Automatic System

Flush Button

1-1/4"

32mm

1-1/2"

40mm 1/4"

6mm

Activation

Area

5

6

18

16

9

11

8

7

13

12

1

10

17 19

2

3

4

15

14

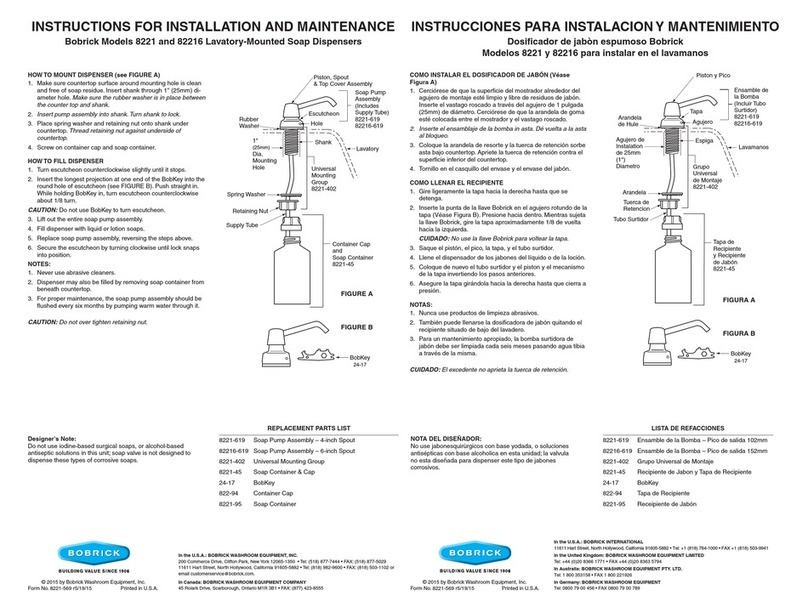

Designer Series Automatic, Counter-Mounted Soap Dispenser

INSTRUCTIONS FOR INSTALLATION, OPERATION & MAINTENANCE

BOBRICK MODELS B-850, B-852, B-855, B-856, B-858 LIQUID SOAP DISPENSER

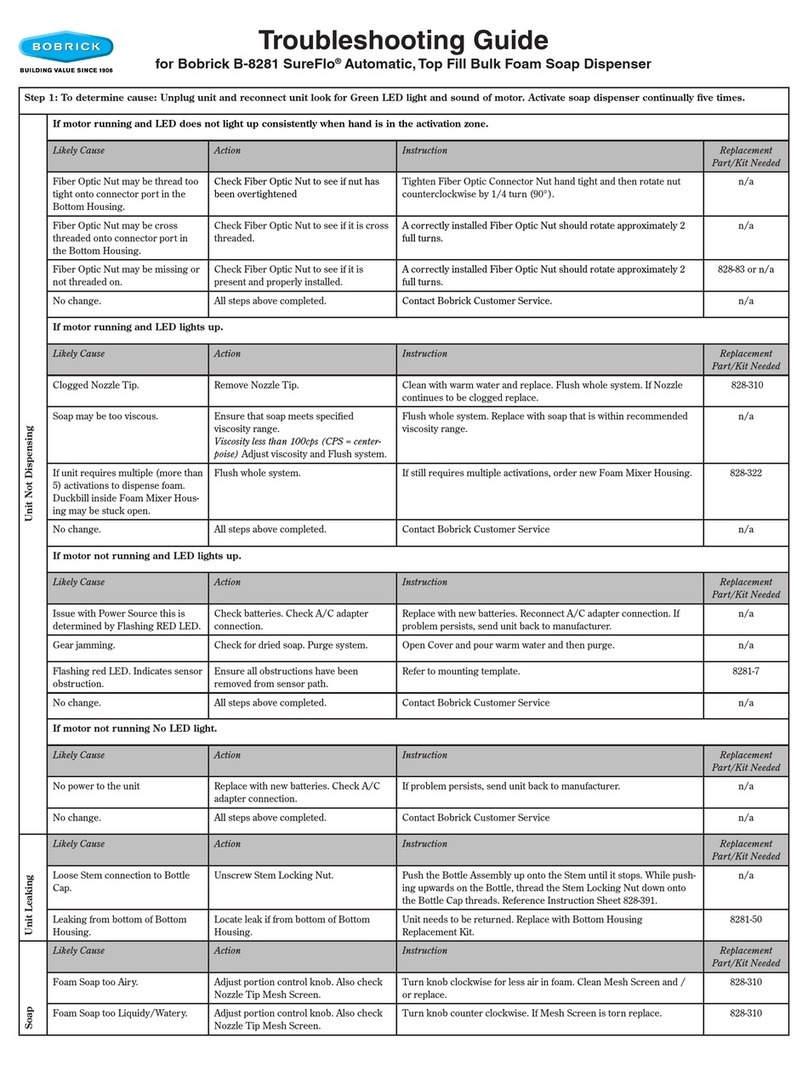

Unit Diagram:

