Quick Coupling

Here

Quick Coupling

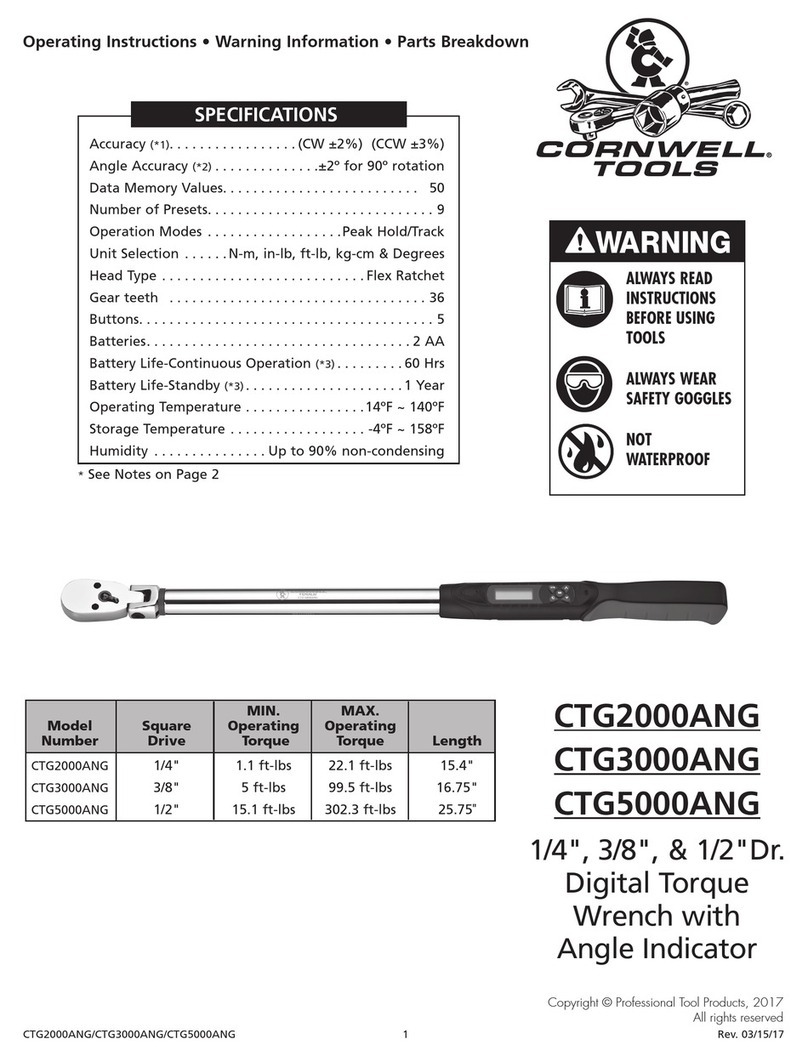

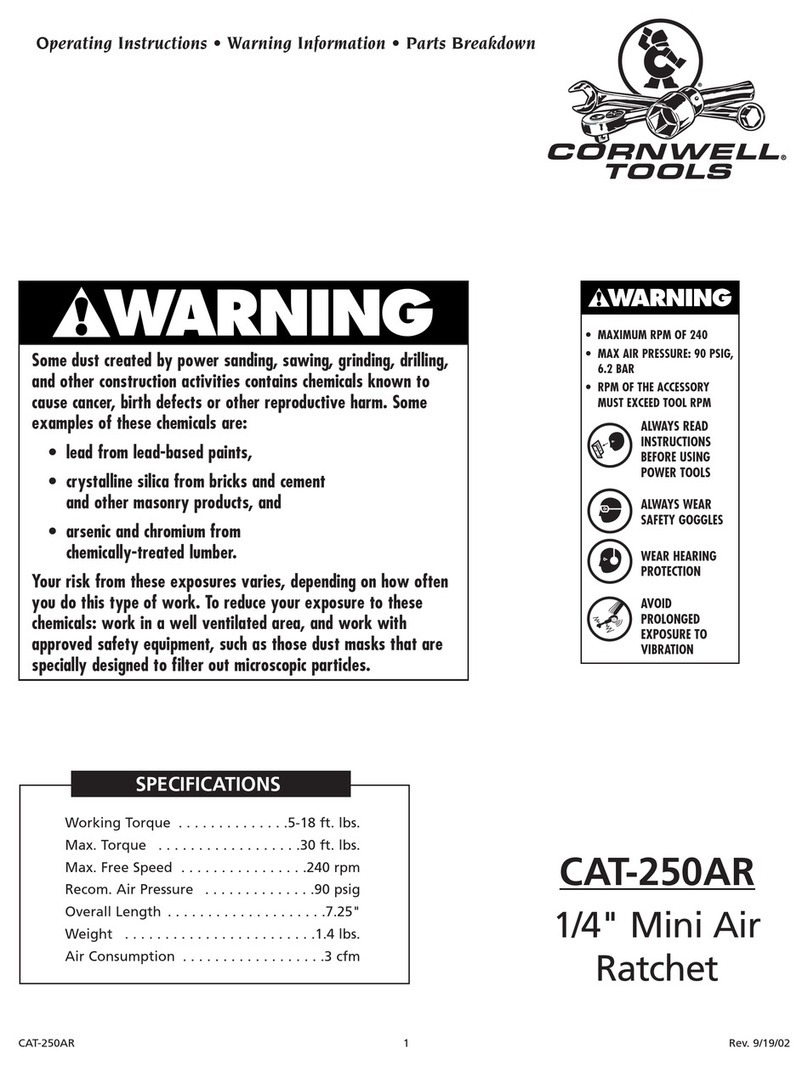

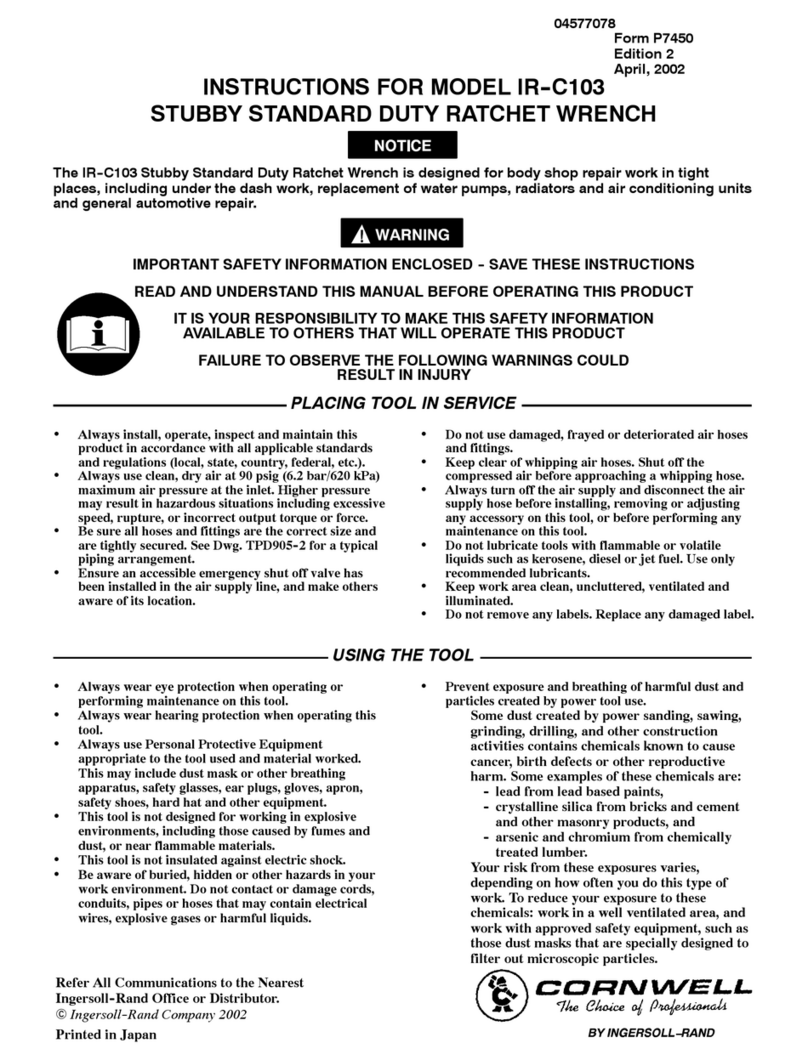

Operating Instructions • Warning Information • Parts Break down

Tools of this class operate on a wide range

of air pres sures. It is recommended that air

pres sure of these tools mea sures 90 PSI at

the tool while running free. Higher pres sure

(over 90 psig; 6.2 bar) raises performance

beyond the rated capacity of the tool which

will short en tool life be cause of faster wear

Always use clean, dry air. Dust, corrosive

fumes and/or water in the air line will

cause damage to the tool. Drain the air

tank daily. Clean the air inlet filter screen

on at least a weekly schedule. The rec om-

mend ed hookup pro ce dure can be viewed

The air inlet used for con nect ing air supply,

has stan dard 1/4" NPT. Line pressure

should be increased to compensate for

unusually long air hoses (over 25 feet).

Minimum hose diameter should be 3/8"

I.D. and fittings should have the same

inside di men sions and be tightly secured.

This ratchet wrench is rated at 3/8" USS

bolt size. Rating must be down graded for

spring U bolts, tie bolts, long cap screws,

double depth nuts, badly rusted conditions

and spring fas ten ers as they absorb much

of the impact power. When possible, clamp

or wedge the bolt to prevent springback.

Soak rusted nuts in pen e trat ing oil and

