–10–

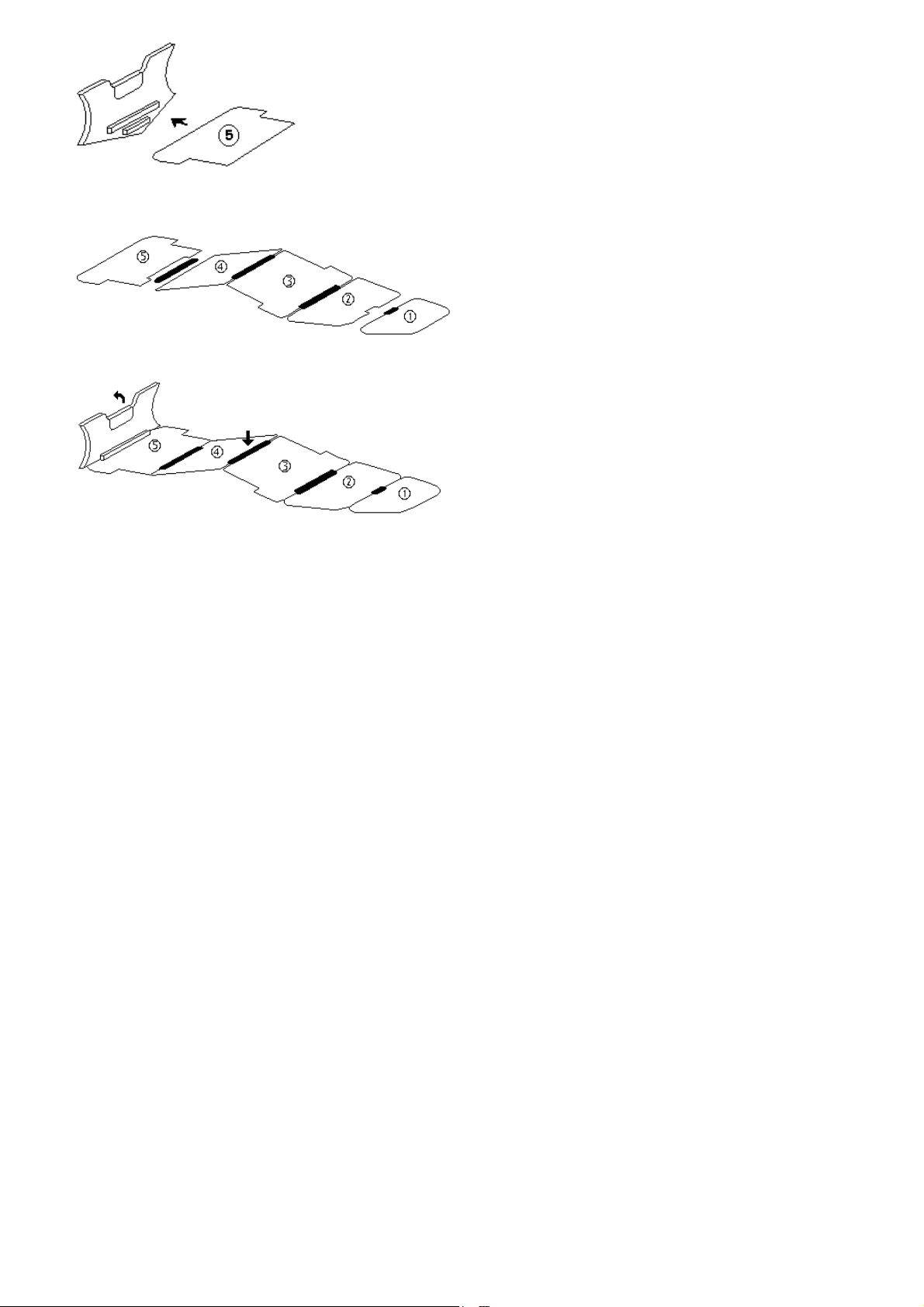

6.9.Set the lateral beams in the cut-outs provided on segments

No.5, No.4, No.3 (Fig.10). To do it, place the beam in the boat

from one side in opposition to the cut-outs, hook the boarding

edge with the beam from below and make a pushing motion from

top to bottom and forward. Thereat, your may hold up the floor

edge from below through the bottom.

Check to ensure that the beams do not "catch" the balloon. The

segment edges should enter the beam cut-outs tightly.

