E503-0003 mainly on installation ......................................................................................................................... 224

E503-0053: Solved by switching service switch (Professional Puncher-C1) ...................................................... 225

E503-0041 with Optional Professional Puncher Integration Unit-B1 ................................................................... 226

[Line image (by Stream Read Glass)] .................................................................................................................. 227

Lines on images when using DADF (Duplex/Color Image Reader Unit-C1) [G] ................................................. 227

There are Lines Through Copies, When Using The ADF (Duplex Color Image Reader Unit-C1) [G] ................ 227

Black line when using DADF stream reading (Duplex Color Image Reader Unit-C1/Color Image Reader Unit-C1)

.............................................................................................................................................................................. 228

Black band appears in sub scanning direction when scanning both sides simultaneously at DADF (Duplex Color

Image Reader Unit-C1) ........................................................................................................................................ 229

[Appendix] ........................................................................................................................................................... 235

[Roller Marks Image (Finisher Roller/Pro Puncher/ Fixing Roller)] ...................................................................... 235

Stain on the backside image due to the soiled pressure roller ............................................................................ 235

When using the puncher, roller marks appears on the image due to the friction of drive roller. (Professional

Puncher-C1) ......................................................................................................................................................... 245

Line (crepe mark) in horizontal scanning direction due to temperature rising on Fixing Roller edges at continuous

print ....................................................................................................................................................................... 248

2 roller-width soils at 143mm from paper edge .................................................................................................... 249

Soiling at back of sheet (Staple Finisher-D1/Booklet Finisher-D1) ...................................................................... 257

Roller marks on images due to the friction of the pull roller when using Booklet/Folding function (Fin-D1) ...... 258

[Light image] ......................................................................................................................................................... 263

Fine line is too fine on output printed with the Printer Driver PCL5e/PCL6 ......................................................... 263

Fine line is too fine on output printed with the Printer Driver PS ......................................................................... 265

Fine line is too fine on output printed with the Printer Driver UFRII ..................................................................... 267

Light image/ extremely narrow thin lines when copying/ printing. ....................................................................... 269

Uneven image density at the front side and the rear side due to the difference of the hight of the primary charging

wire ....................................................................................................................................................................... 271

Light printout in the rear due to soils on the pre-transfer charging wire .............................................................. 273

Light image/ Partially blank image/ Black line ...................................................................................................... 274

Light image/ partially void image owing to poor contact of the transfer H.V. contact point/ the H.V. connector poor

contact/ the defective transfer H.V. PCB

.............................................................................................................. 277

[Others] ................................................................................................................................................................. 284

E840-0001 due to deformation of the fixing shutter ............................................................................................. 284

Toner bottle cannot to be mounted due to breakage of Bottle Cam/Drive Gear ................................................. 289

Paper skew or the right door may open involuntarity due to the half-locked right door ...................................... 301

E677-0080/E315-000d for output from imagePASS-U1 ...................................................................................... 307

E583-8001/E583-8002 due to operation failure of the tray auxiliary guide (Booklet/Staple Fin-D1) ................... 308

[Staple Jam] .......................................................................................................................................................... 312

Stapler does not staple. The finisher will not staple sort any sets. [G] ................................................................ 312

Staple does not work with the printer driver UFRII Ver.20.80 or later ................................................................. 314

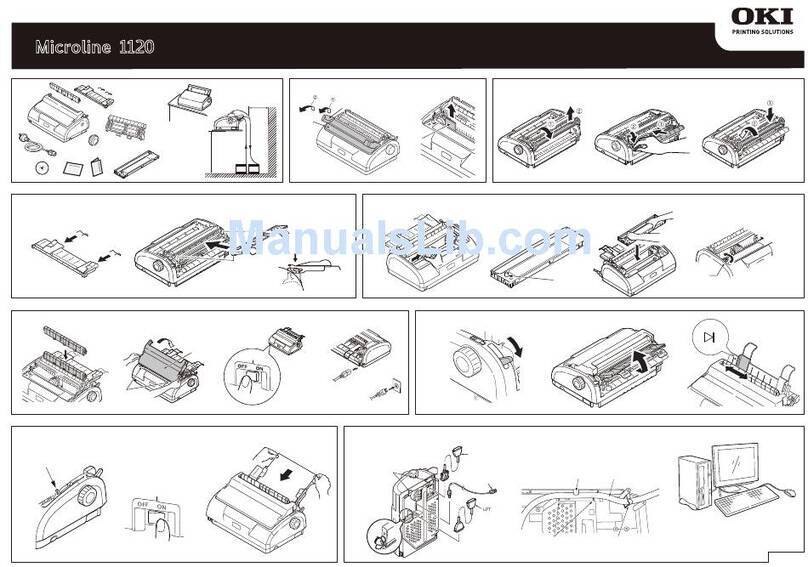

[iR-ADV 8105 Series Cleaning Location inside Machine] .............................................................................. 315

Hopper Assembly ................................................................................................................................................. 316