BEFORE ASSEMBLING YOUR Power Trainer

IMPORTANT: Read this entire manual before attempting to build or use this

product. This manual contains step by step instructions for proper assembly.

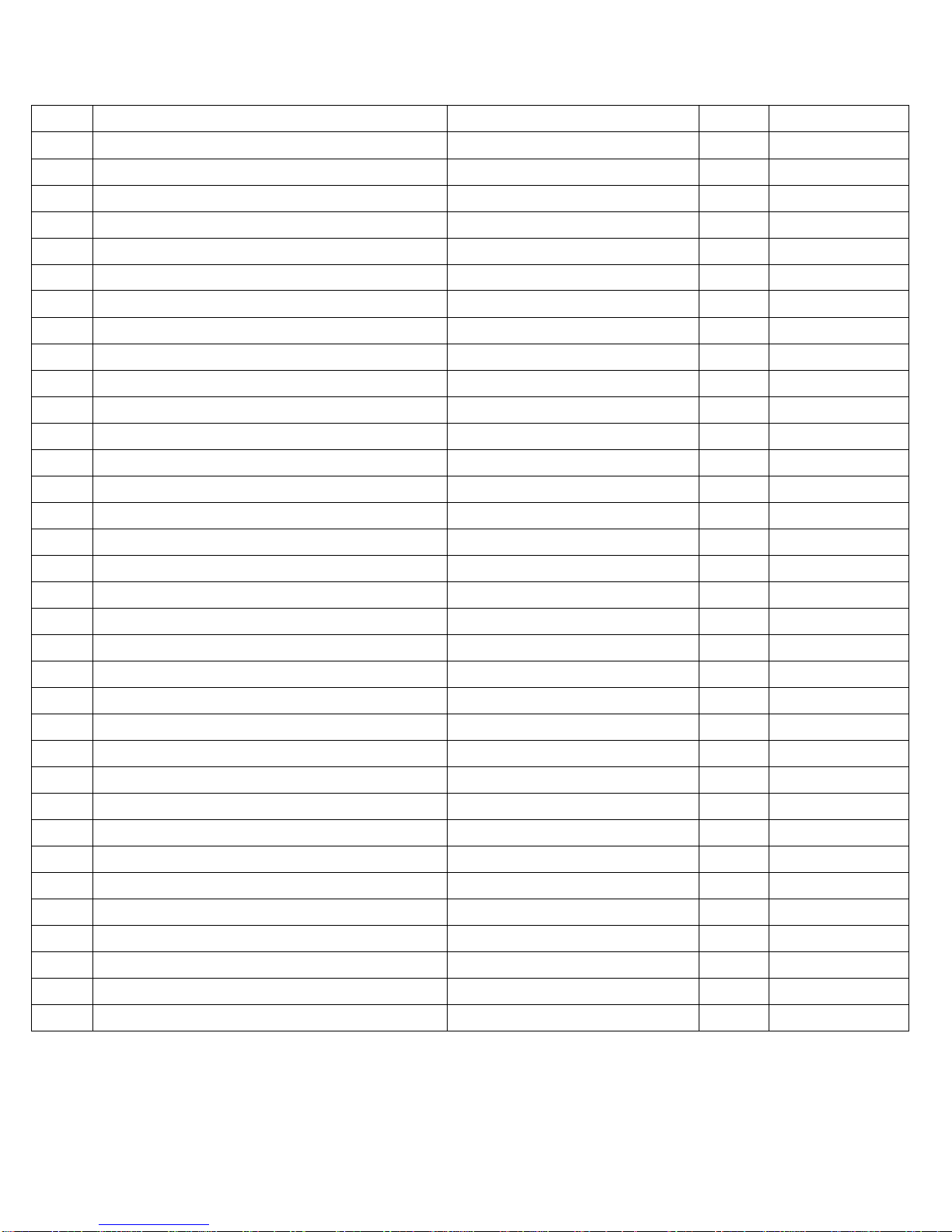

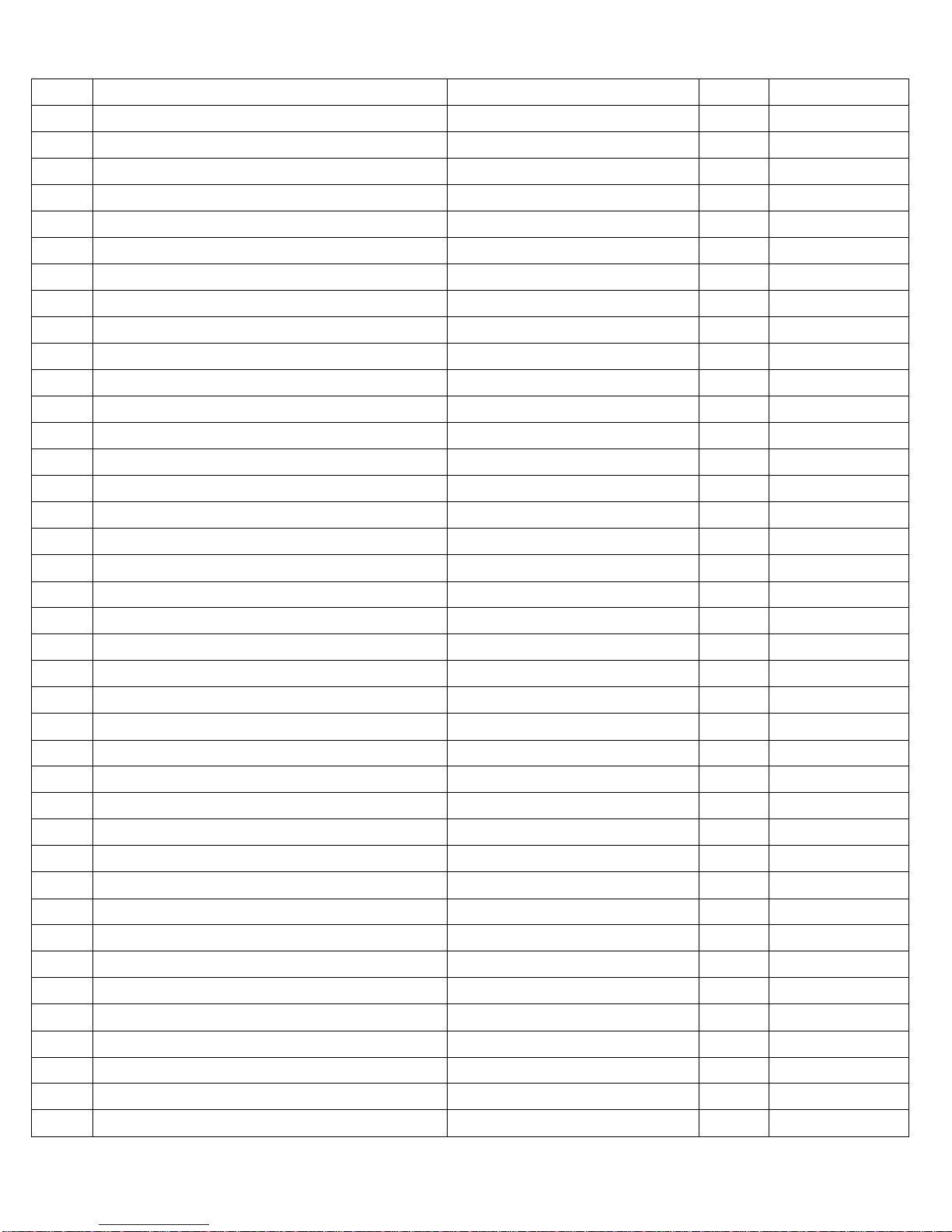

Use the parts list included in this manual to verify that all parts are

accounted for before assembly. If any parts are missing, contact the retailer

of this product for replacement parts. Or, visit service.casall.se for more

information.

