8

МОЙКА ВЫСОКОГО ДАВЛЕНИЯ

ЭЛЕКТРИЧЕСКАЯ

НАЗНАЧЕНИЕ

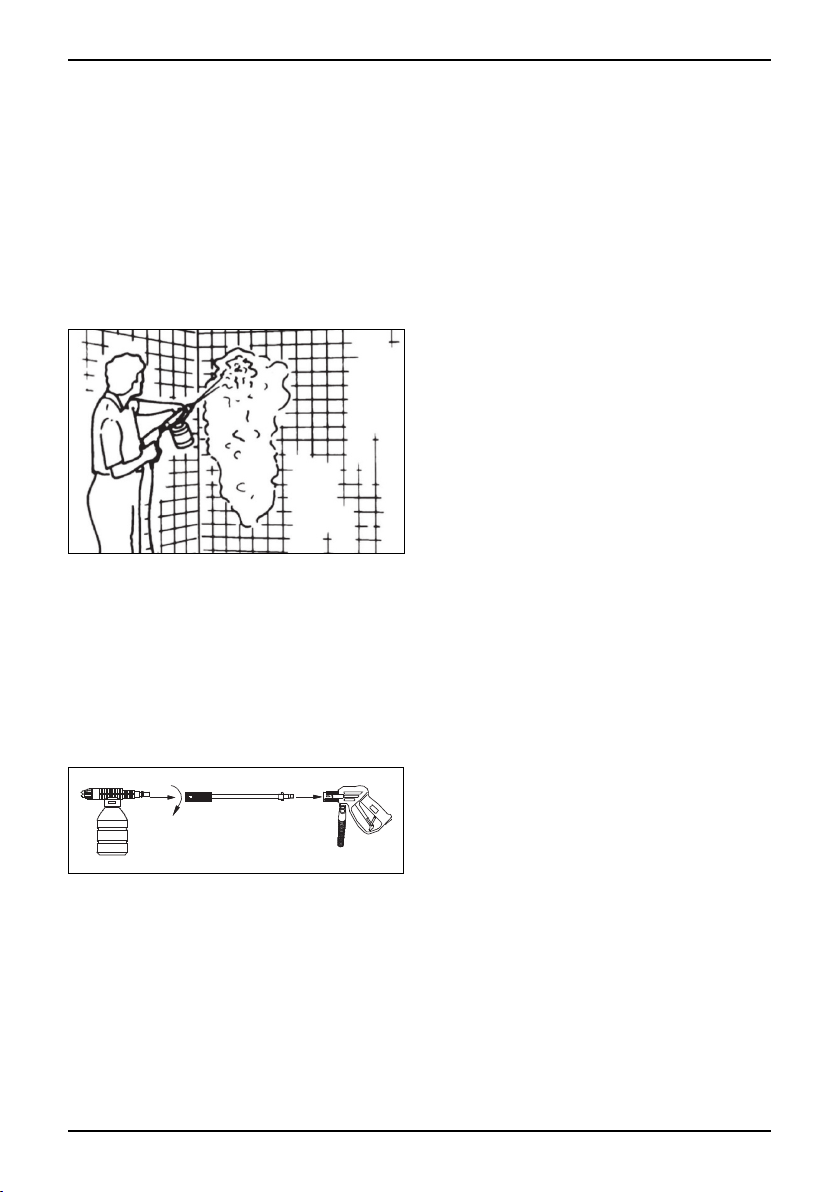

Данное устройство предназначено для быстрой и

эффективной мойки автомобилей, машин, лодок,

зданий ит.д. сиспользованием чистой воды ихими-

ческих моющих средств для удаления устойчивых

загрязнений. Пользуясь химическими моющими

средствами, применяйте только средства, подвер-

женные биологическому разложению.

Автомобильные двигатели промывайте только вме-

стах, оборудованных маслоуловителями.

