CAT2500BP 4 Rev. 02/22/18

Operating Instructions • Warning Information • Parts Breakdown

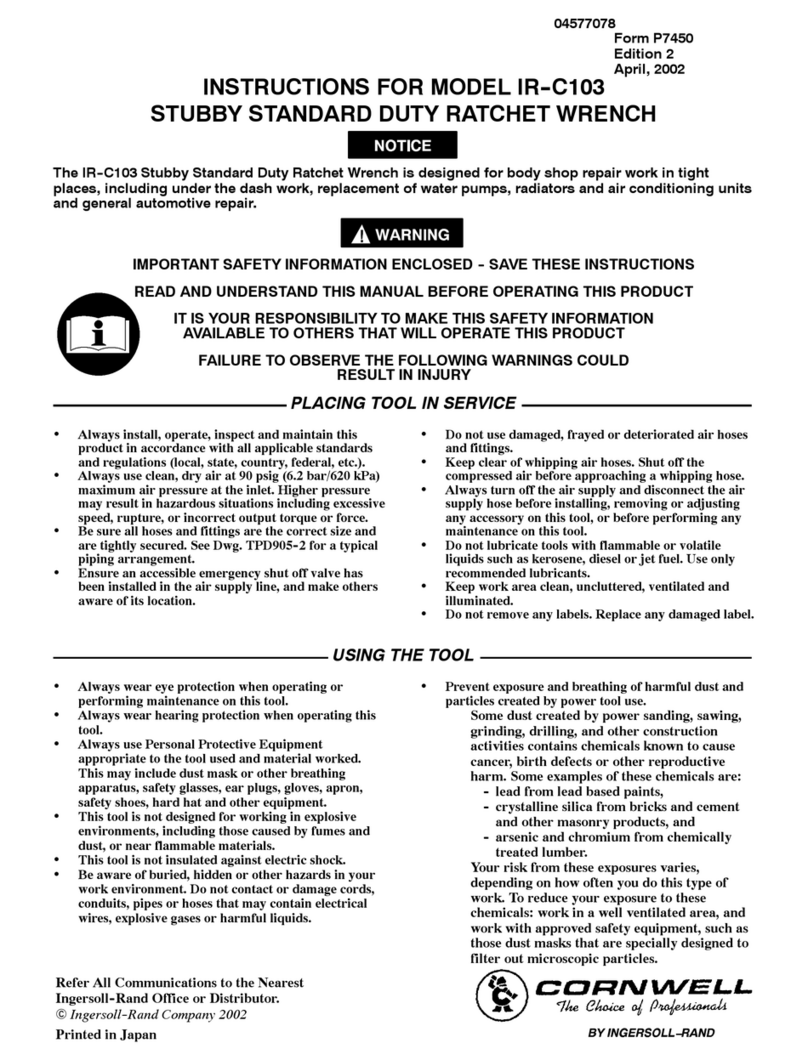

AIR SUPPLY

Tools operate on a wide range of air pressures. It is recommended

that air pressure of these tools measures 90 psig at the tool with

the trigger fully depressed and no load applied to the tool. Higher

pressure (over 90 psig; 6.2 bar) raises performance beyond the

rated capacity of the tool, which will shorten tool life and could

cause injury.

Always use clean, dry air. Dust, corrosive fumes and/or water in the

air line will cause damage to the tool. Drain water from air lines

and compressor prior to running tool. Clean the air inlet filter screen

weekly. The recommended hookup procedure can be viewed in the

above figure.

The air inlet used for connecting air supply has standard 1/4" NPT.

Line pressure should be increased to compensate for unusually long

air hoses (over 25 feet). Minimum hose diameter should be 3/8" I.D.

and fittings should have the same inside dimensions and be tightly

secured.

Ensure an accessible emergency shut off valve has been installed in

the air supply line and make others aware of its location.

LUBRICATION

Lubricate the air motor daily with high quality air tool oil. If no air

line oiler is used, run 1/2 oz. of oil through the tool. The oil can

be squirted into the tool air inlet or into the hose at the nearest

connection to the air supply, then run the tool. A rust inhibitive oil is

acceptable for air tools.

