Cleveland

™

Project ________________________________

Item __________________________________

Quantity_______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio,U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site:www.ClevelandRange.com

Email: Steam@ClevelandRange.com

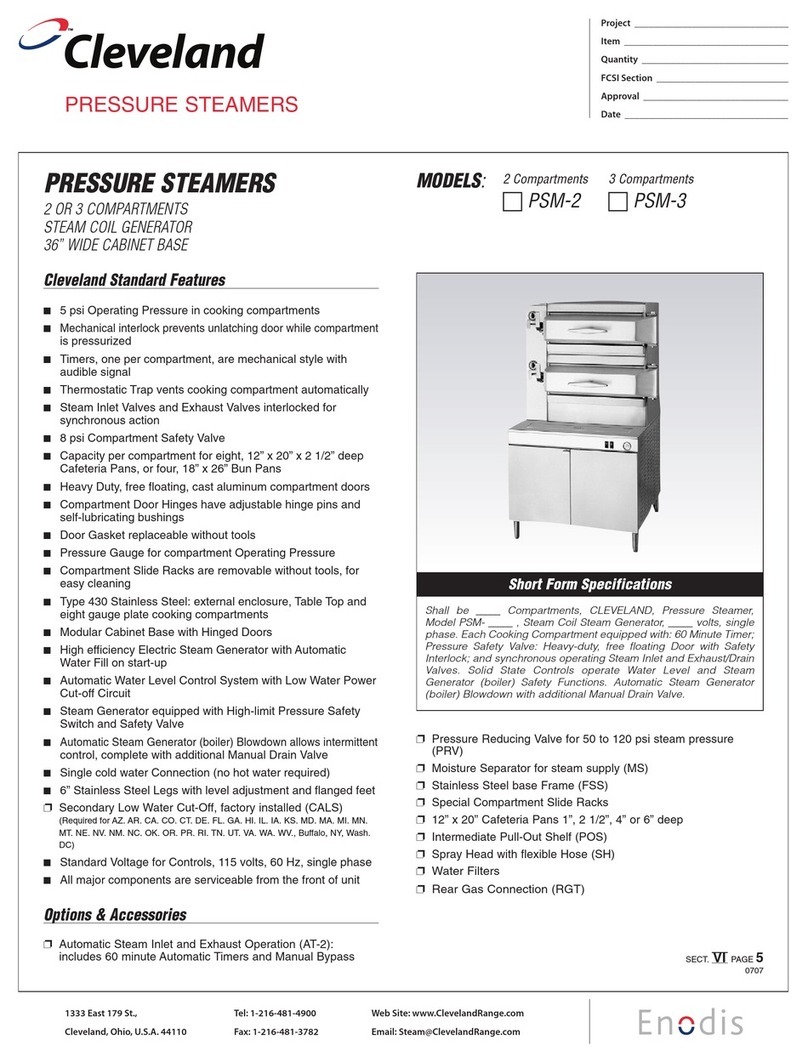

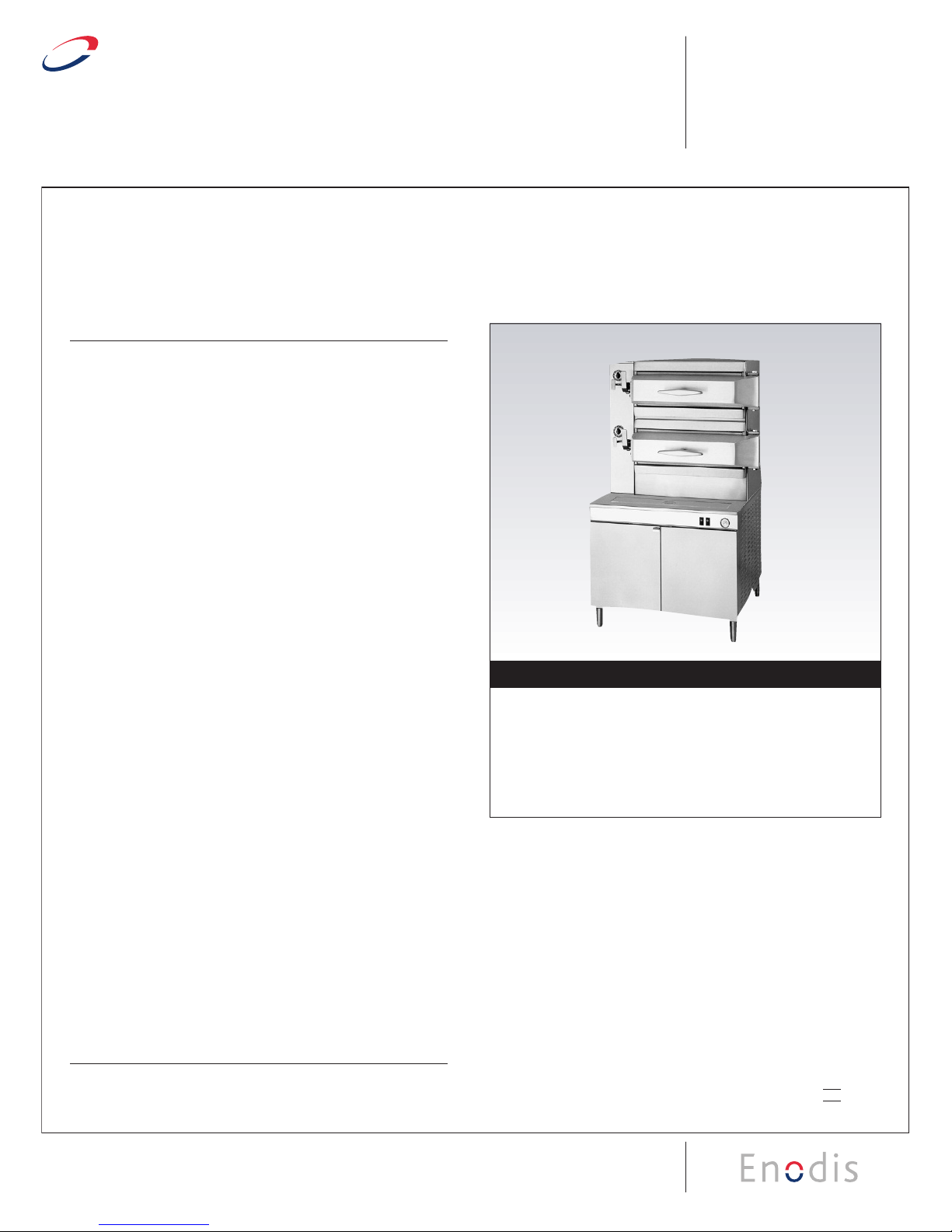

PRESSURE STEAMERS

Cleveland Standard Features

n5psi Operating Pressure in cooking compartments

n

Mechanical interlock prevents unlatching door while compartment

is pressurized

nTimers, one per compartment, are mechanical style with

audible signal

nThermostatic Trap vents cooking compartment automatically

nSteam Inlet Valves and Exhaust Valves interlocked for

synchronous action

n8psi Compartment Safety Valve

nCapacity per compartment for eight, 12” x 20” x 2 1/2” deep

Cafeteria Pans, or four,18” x 26” Bun Pans

nHeavy Duty, free floating, cast aluminum compartment doors

nCompartment Door Hinges have adjustable hinge pins and

self-lubricating bushings

nDoor Gasket replaceable without tools

nPressure Gauge for compartment operating pressure

nCompartment Slide Racks are removable without tools, for

easy cleaning

nType 430 Stainless Steel: external enclosure, Table Top and

eight gage plate cooking compartments

nModular Cabinet Base with Hinged Doors

nHigh efficiency Electric Steam Generator with Automatic

Water Fill on start-up

nAutomatic Water Level Control System with Low Water Power

Cut-offCircuit

nSteam Generator equipped with High-limit Pressure Safety

Switch and Safety Valve

n

Automatic Steam Generator (boiler) Blowdown allows intermittent

control, complete with additional Manual Drain Valve

nSteam Generator Pressure Gauge

