Technical Support Manual – 05/2018 Rel. 2.1.3 Page 1

CONTENTS

1. SERVICE MODE...........................................................................................................................................................................2

2. TEST PROGRAM MENU ACCESS .................................................................................................................................................2

ENC ENCODER disc test ..............................................................................................................................................................3

RPM Shaft rotation speed test ...................................................................................................................................................4

SIG Pick-up signals test...............................................................................................................................................................4

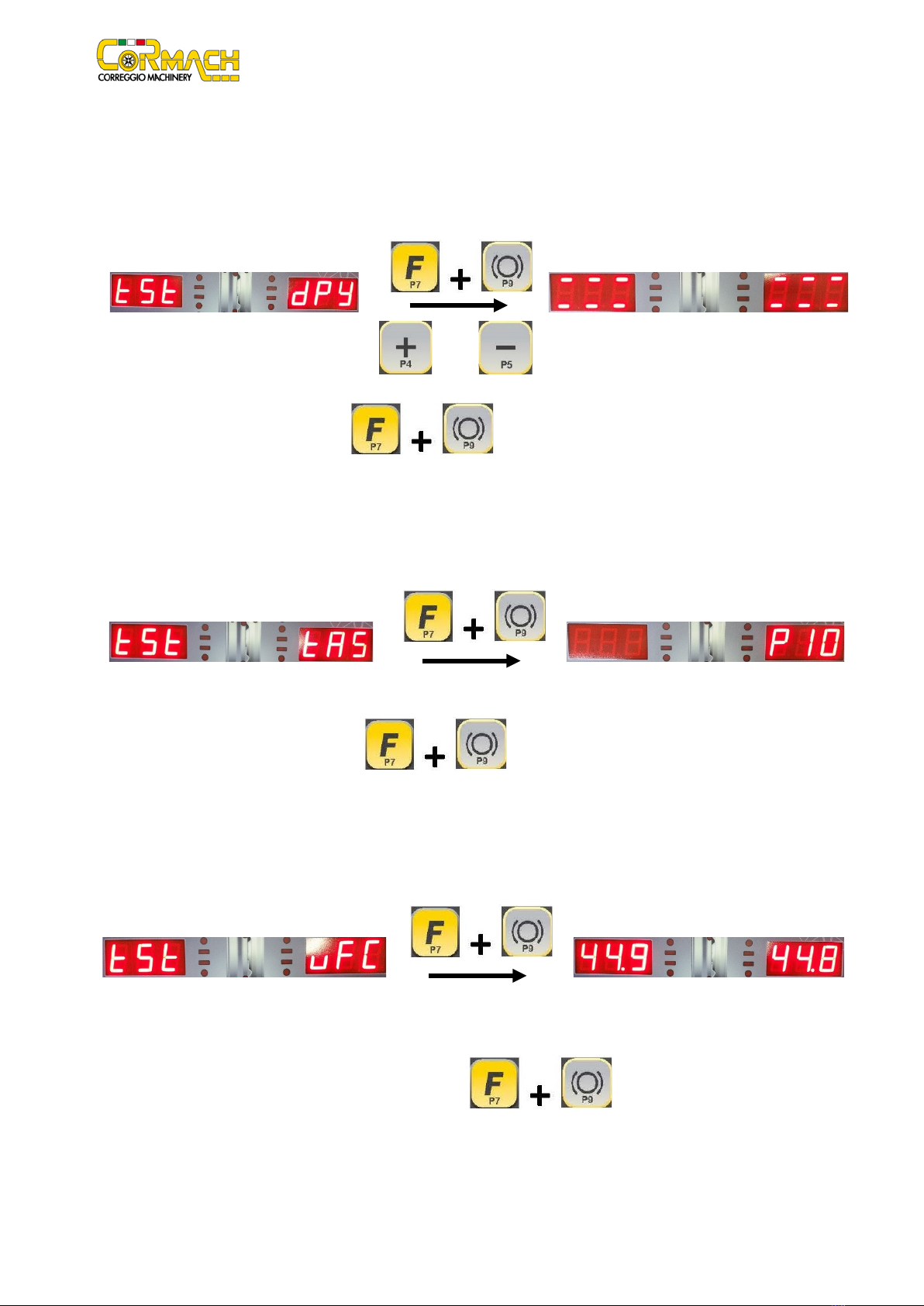

dPy Display Test .........................................................................................................................................................................6

tAS Keyboard Test ......................................................................................................................................................................6

uFC Converter voltage-frequency test .......................................................................................................................................6

RET Return .................................................................................................................................................................................7

CPb

ELECTROMAGNETIC BRAKE Calibration (if present) ............................................................................................................7

MCA

WHEEL GUARD MICRO SWITCH activation or deactivation...............................................................................................8

3. MENU PARAMETERS ACCESS (with password) ..........................................................................................................................9

Gau Activation or deactivation of the distance/diameter sensor ............................................................................................10

Lar Activation or deactivation of the width sensor (if present) ...............................................................................................11

Son

Activation or deactivation of the SONAR device (if present) .............................................................................................13

Las

Activation or deactivation of the LASER device (if present)................................................................................................14

Pbr Activation or deactivation of the clamping brake (if present) ...........................................................................................15

iLL Activation or deactivation of the illumination LEDs (if present) .........................................................................................16

SPn Revolution counter reset (spin).........................................................................................................................................17

ShF Shaft unit static imbalance measurement.........................................................................................................................17

4. PICK-UP SPRING PRE-CHARGE REGULATION............................................................................................................................18

5. ACQUISITION DEVICES CALIBRATION MENU ...........................................................................................................................19

DIS Distance Sensor..................................................................................................................................................................19

DIA Diameter sensor calibration ..............................................................................................................................................21

LAR Width sensor calibration (if present) ................................................................................................................................23

SON

SONAR device calibration (if present)...............................................................................................................................24

RET Return ...............................................................................................................................................................................25

6. MACHINE CALIBRATION...........................................................................................................................................................26

6.1 When to carry out machine calibration .................................................................................................................................26

6.2 Machine calibration for the CAR/SUV Wheel Type................................................................................................................26

6.3 Machine calibration for the MOTO wheel type .....................................................................................................................28

How to exit the MOTO wheel type calibration ............................................................................................................................30

7. ERROR CODES AND WARNINGS ...............................................................................................................................................30

8. ACOUSTIC SIGNALS ..................................................................................................................................................................33

9. SPECIAL VISUAL SIGNALS .........................................................................................................................................................33

10. TROUBLESHOOTING...............................................................................................................................................................34

11. WIRING DIAGRAM..................................................................................................................................................................35

The MANUFACTURER reserves the right to make any change to products in order to improve them.

The MANUFACTURER reserves the right to make any change to this manual without notice.