Cleveland 24CSM Series Manual

Other Cleveland Electric Steamer manuals

Cleveland

Cleveland 42-CKEM-24 User manual

Cleveland

Cleveland ConvectionPro XVI 36-CGM-16-300 User manual

Cleveland

Cleveland SteamPro User manual

Cleveland

Cleveland Enodis 24-CDM User manual

Cleveland

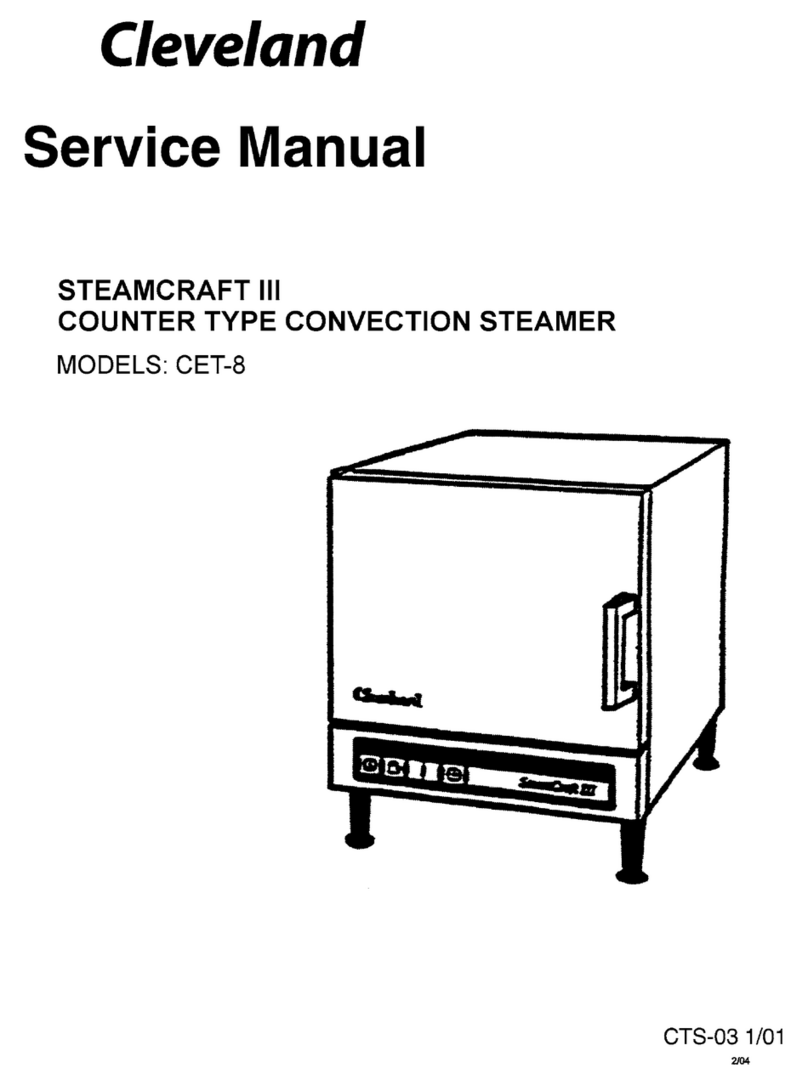

Cleveland 22CET3A User manual

Cleveland

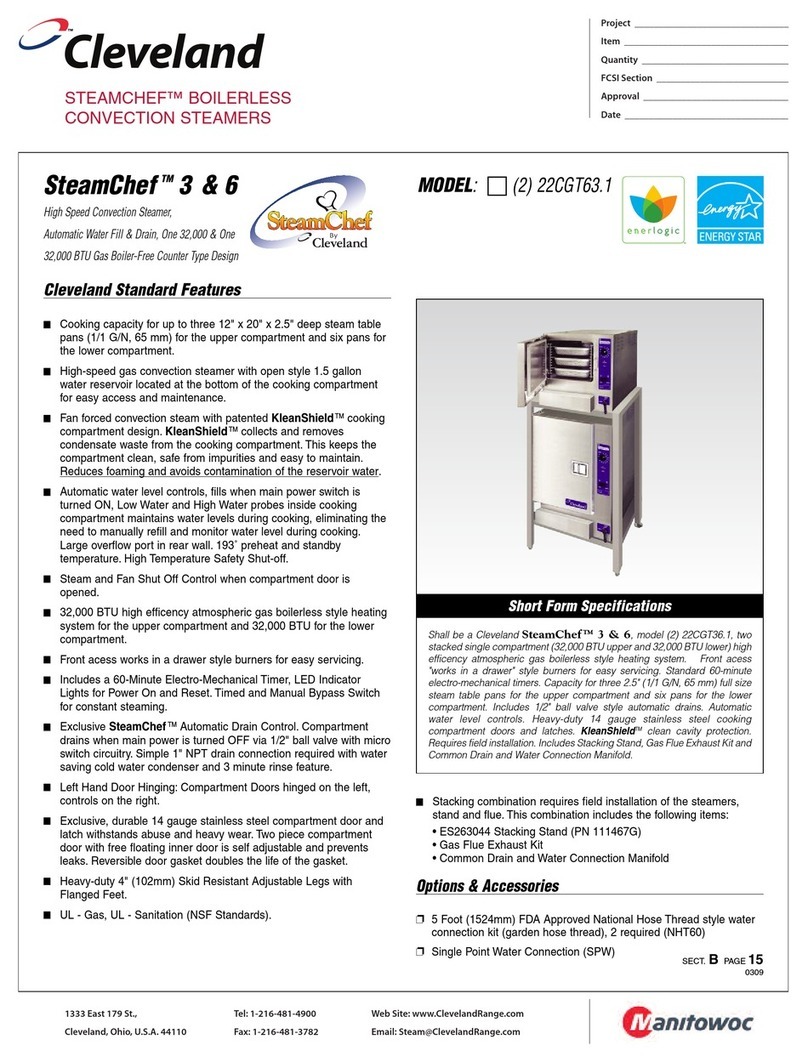