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Напряжение, В230

Потребляемая мощность, Вт 1600

Давление струи, бар 90

Наибольшее давление подачи

воды, бар 120

Наибольшая температура во-

ды, °С50

Производительность, л/мин 7

Длина шланга, м4

Вес, кг 5,3

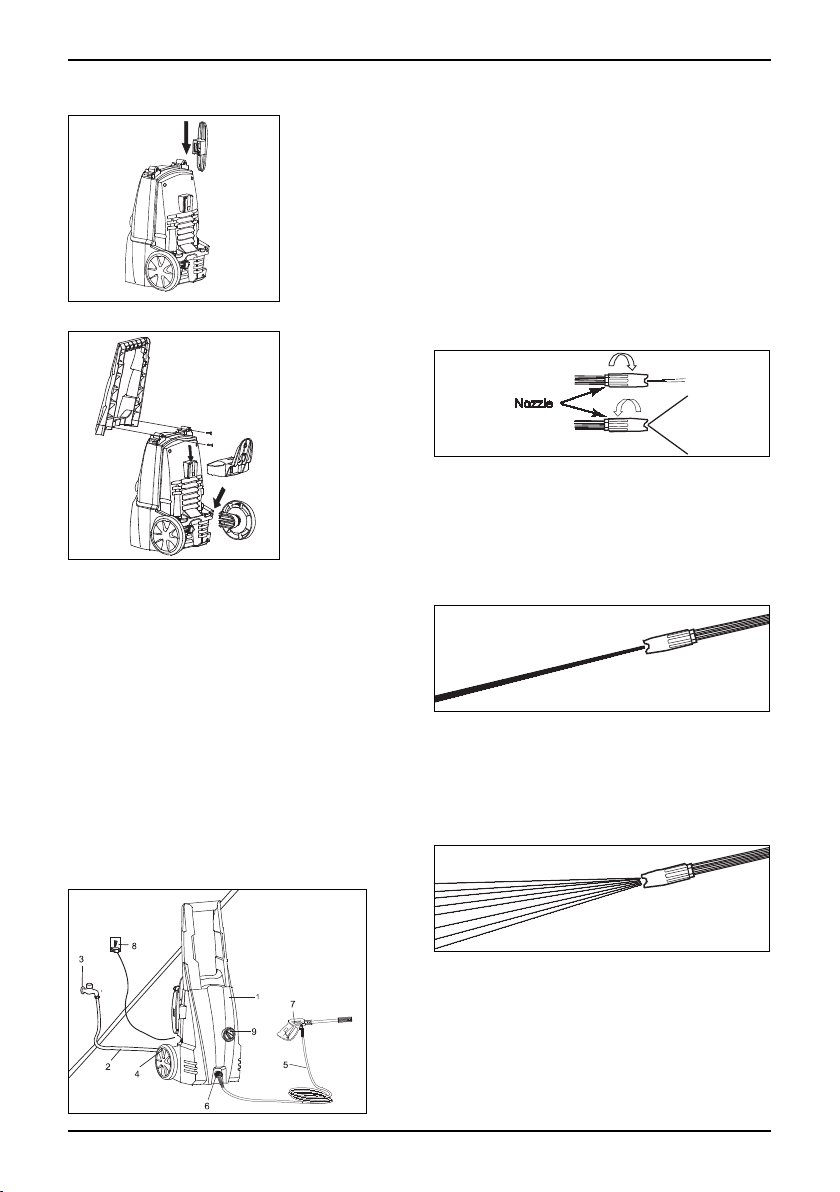

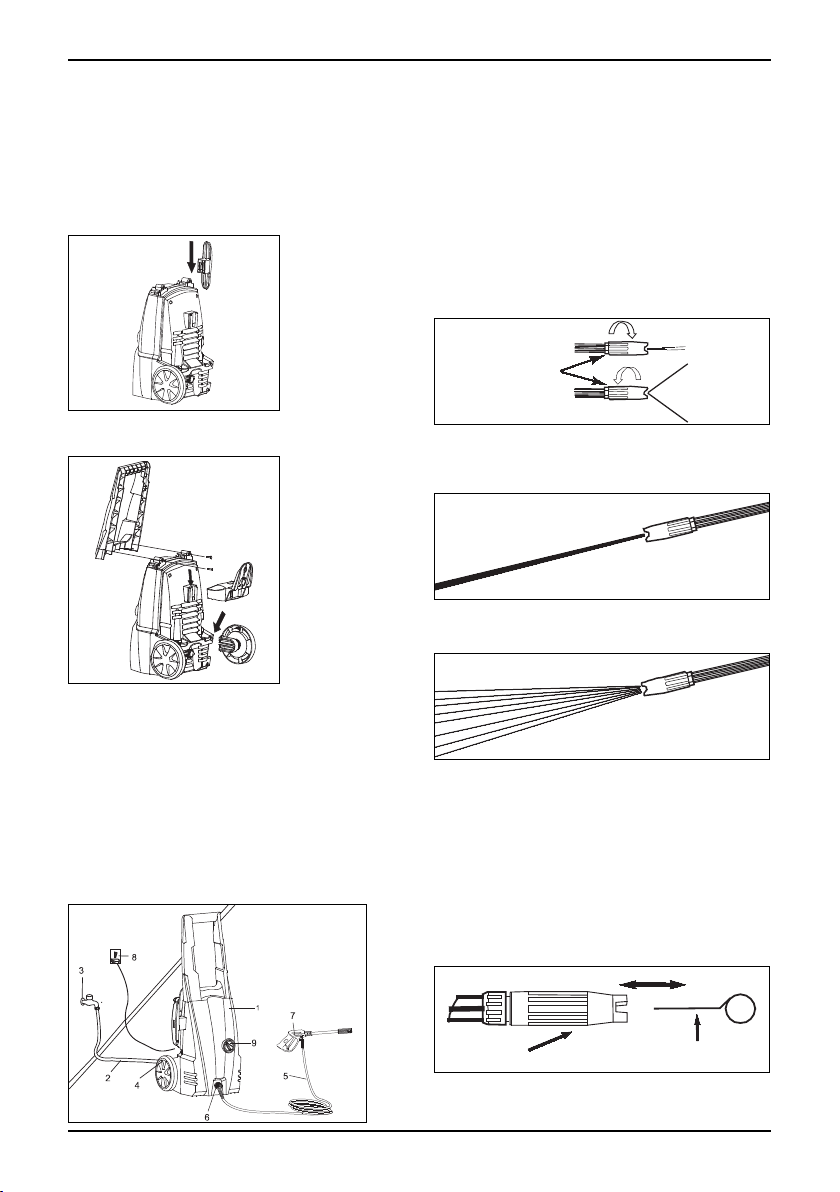

КОМПЛЕКТНОСТЬ

Напорный шланг

Пистолет-распылитель

Шнур питания

ПРАВИЛА ТЕХНИКИ БЕЗОПАСНОСТИ

Во избежание возгорания, поражения электрическим

током итравм электрооборудование следует эксплу-

атировать всоответствии стребованиямиданной

инструкции.

Электротехническая безопасность

●Перед включением следует убедиться, что напря-

жение всети питания соответствует напряжению

электродвигателя мойки.

●Пользуйтесьтольковлагозащищенным удлините-

лем. Не рекомендуется использовать чрезмерно

длинные удлинители. При использовании удлини-

теля на катушке он должен быть полностьюраз-

мотан. Площадьпоперечного сечения проводов

удлинителя должна быть не менее1,5 мм2.

●Мойку необходимоподключать через устройство

защитного отключения (макс. ток утечки– 30 мА).

●Вынимая вилку из розетки, не тяните за шнур питания.

● Во избежание короткого замыкания не направ-

ляйте струю воды на сам аппарат ииное элек-

трооборудование. Не пользуйтесь мойкой вне

помещений вдождливую погоду.

●Не прикасайтесь мокрыми руками квилке и(или)

