11

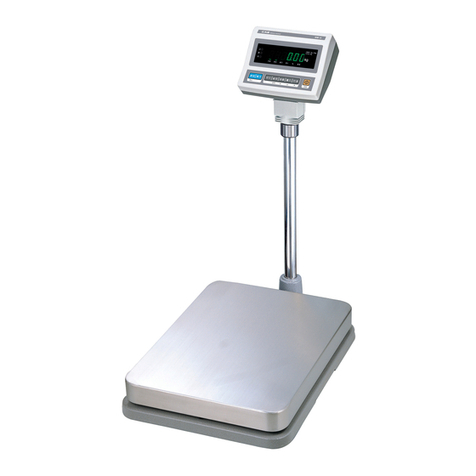

Keyboard

ZERO

Short Turns the weight indication around Zero Point to 0.

(Operates up to 2% of the maximum weight)

PAD

Short

When the PAD is pressed and desired PAD No. pressed, then it will

display only the weight on the corresponding PAD only.

Support display will indicate the No. of the current PAD.

If you wish to find out the weight of other PAD, press the PAD key

again and press the corresponding No. of PAD.

It will not operate if number other than the number of PADs currently

connected.

To display the overall weight again, press the SUM key.

Print function and FIND function does not operate in this mode.

TRUCK No.

Short

Enter the vehicle number after having pressed the TRUCK NO key.

You can print for each axle by pressing the PRINT key after having

entered the vehicle number.

PRINT

Short

You can start printing with PRINT KEY without using the TRUCK NO

key. When printing with the PRINT KEY, the vehicle number will not be

outputted.

Every time the PRINT key is pressed, the weight of the axle will be

printed.

Once it reaches the maximum number of axles (5 axles), overall

weight will be printed automatically, and whether to save the data will

be determined in accordance with the automatic saving option. (Same

as when the SUM key is pressed.)

SUM

Short

Use after having printed all the axles with the PRINT key.

Measured weights of axles will be summed and printed, and

terminates the operation of printer.

Whether to save the data will be determined in accordance with the

automatic saving option.

Long Transfers to the overall weight measurement state from individual

weight measurement state.