Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. ngland

Tel: +44 (0) 1902 773746 Fax: +44 (0) 1902 420639 mail: sales@broycecontrol.com Web: www.broycecontrol.com

The Information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the user’s own risk

P50 FR-4-A.DOCX

Page 2 of 2

1806

•

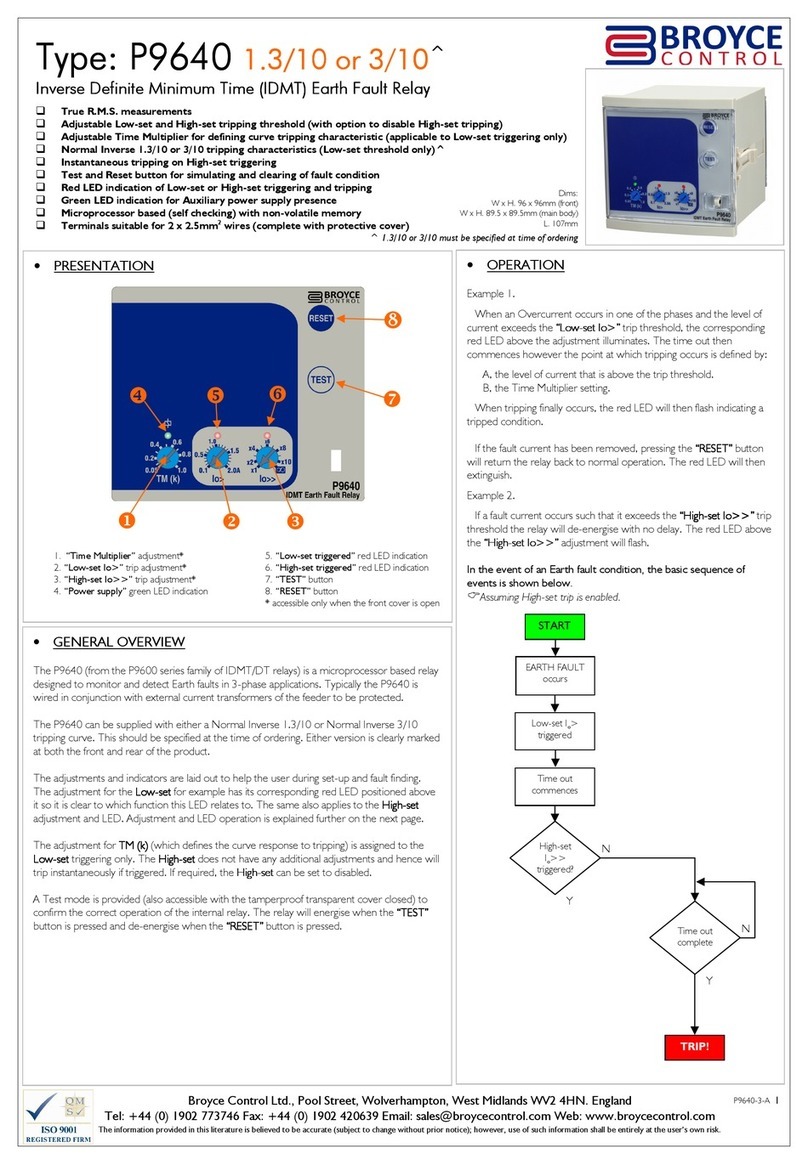

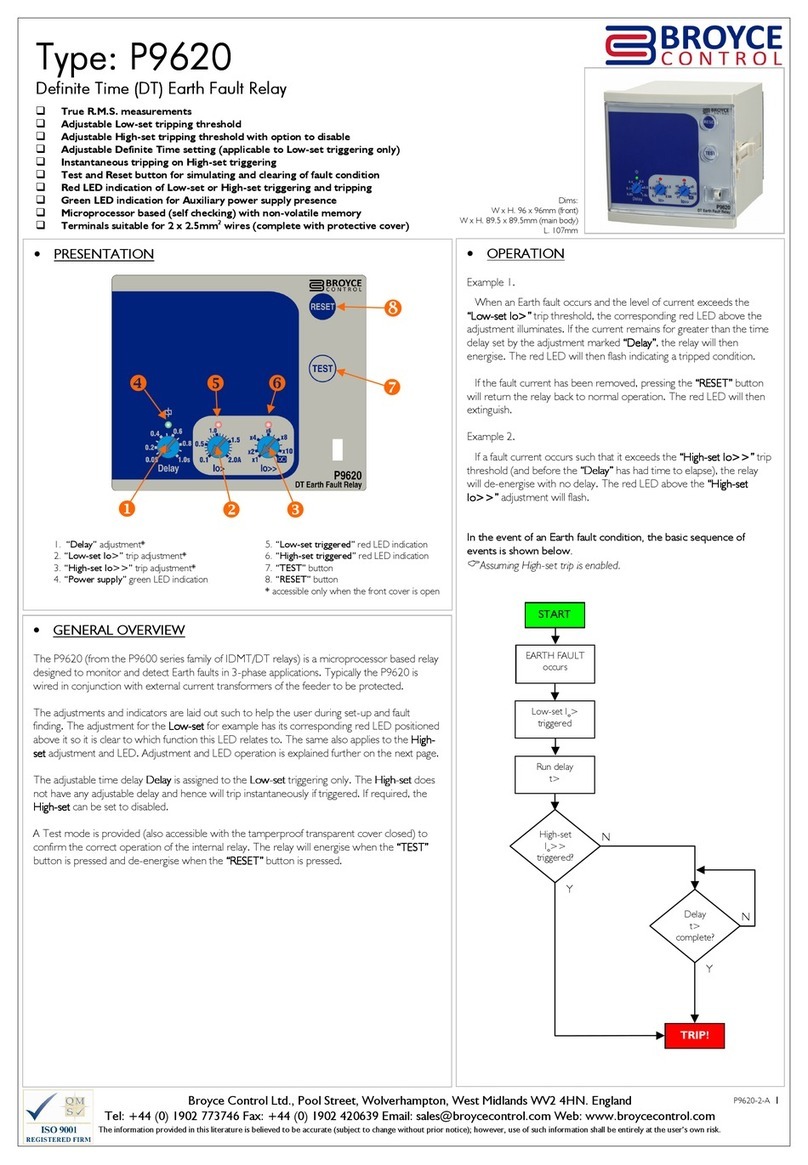

DIMENSIONS

•

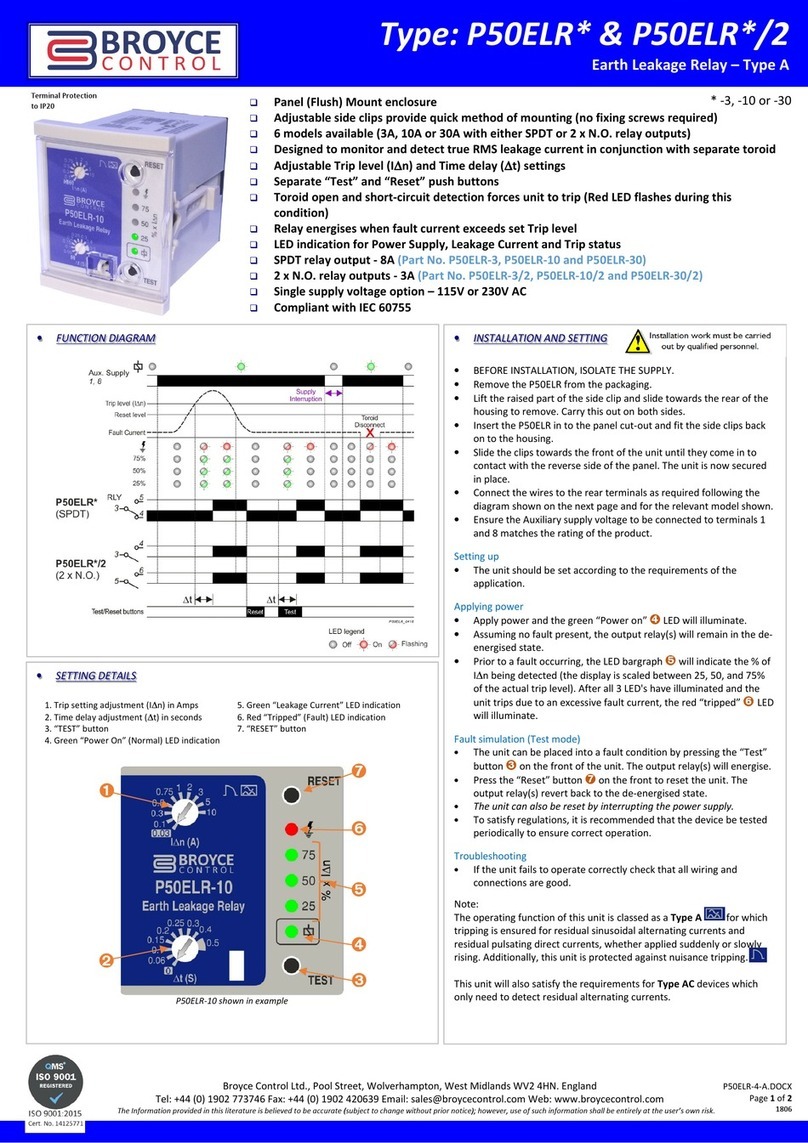

CONNECTION DIAGRAM

•

TECHNICAL SPECIFICATION (continued)

Output (continued)

lectrical life: DC load capacity:

Switching current (A)

DC current (A)

Dielectric voltage: 1kV AC (rms) I C 60947-1

Rated impulse withstand voltage: 4kV (1.2/50µS) I C 60664-1

Housing

Material: Grey flame retardant Lexan UL94 V0

Weight: ≈ 225g

Protection: IP40 (front face) / IP20 (rear)

Mounting: Panel mount. Cut-out (see information below)

Max. panel thickness: 10mm

Rear Terminals

Conductor size:

0.3 – 2mm

2

(22 – 14AWG)

