Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. England

Telephone:

+44

(0)

1902

773746

Facsimile:

+44

(0)

1902

420639

Email:

[email protected] Web:

http://www.broycecontrol.com

The information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the user’s own risk.

ELRV30-2-ARMS

012366 Page 1of 2

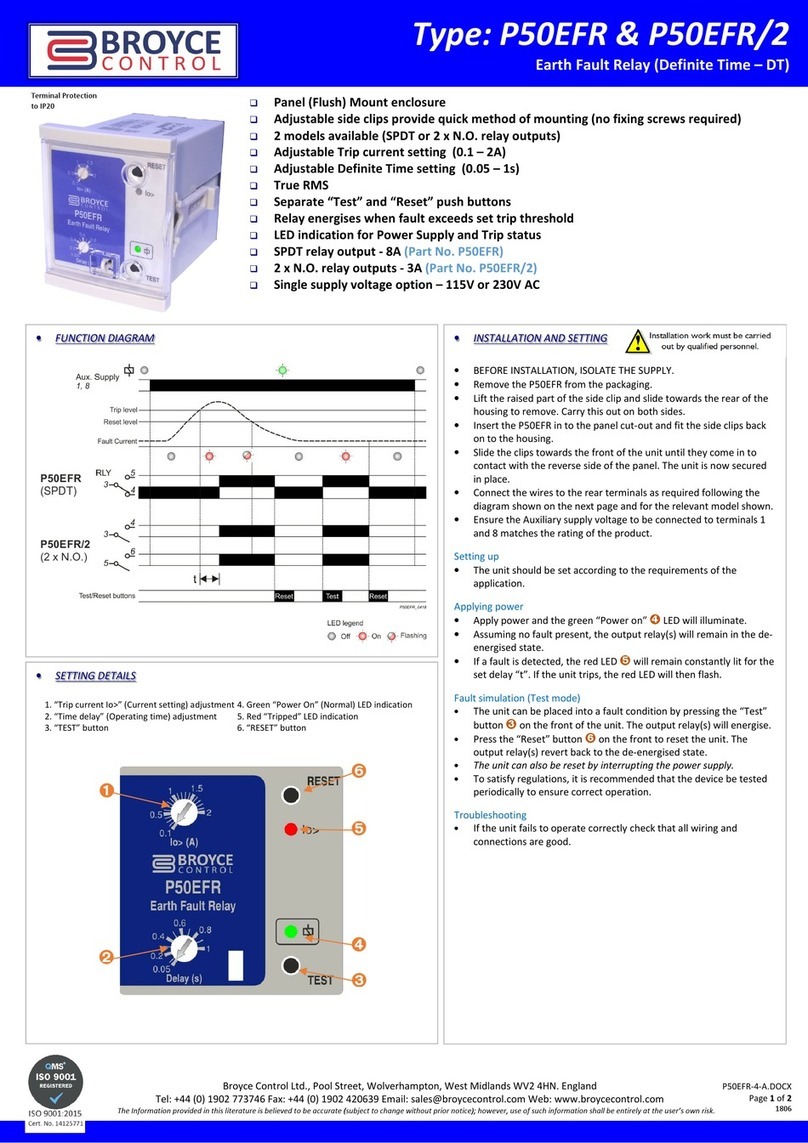

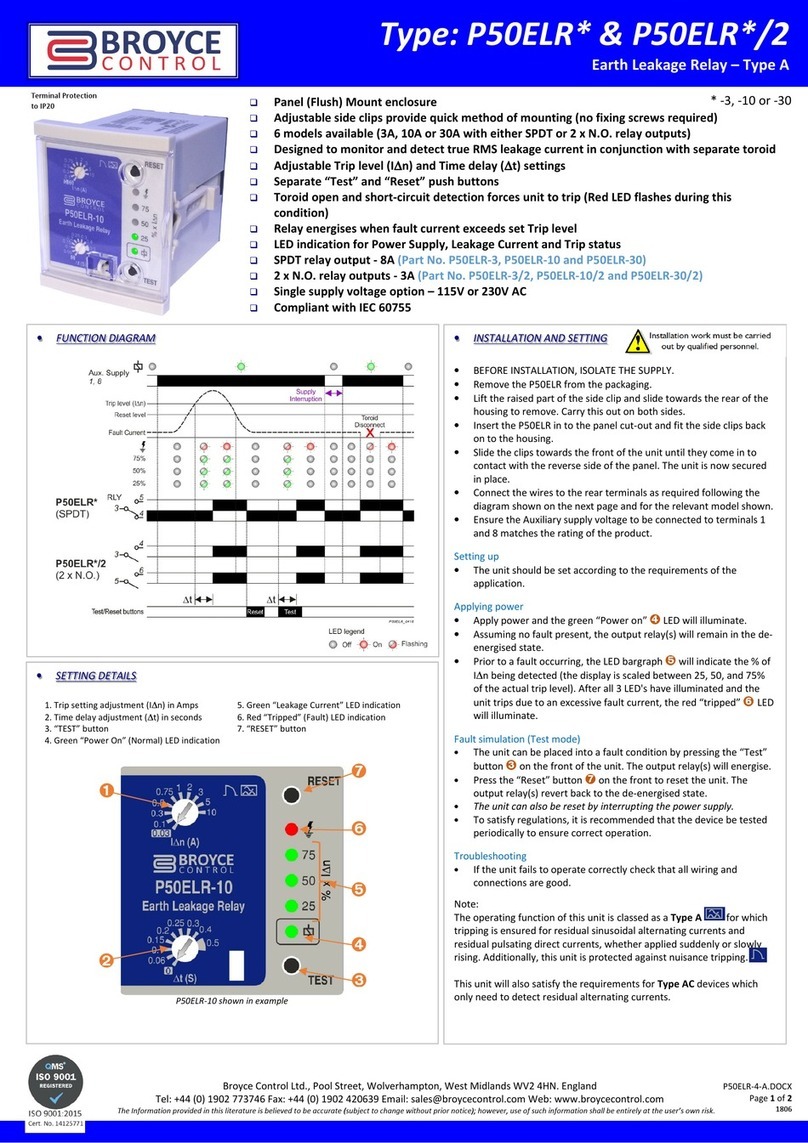

•CONNECTION DIAGRAM

14

1

standard

output

positivesafety

output

test

reset

A1(+ve)

A2(-ve)

Faultleveloutput*

(i.e.lamp)

2

3 5 7 9 11 13

4 6 8 10 12

toroid

50m*max.

50m*max.

L1

L2

L3

N

E

Note:The voltage

across the faultlevel

outputMUSTNOT

exceed 240V~(For

400V~unitsused in

3-Phaseinstallations,

connectthe load between

terminal2and neutral)

The EarthMUSTNOTpass through

the toroid.

Forsinglephaseapplications,onlythe live

and neutralneed tobe passed through the

toroid.

*Cabling:

Fordistances>1m,usetwisted paircablebetween

the unitand toroid.Always ensurecablestotoroid

and remotetest/resetswitchesAREKEPTAWAY

frommainsand datacablesinthe sameinstallation.

Bothrelays areshown

inthe de-energised state

(i.e.wherepowerisnot

presenton terminals1and 3)

E

*Onlyavailableon ACsupplymodels

Type: ELRV-30

True RMS Earth Leakage Relay (Variable) -Type A

q70mm DIN rail housing

qDesigned to monitor and detect true RMS, earth fault currents (up to 30A) in conjunction with a separate toroid

qFast response time of <25mS1to fault currents that are 5 x greater than the set trip current

qDigital LED Display shows measured leakage current, various user settings and diagnostics

qMicroprocessor controlled with internal monitoring (self-checking)

qSensitivity (I∆n) and time delay (∆t) adjustable using simple 2-button operation

q“Display” push button allows user to view settings without needing to open the tamperproof cover. The “last recorded” peak

trip current can also be recalled using the same push button

qSingle button operation for “Test / Reset” and connection facility for remote “Test” and “Reset” push buttons

qConnection for remote lamp facility warning user prior to a trip condition (level adjustable by user)

qToroid open and short circuit detection (unit forced to trip during open circuit condition)

q2 x SPDT relay output 8A. LED indication of user settings / fault condition after unit has tripped 1“inst.” time delay setting / fault current <30A

to DIN 43880

W. 70mm

•TECHNICAL SPECIFICATION

Supply voltage Un (1, 3): 12 –60V DC (85 –115% of U)

24, 115, 230, 400V AC (85 –115% of Un)

Galvanic isolation between the supply and the toroid and

remote test / reset connections on AC supply versions.

