Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. ngland

Tel: +44 (0) 1902 773746 Fax: +44 (0)

1902 420639

mail:

[email protected] Web: www.broycecontrol.com

The information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the user’s own risk

.

P9670-2-A

3

33

3

7. QUICK VI W OF US R S TTINGS

It is not possible to edit settings when these screens are displayed.

This feature can also be activated with the front window closed!

•Press and hold the button to dis lay the initial ower u screen.

•Press the same button again to dis lay the “Last Tri ed Information” screen

(refer to the next section for further information on this feature).

•Press again to dis lay the “Overcurrent Summary” screen.

•Press again to dis lay the contact details for Broyce Control.

•Press again to revert back to Normal o eration.

8. LAST TRIPP D INFORMATION

Refer to next page for detailed information of this feature

Notes during programming

If during programming it is necessary to abort, press the button briefly.

Pressing and holding either or for >1sec. will increment or decrement

the new value at a quicker rate.

Stepping through each User Setting screen is performed by pressing and holding

the button until the desired screen is displayed.

Short presses of the button will allow further editable settings to be changed

within a specific screen.

If the user remains in a setting or summary screen where no adjustments or button

presses are made within a certain period, the screen will revert back to Normal

operation. Additionally, any settings that have been made but not stored will not be

saved.

“O/C” refers to Overcurrent.

