Page

(S520)

1 -21 1. PRODUCT OVERVIEW

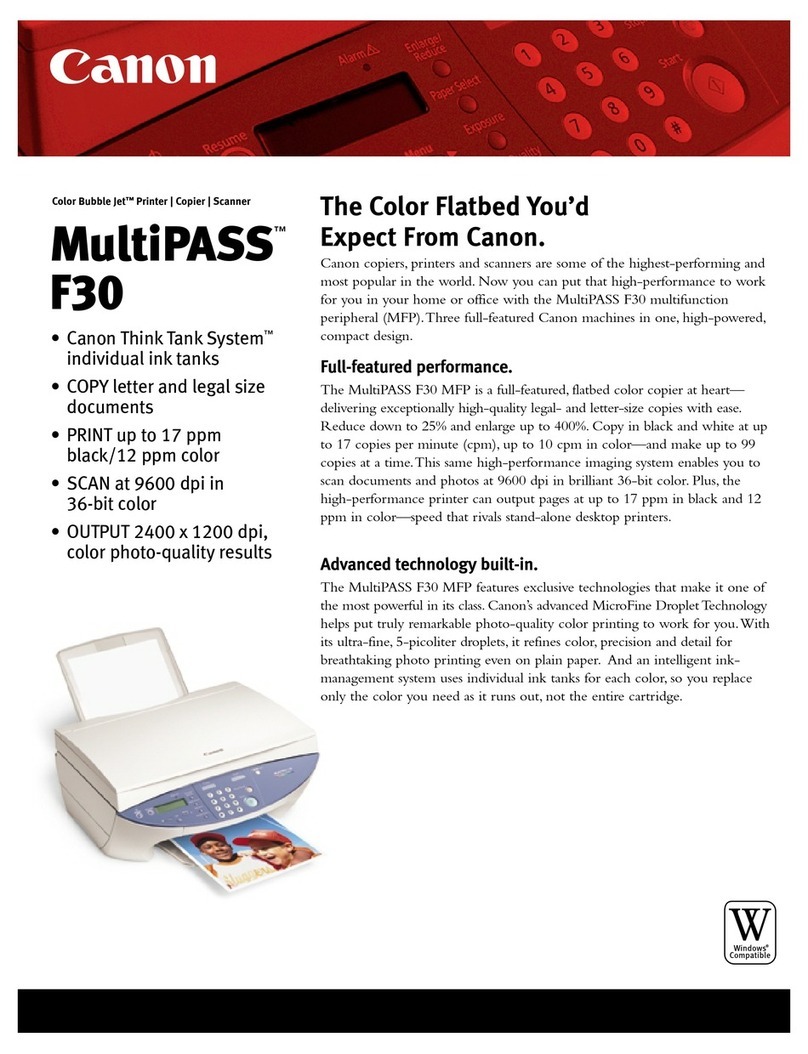

1 -21 1.1 Product Overview

1 -21 1.2 Special Features

1 -22 2. SPECIFICATIONS

1 -22 2.1 Printer Specifications

1 -22 2.1.1 Printer specifications

1 -22 2.1.2 Printer service life

1 -23 2.1.3 Print head service life

1 -23 2.2 Paper Specifications

1 -23 2.2.1 Paper sizes and weights

1 -23 2.2.2 Paper types and settings

1 -23 2.2.3 Printable area

1 -23 2.3 Print Head Specifications

1 -23 2.4 Printer and Scanner Drivers

1 -24 3. PRODUCT CODE LIST

Part 2: TROUBLESHOOTING

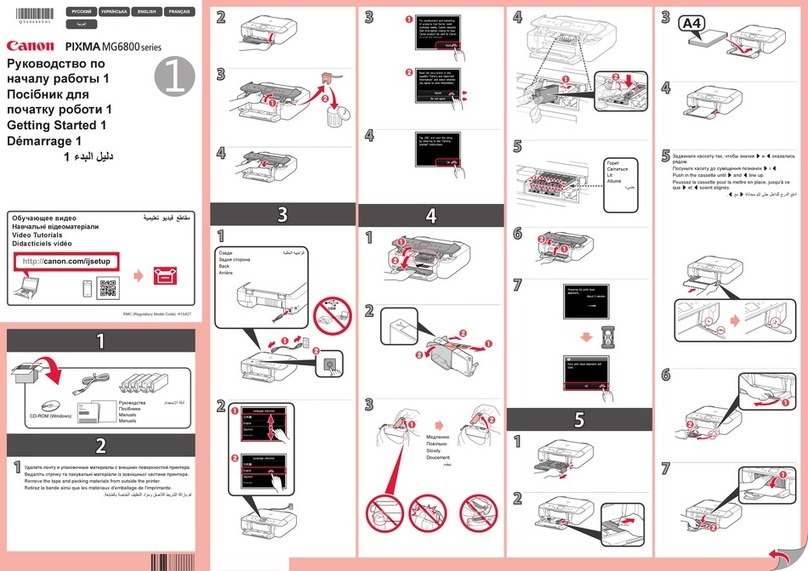

2 - 1 1. PRINTER OPERATION

2 - 1 1.1 Printer Operation

2 - 1 1.2 Status Indicator

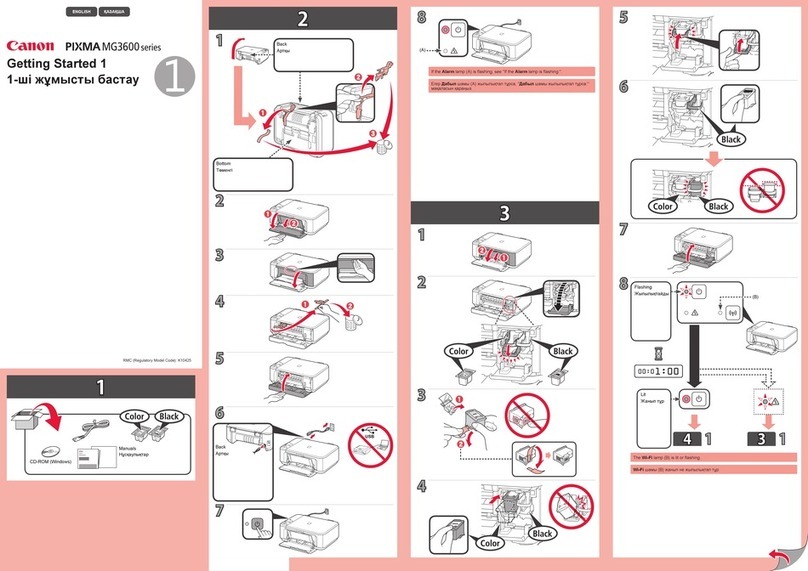

2 - 2 1.3 Simple Printer Operations

2 - 2 1.3.1 Cleaning operation

2 - 2 1.3.2 Printing the nozzle check pattern

2 - 4 1.3.3 Roller cleaning operation

2 - 5 2. SERVICING

2 - 5 2.1 Before Troubleshooting

2 - 6 2.2 Detectable Problems from System Start to Exit

2 - 9 2.3 Troubleshooting Problems

2 -10 2.4 Troubleshooting Error Indications

2 -13 3. DISASSEMBLY AND REASSEMBLY