Supply frequency: 50/60/400Hz (AC supplies)

Isolation: Over voltage cat. III

Rated impulse

withstand voltage:

(1.2 / 50µS) IEC 60664 800V (24V AC supply

2.5kV (115V AC supply)

4kV (230V, 400V AC supplies)

Power consumption (max.): 6VA (AC supplies), 5W (DC supply)

Monitored leakage current: 2mA to 30A (50/60/400Hz)(through external toroid with

1000:1 ratio and connected to terminals 11 and 13)

Sensitivity I∆n: 6, 10, 30, 50, 75, 100, 300, 500, 750mA

1, 3, 5, 7.5, 10, 15, 20, 25, 30A (user selectable)

Trip level: 75% of I∆n (nominal)

Hysteresis: 8% of I∆n or 2mA, whichever greater

Accuracy: ±15% (valid range 10 …. 110% of I∆n or 2mA,

whichever greater)

Time delay ∆t: inst., 50, 250, 500mS, 1, 2.5, 5, 10 sec. (user selectable)

Note: For I∆n settings of 30mA or less, the time delay is fixed

to inst. (instantaneous, <25mS) and is not adjustable.

Measured current: Displayed on auto ranging 2 digit 7-segment red LED display

Display Resolution: 100uA min.

Reset time: <200mS (from supply interruption)

Power on delays: Self test duration: <5 secs.

(from application of supply Delay before P.S.O. relay energises “td”:600mS (Note: relay

to terminals 1 and 3) will energise during self test period assuming no fault present)

Memory: storage of the leakage fault and reset with “test / reset” button

Ambient temp: -5 to +60°C

-5 to +40°C (in accordance with IEC 755)

Relative humidity: +95%

Output : 2 x SPDT relay (4, 6, 8 / 10, 12, 14)

Output rating: AC1 250V 8A (2000VA)

AC15 250V 2.5A

DC1 25V 8A (200W)

Electrical life: ≥150,000 ops at rated load

Dielectric voltage: 2kV AC (rms) IEC 60947-1

Rated impluse

withstand voltage: 4kV (1.2 / 50µS) IEC 60664

Remote “test” / “reset”

(5, 7, 9) Requires two N.O. contacts. (i.e. push buttons)

Contact closure time: >100mS

Fault level output (1, 2): 50% of I∆n (factory set)

User adjustable from 10 -65% in 5% increments

Hysteresis: 8% of I∆n or 2mA, whichever greater

Load (resistive): 40mA max. @ 240V

Note: A remote lamp can only be connected when terminals 1

and 3 are being supplied with an AC supply

Housing: Grey flame retardant Lexan UL94 VO

Weight: ≈250g (AC supplies), ≈170g (DC supply)

Mounting option: On to 35mm symmetric DIN rail to BS5584:1978

(EN50 002, DIN 46277-3)

Terminal conductor size: ≤2.5mm2stranded. ≤4mm2solid

Approvals: Conforms to: IEC 755. IEC 61543 (EMC)

Radiated Immunity: IEC 61000-4-3: 1.89GHz @ 30V/m

and pending. CE and Compliant.

•Options

For other supply voltages, alternative trip levels or time delays, please consult the sales office.

