Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. ngland

Tel: +44 (0) 1902 773746 Fax: +44 (0)

1902 420639

mail:

[email protected] Web: www.broycecontrol.com

The information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the user’s own risk

.

P9620-2-A

2

22

2

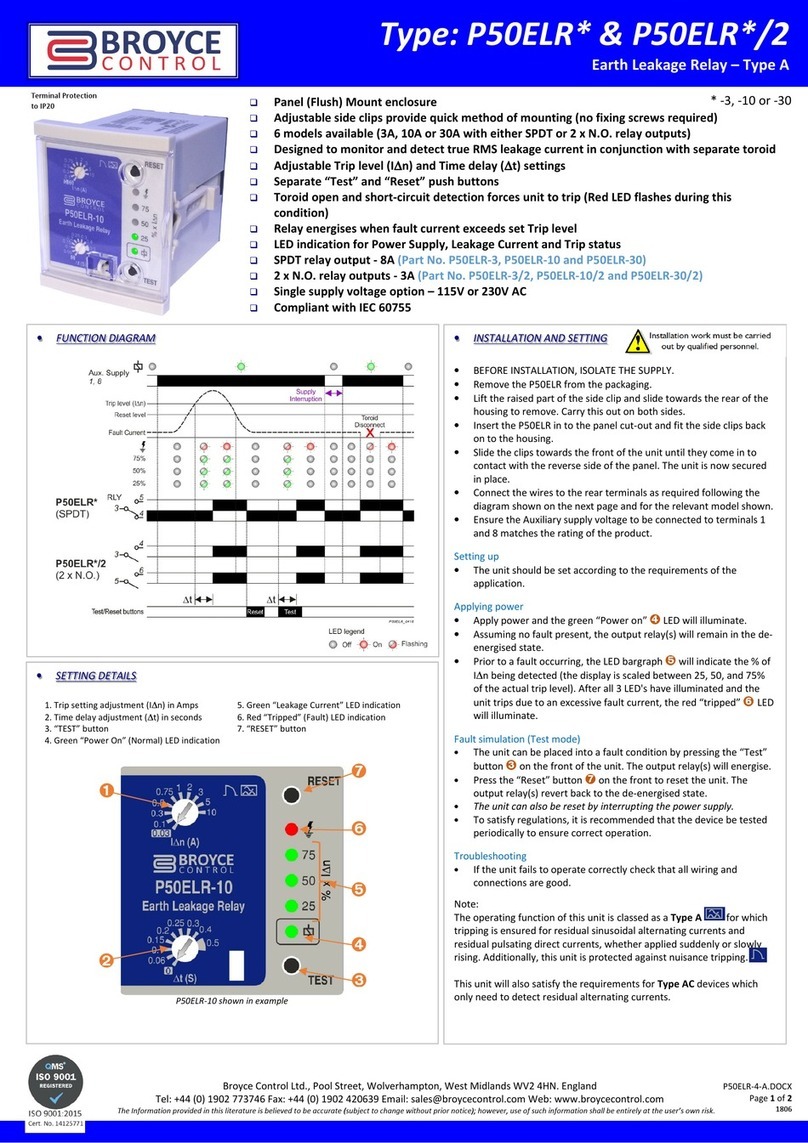

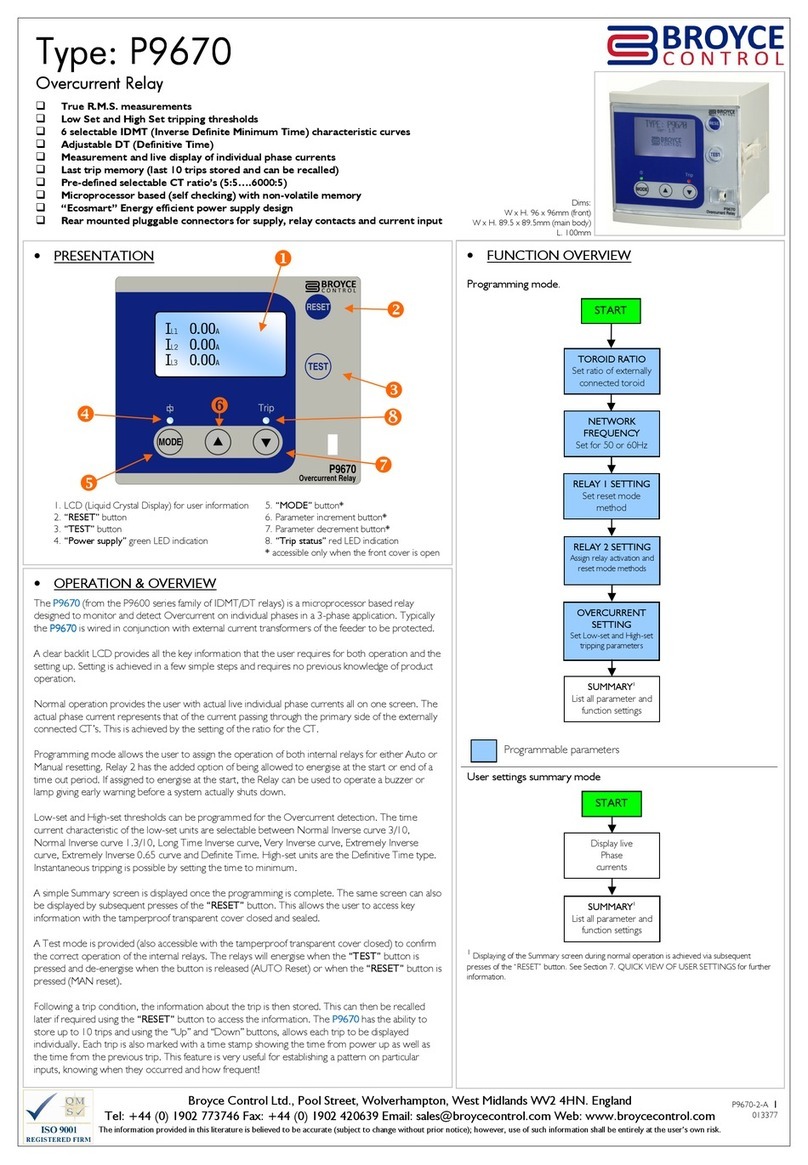