n6” Stainless Steel Legs with level adjustment and flanged feet

nSingle Cold Water Connection (no hot water required)

pSecondary Low Water Cut-Off, factory installed (CALE)

(Required for AZ. AR. CA. CO. CT. DE. FL. GA. HI. IL. IA. KS. MD. MA. MI. MN.

MT.NE. NV.NM. NC. OK. OR. PR. RI. TN. UT. VA. WA. WV., Buffalo, NY, Wash.

DC)

nStandard Voltage 208-240 volts, 60 hz, single phase, three

wire

nAll Major Components are serviceable from the front of unit

Options & Accessories

pAutomatic Steam Inlet and Exhaust Operation (AT-2):

includes 60 minute Automatic Timers and Manual Bypass

Shall be _____ Compartments, CLEVELAND, PressureSteamer,Model

PEM- _____ -_____ ,Electric Steam Generator, _____ kw,

_____ volts, _____ ph, three wire. Each Cooking Compartment equipped

with: 60 Minute Timer; Heavy-duty, free floating Door with Safety

Interlock; and synchronous operating Steam Inlet and Exhaust/Drain

Valves. Solid State Controls operate Water Level and Steam

Generator (boiler) Safety Functions. Automatic Steam Generator (boil-

er) Blowdown with additional Manual Drain Valve.

p15 psi for Kettle Operation, includes Power Take-Off (PTO)

pKettle Interconnecting Kit (IMK)

pStainless Steel base Frame (FSS)

pStainless Steel gas flue cover, insulated (SSF)

pSpecial compartment Slide Racks

p12” x 20” Cafeteria Pans 1”, 2 1/2”, 4” or 6” deep

pIntermediate Pull-Out Shelf (POS)

pSpray Head with flexible Hose (SH)

pVoltages, other than standard

pWater Filters

pCorrectional Packages

Short Form Specifications

PRESSURE STEAMERS

2OR 3 COMPARTMENTS, CABINET MOUNTED

ELECTRIC STEAM GENERATOR

24, 36 OR 48 KW, 36” WIDE CABINET BASE

MODELS:2Compartments 3 Compartments

cPEM-24-2 cPEM-24-3

cPEM-36-2 cPEM-36-3

cPEM-48-2 cPEM-48-3

SECT. VI PAGE 1

0707