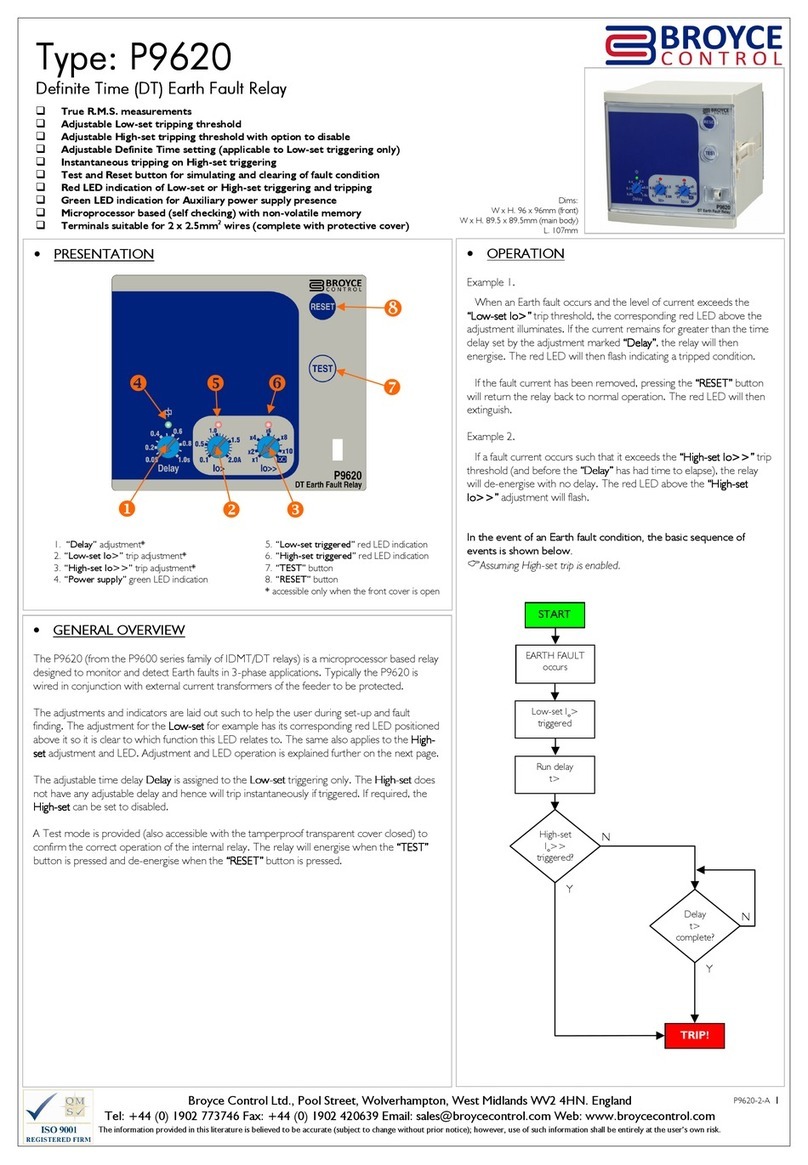

•Accessories –Toroids

Toroid Type: Internal diameter:I∆n (min.) A

BZCT035 35mm ∅0.03

BZCT070 70mm ∅0.03

BZCT120 120mm ∅0.1

BZCT210 210mm ∅0.3

Note:

( ) Numbers in brackets shown above refer to terminal numbers on the relay housing.