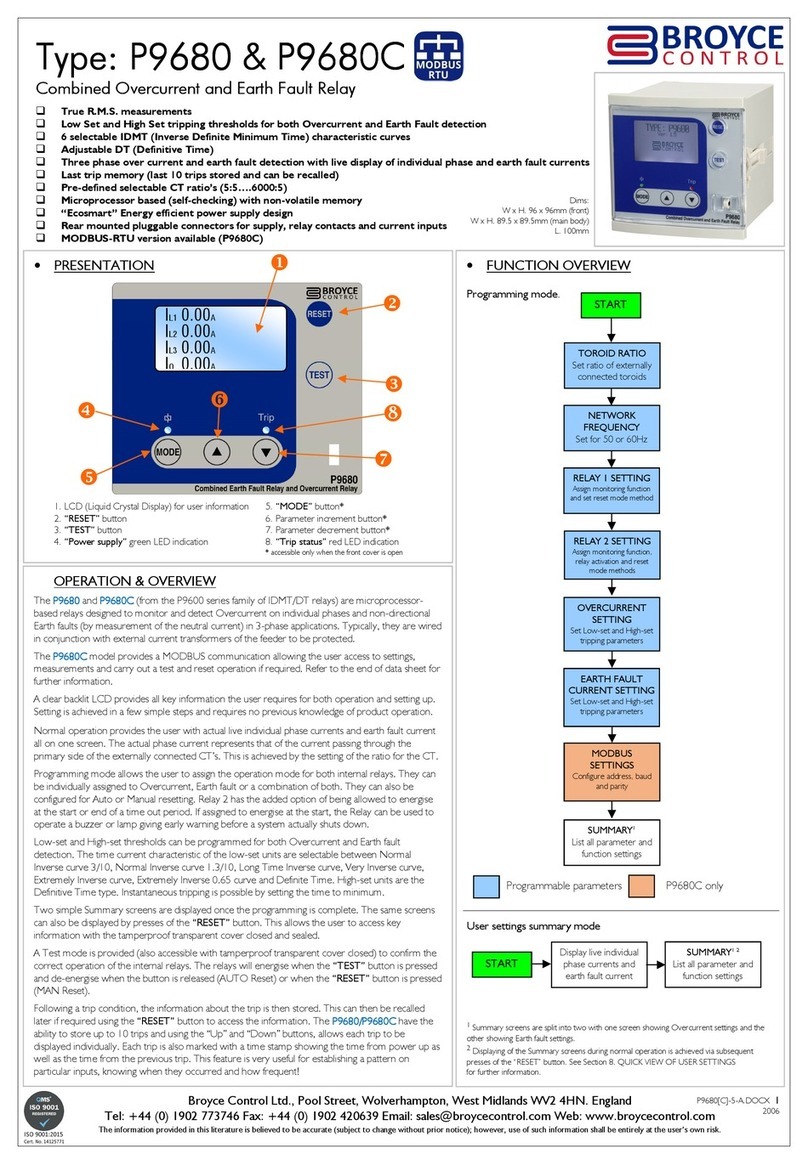

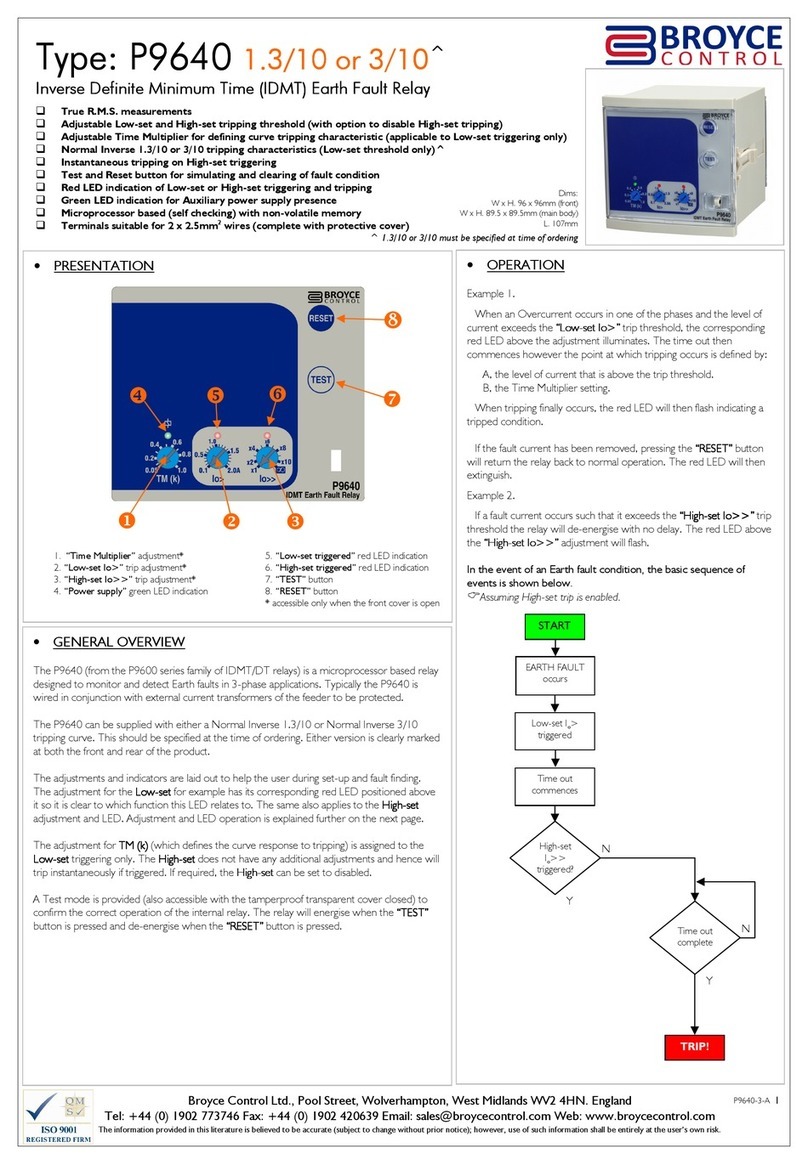

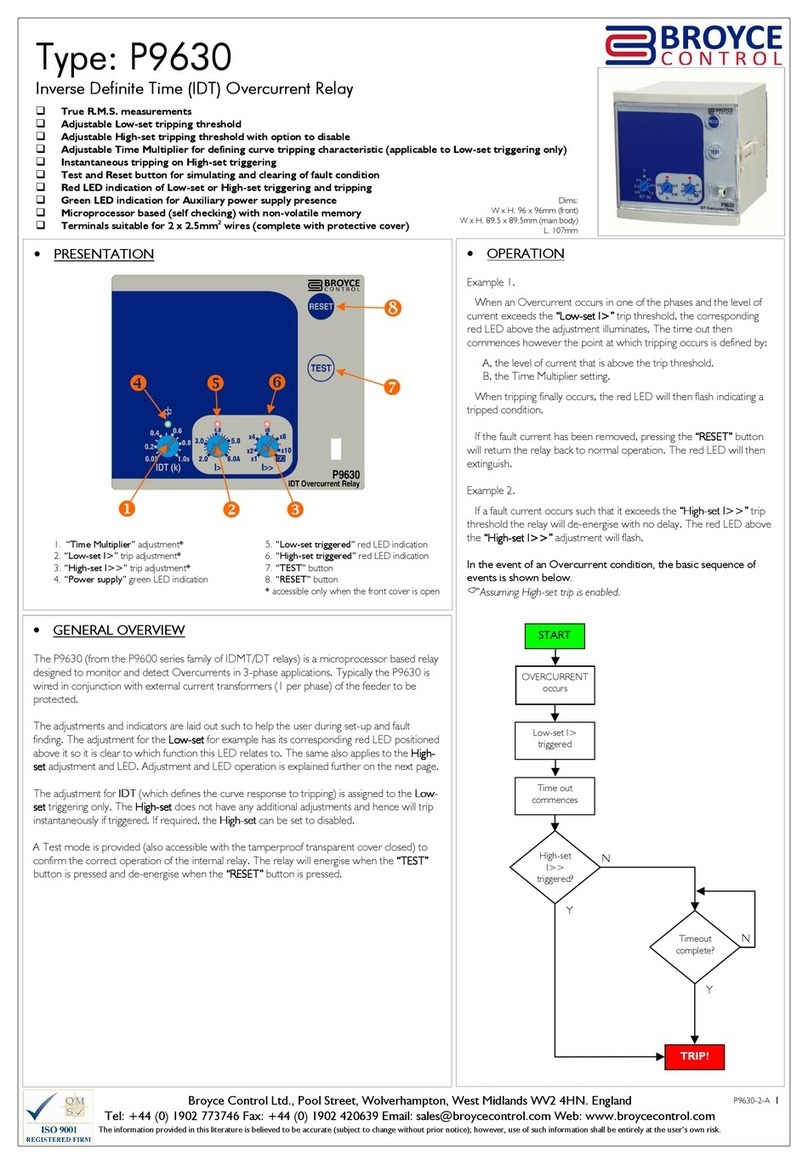

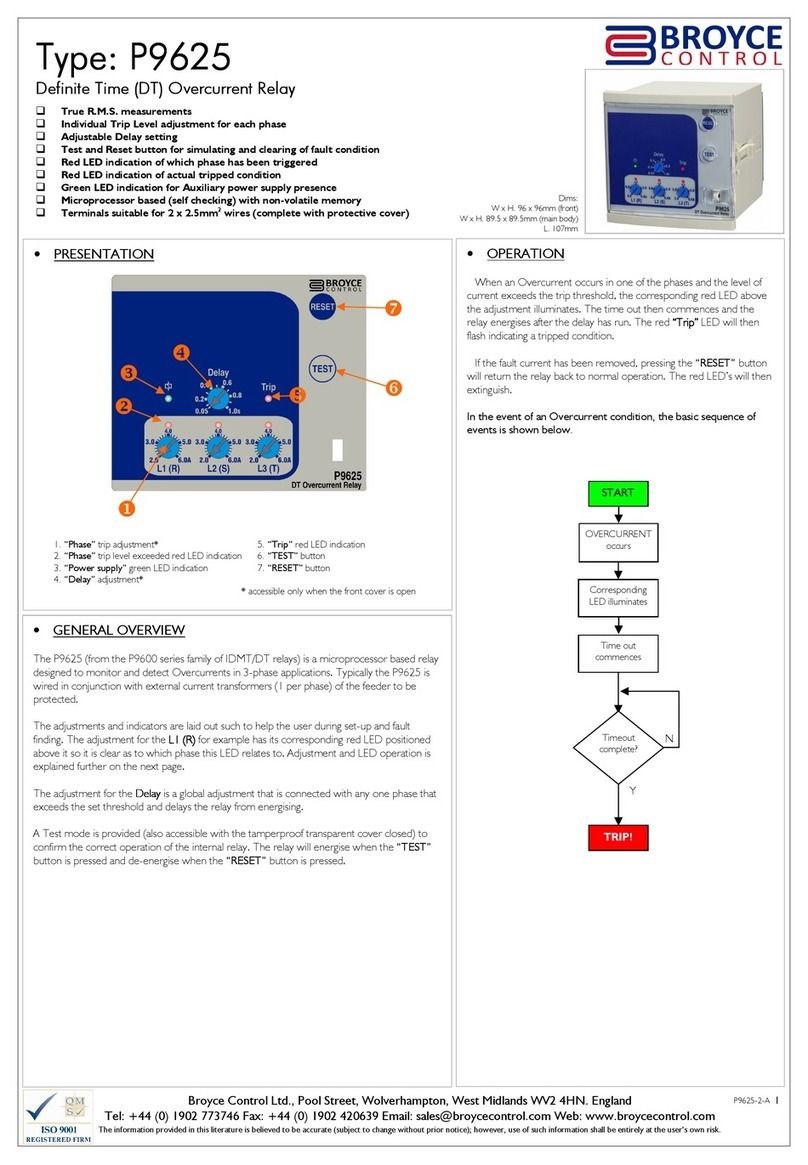

•S TTING & OP RATION

Setting of the P9620 is carried out using the 3 potentiometers located ehind the

transparent cover.

1. Delay

The adjustment for “Delay (s)”

“Delay (s)”“Delay (s)”

“Delay (s)” sets the period that

the P9620 waits efore the relay energises once the

“Low

“Low“Low

“Low-

--

-set”

set”set”

set” threshold “Io>”

“Io>”“Io>”

“Io>” has een exceeded.

