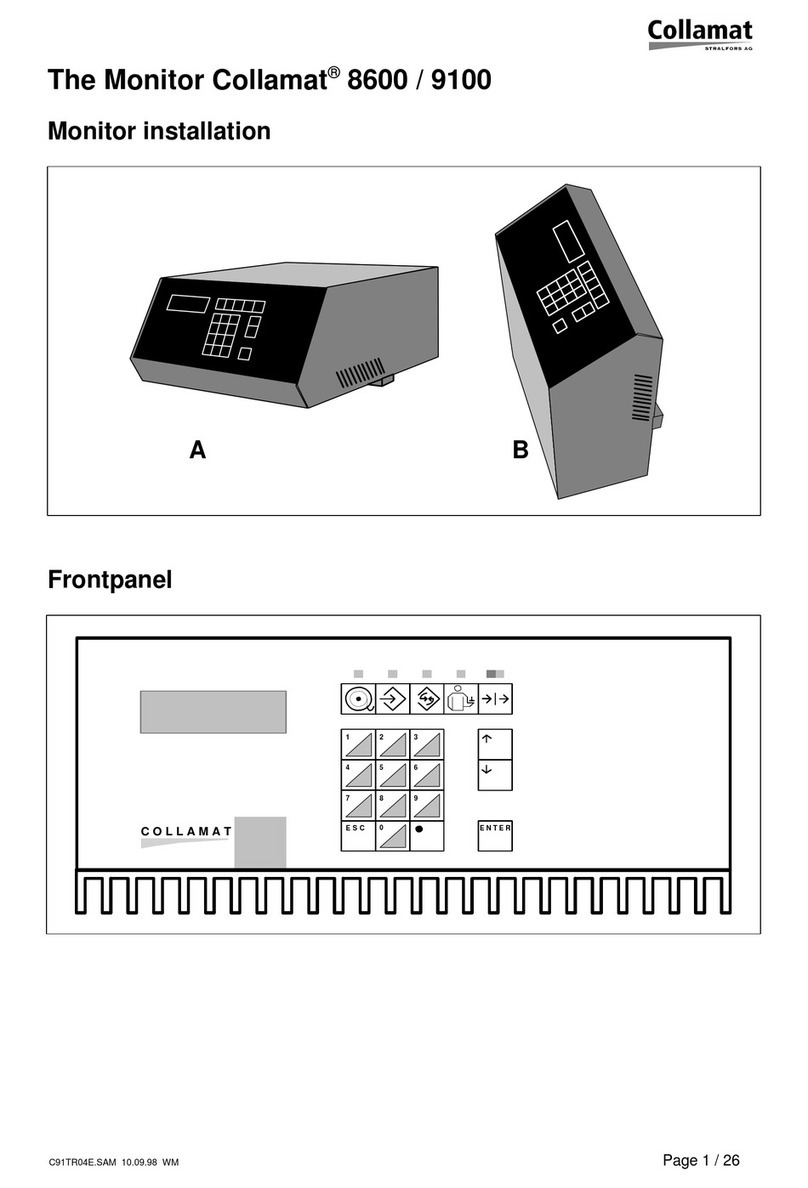

ESC key (9)

The ESC key is used to abort the input of data and to jump back to

the previous branch of the function tree.

UP (13) and DOWN (14) keys

These two keys are used to select a function within a function tree.

When entering data the indicated value can be increased (up key) or

reduced (down key) with these keys.

LABELLING MODE function key (2)

This key is used to select the labelling mode function. When depres-

sed, the LED placed above lights up and indicates that the monitor is

in labelling mode. The Collamat®parameters are entered in this mode.

The Figure "LABELLING MODE" menu tree (page 11) shows the

function tree of the labelling mode.

PROGRAMMING function key (3)

This key is used to select the programming function. When depres-

sed, the LED placed above lights up and indicates that the monitor is in

programming mode. The parameters of labeller and labelling are ente-

red in the programming mode. The Figure "PROGRAMMING menu

tree" (page 14) shows the function tree of the programming mode.

CONFIGURATION function key (4)

This key is used to select the configuration function.When depres-

sed, the LED placed above lights up and indicates that the monitor is

in configuration mode. In this mode the Collamat®is adapted to the

customer's requirements. The "CONFIGURATION menu tree" (page

25) shows the function tree of the configuration mode.

SERVICE DISPLAY function key (5)

This key is used to select the service display function. When depres-

sed, the LED placed above lights up and indicates that the monitor is in

service mode. The "SERVICE FUNCTIONS menu tree" (page 30)

shows the function tree of the service mode.

ESC

5999.530-01B 13.08.98 WM Page 9/

49