розетке сети питания.

Немедленно выключите мойку в случае :

1. Неисправности или повреждения вилки или шну-

ра питания.

2. Поломки выключателя.

3. Появления дыма или запаха горелой изоляции.

4. Повреждения шланга высокого давления.

Перед началом работы :

●Убедитесь втом, что вода поступает вмойку

должным образом. Эксплуатация мойки без во-

ды может привести кее повреждению.

●Проверьте надёжность всех соединений иотсут-

ствие повреждённых или изношенных деталей.

Общие указания по безопасности

●Если вы находитесь слишком далеко от предмета,

который собираетесь вымыть, не перемещайте

аппарат путём перемещения его за шланг высо-

кого давления или за шнур питания; используйте

для этого специальную рукоятку.

●Для моделей, не оснащённых «автостопом», за-

прещено использование мойки втечение более

чем 1-2 минут при закрытом пистолете, так как это

может вывести аппарат из строя.

●Взимних условияххраните аппарат втеплом месте.

●При работе аппарата вентиляционные отверстия

должны быть открыты.

●Располагайте аппарат как можно ближе кисточни-

ку водоснабжения.

●Используйте только те принадлежности иза-

пасные части, которые рекомендованы произво-

дителем. Применение оригинальных принадлеж-

ностей изапасных частей обеспечит надежную и

безопасную работу.

● Устанавливайте мойку вустойчивом положении,

на ровной поверхности.