Wire stripping length: ≈ 6mm

Recommended tightening torque: 1.3Nm (12lb-in)

Standards

Product:

I C 255-3, I C 60255-151

MC: I C 60255-26, I C 61000-4 Series

C and RoHS Compliant. C-tick

Ordering:

Please specify product part number and voltage when ordering.

For example:

P50EFR/2 230V AC

Earth Fault Relay (Definite Time – DT)

•

TECHNICAL SPECIFICATION

Au iliary Power Supply (1, 8)

Supply voltage (Un): 115V or 230V AC (To be specified when ordering)

Frequency range: 50/60Hz

Supply variation: 85 – 115% of Un

Auxiliary supply is galvanically isolated from the CT input

Overvoltage category: III

Rated impulse withstand voltage: 4kV (1.2/50µS) I C 60664-1

Power consumption (max.): 3VA

Monitored input (via e ternal Current Transformer connected to terminals 2 and 7)

Rated current input (In): 5A (directly connected)

Rated frequency: 50Hz

Burden: <0.4VA @ In

Overload: 4 x In (continuous)

CT recommendation: Class P (with 5A secondary)

Device Characteristics

Measurement principle: True R.M.S.

Trip current [Current setting]

(Io>): 0.10 – 2.0A (2 – 40%)

Time delay [Operating time] (t): 0.05 – 1.0s

Pick up value: +2% of trip value

Accuracy:

Trip current: ± 5%

Time delay: ± 5% (with a minimum of 50ms)

Repeat accuracy: ± 0.5% @ constant conditions

LED indication

Power Supply: Green x1

Tripped: Red x 1

Test and Reset

“Test” method

(assuming unit is in the non-

tripped state):

Press once to trip the unit

“Reset” method

(assuming unit is in the tripped

state and fault current cleared):

Press once to reset the unit

Temperature rating

Operating: P50EFR P50EFR/2

-10 to +60°C -10 to +55°C

Storage: -30 to +70°C

Relative humidity: +95% max.

Output - Model No./Type P50EFR P50EFR/2

Rear Terminal No. (3, 4, 5) (3, 4 / 5, 6)

Contact arrangement: 1 x SPDT 2 x SPNO

AC1 (250V) 8A (2000VA) 3A (750VA)

AC15 (250V) 2.5A 1.5A

DC1 (25V) 8A (200W) 3A (75W)

Resistive

AC1

•

CUT-OUT

Key: P50 FR

P50 FR/2