Service of your home gym should only be preformed by an authorized

INSPIRE retailer. Service preformed by anyone else can result in loss of

warranty. Use only Inspire replacement parts on this machine. The use of

any other brand of parts can also result in a loss of warranty. If you need

help finding an authorized retailer, please contact us directly:

Sweden Head office

Casall Sport AB

Västgötegatan 7

Box 6007

600 06 Norrköping

Sweden

Phone: +46 (0) 11 32 56 00

Fax: +46 (0) 11 32 56 10

info@casall.se

REGISTER YOUR GYM ON LINE AT WWW.INSPIREFITNESS.NET

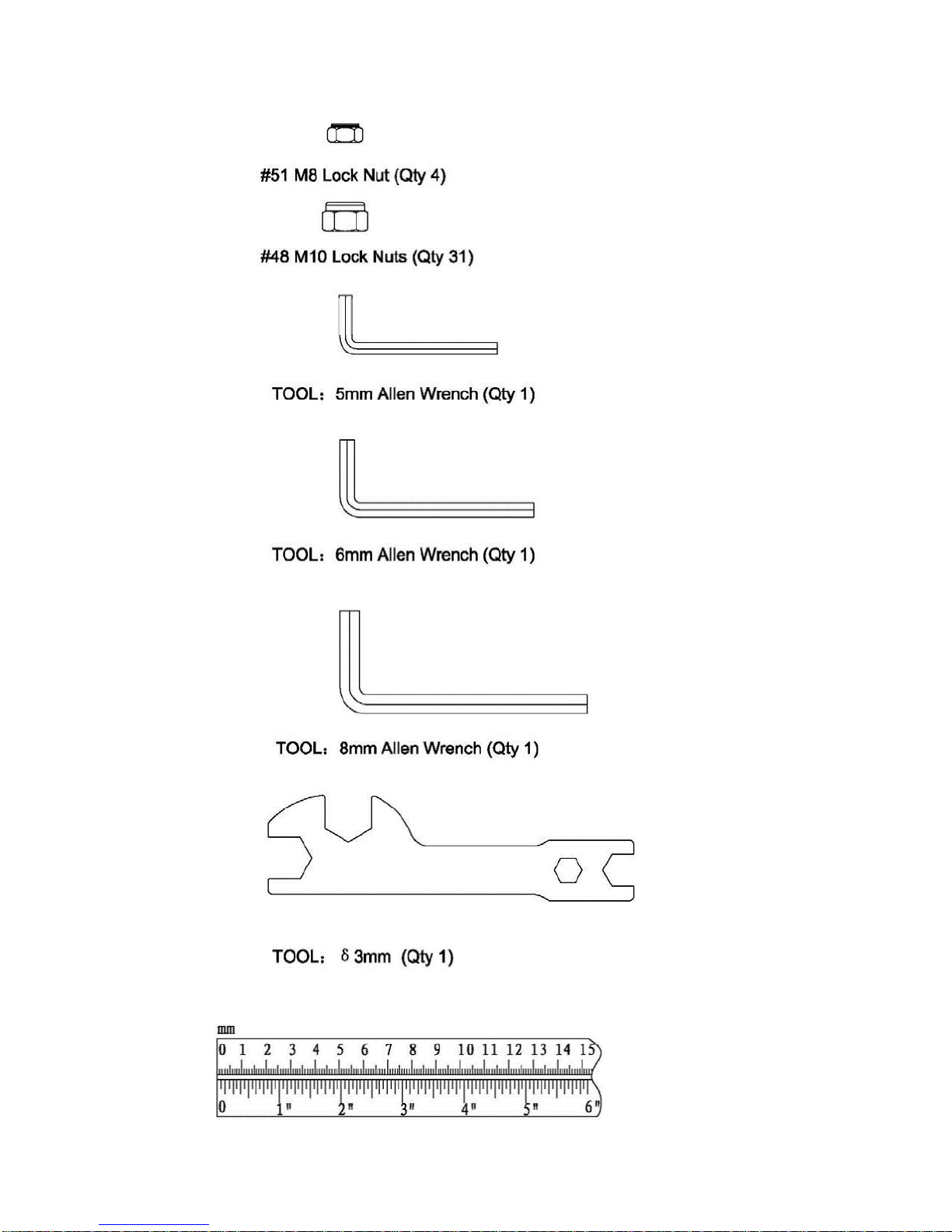

TOOLS REQUIRED FOR ASSEMBLY

Metric socket set

Adjustable wrench

Tape Measure

Rubber Mallet