WARNING: After an air tool has been lubricated, oil will discharge

through the exhaust port during the first few seconds of operation.

The exhaust port must be covered with a towel before applying air

pressure to prevent serious injury.

OPERATION

The CAT2500BP 1/4" ratchet is designed to fasten and unfasten

threaded fasteners while operating under recommended conditions.

Note the directional setting of the reversing lever before depressing

the throttle. Ensure body stance to be in excellent balance and have

full control of the tool before use. Be fully alert as sudden reaction

torques and directional changes may unexpectedly occur. Be aware

that air ratchets are not torque wrenches or pry bars. Joints and

fasteners requiring a specific torque must be checked with a torque

wrench as the final step. Using the air ratchet to tighten or break-

free fasteners, can irreversibly damage its internal mechanism and

will void any remaining warranty.

Always turn off the air supply, drain hose of air pressure

and detach tool from air supply before installing, removing

or adjusting any part or accessory on this tool, or before

performing any maintenance on this tool.

WARNING: Use only impact sockets and accessories on this

tool. Do not use hand sockets and accessories.

TROUBLESHOOTING

Other factors outside the tool may cause loss of power or

erratic action. Reduced compressor output, excessive drain on

the air line, moisture or restrictions in air pipes or the use

of hose connections of improper size or poor conditions may

reduce air supply. Grit or gum deposits in the tool may cut power

and may be corrected by cleaning the air strainer and flushing

out the tool with gum solvent oil or an equal mixture of SAE #10 and

kerosene. If outside conditions are in order, disconnect tool from

hose and take tool to your nearest authorized service center.

Drain Daily

RegulatorOilerQuick CouplerLeader

Hose

Nipple

Do Not Install

Quick Coupling

Here

Nipple

Filter

Air Supply

Whip Hose

WARRANTY

Cornwell Quality Tools Company (“Cornwell”) warrants this product against defects in material and workmanship for a period of TWO (2) YEARS from the date of original retail purchase.

Subject to the conditions and limitations set forth below, Cornwell will, at its option, either repair or replace any part of the product(s) that proves defective by reason of improper

workmanship or materials.

This warranty does not cover any damage to this product that results from accident, abuse, misuse, natural or personal disaster, or any unauthorized disassembly, repair, or

modification. Repairs, disassembly and modification are only authorized to be made by Cornwell or a Cornwell Authorized Warranty Center.

WARRANTY SERVICE

In order to have your tool repaired, return the tool to any Cornwell Authorized Warranty Center, freight prepaid. Please include a copy of your proof of purchase and a brief description

of the problem. The tool will be inspected and if any part or parts are found to be defective in material or workmanship, they will be repaired free of charge, and the repaired tool will

be returned to you freight prepaid.

EXCLUSIONS AND LIMITATIONS

THIS WARRANTY AND THE REMEDIES SET FORTH ABOVE ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, REMEDIES AND CONDITIONS, WHETHER ORAL OR WRITTEN,

EXPRESS OR IMPLIED. CORNWELL SPECIFICALLY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES, INCLUDING, TO THE EXTENT PERMITTED BY APPLICABLE LAW, ANY WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IF CORNWELL CANNOT LAWFULLY DISCLAIM IMPLIED WARRANTIES UNDER THIS LIMITED WARRANTY, ALL SUCH

IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THE DURATION OF THIS WARRANTY.

IN NO EVENT SHALL CORNWELL BE LIABLE TO THE PURCHASER OR TO THE USER OF A CORNWELL PRODUCT FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES BASED

UPON BREACH OF WARRANTY, BREACH OF CONTRACT, NEGLIGENCE, TORT, OR ANY OTHER LEGAL THEORY. SUCH DAMAGES INCLUDE, WITHOUT LIMITATION, EXPENSES, LOST

REVENUES, LOST SAVINGS, LOST PROFITS, OR ANY OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE PURCHASE, USE OR INABILITY TO USE THE CORNWELL

PRODUCT.

Some states do not allow the exclusion or limitation of incidental or consequential damages or exclusions or limitation on the duration of implied warranties or conditions, so the above

limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights that vary by state.

Repair kits and replacement parts are available for many Cornwell products, regardless of whether or not the product is still covered by a warranty plan.