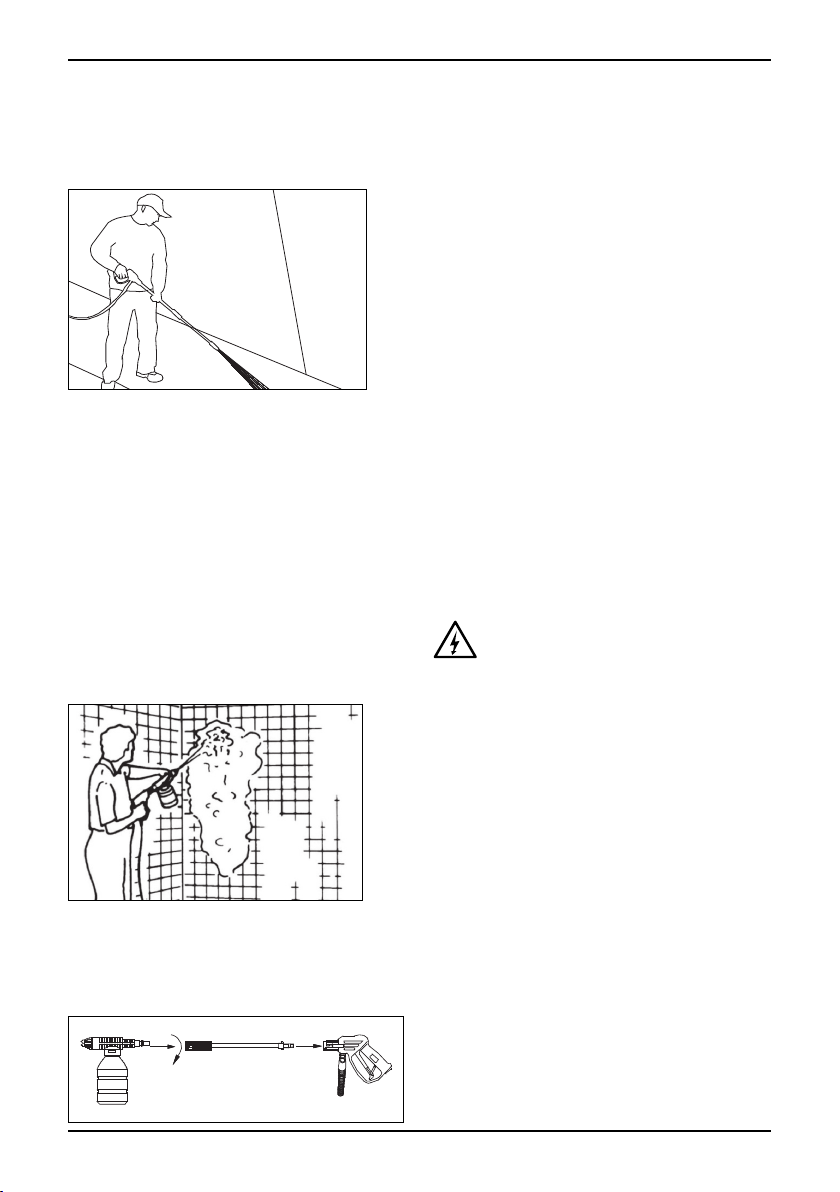

● Не допускайте непреднамеренногонажатия на ку-

рок пистолета-распылителя. Не переносите мойку

всборе спистолетом, держа палец на курке.

● Для предотвращения случайного включения по

окончании работы смойкой убедитесь, что курок

пистолета заблокирован (рис. 5).

●Во избежание взрыва или отравления запреща-

ется использовать при работе смойкой легковос-

пламеняющиеся или токсичные жидкости либо

иные средства, несовместимые справильной ра-

ботой мойки.

● Не направляйте струю воды на людей иживотных:

это травмоопасно. Посторонние люди иживотные

должны находиться на расстоянии не менее 10

метров от места работы.

● Не доверяйте использование аппарата детям или

необученным лицам.

● Не фиксируйте курок пистолета вположении

«Включено».

●Не допускается изменять оригинальный диаметр

распылительнойголовки форсунки.

●Не оставляйте мойку без присмотра.

●Струяводы под большим давлением, попадая на

предметы, может ссилой отбрасывать их, поэто-

му при работе необходимо надевать спецодежду

изащитные очки.

●Перед нажатием курка пистолета крепко сожмите

пистолет, чтобы его не выбило из рукипри отдаче.

●Во избежание загрязнения соблюдайте требования

местнойорганизацииводоснабжения. Всоответ-

Изготовитель: BORT GLOBAL LIMITED

Room 1501, 15/F., SPA Centre, 53-55 Lockhart Road, WANCHAI HONG KONG

Тел/Факс +85 258 194 891

Уполномоченное изготовителем лицо: ООО «Дизайн-строй»

125222, г. Москва, Пенягинская ул., д. 18

Телефон: +7 (499) 700-10-34