Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. ngland

Tel: +44 (0) 1902 773746 Fax: +44 (0) 1902 420639 mail: sales@broycecontrol.com Web: www.broycecontrol.com

The Information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the user’s own risk

LR01PN_30PN-1-A.DOCX

Page 3 of 3

1811

•

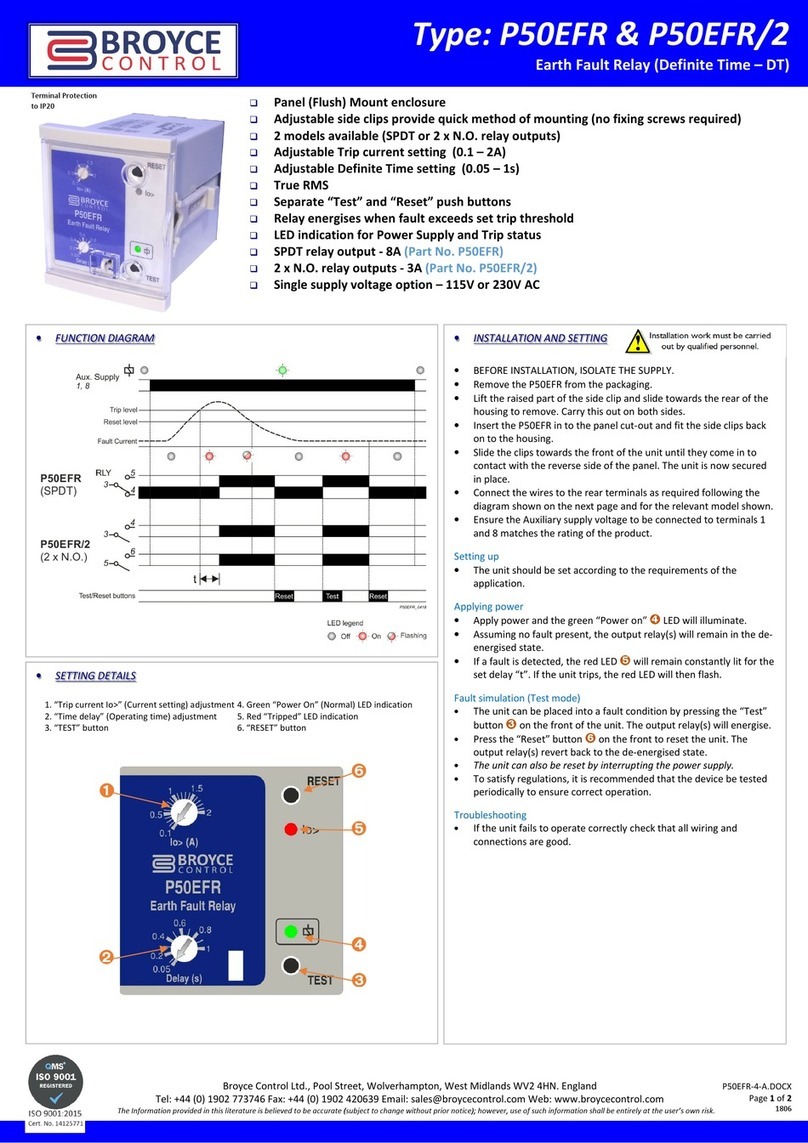

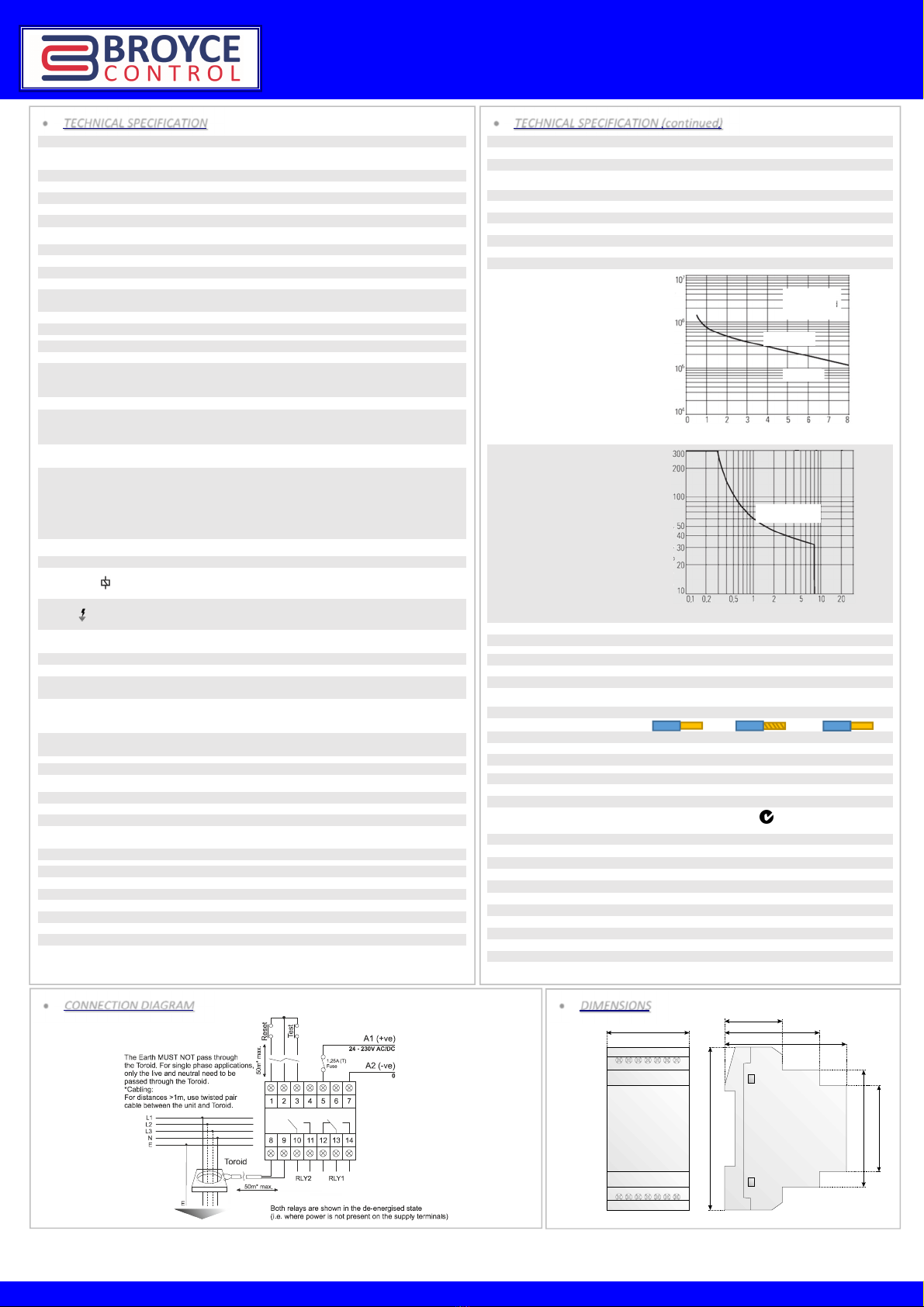

DIMENSIONS

63.5mm

45mm

61mm

85mm

49.5mm

44mm

•

CONNECTION DIAGRAM

•

TECHNICAL SPECIFICATION (continued)

Tem erature rating

Operating: -20 to +60°C

Storage: -30 to +70°C

Relative humidity: +95% max.

Out ut

RLY1 RLY2

Terminals: 12, 13, 14 10, 11

Contact arrangement: 1 x SPDT 1 x SPNO

AC1 (250V) 8A (2000VA) 8A (2000VA)

AC15 (250V) 2.5A 2.5A

DC1 (25V) 8A (200W) 8A (200W)

lectrical life:

Switching current (A)

DC load capacity:

DC current (A)

Dielectric voltage: 2kV AC (rms) I C 60947-1

Rated impulse withstand voltage: 4kV (1.2/50µS) I C 60664

Housing

Material: Grey flame retardant Lexan UL94 V0

Weight: 120g

Mounting option: On to 35mm symmetric DIN rail to BS N 60715

Terminal conductor size

Cable type:

