3

1. QUICKSTART .....................................................................................................4

1.1. Symbols ..............................................................................................4

2. AUTHORIZED USE .........................................................................................5

2.1. Restrictions ........................................................................................5

2.2. Predictable Misuse ..........................................................................5

3. BASIC SAFETY INSTRUCTIONS .............................................................6

4. GENERAL INFORMATION ...........................................................................7

4.1. Contact Address ..............................................................................7

4.2. Warranty ............................................................................................. 7

4.3. Information on the Internet ............................................................. 7

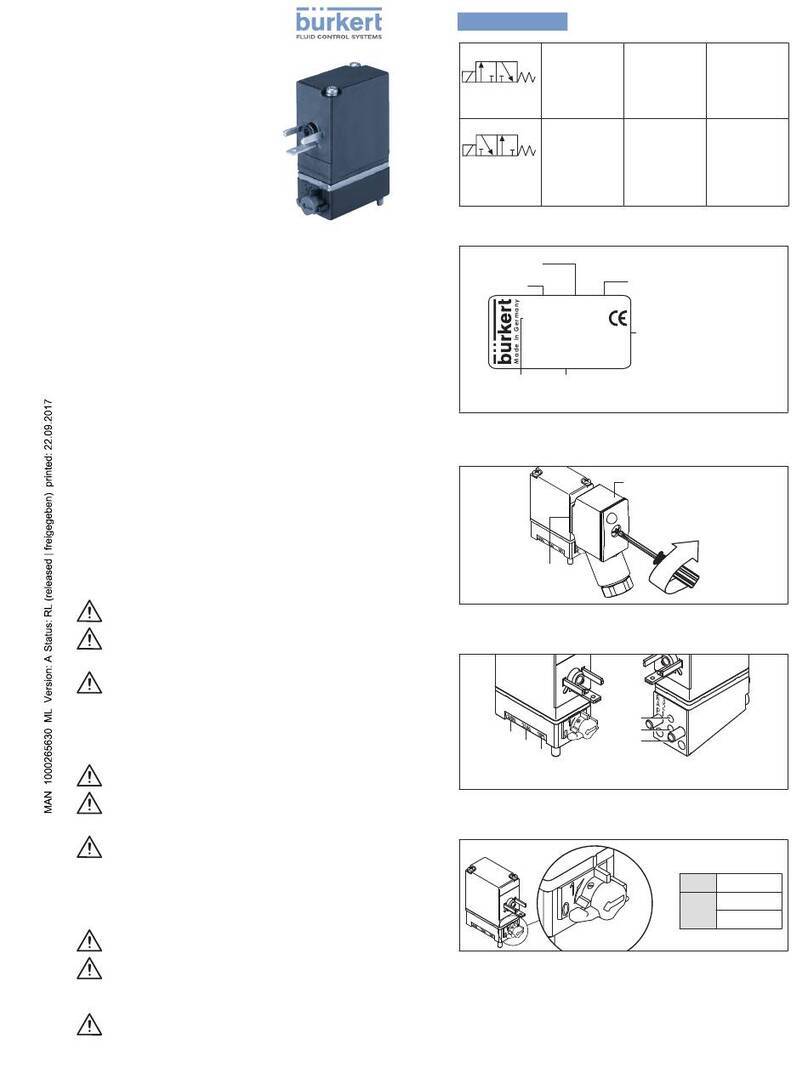

5. SYSTEM DESCRIPTION ...............................................................................7

5.1. Structure and Function ................................................................... 7

6. TECHNICAL DATA ...........................................................................................8

6.1. Conformity ......................................................................................... 8

6.2. Standards ........................................................................................... 8

6.3. Operating Conditions ...................................................................... 8

6.4. Mechanical Data ...............................................................................9

6.5. Type Label .........................................................................................9

6.6. Pneumatic Data ................................................................................9

6.7. Electrical Data .................................................................................10

7. INSTALLATION ...............................................................................................11

7.1. Safety Instructions .........................................................................11

7.2. Installation of the Control Head

on Process Valves of Series 21xx ..............................................11

7.3. Installation of the Control Head

on Process Valves of Series 20xx ..............................................12

8. FLUID INSTALLATION ................................................................................ 14

8.1. Safety Instructions .........................................................................14

8.2. Installing the Process Valve .........................................................15

8.3. Pneumatic Connection of the Control Head ...........................15

9. ELECTRICAL INSTALLATION ..................................................................16

9.1. Safety Instructions .........................................................................16

9.2. Electrical Installation 24 V DC

with Circular Plug-in Connector .................................................16

9.3. Display Elements 24 V DC ..........................................................17

9.4. Electrical Installation AS Interface ...............................................17

9.5. Programming data ..........................................................................18

9.6. Display Elements AS Interface ....................................................19

10. TEACH FUNCTION .................................................................................... 20

10.1. Starting the Teach Function

(Calibrating the End Position) ...................................................20

11. SAFETY POSITIONS ................................................................................21

12. ACCESSORIES ...........................................................................................21

13. PACKAGING, TRANSPORT, STORAGE .......................................... 22

Table of Contents

english

Type 8695