Item Description

1 Top Assembly with Spout, Door and Stem

2 LED Light Pipe

3 Liquid Nozzle Tip

4 Fiber Optic Insert with Sensor Lenses

5 Rubber Counter Gasket

6 Wave Washer

7 Mounting Nut

8 Stem Mounting Nut

9 Duckbill Housing

10 Bottom Housing Assembly (includes Soap Bottle)

11 (3) Fiber Optic Cables for Sensor and LED Light Pipe

12 Fiber Optic Connector Tip Assembly

13 Fiber Optic Nut

14 Portion Control Knob

15 Automatic System Flush Button

16 Key Hole

17 BobKey

18 Fiber Optic Cable Cover

19 A/C Adapter Kit with U.S.Plug, Order Part No.3974-57.

Optional: International AC Adapter Plug Kit

(UK, Europe Australia) 3974-55

© 2019 by Bobrick Washroom Equipment, Inc.

Form No. 858-191 r8/09/19 Printed in U.S.A.

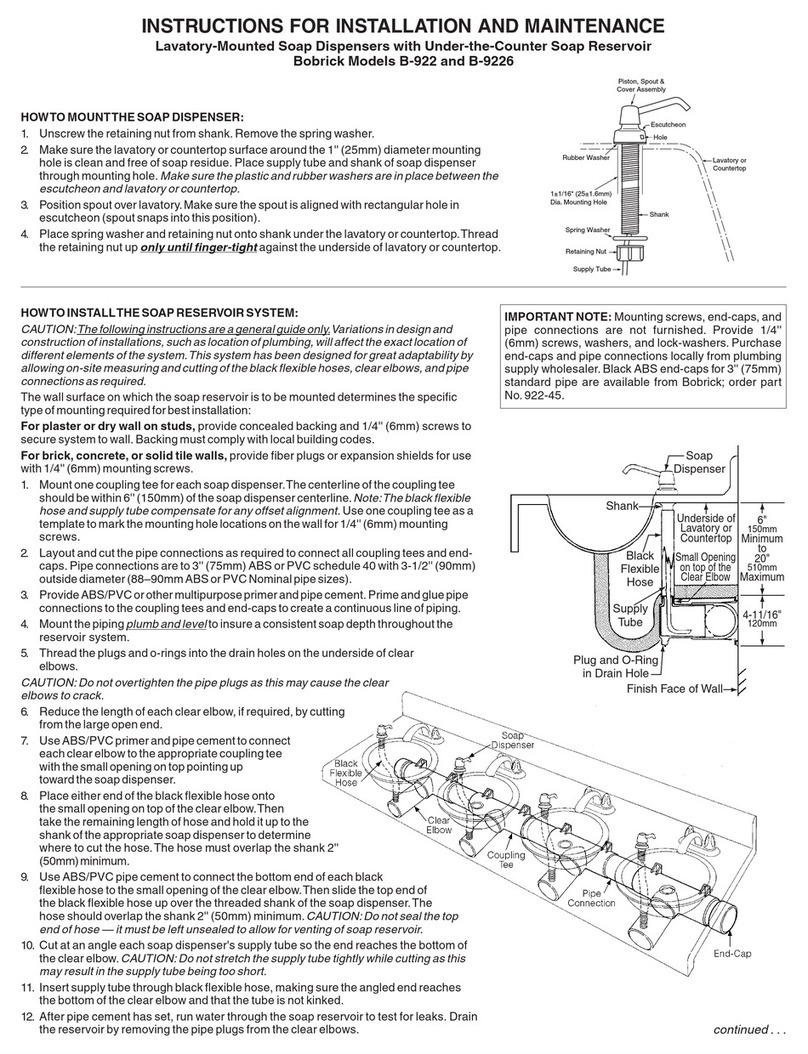

Clearances and Mounting Requirements:

• 1-3/8" (35mm) diameter mounting hole required.

• Minimum 18" (457mm) vertical clearance needed below the counter.

• 5" (127mm) diameter clearance needed below the mounting hole to

accommodate bottle and bottom housing.

• Minimum 2-1/4" (57mm) diameter clearance needed for Mounting nut directly

below the counter to clear sink rim.

• Recommend drilling mounting hole 6" to 8" (152 to 203mm) from the wall,

and 2-1/2" to 3" (64 to 76mm) from sink rim.

