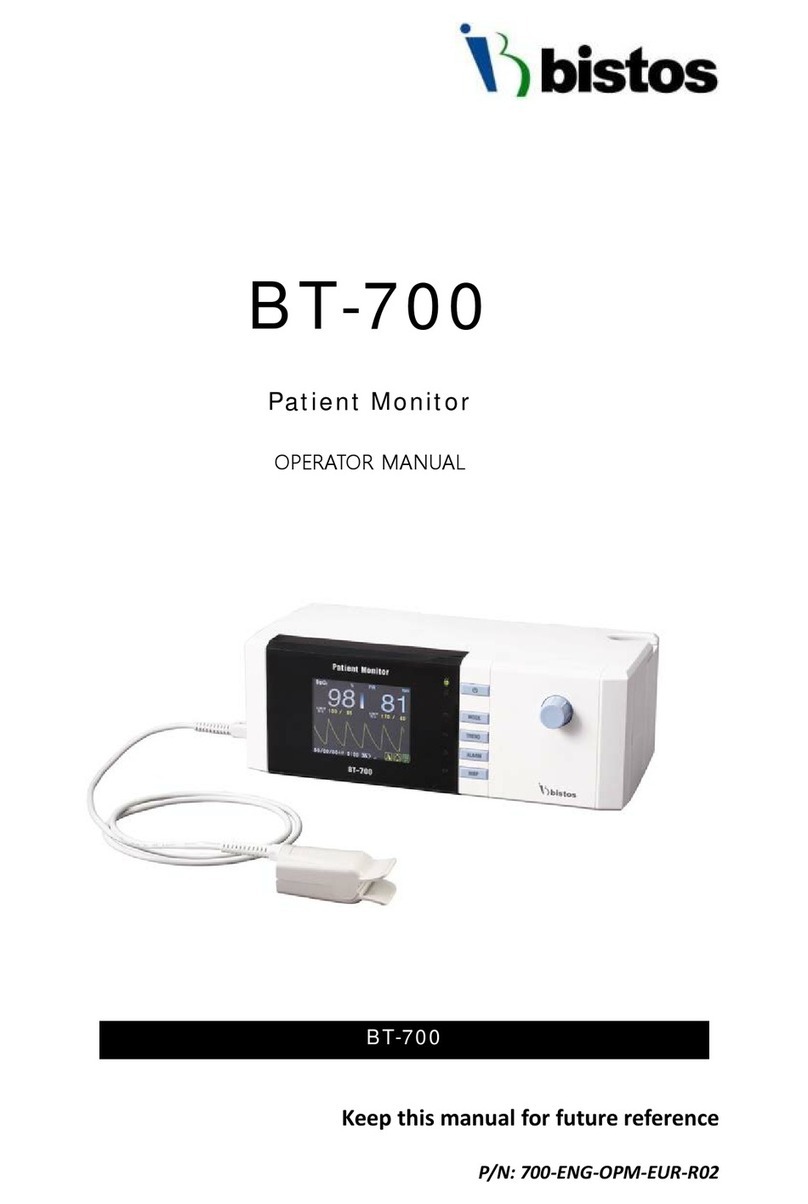

Other manuals for BT-500

1

Table of contents

Other Bistos Medical Equipment manuals

Bistos

Bistos BT-700 User manual

Bistos

Bistos BT-500 User manual

Bistos

Bistos BT-720 User manual

Bistos

Bistos BT-350 User manual

Bistos

Bistos BT-200 User manual

Bistos

Bistos BT-770 User manual

Bistos

Bistos BT-550 User manual

Bistos

Bistos BT-400 User manual

Bistos

Bistos BT-250 User manual

Bistos

Bistos BT-780 User manual

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual