6000 SERIES MANUAL_U.doc 12-12-07 2

TABLE OF CONTENTS

SE CTION

P AG E S

INTRODUCTION

.............................................................. 3

Symbo s and Warnings......................................................... 3

SPECIFICATIONS ........................................................... 5

INSTALLATION ...............................................................

7

Chamber Location ................................................................ 7

Drain Connection .................................................................. 8

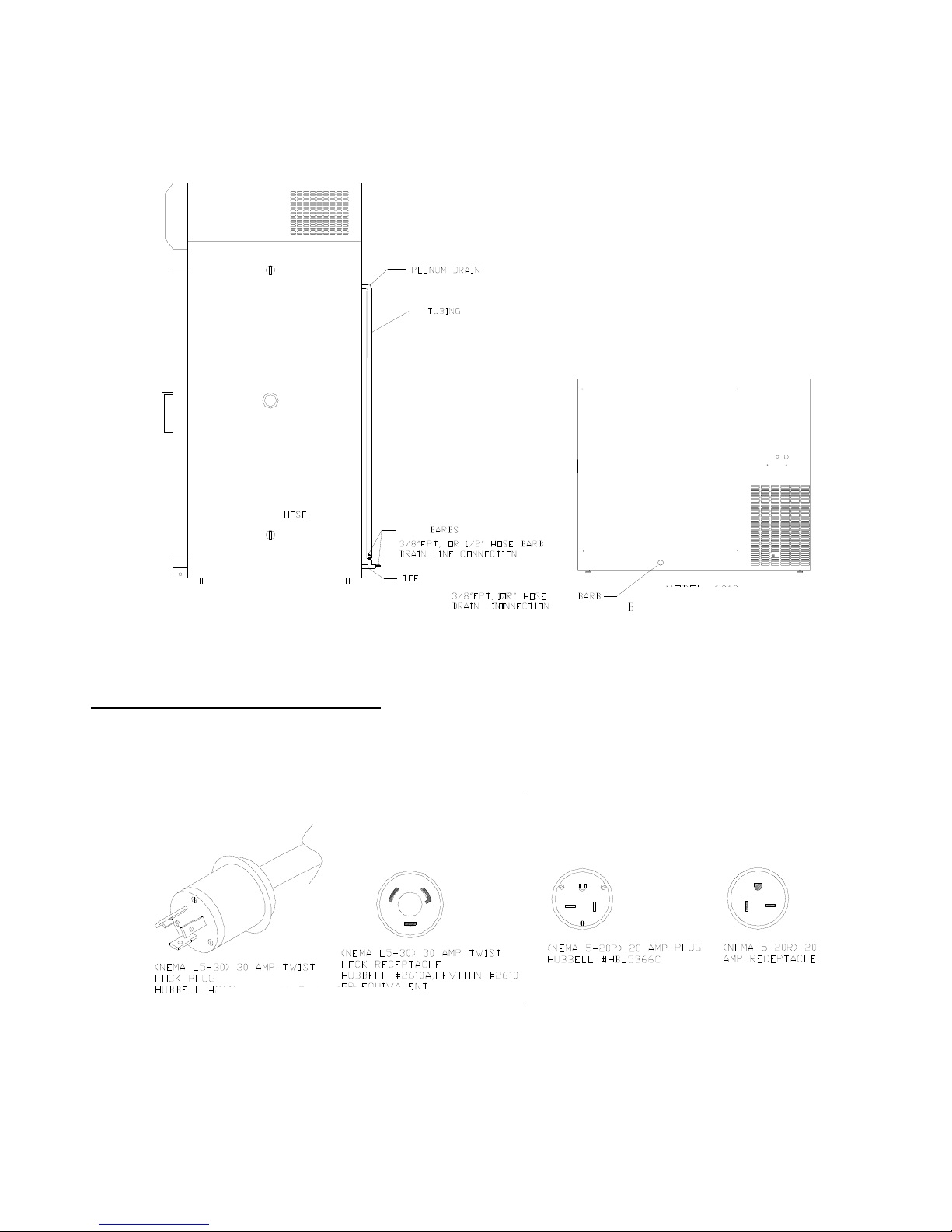

Power ................................................................................... 8

OPERATION

.................................................................. 10

CONTROLLERS

...................................................................... 12

Temperature Deviation A arm ............................................. 12

OPTIONS . ..................................................................... 13

Humidity System & Contro er ............................................. 13

Humidity Contro er Ca ibration ........................................... 14

Humidity Water In et ........................................................... 14

Diurna Lighting System...................................................... 15

Heat ess Dryer Package ..................................................... 16

Dryer Package Insta ation ....................................... 16

Dryer Package Testing & Adjustments .................... 17

Circu ar Chart Recorder...................................................... 18

Setup, Insta ation .................................................... 18

Routine Maintenance ............................................... 21

Contact C osure Timer System ........................................... 22

Condensate Recircu ating System...................................... 23

Remote A arm Contact ....................................................... 25

Product Temperature Safety............................................... 25

Computer Communications ................................................ 12

Defrost Package............................................................................ 26

MAINTENANCE

....................................................................... 27

TROUBLESHOOTING

GUIDE

..............................................

29

APPENDIX A – Watlow 96

Co troller

...............................

30

Genera Contro er Operation.............................................. 30

Light & Contact Timer, Communications ............................ 31

APPENDIX B – Watlow SD

Co troller

..............................

32

APPENDIX C – 230 V Optio al

U it

.................................. 33

Light & Contact Timer ......................................................... 33

APPENDIX D – Declaratio of

Co forma ce

................ 34