2 -13 3.1 Cautions for Disassembly and Reassembly

2 -13 3.1.1 Cautions against ink stains (ink path/ink mist)

2 -13 3.1.2 Damage due to static electricity

2 -13 3.1.3 Deformation of spur tips

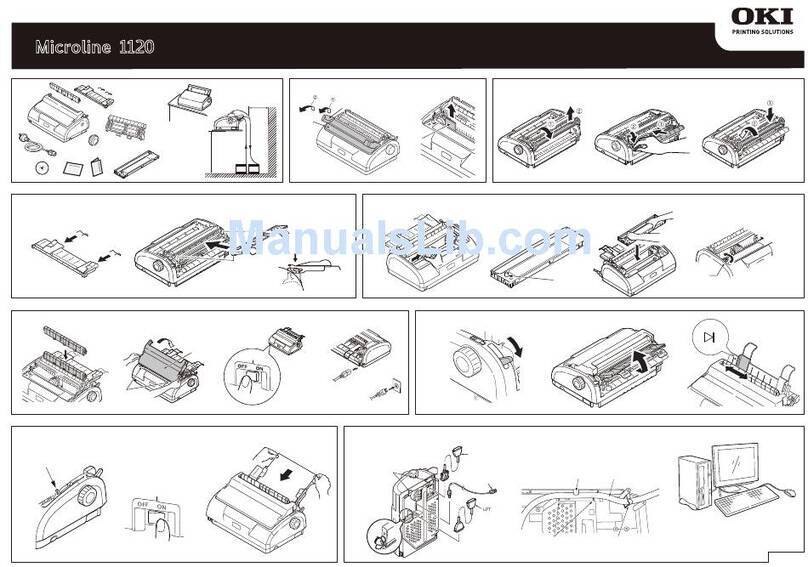

2 -14 3.2 Exploded View

2 -15 3.3 Disassembly and Reassembly

2 -15 3.3.1 Carriage lock release

2 -16 3.3.2 Removing and installing tap screws

2 -16 3.3.3 Installing and removing the timing slit strip

2 -17 3.3.4 Handling the encoder film

2 -17 3.3.5 Removing and installing the logic board

2 -18 3.3.6 Removal of red screws prohibited

2 -18 3.3.7 Installing the logic board cover

2 -19 3.3.8 Installing the control ROM cover

2 -20 4. ADJUSTMENTS AND SETTINGS AFTER DISASSEMBLY AND

REASSEMBLY, AND CONFIRMATION OF OPERATION

2 -20 4.1 Adjustments and Settings after Disassembly and Reassembly

2 -20 4.1.1 Items for adjustment (per necessity/locations/tools)

2 -21 4.1.2 If EEPROM settings adjustment is necessary

2 -22 4.1.3 Print head position adjustment

2 -24 4.1.4 Print head seam stripe adjustment (S750)

2 -25 4.1.5 Grease Application

III