Routine Cleaning and Maintenance:

Using a damp cloth, wipe the chrome-plated exterior of the dispenser daily. Periodically (about 3 to 6 months), it is

recommended to flush the system with lukewarm water for cleaning and maintenance.

1. When minimal amount of soap is left in the bottle, fill dispenser with lukewarm water from top

to dilute soap.

2. Press the Automatic System Flush Button to flush the system.

3. Once unit is flushed, press the Automatic System Flush Button again to stop dispensing.

4. Fill unit with fresh soap and dispense as usual.

For Retrofit:

1. Remove existing dispenser(s).

2. Clean area.

3. Ensure hole is 1-3/8" (35mm) diameter.

4. If necessary, enlarge opening using appropriate hole saw. For granite/marble counters, recommend using a diamond

hole saw (consult with stone and granite specialist). If needed, mounting hole should be offset to clear the sink rim. The Mounting

Nut requires 2-1/4" (57mm) diameter clearance directly below the counter.

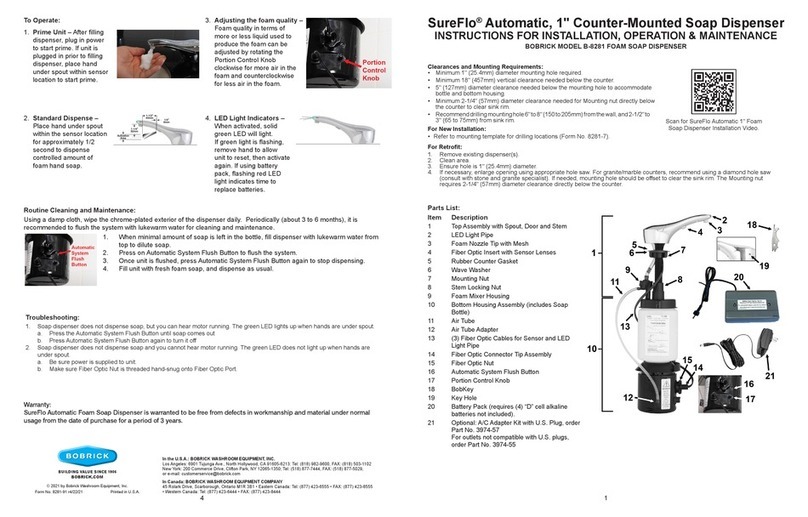

To Operate:

Troubleshooting:

1. Soap dispenser does not dispense soap, but you can hear motor running. The green LED lights up when hands are

under spout.

a. Press the Automatic System Flush Button until soap comes out.

b. Press the Automatic System Flush Button again to turn it off.

2. Soap dispenser does not dispense soap and you cannot hear motor running. The green LED does not light up when

hands are under spout.

a. Be sure power is supplied to unit.

b. Make sure Fiber Optic Nut is tight on Fiber Optic Port.

Warranty:

SureFlo Automatic Liquid Soap Dispenser is warranted to be free from defects in workmanship and material under normal

usage from the date of purchase for a period of 3 years.

For New Installation:

• Refer to mounting template for drilling locations (Form No. 824-307).

1. Prime Unit – After filling

dispenser, plug in power

to start prime. If unit is

plugged in prior to filling

dispenser, place hand

under spout within sensor

location to start prime.

2. Standard Dispense –

Place hand under spout

within the sensor location

for approximately 1/2

second to dispense

controlled amount of

liquid hand soap.

3. Adjusting amount of soap

dispensed – Depending on

viscosity of liquid soap used,

unit may dispense between

0.4 ml to 3 ml of soap. To

reduce output of liquid soap,

rotate Portion Control Knob

counter-clockwise. To

increase the output of liquid

soap, turn the knob clockwise.

4. LED Light Indicators –

When in standby mode,

LED will flash green.

LED will turn off during

dispense. If red light is

flashing, remove hand to

allow unit to reset. Hand

must be removed for a

second activation.

In the United States: BOBRICK WASHROOM EQUIPMENT, INC.

New York: 200 Commerce Drive, Clifton Park, NY 12065-1350 • Tel: (518) 877-7444 • Fax: (518)-877-5029

Los Angeles: 6901 Tujunga Ave, North Hollywood, CA 91605-6213 • Tel: (818) 982-9600 • Fax: (818)-503-9287

or email customerservice@bobrick.com

In Canada: BOBRICK WASHROOM EQUIPMENT COMPANY

45 Rolark Drive, Scarborough, Ontario M1R 3B1 • Eastern Canada: Tel: (877) 423-6555 • Fax: (877) 423-8555

•

Western Canada: Tel: (877) 423-6444 • Fax: (877) 423-8444 or email [email protected]Scan For SureFlo Installation and

Maintenance Instructions.

1

4