break rust seal before removing with ratchet

wrench. If nut does not start to move in

three to five sec onds use an impact wrench.

Do not use impact wrench be yond rated

ca pac i ty as this will dras ti cal ly reduce tool

The forward/reversing button is used to

change the ro ta tion of the tool. When the

button is set to the right, the tool will turn

in a right hand ro ta tion. When the button

is set to the left, the tool will turn in a left

NOTE: Actual torque on a fastener is di rect-

ly related to joint hard ness, tool speed,

condition of socket and the time the tool is

Use the simplest possible tool-to-socket hook

up. Every connection absorbs energy and

Other factors outside the tool may cause

loss of power or erratic action. Reduced

compressor output, ex ces sive drain on the

air line, moisture or restrictions in air pipes

use of hose connections of improper

supply. Grit or gum deposits in the tool

may cut power and may be corrected by

cleaning the air strainer and flushing out

the tool with gum solvent oil or an equal

mixture of SAE #10 and kerosene. If

outside conditions are in order and the tool

continues to perform erratically, disconnect

tool from hose and take tool to your nearest

au tho rized service center.

Lubricate the air motor daily with quality

air tool oil. If no air line oiler is used, run

a teaspoon of oil through the tool. The oil

can be squirted into the tool air inlet or into

the hose at the nearest con nec tion to the

air supply, then run the tool. The amount of

oil to be used is 1/2 ounce. Overfilling will

cause a re duc tion in the power of the tool.

Grease ratchet housing and reverse button

through grease fittings as needed.

Cornwell Tools™ Limited Warranty

Cornwell Tools warrants the CAT-4050SD for a period of 2 years

to the consumer. We will repair any air tool covered under this

warranty which proves to be defective in material or workmanship

during the warranty period. In order to have your tool repaired,

return the tool to any Cornwell Tools Authorized Warranty Center,

freight prepaid. Please include a copy of your proof of purchase

and a brief description of the problem. The tool will be inspected

and if any part or parts are found to be defective in material or

workmanship, they will be repaired free of charge and the repaired

tool will be returned to you freight prepaid.

This warranty gives you specific rights. You may also have other

rights which vary from state to state.

The foregoing obligation is Cornwell Tools' sole liability under this

or any implied warranty and under no circumstances shall Cornwell

Tools be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of

incidental or consequential damages so the above limitation or

exclusion may not apply to you.

CAT-4050SD_OpMan062006.indd 4 6/20/06 3:45:09 PM