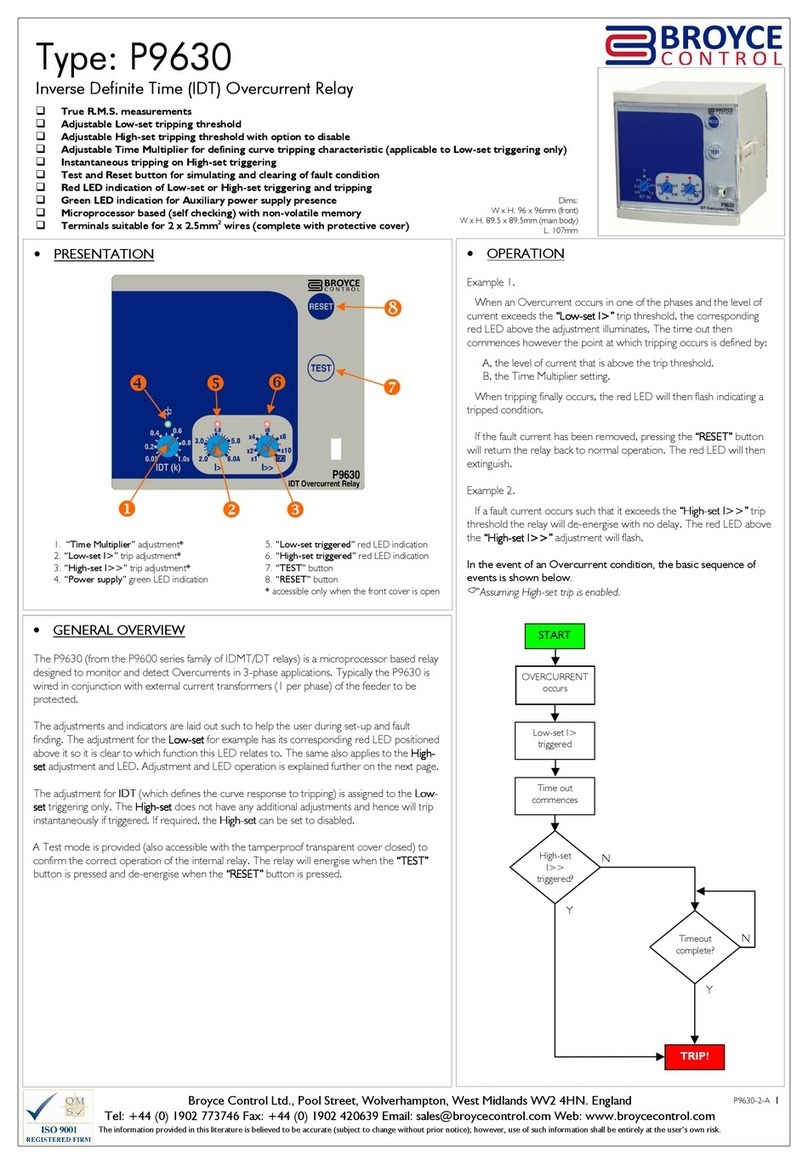

•TRIPPING MOD

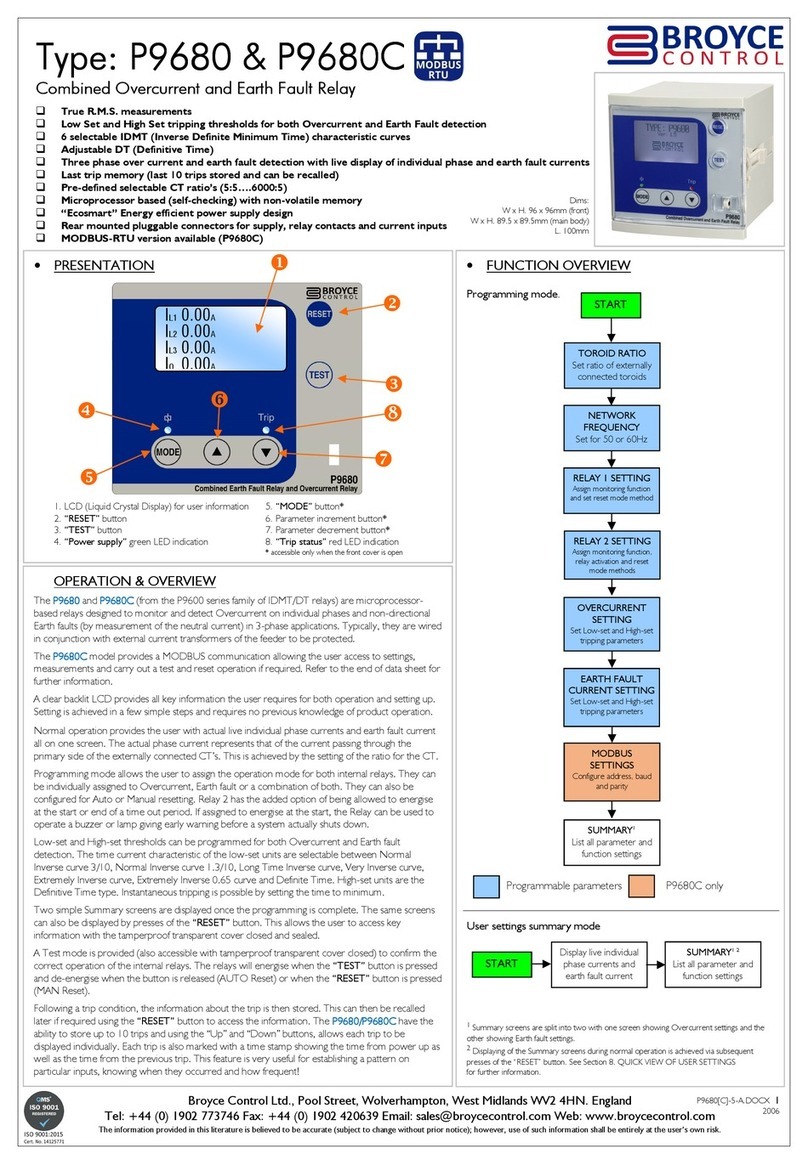

•A fault which develo s on a hase will be indicated by an increase in current

reading on the LCD. When the level of current exceeds the Low-set setting,

the hase at fault will be highlighted by the digits flashing.

•The LCD backlight will flash.

•Relay 2 will energise if assigned to Overcurrent and set to energise at the start

of the time out eriod (See Section 3. RELAY 2 SETTING).

•The characters “I>” will dis lay to indicate the Low-set has been triggered.

•If the current continues to increase above the High-set setting, the characters

“I>” will change and dis lay “I>>” to indicate the High-set has been

triggered.

•When the unit finally tri s, the digits of the hase at fault will sto flashing and

remain highlighted. This allows the user to see which hase was at fault and

caused the unit to tri .

•The red “Tri ed”

“Tri ed”“Tri ed”

“Tri ed” LED will also flash.

•The relays which energised are also dis layed on the screen after tri ing.

•Press to reset and return the unit back to normal o eration (assuming

the fault has been cleared). The LCD reverts back to dis laying the normal

system currents and the red “Tri ed”

“Tri ed”“Tri ed”

“Tri ed” LED sto s flashing.

If either relay is set for Auto resetting, then they would have de-energised after the

fault had cleared. The corresponding relay ident (i.e. R1 and/or R ) on the display

would also disappear. Pressing the “R

“R“R

“RESET”

ESET” ESET”

ESET” button will only clear the LCD. If either

relay is set for Manual resetting, then pressing the “RESET”

“RESET”“RESET”

“RESET” button will de-energise the

relay(s) and clear the LCD.

•PROGRAMMING (continued)

3. R LAY 2 S TTING

Default setting for Relay is to energise at the end of the time out period.

Resetting mode is Auto.

•Setting of “Relay 2”

“Relay 2”“Relay 2”

“Relay 2” is carried out in a similar manner as “Relay 1”

“Relay 1”“Relay 1”

“Relay 1”; however it

is necessary to assign the relay to either energise at the start (S) or end (E) of

the time out eriod.

Actual LCD resentation when adjustable arameters are dis layed.

•Press and hold the button to set the o tions for “

““

“OVERCURRENT”

OVERCURRENT” OVERCURRENT”

OVERCURRENT” as

described in the next section.

