4

Ambient conditions

The manufacturer does not accept any responsibility for dam-

age that may result from the plant being used or stored in am-

bient conditions that do not conform.

• The ambient air temperature range must be as follows:

-

When in use: from -10 °C to +40 °C (from 14 °F to 104 °F).

-

When being transported and stored: from -20 °C to +55 °C

(from -4 °F to 131 °F).

• The relative humidity of the air must be as follows:

- Up to 50% at 40 °C (104 °F).

- Up to 90% at 20 °C (68 °F).

• Altitude (above sea level): up to 2000 m (6561 feet 8.16 in.).

•

Ambient air: free of dust, acids, corrosive substances or gas-

es, etc.

How to lift up the system

Before lifting the unit, open the bag containing the eyebolts (at-

tached to machine), remove the two eyebolts complete with fi-

bre washers and mount them on the upper part of the cover.

Only lift the unit using the two eyebolts.

These lifting and conveying devices conform to the require-

ments laid down by the international standard. Do not use oth-

er hoisting and transportation systems.

The angle of incidence on the chains or cables must be as

small as possible.

Always remove the gas cylinder and feeder.

Serial number

The welding machine’s serial number is shown on the unit’s

data plate.

The serial number provides the key to tracing the production lot

applicable to the product. The serial number may be essential

with ordering spare parts or planning maintenance.

Opening the packaging

The system essentially consists of:

• MAXIQ weld unit.

• Separately:

- MF4 wire-feeder unit (supplied separately).

- MIG-MAG welding torch (optional).

-

Wire-feeder/generator interconnection cable (supplied sep-

arately).

Perform the following operations on receiving the apparatus:

•

Remove the welding generator and all accessories and com-

ponents from the packaging.

•

Check that the welding apparatus is in good condition; other-

wise immediately inform the retailer or distributor.

• Check that all the ventilation grilles are open and that there

is nothing to obstruct the correct air flow.

Installation and connections

The installation site for the system must be carefully chosen

in order to ensure its satisfactory and safe use. The user is re-

sponsible for the installation and use of the system in accord-

ance with the producer’s instructions contained in this manual.

Before installing the system the user must take into consider-

ation the potential electromagnetic problems in the work area.

In particular, we suggest that you should avoid installing the

system close to:

• Signalling, control and telephone cables.

• Radio and television transmitters and receivers.

• Computers and control and measurement instruments.

• Security and protection instruments.

Persons fitted with pace-makers, hearing aids and similar

equipment must consult their doctor before going near a ma-

chine in operation. The equipment’s installation environment

must comply to the protection level of the frame.

The welding unit is characterized by the following classes:

• IP 23 S protection class indicates that the generator can be

used in both interior and exterior environments.

•

The “S” usage class indicates that the generator can be em-

ployed in environments with a high risk of electrical shocks.

This system is cooled by means of the forced circulation of air,

and must therefore be placed in such a way that the air may

be easily sucked in and expelled through the apertures made

in the frame.

Assemble the system in the following way:

• Fitting the feeder unit to the generator.

• Connect up the welder to the mains.

•

Connect up the wire-feeder/generator interconnection cable.

• Connect up the welding cables.

Instructions for fitting the individual components / optional ex-

tras are contained in the relevant packaging.

Connection to the electrical supply

Connection of the machine to the user line (electrical cur-

rent) must be performed by qualified personnel.

Before connecting the welding machine to the mains pow-

er supply, make sure that rated voltage and frequency cor-

respond to those provided by the mains power supply and

that the welding machine’s power switch is turned to “O”.

Use the welder’s own plug to connect it up to the main pow-

er supply. Proceed as follows if you have to replace the plug:

•

3 conducting wires are needed for connecting the machine

to the supply.

•

The fourth, which is YELLOW GREEN in colour is used for

making the “GROUND” connection.

Connect a suitable load of normalised plug (3P+T) to the

power cable and provide for an electrical socket complete

with fuses or an automatic switch. The ground terminal

must be connected to the ground conducting wire (YEL-

LOW-GREEN) of the supply.