Cleveland SteamChef 22CGT3 User manual

Cleveland

Cleveland Convotherm OGB-12.20 User manual

Cleveland

Cleveland SteamChef 3 User manual

Cleveland

Cleveland CET-8 User manual

Cleveland

Cleveland 24-CGA-10.2 User manual

Cleveland

Cleveland SteamCub 1SCEMCS User manual

Cleveland

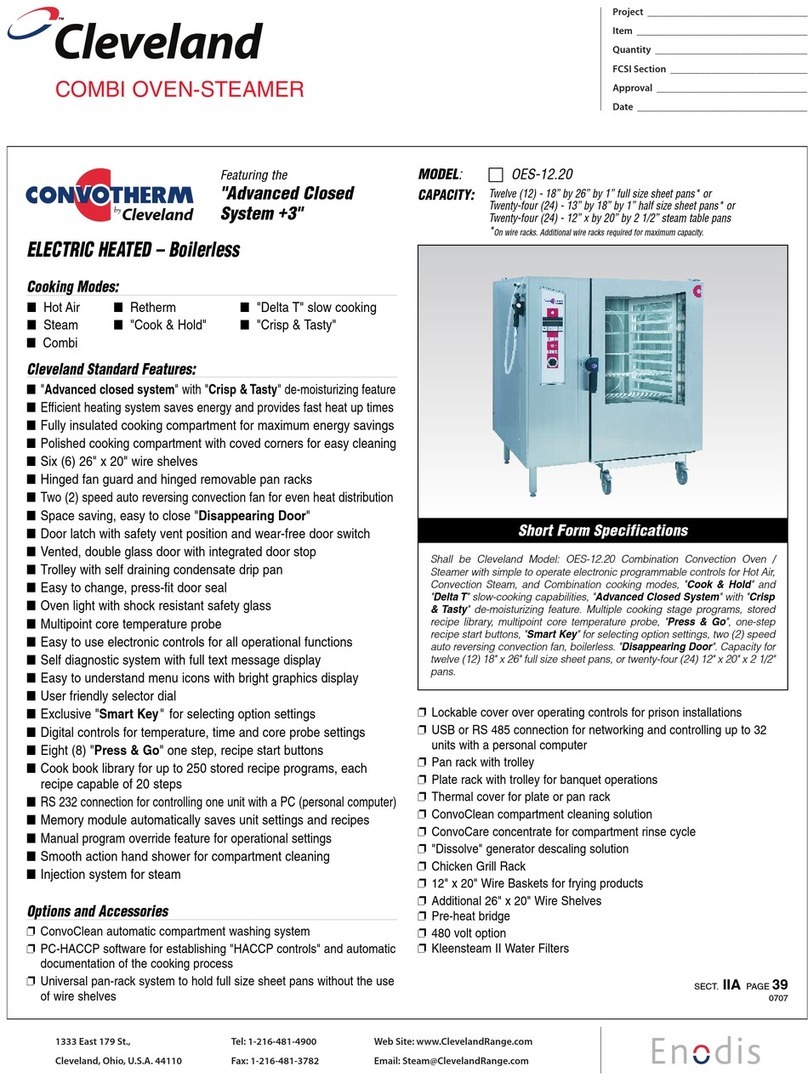

Cleveland OES-12.20 User manual

Cleveland

Cleveland SteamCub 1SCEMCS Owner's manual

Cleveland

