10 | English

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

uAvoid dust accumulation at the workplace. Dust can

easily ignite.

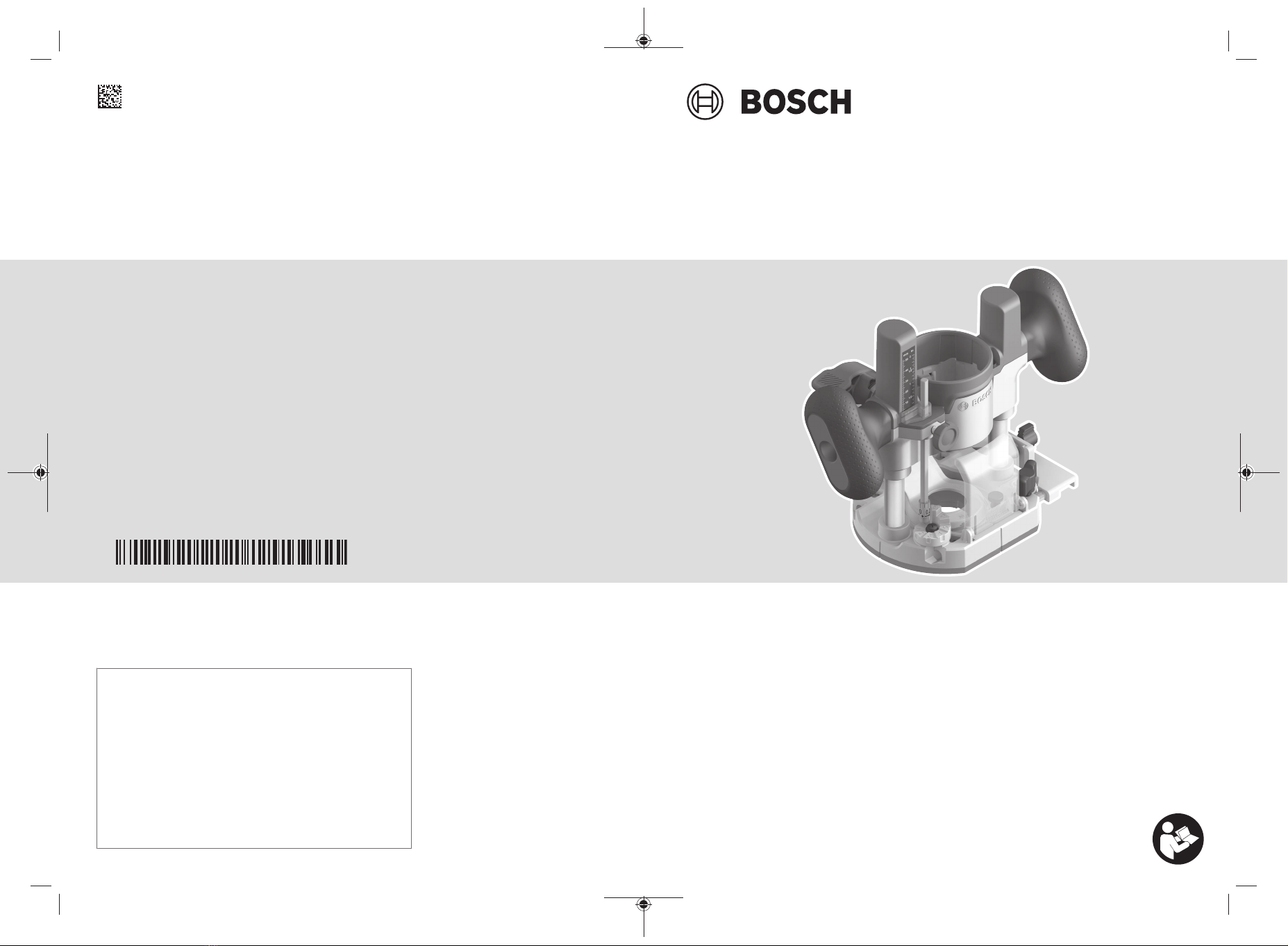