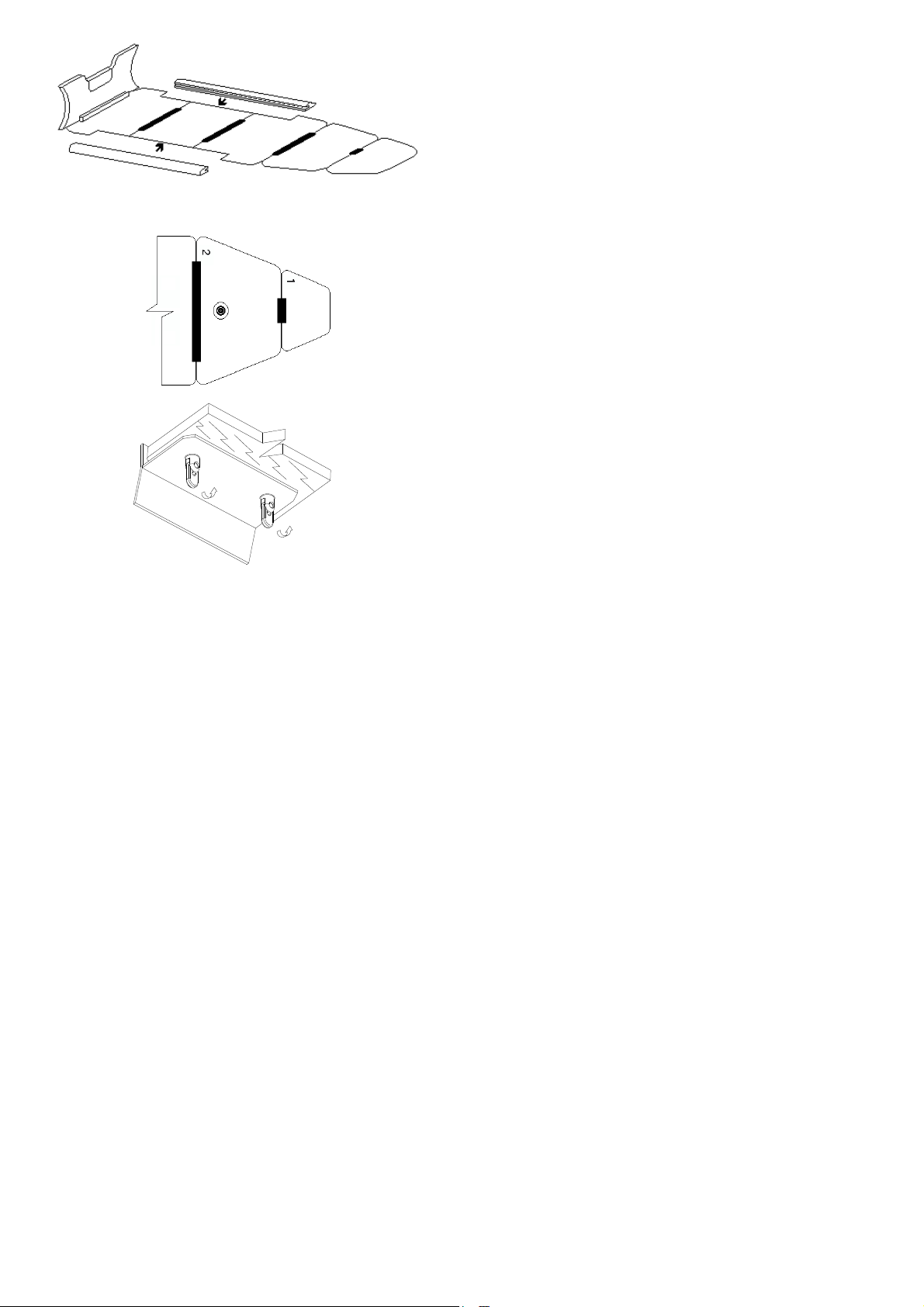

6.10.Make sure again that the edges of the segments and beams fall

within the folding line of the balloon and bottom connecting tape.

6.11.Check to ensure that the rigid boarding was assembled

correctly: the segments should be arranged closely to each other

without misalignment in the increasing order of the numbers from

the bow to the aft of the boat. The keel valve should fall within

the centre of the hole of segment No.2 (Fig.11). If the keel

valve is outside the centre of the hole of segment No.2 adjust the

keel position by taking hold of the valve flange and raising the

boat bow by the lifeline. Reset the valve.