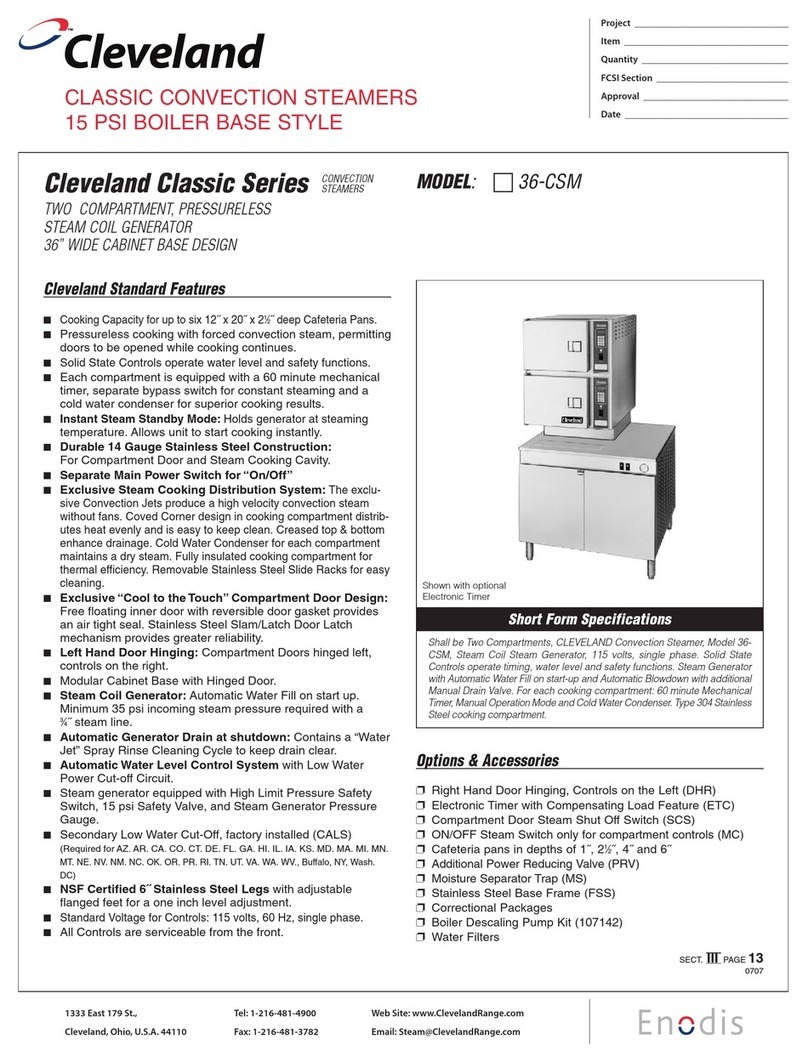

Cleveland 36CSM Series User manual

Cleveland

Cleveland ConvectionPro XVI 36-CEM-16-48 User manual

Cleveland

Cleveland SteamChef 22CET3.1 User manual

Cleveland

Cleveland SteamCraft 24-CGA-10 User manual

Cleveland

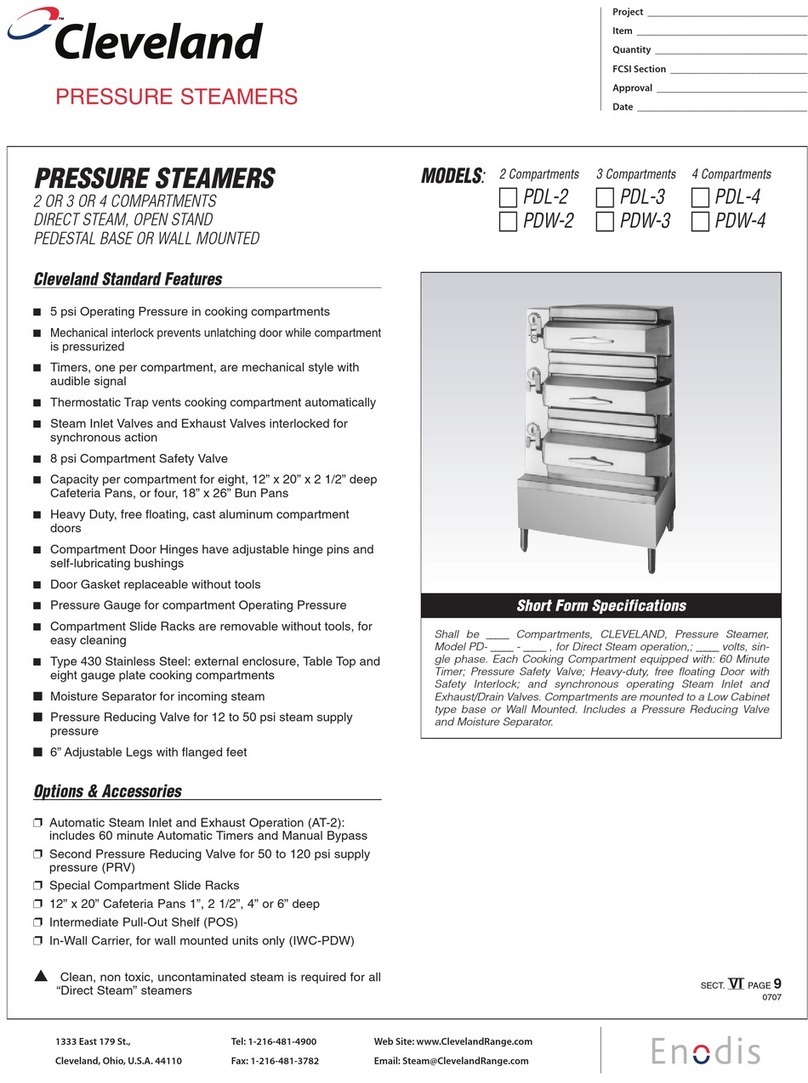

Cleveland PDL-3 User manual

Cleveland

Cleveland SteamCraft 21-CGA-5 User manual

Cleveland

Cleveland 36-CGM-300 User manual

Popular Electric Steamer manuals by other brands

Morphy Richards

Morphy Richards FS48751MEE manual

Cuisinart

Cuisinart STM1000AR instructions

Hastings

Hastings DIRECT GAS FIRED ELECTRIC STEAM Installation and service instructions

Galantine

Galantine SILVER Style SC-5003B instruction manual

Oster

Oster 5711 instruction manual

Back to Basics

Back to Basics NUTRI STEAMER L5725A 01/09 instruction manual