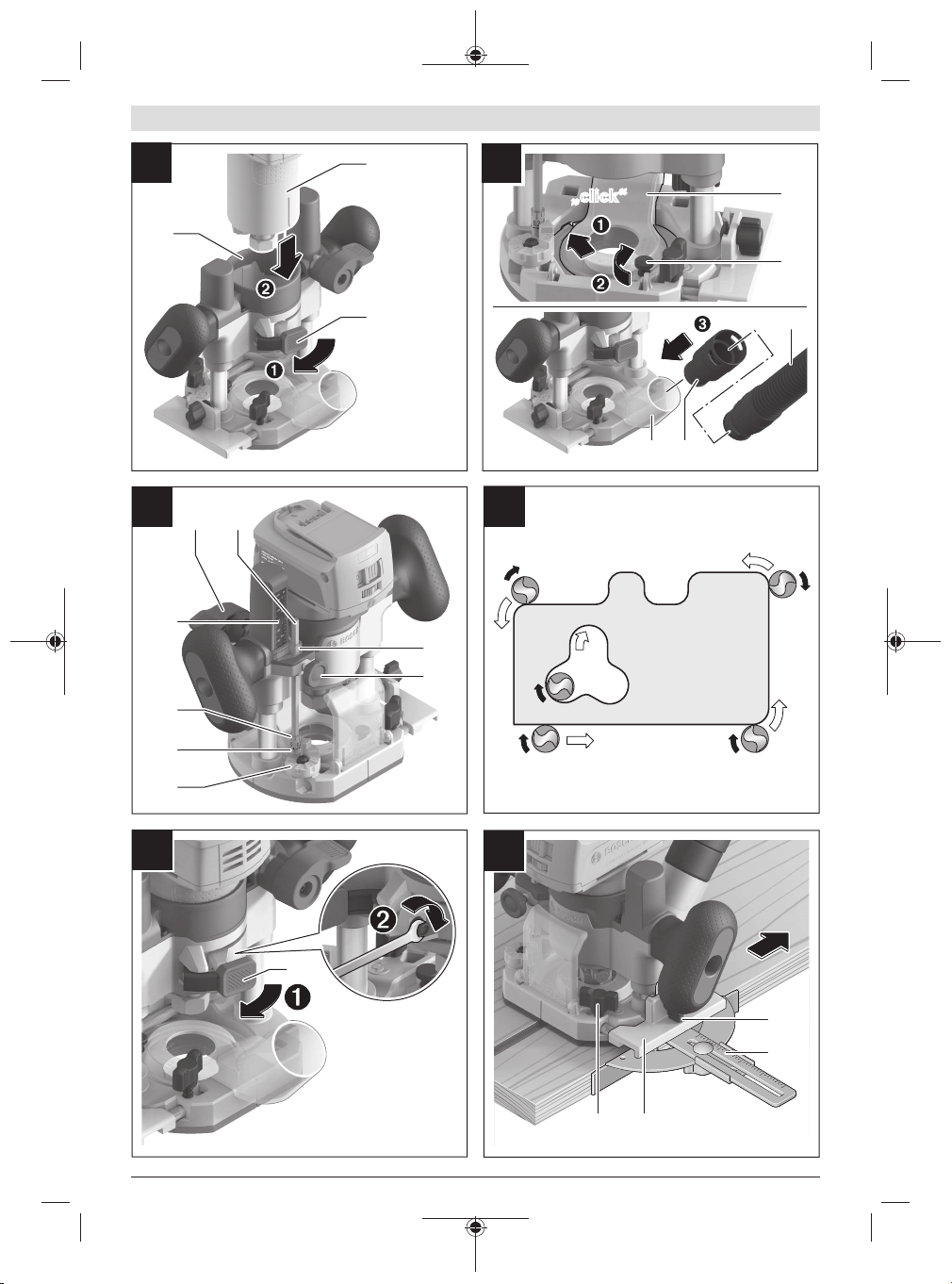

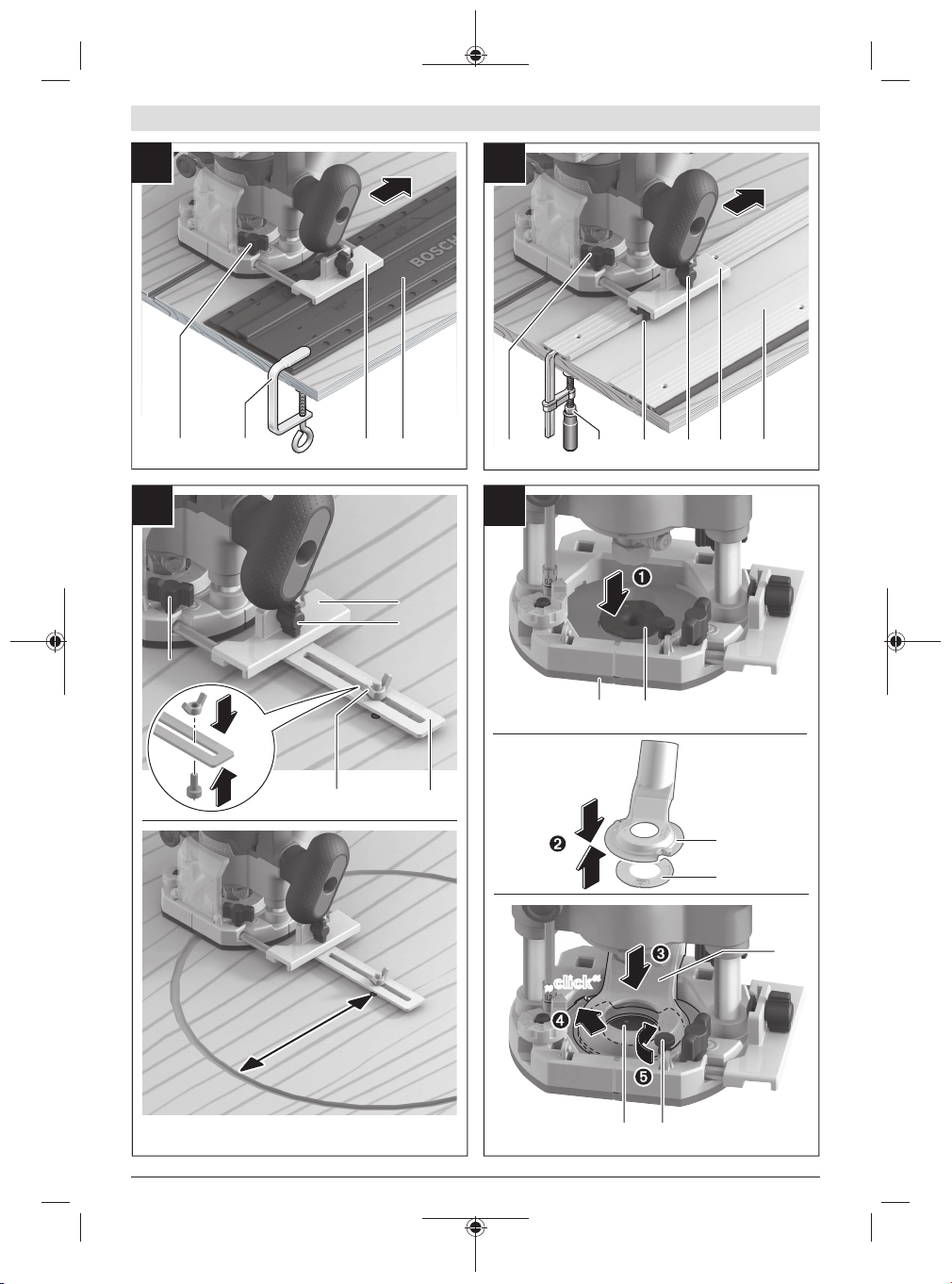

Connecting the Dust Extraction System (seefigureB)

Insert the dust extraction adapter(17) into the router

plunge base(2). Push the part of the adapter(17) that is op-

posite the screw(18) into the router plunge base(2). Fix

the adapter in place using the screw(18).