Nominal cross section: 0.2 – 4mm

0.2 – 2.5mm

0.2 – 2.5mm

30 – 12AWG 30 – 12AWG 30 – 12AWG

Stripping length: 6mm

Standards

Product: I C 60947-2 / Annex M, I C 60755, I C 62020

MC: I C 61543, I C 61000-4 Series, CISPR 22

C and RoHS Compliant. C-tick

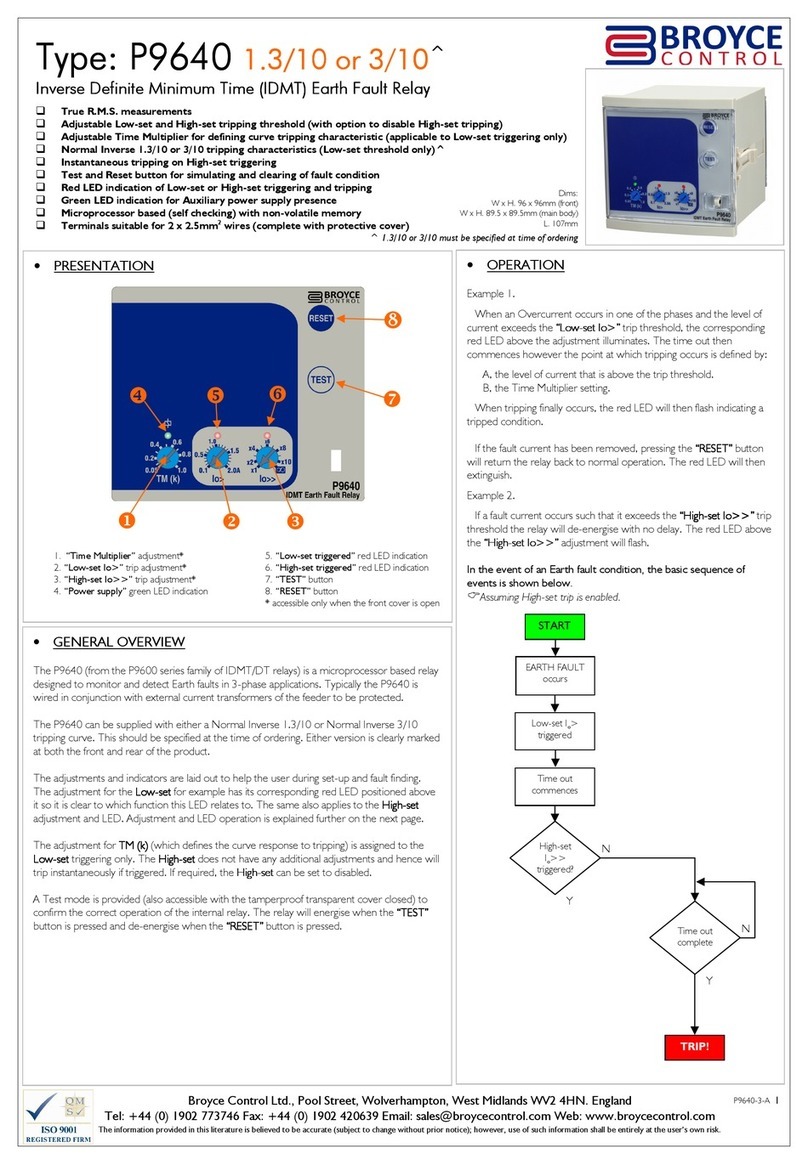

Toroid o tions

Part number: Aperture Internal diameter/size: I∆n (min.) A

BZCT035 35mm ∅ 0.006

BZCT050 50mm ∅ 0.006

BZCT070 70mm ∅ 0.03

BZCT120 120mm ∅ 0.1

BZCT160 160mm ∅ 0.1

BZCT210 210mm ∅ 0.3

BZCTR305

115 x 305mm 0.3

BZCTR350

150 x 350mm 0.3

BZCTR470

160 x 470mm 0.3

•

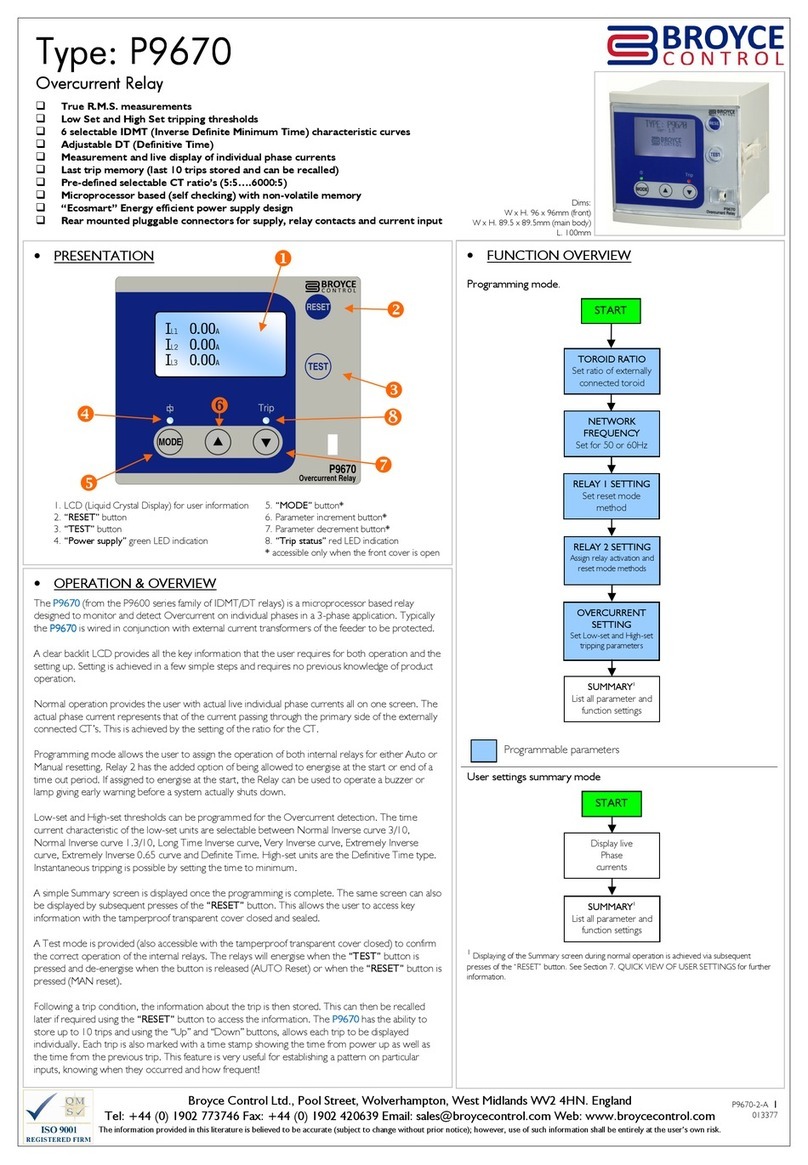

TECHNICAL SPECIFICATION

Auxiliary Power Su ly (5, 7)

Voltage range (Us): 24 – 230V AC/DC

1 25A (T) rated fuse should be installed in line with terminal 5 (A1)

Frequency range (AC supply): 50/60Hz

Supply variation: 85 – 115% of Us

Auxiliary supply is galvanically isolated from the Toroid and Remote Test/Reset connections

Overvoltage category: III (I C 60664)

Rated impulse withstand voltage: 4kV (1.2/50µS) I C 60664

Power consumption (max.): AC: 6VA, DC: 5W

Monitored in ut (via external Toroid connected to terminals 8 and 9)

Unit classification: Type A

