CAT4000SDR 4 Rev. 11/10/15

Operating Instructions • Warning Information • Parts Breakdown

WARRANTY

CornwellQualityToolsCompany(“Cornwell”)warrantsthisproductagainstdefectsinmaterialandworkmanshipforaperiodofTWO(2)YEARSfromthedateoforiginalretailpurchase.

Subjecttotheconditionsandlimitationssetforthbelow,Cornwellwill,atitsoption,eitherrepairorreplaceanypartoftheproduct(s)thatprovesdefectivebyreasonofimproper

workmanshipormaterials.

This warranty does not cover any damage to this product that results from accident, abuse, misuse, natural or personal disaster, or any unauthorized disassembly, repair, or

modification.Repairs,disassemblyandmodificationareonlyauthorizedtobemadebyCornwelloraCornwellAuthorizedWarrantyCenter.

WARRANTY SERVICE

Inordertohaveyourtoolrepaired,returnthetooltoanyCornwellAuthorizedWarrantyCenter,freightprepaid.Pleaseincludeacopyofyourproofofpurchaseandabriefdescription

oftheproblem.Thetoolwillbeinspectedandifanypartorpartsarefoundtobedefectiveinmaterialorworkmanship,theywillberepairedfreeofcharge,andtherepairedtoolwill

bereturnedtoyoufreightprepaid.

EXCLUSIONS AND LIMITATIONS

THISWARRANTYANDTHEREMEDIESSETFORTHABOVEARE EXCLUSIVEANDINLIEUOFALL OTHERWARRANTIES, REMEDIESANDCONDITIONS,WHETHER ORAL ORWRITTEN,

EXPRESSORIMPLIED.CORNWELLSPECIFICALLYDISCLAIMSANYANDALLIMPLIEDWARRANTIES,INCLUDING,TOTHEEXTENTPERMITTEDBYAPPLICABLELAW,ANYWARRANTIES

OFMERCHANTABILITYANDFITNESSFORAPARTICULARPURPOSE.IFCORNWELLCANNOTLAWFULLYDISCLAIMIMPLIEDWARRANTIESUNDERTHISLIMITEDWARRANTY,ALLSUCH

IMPLIEDWARRANTIESARELIMITEDINDURATIONTOTHEDURATIONOFTHISWARRANTY.

INNOEVENTSHALLCORNWELLBELIABLETOTHEPURCHASERORTOTHEUSEROFACORNWELLPRODUCTFORANYSPECIAL,INCIDENTALORCONSEQUENTIALDAMAGESBASED

UPON BREACH OFWARRANTY, BREACH OF CONTRACT, NEGLIGENCE, TORT, ORANY OTHER LEGALTHEORY. SUCH DAMAGES INCLUDE, WITHOUT LIMITATION, EXPENSES, LOST

REVENUES,LOSTSAVINGS,LOSTPROFITS,ORANYOTHERINCIDENTALORCONSEQUENTIALDAMAGESARISINGFROMTHEPURCHASE,USEORINABILITYTOUSETHECORNWELL

PRODUCT.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamagesorexclusionsorlimitationonthedurationofimpliedwarrantiesorconditions,sotheabove

limitationsorexclusionsmaynotapplytoyou.Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightsthatvarybystate.

RepairkitsandreplacementpartsareavailableformanyCornwellproducts,regardlessofwhetherornottheproductisstillcoveredbyawarrantyplan.