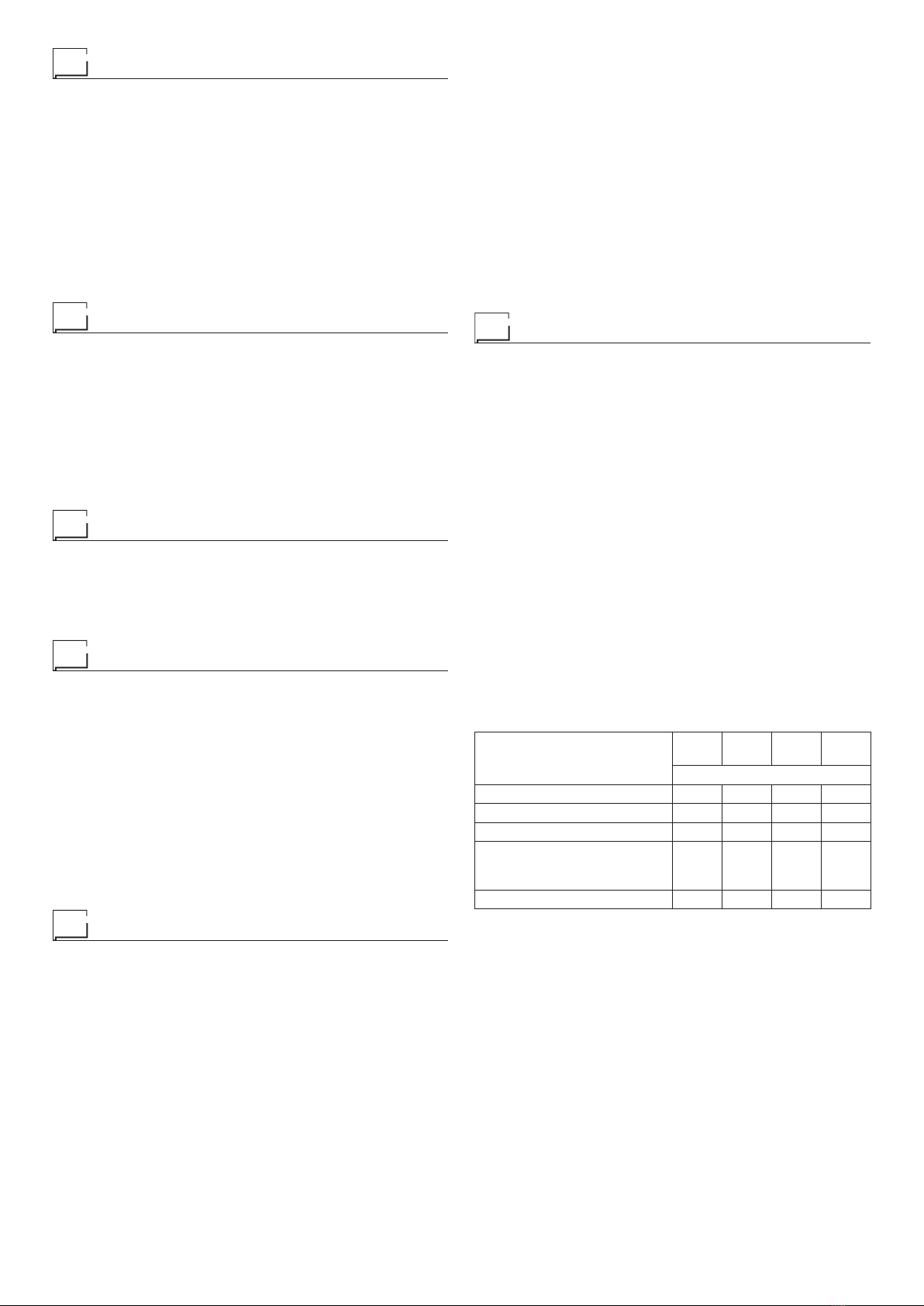

Table 3 shows the capacity values that are recommended for

fuses in the line with delays.

NOTE: Any extensions to the power cable must be of a suita-

ble diameter, and absolutely not of a smaller diameter than the

special cable supplied with the machine.

Table 2

Model

MAXIQ

400

MAXIQ

400w

MAXIQ

500

MAXIQ

500w

MIG-MAG welding

Input power @ I2Max kVA 19 19,5 25,5 26

Delayed fuse (I eff) A32 32 32 32

Duty cycle @ 35% (40°C) A400 400 500 500

Mains cable

Length / Section m

mm2

4,5

4 × 6

4,5

4 × 6

4,5

4 × 6

4,5

4 × 6

Ground cable mm250 50 70 70