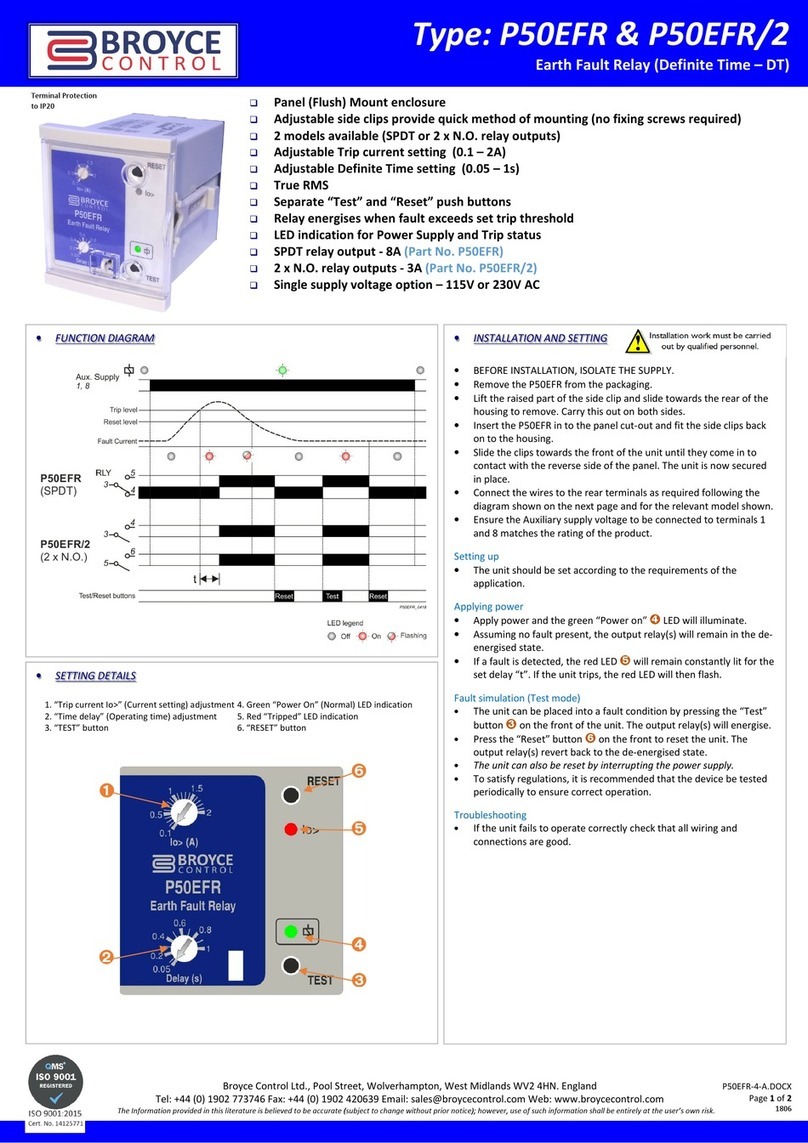

2. Low-Set Trip threshold (Io>)

The adjustment for the “Low

“Low“Low

“Low-

--

-set”

set”set”

set” can e set from

0.1 to 2A. When the threshold is exceeded due to an

Earth fault condition, the corresponding red LED a ove

the adjustment illuminates indicating activity. When

tripping finally occurs, the red LED will then flash.

3. High-Set Trip threshold (Io>>)

The adjustment for the “High

“High“High

“High-

--

-set”

set”set”

set” can e set from

x1 to x10 then disa le i.e.

The scale markings are multipliers of what has een

set on the “Low

“Low“Low

“Low-

--

-set”

set”set”

set” threshold. For example if the

“Low

“Low“Low

“Low-

--

-set”

set”set”

set” is set to 1.5A and “High

“High“High

“High-

--

-set”

set”set”

set” x6, this will e

the equivalent of 1.5 x 6 = 9A.

When the threshold is exceeded due to an Earth

fault condition, the corresponding red LED a ove the

adjustment illuminates indicating activity. When tripping

finally occurs, the red LED will then flash.

If tripping occurs whereby the High-set level is exceeded, only the LE for the

High-set will illuminate/flash. This allows the user to clearly identify which threshold

was triggered causing the trip.

There is no delay associated with High-set therefore, tripping is instantaneous.

•L D FUNCTION SUMMARY

The green LE will remain illuminated for as long as power is applied to the Aux.

connections (Terminals 1 and 2).

In response to an Earth fault condition:

Status Io> Io>>

Normal

Low-set triggered

Low-set Tripped

High-set triggered

High-set Tripped

In response to Test and Reset utton operation:

Button press Io> Io>>

Key:

LED off

LED on

LED flashing

•INSTALLATION

•B FOR INSTALLATION, ISOLAT TH SUPPLY. THIS PRODUCT IS

D SIGN D TO CONN CT TO S V RAL TYP S OF CIRCUITS.

NSUR ALL AR ISOLAT D

•Remove the P9620 from the packaging.

•Lift the raised part of the side clip in order to remove from the housing. Carry

this out on each side.

•Insert the P9620 into the panel cut-out and fit the side clips ack on to the

housing.

•Slide the clips towards the front of the unit until they come in to contact with

the reverse of the panel. The unit is now secured in place.

•Connect wires to the rear terminals as required.

•The P9620 is now ready for powering and setting.

The front window of the P9620 is supplied with a clear protective film which can be

removed as and when necessary.

•NORMAL OP RATION

•Apply power to the unit and the green “Power supply”

“Power supply”“Power supply”

“Power supply” LED will illuminate.

•T ST MOD

•Press and hold the utton and the relay will energise. Both the red

“Io>”

“Io>”“Io>”

“Io>” and “I

“I“I

“Io>>”

o>>” o>>”

o>>” LED’s will illuminate.

•Release the utton and the relay will remain energised.

•Press the utton to de-energise the relay. Both red LED’s will

extinguish.

Testing should be carried out on a regular basis to check the integrity of the

P9620.

O NOT use this product to provide a means of isolating circuits in

order to work on when placed in the “TEST”

“TEST”“TEST”

“TEST” mode. This should only be

done by means of operating isolators, circuit breakers or other

methods of removing power in this application.

Installation work must be carried

out by qualified personnel.