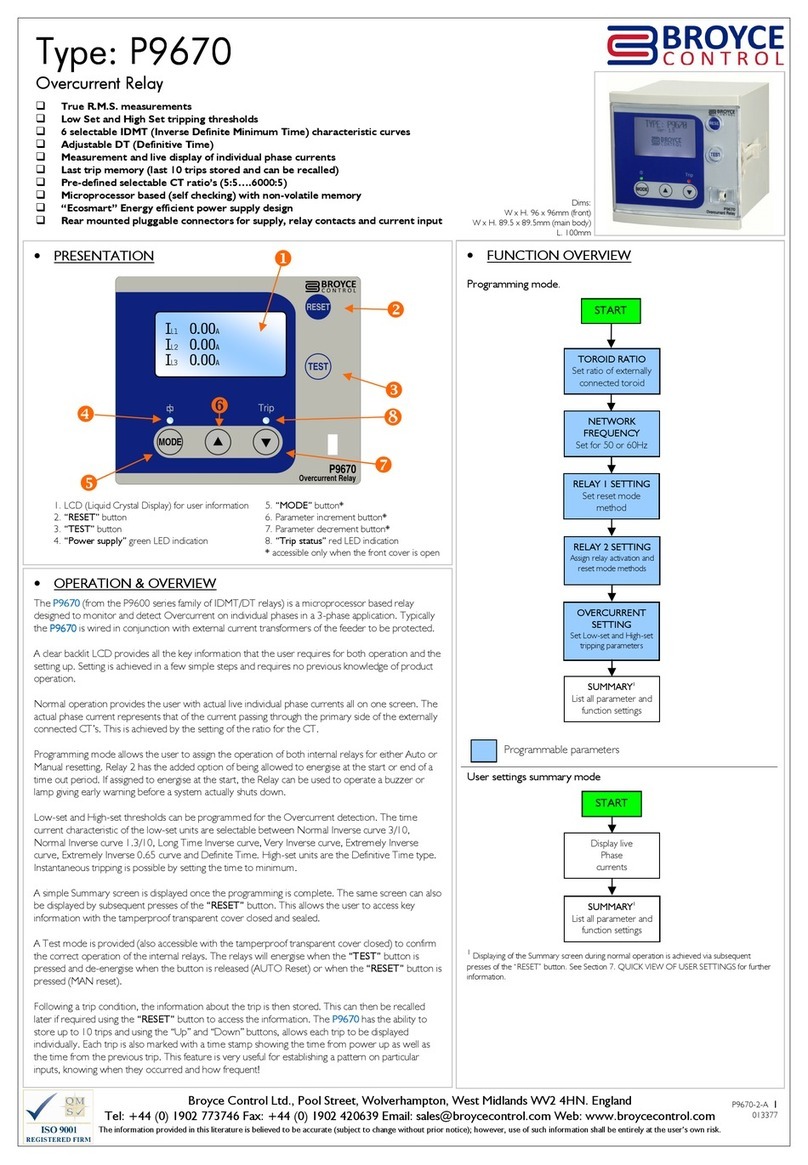

•FUNCTION DIAGRAM

Standard

output

fault

current

failureofconnection

totoroid

"reset" "test"

interrupted

Triplevel(In)

∆

Positivesafety

output

∆

t

Resetlevel

tdtd

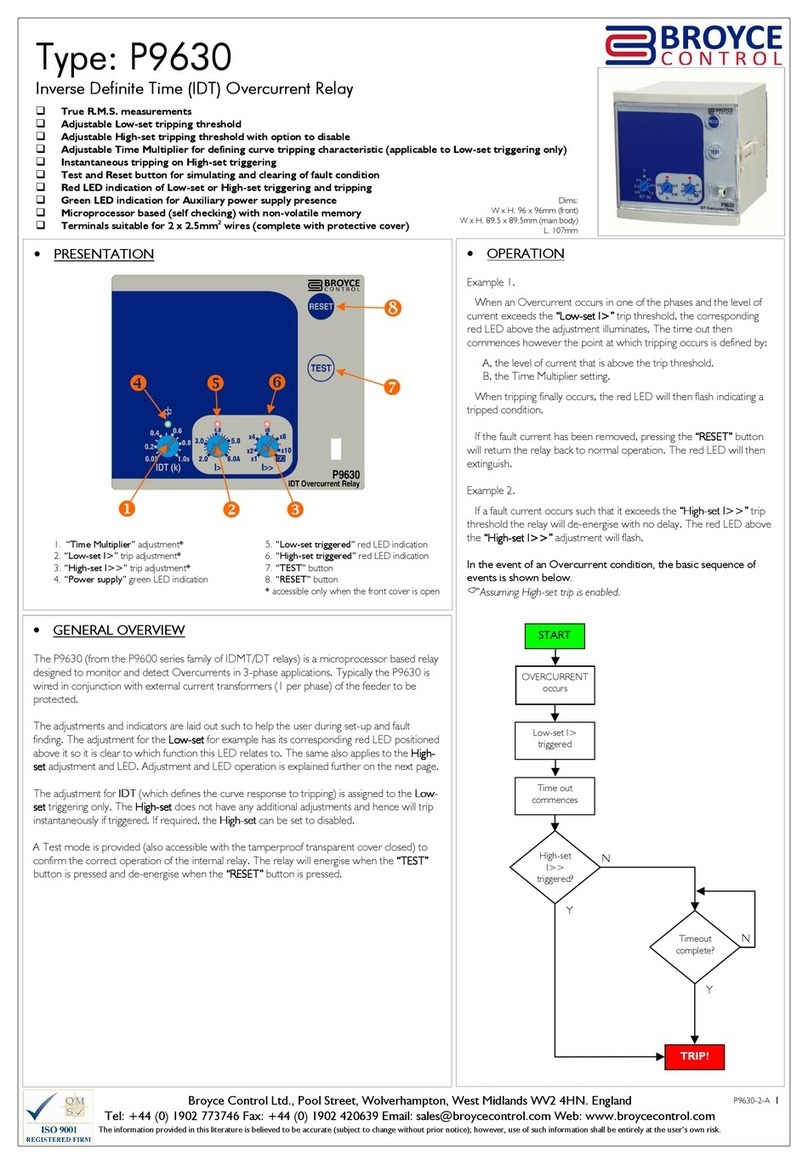

Terminal Protection to IP20

•INSTALLATION

•BEFORE INSTALLATION, ISOLATE THE SUPPLY.

•Connect the unit as shown in the diagram below (N.B. certain features may not be required and

therefore do not need to be connected).

•Operational and setting information can be found on the reverse of this data sheet.

This unit should be installed in conjunction with the latest wiring regulations and practices (IEE, etc)

•MOUNTING DETAILS

Insertscrewdriver

toreleaseclip

49.5

33

45

Installationworkmustbecarried

outbyqualifiedpersonnel.

voltage when ordering.