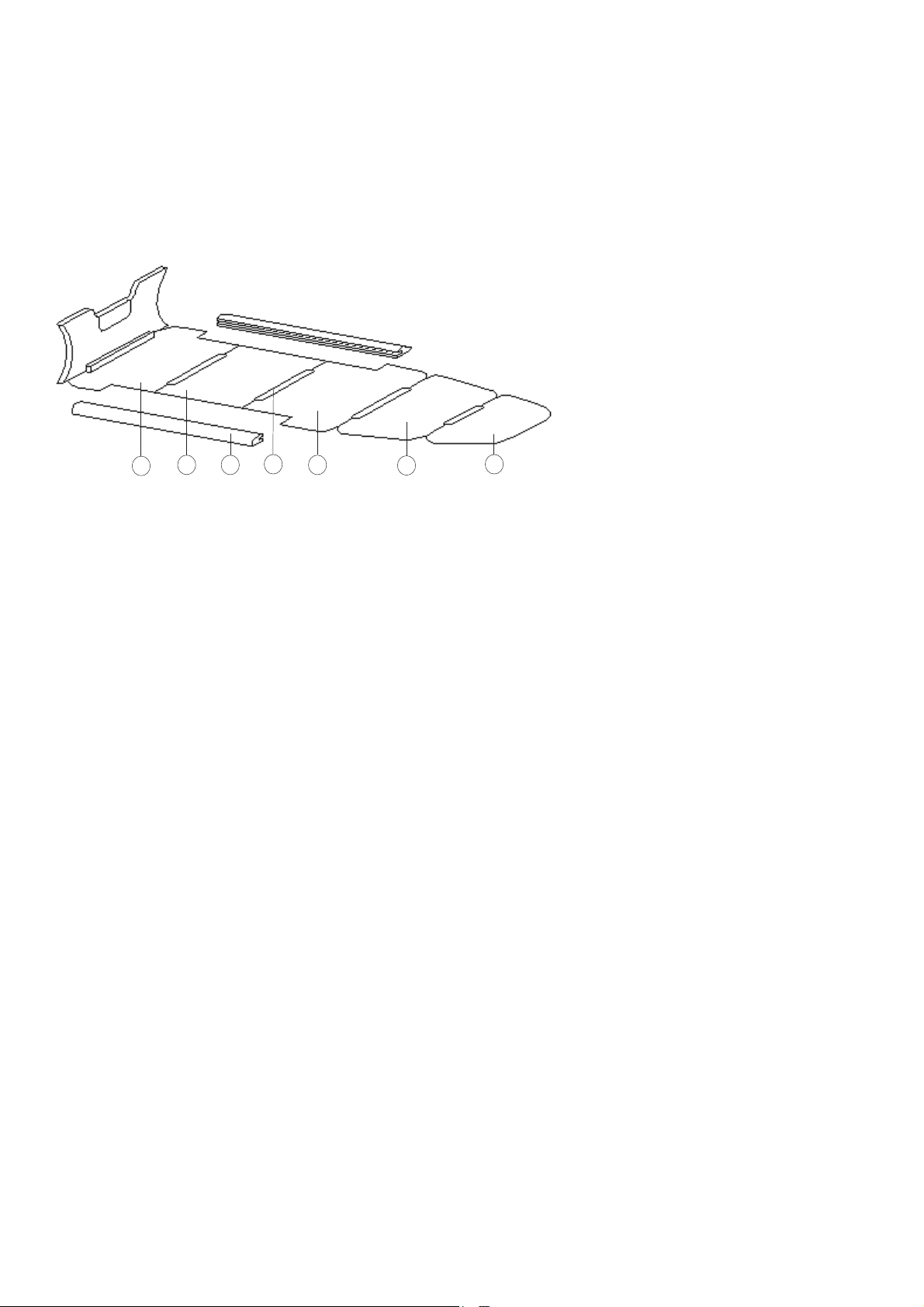

6.12.Set the rigid seat as shown in the figure 12.

To do it, insert the fixing devices arranged on the lower surface of

the wooden seats into the holes of the brackets pasted onto the

balloon. Turn and fix lugs of the fixing devices till they clicked as

shown in the figure.

6.13.Fill the balloon compartments with air using the pump from the

complete set. First fill the aft compartments, then medium compart-

ments and, finally, bow compartment. Thereat, do not bring the

pressure up to its operating value.

6.14.After all the compartments are filled check to ensure that the

boarding is arranged correctly inside the Boat.

If necessary, set the boarding as required by applying a force to the

edges of the boarding segments.

Fig.10

Fig.11

Fig.12a