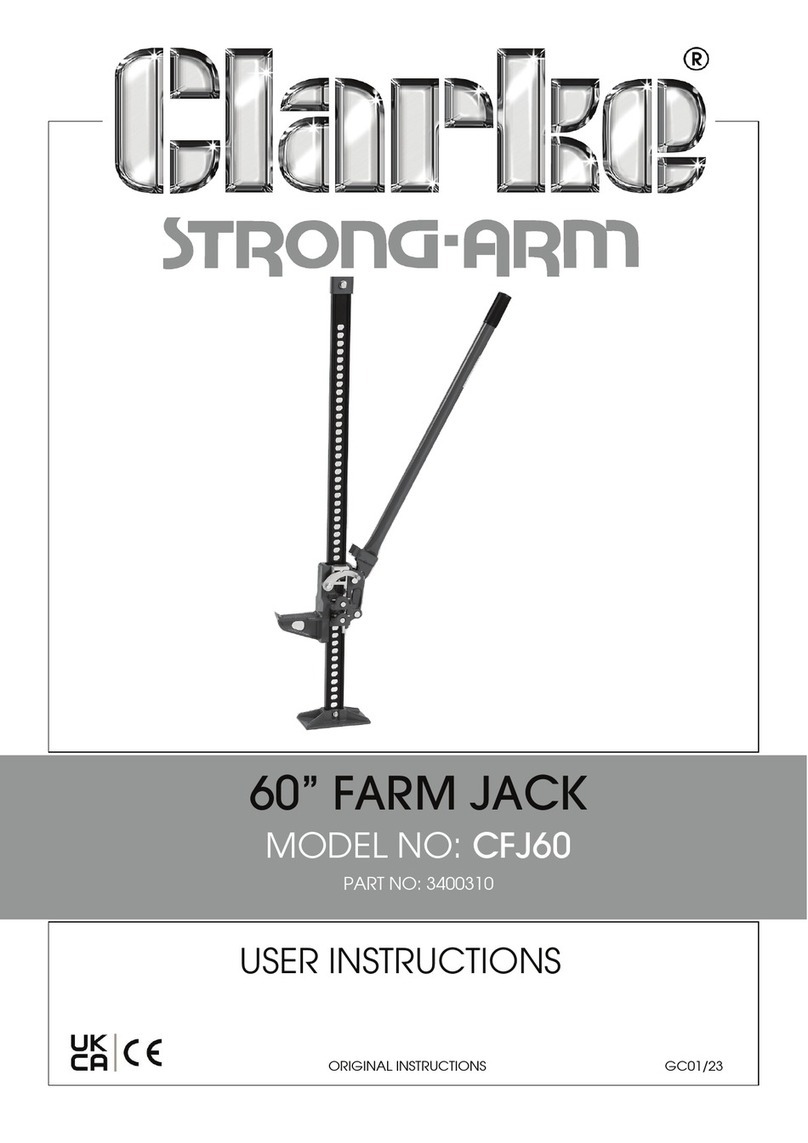

Thank you for purchasing thisClarke 48" Farm Jack.

This extremely versatile device,is designed to lift, pull or push, a maximum load of

2000 kg (4400lbs - 2Tonnes), and can raise a load up to 1.09mtrs (43"). Its applications

are many and varied, from lifting equipment and machinery, to removing tree

stumps or fence posts etc.

Before attempting to assemble or operate the unit, please read this instruction

booklet thoroughly, and follow all directions carefully, paying particular attention

to the safety precautions. By doing so, you will ensure the safe operation of the

unit, and the safety of yourself and others around you. You can then look forward

to long and reliable service from your CLARKE Farm Jack.

SAFETY PRECAUTIONS

1. Always inspect the jack before use. Ensure that all parts are in good condition

and operating smoothly, and that no cracks or distortion is apparent. If in

doubt do not use.

2. Ensure the jack is on a firm solid base, and that there is no likelihood of it

slipping when under load.

3. Ensure the load is taken by the FULL lifting nose (parts Diagram item A), and that the

point of lift on the load, is of sufficient strength to support the full load adequately.

4. Always ensure that the load is stabilised or supported in such a way that it will

not shift during lowering or lifting operations.

5. Always use supports to stabilise the load once lifted. NEVER work on or under

a load unless it is fully and adequately supported. Do not rely upon jack to

hold load in position.

6. Never push a load off the jack.

7. Ensure that all personnel are well clear of a load being raised, lowered or pulled.

8. It is strongly advised that industrial gloves are worn at all times when using the

jack. Take care not to trap fingers within the moving parts.

9. When using the jack to pull or drag a load, be aware that the load may

suddenly ‘give’, eg. Pulling a tree stump etc. Take the necessary precautions.

10. NEVER carry the jack by the handle, as the column may drop and cause

damage to persons or property, ALWAYS carry via the column.

A. TO RAISE A LOAD.

1. Following all safety precautions, place the foot of the jack beneath the load.

Lift the Reversing Latch (10) to its’ “UP” position and ensure it is locked in place,

with the indentation in the Latch, firmly engaged in the notch on the Reversing

Switch (11) - refer to fig. 1. Jack up the nose until it comes into contact with the

load at the desired point of lift. Pause at this stage and check to ensure there are

no obstacles to a clean lift.

OPERATING INSTRUCTIONS

2

2. Pull down firmly and evenly on the handle and observe the load rising. As the

handle is pulled down, you will hear the locking pin (20) click into place as it

locates in a hole in the column (2). At this point, relax the handle allowing the

pin (20) to take the load. Raise the handle to the top of its stroke to take a

fresh purchase, and pump the handle once again.

IMPORTANT:

1. DO NOT use extensions on the handle.

2. ALWAYS keep a firm hold on the handle.

To raise a load To lower a load

B. TO LOWER A LOAD

IMPORTANT:

The jack must be loaded with a minimum 50kg (110lbs) to lower step by

step, otherwise the lifting nose will drop.

Taking all necessary precautions, take the load with the jack, (i.e. jack the load up

slightly), and ensuring the handle is in the FULLY UPRIGHT position, trip the Reversing

Latch (11), so that it is in the “Down” position, i.e. the indentation on the latch,

becomes disengaged from the notch on the reversing switch (see fig. 2). Keeping

a firm grip on the handle, pump it as you would for ‘raising a load’.

MAINTENANCE

Inspect for distortion of the column and locking pins, and security of all nuts and bolts. Keep

all parts of the jack well lubricated to prevent any possibility of corrosion. Store in a dry place

where it cannot be attacked by the elements.

If stored for long periods, inspect at least twice a year; clean, and re-oil

Fig. 1 Fig. 2.

3