Put an extraction hose(26) (dia.35mm) (accessory) on the

installed dust extraction adapter(25). Connect the dust ex-

traction hose(26) to a dust extractor (accessory).

The dust extractor must be suitable for the material being

worked.

When extracting dust that is dry, especially detrimental to

health or carcinogenic, use a special dust extractor.

Operation

Setting the Routing Depth (seefigureC)

uThe routing depth must only be set while the power

tool is switched off.

Rough Adjustment of the Routing Depth using the

Infinitely Variable Depth Stop and Scale

– Place the power tool with a fitted router bit onto the work-

piece you want to machine.

– Set the scale for fine adjustment(10) to "0".

– Set the turret stop(8) to the lowest setting; you will feel

the turret stop engage.

– Loosen the handle screw for the depth stop(5) so that

the depth stop(3) moves freely.

– Slowly guide the router(1) by pressing the handle(14)

down slowly until the router bit is touching the workpiece

surface. Push the locking lever(12) to lock the plunge

depth.

– Push the depth stop(3) down until it is resting on the tur-

ret stop(8). Set the slide with the index mark(4) to posi-

tion "0" on the routing depth scale(11).

– Set the depth stop(3) to the required routing depth and

tighten the handle screw for the depth stop(5). Take care

not to accidentally move the index mark(4).

– Release the locking lever for the plunge action(12) and

guide the router to the uppermost position.

The set routing depth is only reached when the depth

stop(3) touches the turret stop(8) while plunging.

For larger routing depths, you should perform the cut in sev-

eral phases, so that only a small amount of material is re-

moved after each cut. By using the turret stop(8), the rout-

ing process can be divided into several steps.

Rough Adjustment of the Routing Depth using the Turret

Stop Settings

– Place the power tool with a fitted router bit onto the work-

piece you want to machine.

– Set the scale for fine adjustment(10) to "0".

– Set the turret stop(8) to the lowest setting you require;

you will feel the turret stop engage.

– Loosen the handle screw for the depth stop(5) so that

the depth stop(3) moves freely.

– Slowly guide the router(1) by pressing the handle(14)

down slowly until the router bit is touching the workpiece

surface. Push the locking lever(12) to lock the plunge

depth.

– Tighten the handle screw(5).

– By turning the turret stop(8), you can now set the depth

using the predefined settings.

Example:

Required routing depth: 8mm

First routing operation from setting "10" to setting

"5"5mm

Second routing operation from setting "5" to setting

"2"3mm

Note: For precision routing results, it is advisable to stay

within the maximum routing depth of 5mm per routing oper-

ation.

Fine Adjustment of the Routing Depth

After making a test cut, you can set the routing depth to the

exact level you require by turning the bushing(9). Turning it

clockwise increases the routing depth; turning it anticlock-

wise decreases the routing depth. The scale(10) can be

used for guidance. One turn corresponds to an adjustment

range of approx. 0.8mm; the maximum adjustment range is

approx. 4mm (i.e. five turns correspond to 4mm).

When the router plunge base(2) is lowered to the maximal

plunge depth, it is not possible to use the fine adjustment to

make deeper cuts, as the maximum adjustment range has

been utilised.

Fine adjustment is also not possible when the depth stop(3)

sits against the turret stop(8).

Working Advice

Routing Direction and Routing Process (seefigureD)

uRouting must always be carried out with the work-

piece being moved against the direction in which the

router bit is turning (up cut). If the workpiece is moved

in the same direction as the router bit is turning (down

cut), the power tool may be pulled out of your hands.

To rout with the router plunge base(2), proceed as follows:

– Set the required routing depth, (see "Setting the Routing

Depth (seefigureC) ", page10).

– Place the power tool with a fitted router bit onto the work-

piece you want to machine and switch on the power tool.

– Slowly guide the router(1) down until the set routing

depth is reached. Push the locking lever(12) to lock the

plunge depth.

– Carry out the routing process with a uniform feed.

– When routing is complete, move the router back to the

uppermost position.

– Switch the power tool off.

1 609 92A 8WV | (14.06.2023) Bosch Power Tools