Measurement principle: True R.M.S.

Input DSP filter cut-off 150, 300 or 450Hz (factory default = 150Hz)

xternal Toroid ratio: Selectable between 600:1 and 1000:1 in 100:1 steps (factory default

= 1000:1)

Monitored leakage current range: ELR01PN ELR30PN

1.5mA – 1A 7.5mA – 30A

User adjustments

ELR01PN ELR30PN

Trip level settings (I∆n):

6mA, 10mA, 30mA, 50mA,

100mA, 200mA, 300mA,

500mA, 750mA, 1A

30mA, 100mA, 300mA, 500mA, 1A,

3A, 5A, 10A, 20A, 30A

Actual trip level: 85% of I∆n (+/- 5%)

Rated residual non-operating

current (I∆no): <80% of I∆n

Reset level: ≈ 85% tripped level

Time delay (Non-operate) settings

(∆t):

0

, 60ms, 150ms, 250ms, 500ms, 800ms, 1s, 2.5s, 5s, 10s

1

actual delay when set to 0 (instantaneous) is <25ms @ 5 x I

∆

n

Note:

1.

For I∆n of 30mA or less (model dependant) the Time delay is fixed to 0 (instantaneous) and is not adjustable

(i.e. any other delay cannot be set)

2.

The unit is factory set to 30mA (or 6mA) (and instantaneous delay). Adjustment of these settings can be

made if necessary to suit the requirements of the installation. To prevent tampering of the settings, the clear

window can be secured in place using a 2mm or 2.5mm wide cable tie (not supplied).