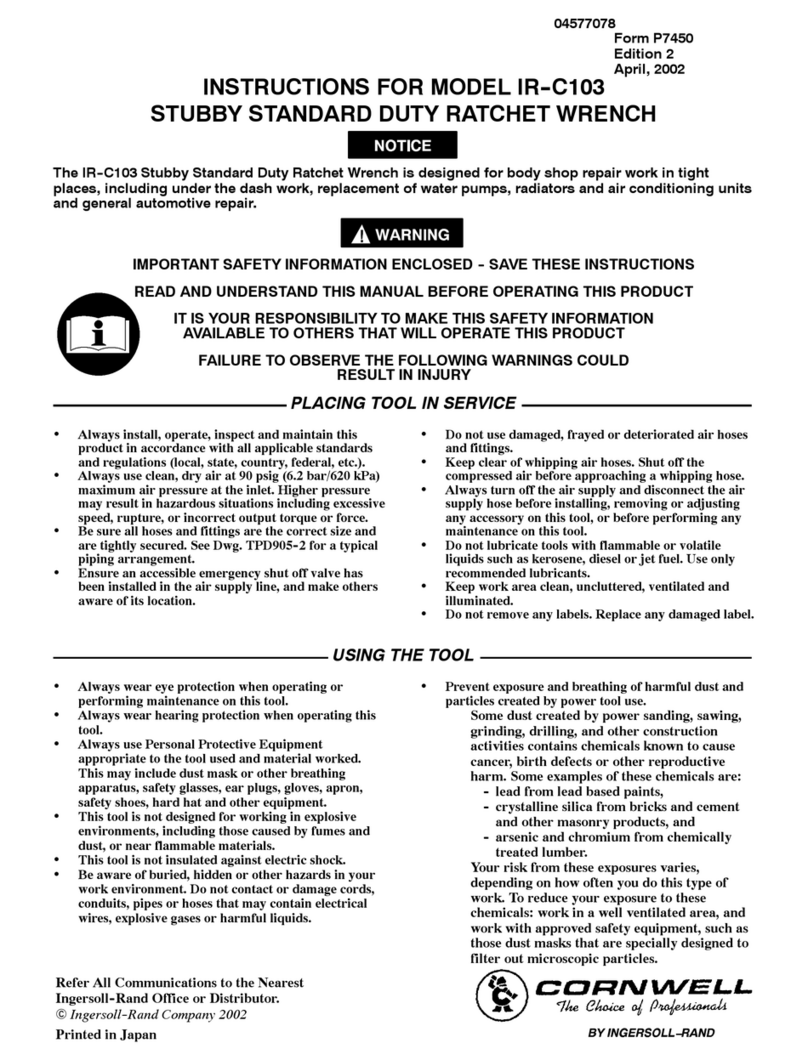

AIR SUPPLY

Toolsoperateonawiderangeofairpressures.Itisrecommended

that airpressure ofthese toolsmeasures90 psigat thetoolwith

thetriggerfully depressedand no loadappliedto thetool. Higher

pressure (over 90 psig; 6.2 bar) raises performance beyond the

rated capacity of the tool, which will shorten tool life and could

causeinjury.

Alwaysuseclean,dryair.Dust,corrosivefumesand/orwaterinthe

air line will cause damage to the tool. Drain water from air lines

andcompressorpriortorunningtool.Cleantheairinletfilterscreen

weekly.Therecommendedhookupprocedurecanbeviewedinthe

abovefigure.

Theairinletusedforconnectingairsupplyhasstandard1/4"NPT.

Linepressureshouldbeincreasedtocompensateforunusuallylong

airhoses(over25feet).Minimumhosediametershouldbe3/8"I.D.

andfittingsshouldhavethesameinsidedimensionsandbetightly

secured.

Ensureanaccessibleemergencyshutoffvalvehasbeeninstalledin

theairsupplylineandmakeothersawareofitslocation.

LUBRICATION

Lubricatetheairmotor dailywith highquality airtooloil. Ifnoair

line oiler is used, run 1/2 oz. of oil through the tool.The oil can

be squirted into the tool air inlet or into the hose at the nearest

connectiontotheairsupply,thenrunthetool.Arustinhibitiveoilis

acceptableforairtools.

WARNING:After anair toolhas beenlubricated, oilwill discharge

throughtheexhaustportduringthefirstfewsecondsofoperation.

Theexhaustportmustbecoveredwithatowelbeforeapplyingair

pressuretopreventseriousinjury.

OPERATION

Thisratchetwrenchisratedat1/4"USSboltsize.Ratingmustbe

downgradedforspringUbolts,tiebolts,longcapscrews,double

depth nuts, badly rusted conditions and spring fasteners as they

absorbmuchoftheimpactpower.Whenpossible,clamporwedge

thebolttopreventspringback.

Theforward/reversingbuttonisusedtochangethedirectionofthe

tool.Whenthebuttonissettotheright,thetoolwillturninaright

handdirection.Whenthebuttonissettotheleft,thetoolwillturn

inalefthanddirection.

NOTE: Always turn off the air supply, drain hose of air pressure

and detach tool from air supply before installing, removing or

adjusting any accessory on this tool, or before performing any

maintenance on this tool.

NOTE: Actual torque on a fastener is directly related to joint

hardness,toolspeed,conditionofsocketandthetimethetool is

allowedtoimpact.Usethesimplestpossibletooltosockethookup.

Everyconditionabsorbsenergyandreducespower.

NOTE: During operation, safety goggles must always be worn

to guard against flying rust and chips (users and bystanders).

TROUBLESHOOTING

Otherfactorsoutside thetoolmaycauseloss ofpoweror erraticaction.

Reduced compressor output, excessive drain on the air line, moisture or

restrictionsinairpipesortheuseofhoseconnectionsofimpropersizeor

poorconditionsmayreduceairsupply.Gritorgumdepositsinthetoolmay

cutpowerandmaybecorrectedbycleaningtheairstrainerandflushing

out the tool with gum solvent oil or an equal mixture of SAE #10 and

kerosene.Ifoutsideconditionsareinorder,disconnecttoolfromhoseand

taketooltoyournearestauthorizedservicecenter.

Drain Daily

RegulatorOilerQuick CouplerLeader

Hose

Nipple

Do Not Install

Quick Coupling

Here

Nipple

Filter

Air Supply

Whip Hose