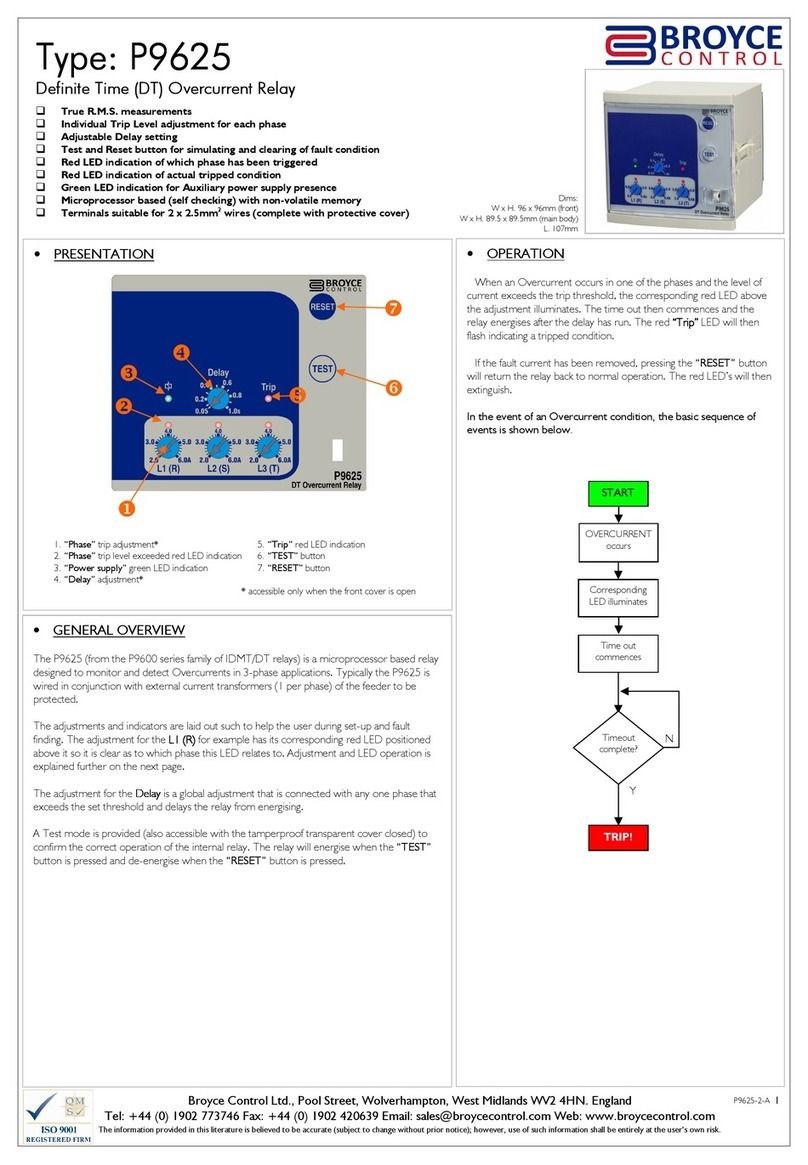

4. OV RCURR NT S TTING

The description for the Curves is abbreviated when displayed on the screen. Refer

to “IDMT Characteristic Curves” for further explanation.

Default settings for Overcurrent are shown in the last LCD screen example in this

section.

•Settings for Overcurrent are dis layed in turn following subsequent resses of

the button. The Low-set tri current (I>) is dis layed first.

•Press either or to change the current.

•Press the button to select the remaining settings and use the and

buttons to change them.

Actual LCD resentation when adjustable arameters are dis layed.

Screen exam le above also shows the default settings for OVERCURRENT.

•Press and hold the button to set the o tions for “

““

“EARTH FAULT”

EARTH FAULT” EARTH FAULT”

EARTH FAULT” as

described in the next section.

If the Curve in selection “ :” is set to Definite Time, then selection “3:” will display

“3: t>” and the required delay can then be set.

If High-set is set to Disable in selection “4:”, then I>> or t>> cannot be

adjusted.

5. OV RCURR NT SUMMARY

It is not possible to edit settings when this screen is displayed.

•Following the setting of “Overcurrent”, the LCD dis lays the “Overcurrent”

screen showing a summary of the settings made during rogramming. All

settings are dis layed. The selected CT ratio, Network Frequency and Relay

o eration (following a Reset) information is also dis layed.

6. SAVING OF S TTINGS

•If after viewing the Summary screen the settings are correct, ress and hold

the button until the word “

““

“Saved.

Saved.Saved.

Saved.”

””

” a ears. Any new settings are now

stored.

•The screen will revert back to Normal o eration.

I> 5.00A

NI 3/10

k> 0.1

I>>50.00A

t>>0.05s

R1 = MAN R2 = A TO (E)

RELAY 1: RELAY 2:

A TO A TO (E)

MAN MAN (E)

A TO (S)

MAN (S)

Low set

1: I> 5.00A

The letter in brackets refers to

whether Relay 2 has been set

to trigger at the start or end of

the time out eriod.

(E) = E

EE

End of time out

(S) = S

SS

Start of time out

Either abbreviation can a ear

after the word MAN or

AUTO

See Section 3. RELAY

SETTING

I

L1

20.70

A

I>

I

L2

40.00

A

I

L3

27.50

A

I

L1

20.70

A

I>>

I

L2

89.00

A R1 R2

I

L3

27.50

A

Low-set

triggered

High-set

triggered

Relay(s) which

energised on

tri ing

Low Set:

1: I> 5.00A

2: Curve NI 3/10

3: k> 0.1

High Set:

4: I>> 50.00A