Reset time: <1s (from supply interruption)

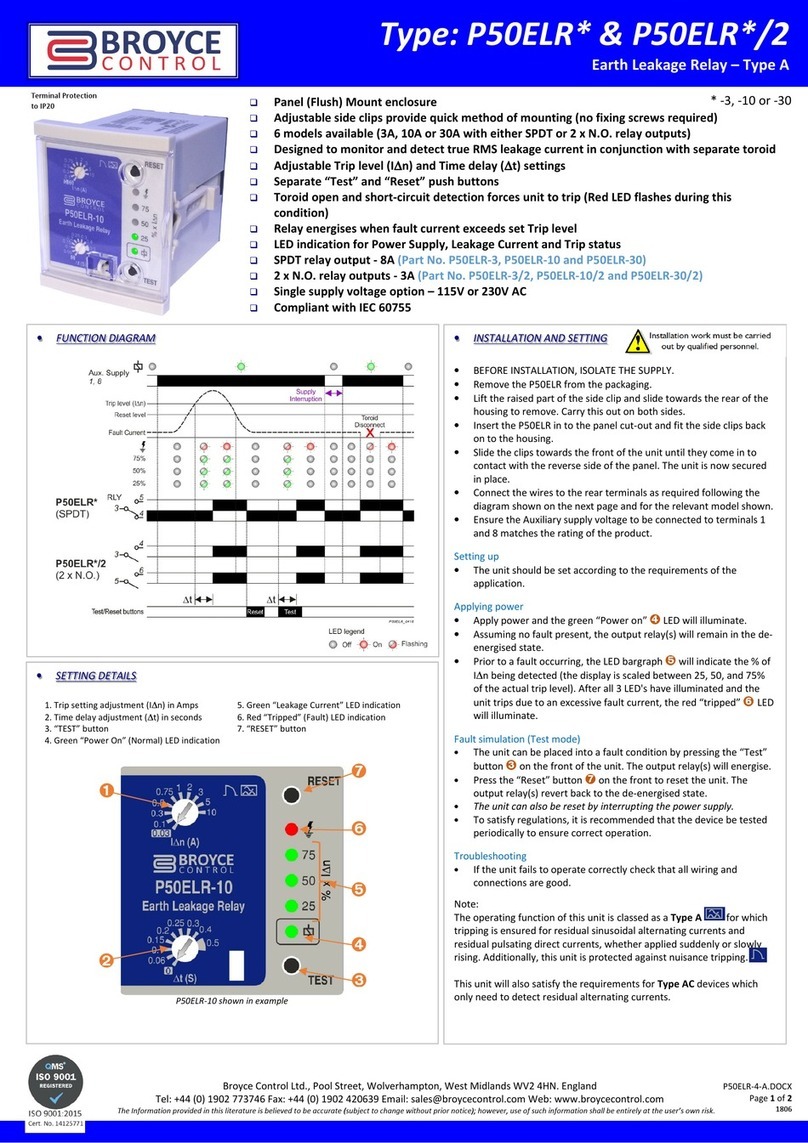

LED indication

Power Supply Green x1

LED is usually permanentl

y lit but will flash if no valid

profile has been selected or there was a communication

error with the smartphone

Tripped Red x 1

time out (i e before tripping) or

external toroid is disconnected LED will also flash prior to

unit reclosing if “auto-reclosure” mode enabled

Bargraph (25, 50, 75%) Yellow x3

Test and Reset

Front ush button Remote N.O. ush button(s)

“Test” method (assuming unit is

in the non-tripped state)

Press once to trip the

unit

Press “Test” button to trip the unit

(connected to terminals 2 and 3)

“Reset” method (assuming unit is

in the tripped state and fault

current cleared)

Press once to reset

the unit

Press “Reset” button to reset the unit

(connected to terminals 1 and 2)

Minimum trigger time: >∆t >80ms + ∆t setting

(only applicable to remote “Test”)

Auto-reset

To enable: Via app (or place wire link between terminals 1 and 2)

Auto-reclosure

To enable and adjust parameters: Via app only

Reclosure attempts: Selectable between 1 and 10 (factory default = 6)

Time between reclosure attempts

(t

r

):

t

r

after first attempt which doubles after each attempt i.e. 2t

r

, 4 t

r

, 8

t

r

, etc. Options are: 1, 2.5, 5, 7.5 and 10s (factory default = 7 5s)

Timeout: Selectable between 1 and 20mins (factory default = 15mins)

Relay o erational modes

To change modes: Via app only

RLY1 RLY2

Key (assuming non-tripped state): S.O. (factory default) P.S.O. (factory default)

S.O. = Standard Output S.O. Pre-alarm*

(relay normally de-energised) P.S.O. P.S.O.

P.S.O = Positive Safety Output S.O. S.O.

(relay normally energised) * Relay energises when Pre-alarm threshold exceeded (factory

default = 50% of I

∆

n) Threshold can be changed via app

Resistive

250V AC

Earth Leakage Relay – Ty e A (with NFC Technology)